When it comes to keeping small engine units in optimal condition, understanding the intricacies of their components is crucial. A comprehensive resource can serve as a valuable tool for both novices and seasoned enthusiasts, enabling them to navigate the challenges of troubleshooting and upkeep effectively. From performance issues to routine servicing, having access to detailed information can make all the difference in ensuring longevity and reliability.

Many users encounter various obstacles with their power equipment over time. Whether it’s an unexpected failure or a decline in efficiency, identifying the root cause is essential. This guide provides insight into common problems and practical solutions, empowering individuals to address concerns confidently. Through systematic analysis and step-by-step instructions, anyone can enhance their skills and knowledge.

Equipping oneself with the right information not only saves time and resources but also fosters a deeper appreciation for the mechanics at play. This guide highlights the importance of regular maintenance and informed troubleshooting, paving the way for smoother operations. Emphasizing preventive measures and timely interventions can lead to improved performance and reduced downtime.

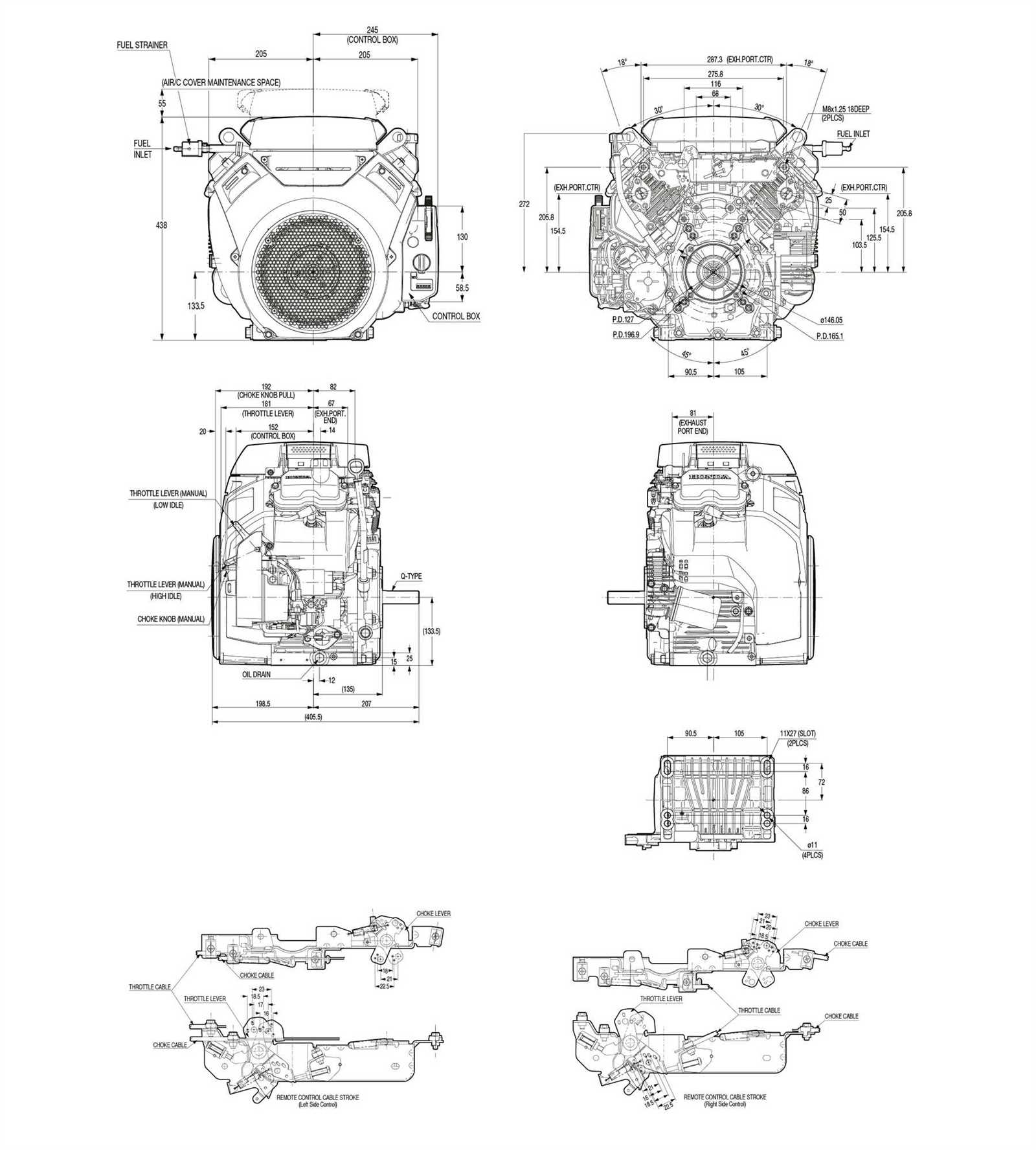

Understanding the Honda GX630 Engine

This section aims to provide a comprehensive overview of a specific power unit widely used in various applications, highlighting its features, functionalities, and maintenance requirements. Understanding the mechanics behind this engine can greatly enhance its performance and longevity.

Key Features

This engine is known for its robust design and reliability. Some of its notable characteristics include:

| Feature | Description |

|---|---|

| Type | V-twin, air-cooled |

| Displacement | 688 cc |

| Power Output | 22.0 HP at 3600 RPM |

| Fuel System | Electronic fuel injection |

Maintenance Tips

To ensure optimal operation, regular maintenance is crucial. Here are some essential practices:

- Check and change the oil periodically.

- Inspect air filters for cleanliness.

- Ensure spark plugs are in good condition.

- Keep fuel lines free of blockages.

Common Issues with GX630 Models

Engines of this type often encounter various challenges that can affect performance and reliability. Understanding these typical problems can aid in maintaining optimal functionality and prolonging the lifespan of the unit.

| Issue | Description | Possible Solutions |

|---|---|---|

| Hard Starting | Difficulty in initiating the engine can occur due to fuel or ignition issues. | Check fuel levels, inspect spark plugs, and ensure the battery is charged. |

| Overheating | Excessive heat can lead to engine damage if not addressed. | Ensure proper cooling system function, clean air filters, and check coolant levels. |

| Oil Leaks | Fluid leaks can signal seal or gasket failures. | Inspect seals, gaskets, and oil levels regularly; replace damaged components. |

| Unusual Noises | Unexpected sounds may indicate internal wear or damage. | Conduct a thorough inspection; replace worn parts as necessary. |

Tools Required for Repairing GX630

When addressing maintenance or restoration tasks for small engines, having the right set of instruments is crucial for effective and efficient work. Proper tools not only enhance the process but also ensure safety and precision during the task at hand.

Essential items for these procedures typically include basic hand tools such as wrenches, pliers, and screwdrivers. Additionally, specialized equipment like torque wrenches and compression testers can provide more in-depth analysis and adjustments. A well-equipped toolkit is vital for tackling various components, from ignition systems to fuel lines.

Furthermore, safety gear should not be overlooked. Gloves, goggles, and protective clothing help safeguard against potential hazards during disassembly and reassembly. By preparing adequately with the right tools and protective equipment, one can significantly streamline the service experience and achieve optimal results.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to troubleshooting and fixing common issues that may arise in small engines. Following a structured approach not only enhances efficiency but also ensures that every aspect of the engine is thoroughly addressed.

Identifying the Problem

The first step in the process is to accurately diagnose the issue. Begin by observing any unusual sounds or performance drops. Make a list of symptoms and potential causes, as this will guide you in the next steps. Pay attention to:

- Engine noise

- Starting difficulties

- Loss of power

- Fuel consumption

Disassembly and Inspection

Once the problem is identified, it’s time to disassemble the components for a closer look. Use appropriate tools to avoid damage during this process. Focus on:

- Checking spark plugs for wear

- Inspecting the air filter for blockages

- Examining fuel lines for leaks

- Assessing the condition of gaskets and seals

After inspection, replace any worn or damaged parts with new, compatible components. Ensure that all connections are secure before reassembling.

Maintenance Tips for Longevity

Ensuring the prolonged lifespan of your engine requires diligent care and regular upkeep. By following a structured maintenance routine, you can prevent unexpected breakdowns and enhance performance over time.

- Regular Oil Changes: Change the oil according to the manufacturer’s schedule. Clean oil reduces friction and wear on internal components.

- Air Filter Maintenance: Inspect and clean or replace the air filter frequently. A clean filter promotes optimal airflow and improves efficiency.

- Fuel Quality: Use high-quality fuel to avoid deposits and maintain engine cleanliness. Consider fuel stabilizers for prolonged storage.

- Inspect Spark Plugs: Regularly check and replace spark plugs as needed. Properly functioning plugs ensure reliable ignition and performance.

In addition to these key points, consider the following practices:

- Cooling System Checks: Regularly inspect the cooling system to prevent overheating. Ensure coolant levels are adequate and hoses are in good condition.

- Inspect Belts and Hoses: Look for signs of wear, cracking, or fraying. Replace any damaged components promptly to avoid further issues.

- Clean External Surfaces: Keep the exterior free from debris and dirt. This helps in maintaining proper airflow and cooling efficiency.

By adhering to these maintenance guidelines, you can significantly extend the life of your engine and enjoy reliable performance for years to come.

How to Troubleshoot Starting Problems

Starting difficulties can often stem from a variety of issues, and identifying the root cause is essential for effective resolution. This guide will help you systematically address common obstacles that prevent smooth ignition, ensuring optimal performance.

Check the Fuel System: First, ensure that there is adequate fuel in the tank and that it is clean and fresh. Old or contaminated fuel can lead to starting issues. Additionally, inspect the fuel lines for any clogs or leaks.

Inspect the Battery: A weak or dead battery is a frequent culprit. Verify the battery’s charge level and connections. Corroded terminals can impede power delivery, so clean them if necessary.

Examine the Spark Plug: The spark plug plays a crucial role in ignition. Remove it to check for wear or damage. Clean or replace it if it shows signs of fouling or excessive wear.

Assess the Electrical System: Look for any frayed wires or loose connections within the electrical system. Faulty components, such as relays or fuses, can also disrupt the starting process.

Consider Engine Compression: Low compression can prevent the engine from starting. A compression test can help determine if this is the issue, guiding you toward the necessary repairs.

By addressing these areas, you can delve into the complexities of starting problems and find the ultimate solution for efficient operation.

Replacing Key Components in GX630

Maintaining the functionality of essential parts is crucial for the longevity and performance of any engine. This section focuses on the process of swapping out critical components to ensure optimal operation. Whether for routine upkeep or troubleshooting issues, understanding how to effectively replace these elements is key to efficient maintenance.

Common Components to Replace

- Fuel Filter

- Oil Filter

- Spark Plug

- Air Filter

- Starter Motor

Steps for Component Replacement

- Gather Necessary Tools: Ensure you have the right tools for the job, such as wrenches, screwdrivers, and pliers.

- Disconnect Power: Always disconnect the power source before beginning any work to prevent accidents.

- Remove the Old Component: Carefully detach the old part, following manufacturer guidelines to avoid damage.

- Install the New Component: Position the new part correctly and secure it in place, ensuring all connections are tight.

- Reconnect Power: Once everything is in place, reconnect the power source and conduct a brief test.

Following these steps will help maintain the engine’s efficiency and performance, reducing the likelihood of future issues.

Fuel System Maintenance Guidelines

Ensuring the optimal performance of the fuel delivery system is essential for the longevity and efficiency of any engine. Regular upkeep can prevent issues such as clogs, leaks, and diminished power output. This section provides essential practices for maintaining the fuel system to keep it functioning smoothly.

Key components of the fuel system include the fuel tank, filters, lines, and injectors. Each part plays a critical role in ensuring that the engine receives the correct amount of fuel in a timely manner. By following these guidelines, users can extend the lifespan of their equipment and enhance its performance.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Inspect Fuel Lines | Every 3 months | Check for cracks, leaks, and wear. Replace damaged lines immediately. |

| Replace Fuel Filter | Every 6 months | Ensure the filter is free of debris to prevent clogs and maintain fuel flow. |

| Clean Fuel Tank | Annually | Remove sediment and contaminants to avoid fuel quality issues. |

| Check Fuel Quality | Monthly | Use fresh fuel and avoid storing for long periods. Discard stale fuel. |

| Inspect Injectors | Every 6 months | Look for signs of clogging or wear; clean or replace as needed. |

By adhering to these maintenance tasks, operators can ensure that the fuel system remains in peak condition, thus supporting efficient engine operation and reducing the likelihood of unexpected breakdowns.

Electrical System Diagnostics Explained

Understanding the intricacies of an electrical system is essential for effective troubleshooting and maintenance. This section delves into the diagnostic processes that enable users to identify issues, ensuring reliable performance and longevity of the equipment.

Key Components of the Electrical System

The electrical setup comprises several critical elements that work together seamlessly. Familiarity with these components aids in diagnosing faults:

- Battery

- Starter Motor

- Alternator

- Wiring Harness

- Control Module

Diagnostic Procedures

Effective diagnostics involve systematic checks and measures to pinpoint problems. Here are some essential steps to consider:

- Visual Inspection: Examine components for signs of wear, corrosion, or damage.

- Voltage Testing: Use a multimeter to assess voltage levels across various points.

- Continuity Testing: Check for uninterrupted electrical flow in wiring and connectors.

- Component Testing: Verify the functionality of individual parts like the starter and alternator.

- Load Testing: Evaluate performance under operational conditions to ensure reliability.

By following these guidelines, users can efficiently troubleshoot and maintain the electrical system, leading to optimal performance and reduced downtime.

Upgrading Parts for Enhanced Performance

Improving the efficiency and capabilities of your engine can lead to significant benefits, from increased power output to better fuel economy. By selecting high-quality components and making strategic modifications, you can transform the overall functionality of your equipment. This section explores various enhancements that can elevate performance and provide a more enjoyable user experience.

One of the most effective ways to boost performance is by upgrading the air intake system. A high-flow air filter can reduce restrictions, allowing for better airflow and improved combustion. Similarly, an optimized exhaust system can facilitate the expulsion of gases, enhancing overall efficiency and power delivery.

Another area to consider is the ignition system. Investing in a high-performance ignition coil and spark plugs can lead to more reliable starts and improved throttle response. Additionally, tuning the carburetor or fuel injection system can ensure that the right air-fuel mixture is maintained, maximizing power and efficiency.

Don’t overlook the potential of enhancing the cooling system. A more efficient radiator or upgraded fans can help maintain optimal operating temperatures, reducing the risk of overheating and prolonging engine life. Lastly, examining the drivetrain for potential upgrades can ensure that power is effectively transmitted to the wheels, further improving performance.

By focusing on these key areas, you can significantly enhance the performance of your engine, ensuring that it meets your needs and performs at its best for years to come.

Resources for Further Assistance

When encountering issues with small engines, accessing a variety of support resources can greatly enhance your troubleshooting and repair capabilities. Whether you are a novice or an experienced user, having the right materials at your disposal is essential for effective maintenance and problem-solving.

Online Forums and Communities are excellent places to connect with fellow enthusiasts. These platforms allow users to share experiences, offer solutions, and provide valuable tips that can lead to quicker resolutions.

Video Tutorials on platforms like YouTube can serve as visual aids, demonstrating step-by-step processes for various tasks. These resources can be especially helpful for those who prefer a hands-on approach to learning.

Manufacturer Websites often contain a wealth of information, including specifications, updates, and downloadable documents that can guide you through different aspects of engine care. Checking these sites regularly ensures you stay informed about any new developments.

Local Workshops and Classes provide opportunities for practical learning and hands-on experience. Engaging with professionals in these settings can deepen your understanding and build your confidence in handling machinery.

Utilizing these varied resources will empower you to tackle engine issues more effectively, ensuring optimal performance and longevity of your equipment.