Barrel Misalignment: If accuracy declines, barrel alignment may be affected. This can happen over time due to regular use. Inspect the ba

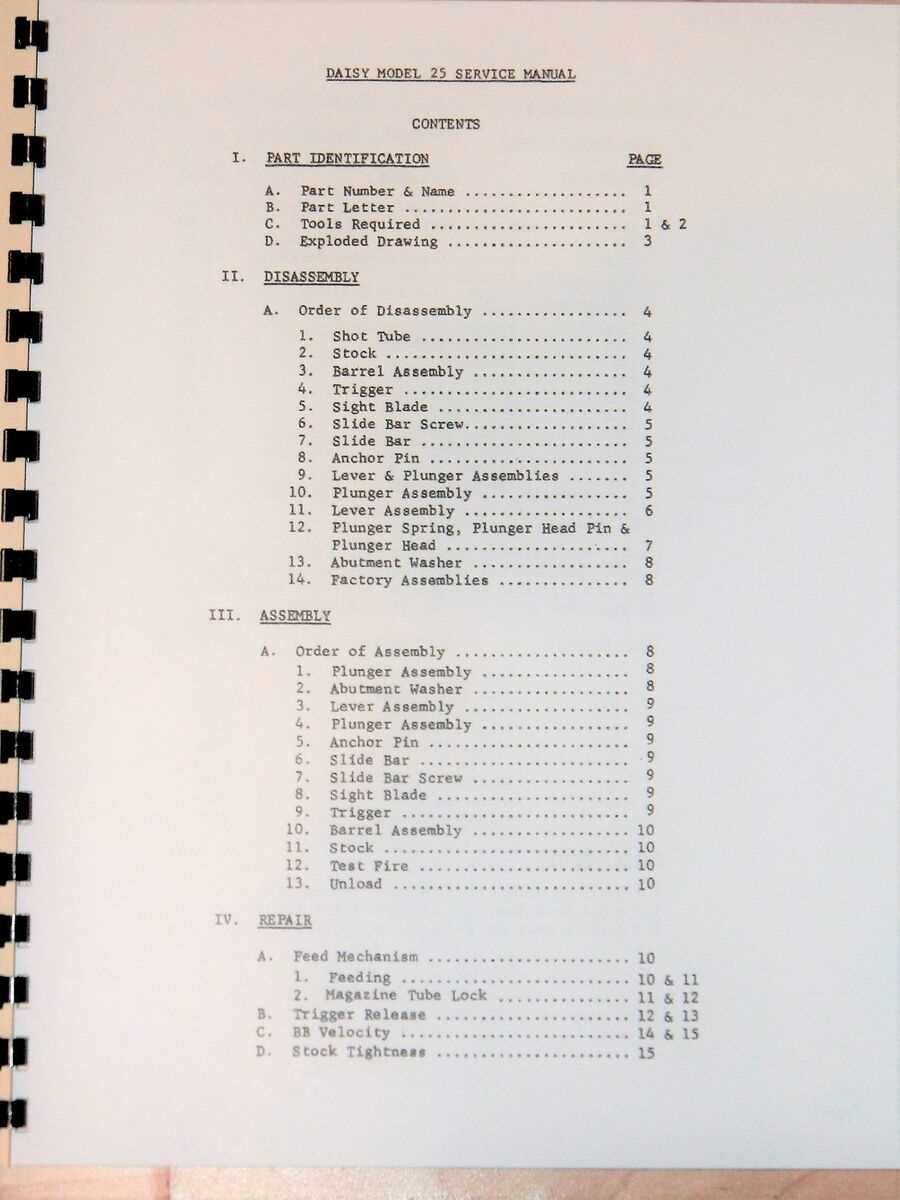

Disassembly Steps for Safe Repairs

In this section, we’ll outline the essential steps for carefully taking apart your equipment to ensure each component remains intact and accessible. Following these steps will help maintain the integrity of the parts while allowing for any necessary adjustments.

1. Preparation and Safety Measures

Begin by gathering all necessary tools and ensuring a clean, organized workspace. It’s important to wear protective gear, such as gloves and safety glasses, to prevent any accidental injuries. Familiarize yourself with each part’s placement so that reassembly will be straightforward.

2. Systematic Part Removal

Start with external components, gradually working towards the internal parts. Loosen screws carefully and keep them in a labeled container to avoid confusion later. When removing each component, gently set it aside in the order of removal to make reassembly easier. Pay special attention to any small springs or clips that may be hidden within the internal structure.

By following these organized steps, you can disassemble the equipment efficiently while reducing the risk of damage to each component.

Cleaning and Lubrication Techniques

Maintaining the functionality of a mechanical device requires regular attention to its cleanliness and lubrication. These practices not only enhance performance but also extend the lifespan of the components. Understanding the proper methods for cleaning and applying lubricants is essential for ensuring optimal operation.

Effective Cleaning Methods

To begin, disassemble the unit carefully to access all parts that require attention. Use a soft brush or cloth to remove dust, dirt, and debris from surfaces. For stubborn grime, a mild solvent may be employed, but caution is advised to prevent damage to sensitive materials. Once cleaned, ensure all parts are thoroughly dried before reassembly to avoid moisture-related issues.

Proper Lubrication Techniques

Once the device is clean, apply an appropriate lubricant to the moving components. Select a high-quality lubricant that is compatible with the materials involved. A few drops are usually sufficient; too much can attract dust and create a buildup that hinders performance. Regularly inspect and reapply lubricant as necessary to maintain smooth operation.

Replacing Worn Parts Effectively

Ensuring optimal performance and longevity of your device often necessitates the timely substitution of aged components. Recognizing the signs of wear and understanding the appropriate methods for replacement can significantly enhance functionality and safety.

Begin by identifying the specific parts that exhibit signs of deterioration. Common indicators include reduced efficiency, unusual noises, or physical damage. Once these components are recognized, the following steps can guide you through the replacement process:

| Step |

Description |

| 1 |

Gather necessary tools and replacement parts suitable for the device. |

| 2 |

Carefully disassemble the relevant sections, taking note of the order of components for reassembly. |

| 3 |

Remove the worn parts and clean the surrounding area to prevent debris contamination. |

| 4 |

Install the new components, ensuring they are properly fitted and secured. |

| 5 |

Reassemble the device in the reverse order of disassembly, checking for any misplaced parts. |

| 6 |

Test the device to confirm that the new parts function correctly and the issues have been resolved. |

Following these guidelines not only facilitates a smoother replacement process but also contributes to maintaining the overall efficiency of your equipment. Regular checks and timely replacements can prevent more significant issues and extend the lifespan of your device.

Troubleshooting Firing Mechanism Problems

Understanding and diagnosing issues with the firing mechanism is crucial for ensuring optimal performance of your air-powered device. Several factors can contribute to malfunctions, and recognizing these can help you restore functionality effectively.

Here are common issues you might encounter with the firing mechanism:

- Misalignment: Components may become misaligned over time, affecting the operation of the firing mechanism.

- Blockages: Dirt or debris can obstruct the firing system, preventing it from functioning properly.

- Wear and Tear: Continuous use may lead to wear on critical components, which can impair performance.

- Spring Issues: A malfunctioning spring can result in insufficient power during firing.

To address these problems, consider the following steps:

- Inspect the firing mechanism for any visible signs of misalignment or obstruction.

- Carefully clean all components to remove any dirt or debris.

- Check the condition of springs and replace them if necessary.

- Reassemble all parts, ensuring everything is aligned correctly.

Regular maintenance and prompt troubleshooting can significantly enhance the longevity and reliability of your air-powered device.

Adjusting Sight and Accuracy Settings

Ensuring optimal precision in shooting requires meticulous attention to the alignment and calibration of the aiming apparatus. This section provides guidance on how to modify these settings effectively to enhance your overall performance and achieve your desired accuracy.

To begin the adjustment process, it is essential to familiarize yourself with the components involved. The main elements include the front and rear sights, which play a critical role in aiming accurately at your target. Properly aligning these components will significantly influence the effectiveness of your shots.

The following table outlines the key steps for adjusting the sight settings:

| Step |

Description |

| 1 |

Loosen the screws on the rear sight using a suitable tool to allow for movement. |

| 2 |

Align the rear sight with the front sight by looking down the barrel while aiming at a distant target. |

| 3 |

Adjust the rear sight left or right as necessary to ensure that the point of aim corresponds with the point of impact. |

| 4 |

Tighten the screws to secure the rear sight in its new position, ensuring it remains stable during use. |

| 5 |

Conduct a series of test shots to evaluate the accuracy and make further adjustments if needed. |

By following these steps and regularly checking your settings, you can maintain precision and improve your shooting experience. Consistency in adjustments will lead to better results over time, enhancing your skill and confidence.

Testing Functionality after Repairs

Ensuring that a device operates correctly after servicing is crucial for its longevity and reliability. This section outlines key steps to confirm that all components are functioning as intended, providing peace of mind to the user.

Initial Checks

- Inspect all external parts for proper alignment and secure attachment.

- Verify that there are no visible signs of damage or wear.

- Ensure that all necessary tools and equipment are available for testing.

Operational Tests

- Power on the device and listen for any unusual sounds.

- Perform basic functionality tests to confirm that each feature works correctly.

- Conduct a thorough test under normal operating conditions to evaluate overall performance.

- Document any irregularities observed during testing for future reference.

Maintaining the Model 95 for Longevity

Ensuring the extended life of your air-powered device involves regular attention and proper care. By following best practices in maintenance, users can significantly enhance the performance and reliability of their equipment. This section outlines key procedures and considerations that contribute to the durability of your device.

To begin with, routine inspections play a crucial role in identifying potential issues before they escalate. Regularly check for wear and tear, as well as the functionality of moving parts. Keeping the components clean and free from debris will also improve performance.

| Maintenance Task |

Frequency |

Description |

| Visual Inspection |

Monthly |

Check for any signs of damage or unusual wear on the exterior and internal mechanisms. |

| Cleaning |

After each use |

Remove dirt and residue from all accessible areas to maintain optimal operation. |

| Lubrication |

Every three months |

Apply suitable lubricant to moving parts to ensure smooth functioning. |

| Pressure Check |

Monthly |

Ensure that the pressure settings are within recommended limits to prevent malfunctions. |

Adhering to these guidelines will not only preserve the integrity of your equipment but also enhance its efficiency, allowing you to enjoy reliable performance for years to come.

Safety Precautions during Repair Work

When undertaking maintenance activities, it is essential to prioritize safety to prevent accidents and ensure a smooth workflow. Adopting proper safety measures not only protects the individual performing the task but also safeguards the equipment and surrounding environment. Following a few basic guidelines can significantly reduce the risk of injury and promote a more efficient repair process.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and dust masks. This gear is crucial in shielding oneself from potential hazards, including sharp tools and harmful substances. Additionally, using non-slip footwear can provide better traction, minimizing the risk of falls.

Work Area Organization

Maintain a clean and organized workspace to facilitate efficient work and reduce the likelihood of accidents. Ensure that all tools and materials are easily accessible and stored properly when not in use. By keeping the area clutter-free, one can avoid tripping hazards and create a safer environment for all individuals involved.