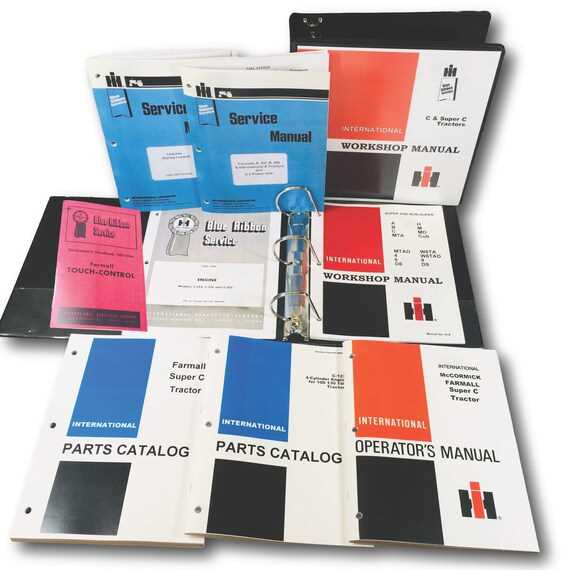

Maintaining vintage agricultural machinery is a rewarding endeavor that connects enthusiasts with the roots of farming history. These robust machines, crafted to withstand the test of time, require attention and knowledge to keep them running smoothly. In this guide, we will explore essential techniques and best practices for ensuring your classic tractor remains in peak condition.

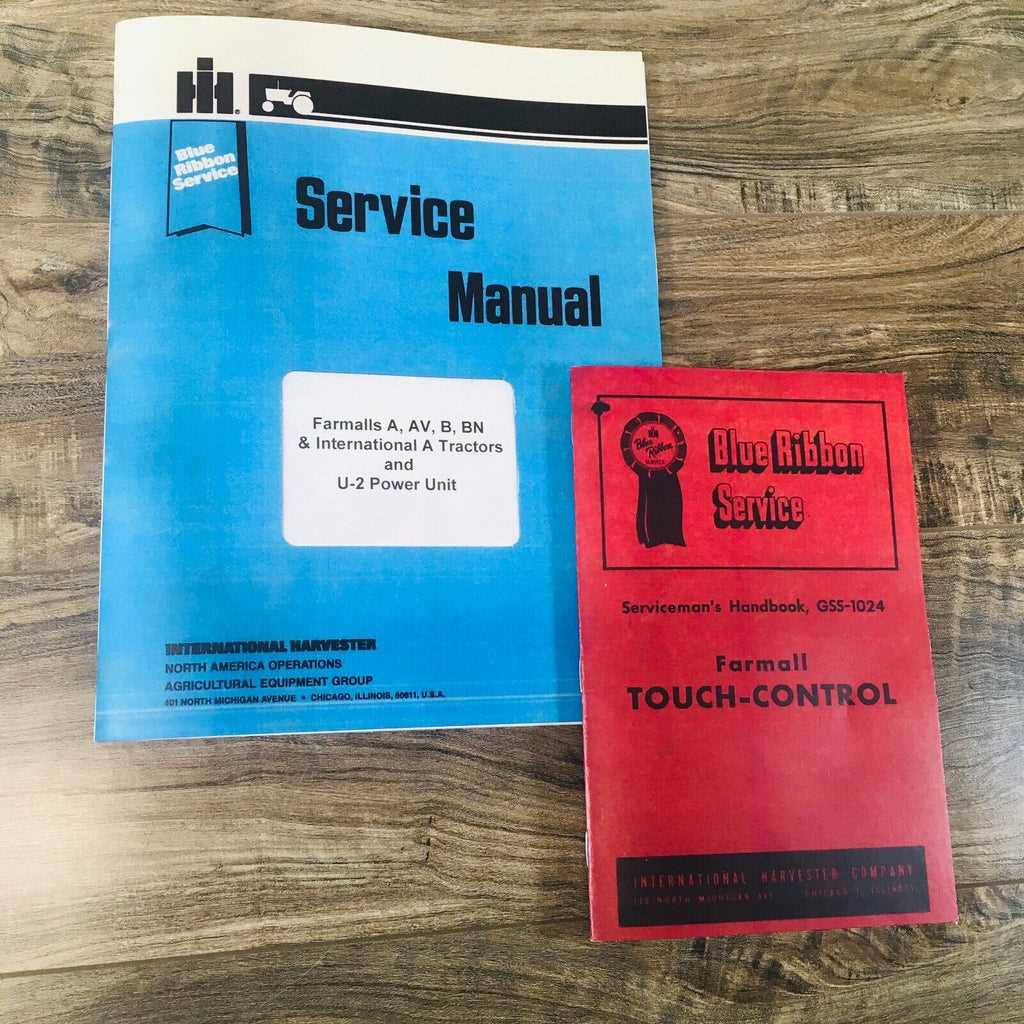

Understanding the intricacies of your equipment is crucial for anyone passionate about preserving these iconic machines. From troubleshooting common issues to performing necessary adjustments, having a detailed resource can significantly enhance your ability to tackle various challenges. With the right approach, even complex problems can be addressed effectively, allowing you to enjoy your machinery for years to come.

As you embark on this journey of restoration and maintenance, you’ll find that each step not only enhances the functionality of your equipment but also deepens your appreciation for its engineering. The satisfaction derived from reviving a classic piece of machinery is unparalleled, transforming the mundane into an exciting project that celebrates heritage and craftsmanship.

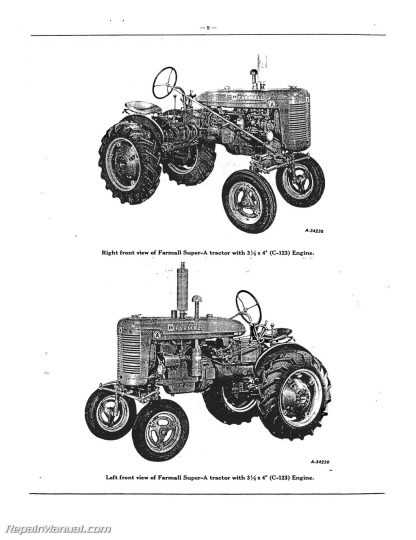

Understanding Farmall Super A Specifications

Gaining insight into the technical characteristics of agricultural machinery is essential for effective operation and maintenance. Knowing the specific attributes helps users make informed decisions and ensures optimal performance in various farming tasks.

Key specifications often include aspects such as engine capacity, horsepower, weight, and dimensions. These factors play a crucial role in determining the machine’s efficiency and suitability for specific tasks. Here are some critical components to consider:

- Engine Type: Typically features a four-cylinder configuration that provides reliable power.

- Horsepower: Usually rated between 15 to 30 horsepower, ideal for light to moderate agricultural work.

- Transmission: Often equipped with a standard gear-driven transmission, offering multiple speed options for versatility.

- Weight: Generally weighs around 2,500 to 3,000 pounds, providing stability during operation.

- Dimensions: Compact size facilitates maneuverability in tight spaces, enhancing usability in diverse environments.

Understanding these specifications allows operators to match the machinery effectively with their farming needs, ensuring a productive and efficient workflow. Regular familiarity with these details also aids in troubleshooting and potential upgrades.

Common Issues with Farmall Super A

Operating vintage agricultural machinery can come with a set of challenges that many owners encounter. Understanding these potential problems can lead to better maintenance and enhanced performance. This section highlights some frequently observed difficulties faced by users of these iconic tractors.

Engine Performance Problems

One of the most common concerns relates to engine performance. Issues such as hard starting, stalling, or inconsistent power output may arise due to factors like fuel contamination, improper timing, or worn components. Regular checks of ignition systems and fuel delivery can help mitigate these problems.

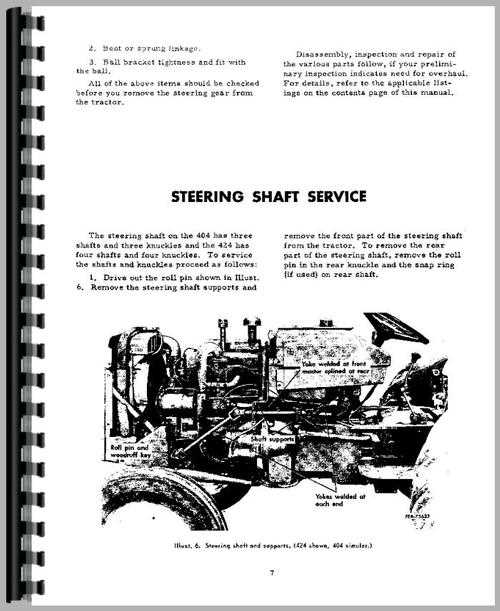

Transmission and Gear Issues

Transmission complications can also occur, affecting gear shifting and overall drivability. Symptoms might include grinding noises, difficulty in engaging gears, or slipping. Proper lubrication and timely inspections of the transmission system are crucial to prevent long-term damage and ensure smooth operation.

Essential Tools for Repairing Tractors

When it comes to maintaining agricultural machinery, having the right equipment is crucial for efficiency and effectiveness. Various implements are necessary to ensure smooth operation and longevity of the vehicles, whether it’s for routine upkeep or more extensive fixes.

Basic Hand Tools are the foundation of any workshop. Wrenches, screwdrivers, and pliers are essential for loosening and tightening bolts and fasteners. A good set of socket wrenches can significantly speed up the process of disassembling components.

Diagnostic Equipment plays a vital role in identifying issues. Multimeters, pressure gauges, and specialized diagnostic tools help in understanding the machine’s performance and pinpointing faults, allowing for informed troubleshooting.

Power Tools can enhance efficiency, especially when dealing with larger parts or tougher materials. Electric or pneumatic impact wrenches and drills are invaluable for speeding up tasks that would otherwise require significant manual effort.

Safety Gear is non-negotiable in any maintenance endeavor. Wearing gloves, goggles, and steel-toed boots protects against potential hazards while working on machinery. Prioritizing safety ensures a secure working environment, allowing focus on the task at hand.

Lastly, Storage Solutions like toolboxes and shelving units keep the workspace organized. An orderly area not only saves time but also minimizes the risk of losing tools or equipment, making every maintenance session more productive.

Step-by-Step Maintenance Procedures

Regular upkeep of your agricultural machinery is crucial for optimal performance and longevity. Following a structured approach to maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. This section provides a comprehensive guide to essential procedures that should be performed systematically to ensure your equipment remains in peak condition.

Routine Inspections

Begin with routine inspections to identify any signs of wear or potential issues. Check fluid levels, including oil, coolant, and hydraulic fluids. Inspect belts and hoses for cracks or fraying, and ensure all connections are secure. This proactive approach helps to catch minor problems before they escalate into major repairs.

Cleaning and Lubrication

Maintaining cleanliness is vital for the proper functioning of your machinery. Regularly clean components to remove dirt, grease, and debris that could hinder performance. Additionally, apply appropriate lubricants to moving parts, such as joints and bearings, to reduce friction and wear. Establish a cleaning schedule to keep your equipment in optimal working order.

Replacing Engine Components Effectively

Efficiently changing engine parts is crucial for maintaining optimal performance and longevity. This process involves careful planning, appropriate tools, and a methodical approach to ensure that each component is correctly installed and functions as intended. Understanding the specific requirements for each part is essential for successful replacement and overall engine health.

Preparation Steps

Before beginning the component replacement, take the following steps to ensure a smooth operation:

| Step | Description |

|---|---|

| 1. Gather Tools | Collect all necessary tools, including wrenches, sockets, and any specialty equipment. |

| 2. Read Documentation | Consult relevant resources to understand specifications and procedures for the parts involved. |

| 3. Prepare Workspace | Ensure the workspace is clean and organized to facilitate easy access to tools and parts. |

| 4. Safety Precautions | Wear appropriate safety gear, including gloves and goggles, to protect against hazards. |

Installation Tips

Following the preparation phase, adhere to these installation tips for effective component replacement:

Ensure that all old gaskets and seals are removed to prevent leaks. Use lubrication on moving parts during installation to reduce friction and wear. Torque fasteners to the manufacturer’s specifications to avoid over-tightening, which can lead to damage. Finally, after installation, run the engine at idle and check for any unusual sounds or leaks, addressing any issues immediately.

Hydraulic System Troubleshooting Guide

The efficiency of a hydraulic system is crucial for optimal performance in agricultural machinery. When issues arise, identifying the root cause is essential for restoring functionality. This guide outlines common problems and solutions to help users diagnose and resolve hydraulic system faults effectively.

Low Fluid Levels: Insufficient hydraulic fluid can lead to poor performance. Always check the fluid level and replenish as needed to ensure proper operation.

Leakages: Leaks can occur in hoses, fittings, or seals. Inspect the entire system for signs of fluid escape. If leaks are found, replace damaged components promptly to prevent further issues.

Poor Performance: If the machinery is sluggish or unresponsive, air in the system might be the culprit. Bleed the hydraulic lines to remove trapped air and restore normal function.

Contamination: Dirty fluid can hinder the system’s efficiency. Regularly change the hydraulic fluid and use filters to minimize the risk of contamination.

Faulty Components: Malfunctions in pumps or valves can significantly impact operation. Test these components for functionality and replace any that do not meet specifications.

By following this guide, users can systematically address common hydraulic issues, ensuring their machinery operates smoothly and efficiently.

Electrical System Diagnosis Techniques

Diagnosing electrical systems in agricultural machinery requires a systematic approach to identify and resolve issues effectively. Understanding the components and their interactions is crucial for troubleshooting. Proper techniques can lead to quicker resolutions and ensure optimal performance.

Essential Tools for Diagnosis

Utilizing the right tools is fundamental for accurate troubleshooting. Here are some essential instruments:

- Multimeter: For measuring voltage, current, and resistance.

- Oscilloscope: For visualizing electrical signals and waveforms.

- Test Light: For simple circuit testing and identifying power sources.

- Wire Strippers and Connectors: For repair and modification of wiring.

Step-by-Step Troubleshooting Process

Follow these steps for an effective diagnosis:

- Inspect Wiring: Check for frayed wires, corrosion, or loose connections.

- Test Voltage: Use a multimeter to verify power supply at key points.

- Check Ground Connections: Ensure that all grounds are secure and free from rust.

- Evaluate Components: Test switches, relays, and fuses for functionality.

- Analyze Results: Compare readings with standard values to identify anomalies.

By adhering to these techniques, operators can maintain the efficiency and reliability of their electrical systems, ultimately enhancing the machinery’s overall performance.

Restoration Tips for Vintage Tractors

Restoring classic agricultural machinery can be a rewarding endeavor, allowing enthusiasts to breathe new life into machines that have stood the test of time. This process not only preserves history but also revives the mechanical wonders of yesteryear. Below are some valuable suggestions to guide you through your restoration journey.

Assessment and Planning

Before diving into the project, a thorough evaluation is essential. Consider the following steps:

- Conduct a detailed inspection to identify areas needing attention.

- Document all findings, including mechanical and cosmetic issues.

- Research parts availability and the cost of restoration materials.

- Create a timeline and budget for the restoration process.

Restoration Process

Once you have a plan, follow these guidelines to ensure a successful restoration:

- Start with disassembly, labeling each part for easier reassembly.

- Clean all components thoroughly to remove dirt and grease.

- Repair or replace damaged parts, prioritizing essential components.

- Repaint or refinish surfaces to restore their original appearance.

- Reassemble with care, ensuring all parts fit securely and function properly.

By following these steps, you’ll enhance not only the aesthetics but also the functionality of your vintage machinery, ensuring it remains a cherished piece for years to come.

Safety Practices During Repairs

Ensuring a secure environment while conducting maintenance tasks is essential for both the individual and the equipment involved. Adhering to established safety protocols minimizes the risk of accidents and enhances overall efficiency. This section outlines key practices that should be implemented to safeguard against potential hazards.

Personal Protective Equipment (PPE)

Utilizing appropriate protective gear is crucial in preventing injuries. This equipment should be selected based on the specific tasks at hand. Common types of PPE include:

| Type of Equipment | Purpose |

|---|---|

| Safety Glasses | Protect eyes from debris and chemicals |

| Gloves | Prevent cuts and chemical exposure |

| Steel-Toed Boots | Guard against heavy objects |

| Ear Protection | Reduce noise exposure |

| Respirators | Filter harmful particles and fumes |

Work Area Organization

Maintaining a clean and organized workspace is vital for preventing accidents. Properly arranging tools and materials not only enhances safety but also promotes efficiency. Key tips for workspace organization include:

- Keep tools in designated locations to avoid trips and falls.

- Ensure that walkways are clear of obstacles.

- Store hazardous materials securely and label them appropriately.

Finding Replacement Parts for Farmall

Locating suitable components for vintage agricultural machinery can be a challenging yet rewarding task. Enthusiasts and owners often seek authentic or compatible parts to maintain the functionality and integrity of their equipment. Understanding where to search and what resources are available can simplify this process significantly.

Several avenues can be explored to find the necessary parts, ranging from online marketplaces to specialized suppliers. Each option has its unique advantages, and it’s important to weigh them based on availability, cost, and quality.

| Source | Description | Advantages |

|---|---|---|

| Online Marketplaces | Websites like eBay and Craigslist offer a wide range of components from various sellers. | Convenience, variety, often competitive prices. |

| Local Dealers | Authorized dealers provide genuine parts tailored for specific models. | Quality assurance, knowledgeable staff, support for installation. |

| Specialty Stores | Shops focused on vintage equipment can carry hard-to-find items. | Expertise, a curated selection, community connections. |

| Online Forums | Communities where enthusiasts share tips and parts for sale. | Peer advice, direct connections with other owners, potential deals. |

By exploring these sources, owners can effectively track down the components they need to keep their machinery in optimal condition. Each option offers distinct benefits, making it easier to find the right parts to suit individual needs and preferences.