Ensuring the longevity and optimal performance of your outdoor equipment is essential for any enthusiast. This section delves into essential procedures and techniques that empower users to tackle common issues and enhance the functionality of their machines. With proper guidance, even novice users can become adept at managing their tools effectively.

Understanding your equipment is key to addressing potential problems. Each component plays a vital role, and familiarity with their functions enables you to identify when something isn’t operating as it should. By gaining insight into the mechanics, you can make informed decisions and take appropriate actions.

Furthermore, regular upkeep not only prolongs the life of your machinery but also improves efficiency. This guide will walk you through necessary steps, from routine checks to more involved interventions, ensuring that your outdoor equipment remains in peak condition season after season.

Understanding the Troy-Bilt Bronco

The purpose of this section is to delve into the key features and characteristics that define this popular garden equipment. By exploring its design, functionality, and overall performance, users can gain a clearer understanding of its capabilities and how it can effectively meet their gardening needs.

Key Features

This piece of machinery is known for its user-friendly design and robust construction. It often includes a powerful engine, reliable transmission, and an adjustable cutting system, allowing it to handle various terrain types with ease. Users appreciate the comfortable seating and intuitive controls, which enhance the overall experience of operating this tool.

Performance and Versatility

When it comes to performance, this equipment excels in both efficiency and effectiveness. Its versatility allows it to tackle a wide range of tasks, from mowing to tilling, making it a valuable asset for any gardening enthusiast. With proper understanding of its features and maintenance, users can maximize its potential and achieve outstanding results in their outdoor projects.

Common Issues with the Bronco

Every machine has its quirks, and this model is no exception. Users often encounter a range of challenges that can hinder performance or lead to frustrating situations. Understanding these typical problems can help in identifying symptoms early and addressing them effectively.

- Engine Starting Problems:

Difficulty in starting the engine can arise from various factors such as:

- Old or faulty spark plugs

- Clogged fuel filter

- Battery issues

- Uneven Cutting:

When the cutting height is inconsistent, it can be attributed to:

- Dull blades

- Uneven tire pressure

- Improperly adjusted deck height

- Transmission Issues:

Problems with shifting gears or sluggish response may stem from:

- Low fluid levels

- Worn belts

- Blocked filters

- Overheating:

This can occur due to:

- Low coolant levels

- Clogged air filters

- Defective thermostat

Addressing these common issues promptly can ensure better longevity and efficiency of the machine, making maintenance a key factor in its upkeep.

Essential Tools for Repairing

When it comes to maintaining outdoor equipment, having the right instruments is crucial. A well-equipped workspace not only streamlines the process but also enhances safety and efficiency. Below is a guide to some fundamental items that every enthusiast should consider having on hand.

Basic Hand Tools

Hand tools form the backbone of any maintenance project. They are versatile and can handle various tasks with ease.

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for tightening or loosening screws in different sizes. |

| Wrench Set | Ideal for fastening or loosening nuts and bolts. |

| Pliers | Useful for gripping, bending, and cutting wires. |

| Socket Set | Provides a range of socket sizes for various fasteners. |

Power Tools

In addition to hand tools, power tools can significantly speed up tasks and improve precision.

| Tool | Purpose |

|---|---|

| Drill | Facilitates creating holes or driving screws with power. |

| Angle Grinder | Effective for cutting, grinding, and polishing surfaces. |

| Impact Wrench | Excellent for loosening tight bolts quickly. |

| Air Compressor | Useful for powering pneumatic tools and inflating tires. |

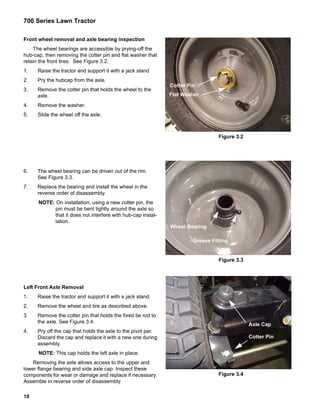

Step-by-Step Maintenance Procedures

Regular upkeep is essential for optimal performance and longevity of your equipment. Following a structured approach not only enhances efficiency but also helps prevent potential issues down the line. Below are detailed steps to ensure your machinery remains in top condition.

-

Inspect Fluids

- Check oil levels and quality.

- Examine coolant for proper concentration.

- Look at fuel system for any leaks or contamination.

-

Clean Air Filters

- Remove filters and assess for dirt and debris.

- Clean or replace as necessary.

-

Examine Belts and Hoses

- Inspect for cracks, fraying, or wear.

- Ensure all connections are secure.

-

Sharpen Blades

- Detach blades carefully.

- Use a sharpening tool to maintain the cutting edge.

-

Check Tires

- Verify tire pressure against manufacturer specifications.

- Inspect tread for even wear and damage.

-

Test Battery

- Clean terminals and ensure connections are tight.

- Check charge level and replace if necessary.

By adhering to these procedures, you can enhance the reliability and efficiency of your machinery, ultimately extending its lifespan.

Engine Troubleshooting Tips

When faced with performance issues, understanding the underlying causes can significantly enhance your approach to resolving them. This section provides practical advice for diagnosing common engine problems, empowering you to take informed steps towards restoring optimal functionality.

Identifying Common Symptoms

Start by observing any irregular behaviors. If the engine struggles to start, exhibits unusual noises, or shows inconsistent power, these signs often indicate specific issues. Listen carefully for sounds such as knocking or sputtering, which may reveal underlying mechanical or fuel system concerns.

Checking Fuel and Air Supply

Insufficient fuel or air can lead to performance problems. Ensure that the fuel tank has an adequate supply and that the fuel filter is clean. Additionally, examine the air intake for blockages. A clear path for airflow is essential for efficient operation, as any obstructions can hinder engine performance.

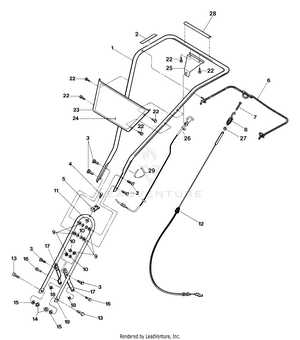

Replacing Belts and Cables

Ensuring optimal performance of your equipment often involves addressing the components that facilitate movement and control. Regularly checking and changing these elements can significantly enhance functionality and extend the lifespan of your machine. This section provides guidance on how to efficiently manage the process of substituting these essential parts.

Identifying Components

Before starting the replacement process, it’s crucial to recognize the various belts and cables that may require attention. Familiarizing yourself with these components will help streamline your efforts and ensure that the correct parts are selected for substitution.

Replacement Procedure

Follow these steps to successfully replace worn belts and cables:

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent accidents. |

| 2 | Locate the belts and cables needing replacement. |

| 3 | Carefully remove the old components, taking note of their routing. |

| 4 | Install the new belts and cables, ensuring proper alignment. |

| 5 | Reconnect the power source and test the equipment. |

By following these steps, you can maintain the effectiveness of your machine, ensuring it operates smoothly and efficiently.

Blade Sharpening and Replacement Guide

Maintaining the sharpness and integrity of your cutting tool’s blade is essential for optimal performance. This section will provide you with the necessary steps to ensure that your blade remains effective and ready for use.

Regular attention to blade condition can significantly enhance your equipment’s efficiency. Here’s a detailed approach to sharpening and replacing the blades.

Sharpening the Blade

To keep the blade in peak condition, follow these steps:

- Ensure safety by disconnecting the power source or removing the spark plug.

- Remove the blade from the cutting tool carefully.

- Inspect the blade for any signs of wear or damage.

- Use a sharpening tool or file to hone the cutting edges. Maintain an angle of about 30 degrees for optimal sharpness.

- Check for uniformity on both sides of the blade to ensure balanced performance.

- Clean the blade thoroughly to remove any debris or residue after sharpening.

Replacing the Blade

When sharpening is no longer sufficient, it may be time to replace the blade. Here’s how to do it:

- Again, ensure safety by disconnecting the power source or removing the spark plug.

- Remove the old blade, following the manufacturer’s specifications for disassembly.

- Select a compatible replacement blade that fits your equipment’s model.

- Install the new blade, making sure it is aligned correctly and securely fastened.

- Reconnect the power source or replace the spark plug.

- Perform a test run to confirm proper installation and functionality.

By following these guidelines, you can maintain the effectiveness of your cutting tool and prolong its lifespan. Regular upkeep not only enhances performance but also ensures safety during operation.

Electrical System Diagnostics

This section focuses on identifying and troubleshooting issues within the electrical framework of your equipment. Proper assessment ensures optimal performance and longevity, allowing for a systematic approach to pinpointing faults and restoring functionality.

Common Issues to Identify

- Battery failures

- Faulty wiring connections

- Defective switches

- Malfunctioning ignition systems

- Issues with fuses and relays

Diagnostic Steps

- Begin with a visual inspection of all wiring and connectors for signs of wear or damage.

- Check the battery voltage using a multimeter; it should typically read between 12.4 and 12.6 volts when fully charged.

- Test individual components, such as switches and fuses, to ensure they function correctly.

- Examine the ignition system, verifying that all connections are secure and free of corrosion.

- Conduct continuity tests on wiring to identify any breaks or shorts.

By following these steps, you can effectively diagnose and address electrical issues, enhancing the reliability of your equipment.

Seasonal Maintenance Checklist

Regular upkeep is essential to ensure optimal performance and longevity of your equipment throughout the changing seasons. By following a systematic approach to maintenance, you can prevent issues and enhance the efficiency of your machinery. This checklist provides essential tasks to be performed at the beginning of each season, ensuring that your equipment remains in peak condition.

Spring Maintenance Tasks

| Task | Description |

|---|---|

| Inspect Belts | Check for wear, cracks, or fraying, and replace if necessary. |

| Change Oil | Replace old oil with fresh lubricant to ensure smooth operation. |

| Sharpen Blades | Ensure blades are sharp for effective cutting performance. |

| Clean Air Filter | Remove dirt and debris from the air filter for optimal airflow. |

Fall Maintenance Tasks

| Task | Description |

|---|---|

| Inspect Tires | Check for proper inflation and tread wear; adjust as needed. |

| Fuel System Check | Inspect fuel lines and filter; replace old fuel to prevent contamination. |

| Battery Maintenance | Clean terminals and ensure secure connections; test charge level. |

| Store Properly | Prepare equipment for winter storage, ensuring it’s clean and protected. |

Upgrading Parts for Enhanced Performance

Improving the capabilities of your outdoor equipment can significantly enhance its efficiency and longevity. By selecting superior components, you can elevate the overall functionality and adapt the machine to better suit your specific needs. This approach not only optimizes performance but also ensures a smoother operation in various conditions.

When considering enhancements, focus on key areas such as the engine, transmission, and cutting system. Upgrading to a more powerful engine can provide increased torque and horsepower, enabling better handling of tough terrains. Additionally, refining the transmission system can improve speed and responsiveness, allowing for a more agile experience.

Another crucial aspect is the cutting mechanism. Investing in high-quality blades or attachments can lead to cleaner cuts and a more efficient workflow. Consider materials designed for durability and resistance to wear, which will reduce maintenance needs and extend the life of your equipment.

Finally, don’t overlook the importance of maintaining compatibility with existing parts. Ensuring that new components integrate seamlessly with the current system is vital for achieving the desired performance improvements. By strategically upgrading parts, you can transform your machine into a more robust and reliable tool, ready to tackle any task.

Finding Replacement Parts Online

Locating suitable components on the internet can significantly enhance your equipment’s performance. With a variety of options available, it’s essential to know where to look and how to ensure you select the right items for your needs.

Where to Search

- Manufacturer’s Website: Start with the official site for authentic parts and specifications.

- Online Marketplaces: Websites like eBay and Amazon often have a wide selection of components from various sellers.

- Specialty Retailers: Look for stores that specialize in outdoor equipment; they may offer both new and used items.

- Forums and Community Groups: Engage with enthusiasts who can recommend trustworthy sources and share their experiences.

Tips for Choosing the Right Parts

- Verify compatibility by checking model numbers and specifications.

- Read customer reviews to gauge quality and performance.

- Compare prices to ensure you get the best deal available.

- Inquire about return policies in case the item does not meet your expectations.

By following these guidelines, you can efficiently navigate the online marketplace to find the right components for your needs.