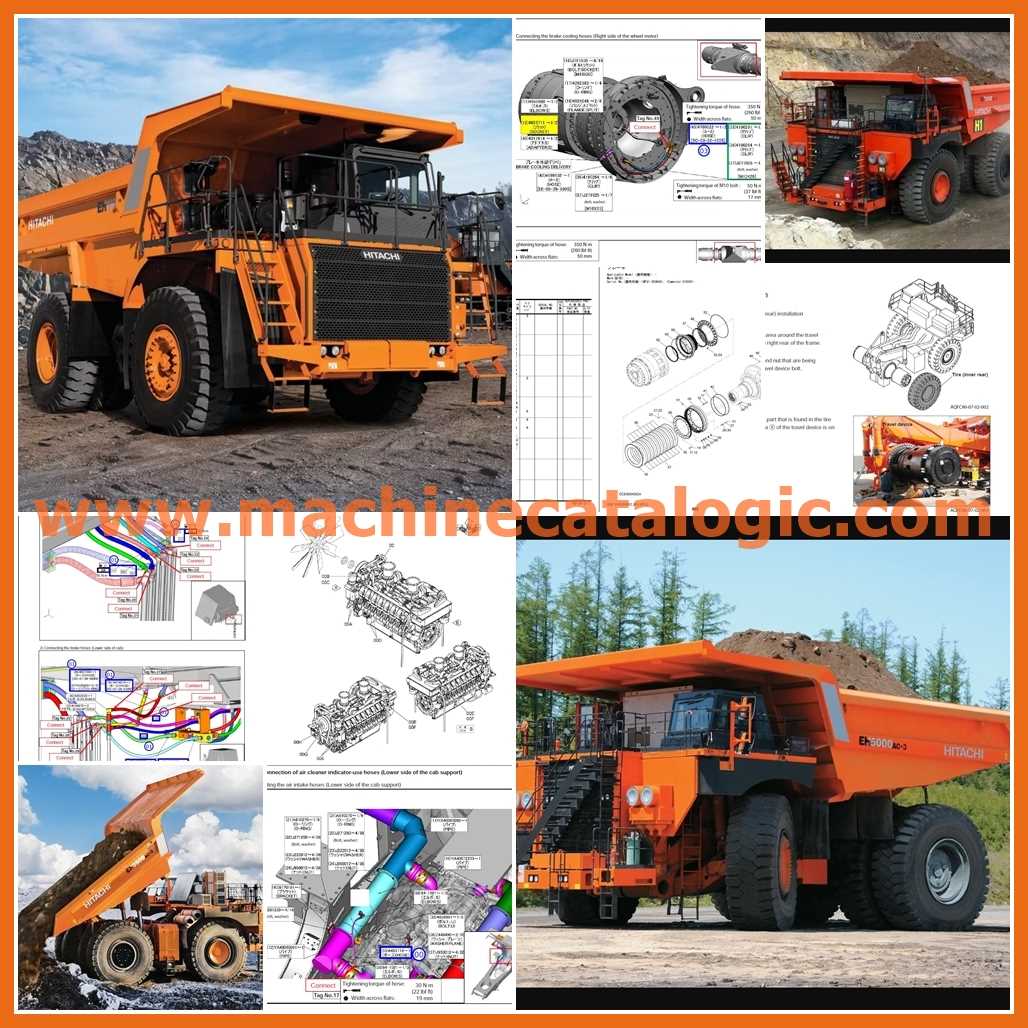

This section provides essential insights into the upkeep and service protocols for large construction vehicles. Understanding the intricacies of these machines is crucial for ensuring their longevity and optimal performance in various operational conditions.

Proper maintenance practices not only enhance the efficiency of these vehicles but also minimize downtime and repair costs. By following a systematic approach to care and management, operators can safeguard their investment and ensure safety on the job site.

In this guide, you will find valuable information regarding troubleshooting techniques, routine checks, and best practices for keeping these powerful machines in peak condition. Implementing these strategies will help in extending the life of the equipment while maintaining high productivity levels.

Recognizing signs of mechanical problems at an early stage can significantly enhance the longevity and efficiency of heavy equipment. Proactive detection not only reduces downtime but also minimizes repair costs. Understanding the common indicators of potential malfunctions is crucial for operators and maintenance personnel alike.

Operators should stay vigilant for unusual noises, vibrations, or changes in performance. Regular inspections and routine maintenance are essential practices that help identify minor issues before they escalate into major concerns.

| Indicator | Possible Issue | Recommended Action |

|---|---|---|

| Unusual Noises | Loose components or failing bearings | Inspect and tighten or replace parts |

| Vibrations | Imbalance or misalignment | Check alignment and balance |

| Decreased Performance | Fuel or air intake issues | Examine filters and connections |

| Fluid Leaks | Worn seals or hoses | Replace damaged components |

Tools Required for Effective Repairs

To ensure successful maintenance and restoration of heavy machinery, having the right instruments is crucial. A well-equipped toolkit enables technicians to perform tasks efficiently and effectively, minimizing downtime and maximizing performance.

Essential Instruments

Key tools include wrenches, screwdrivers, and pliers, which are fundamental for disassembling components and making necessary adjustments. Additionally, specialized equipment such as hydraulic jacks and diagnostic devices play a vital role in troubleshooting issues and facilitating repairs.

Safety Gear

In conjunction with the right tools, safety gear is indispensable. Personal protective equipment (PPE) such as gloves, goggles, and hard hats should always be used to safeguard against potential hazards during maintenance tasks.

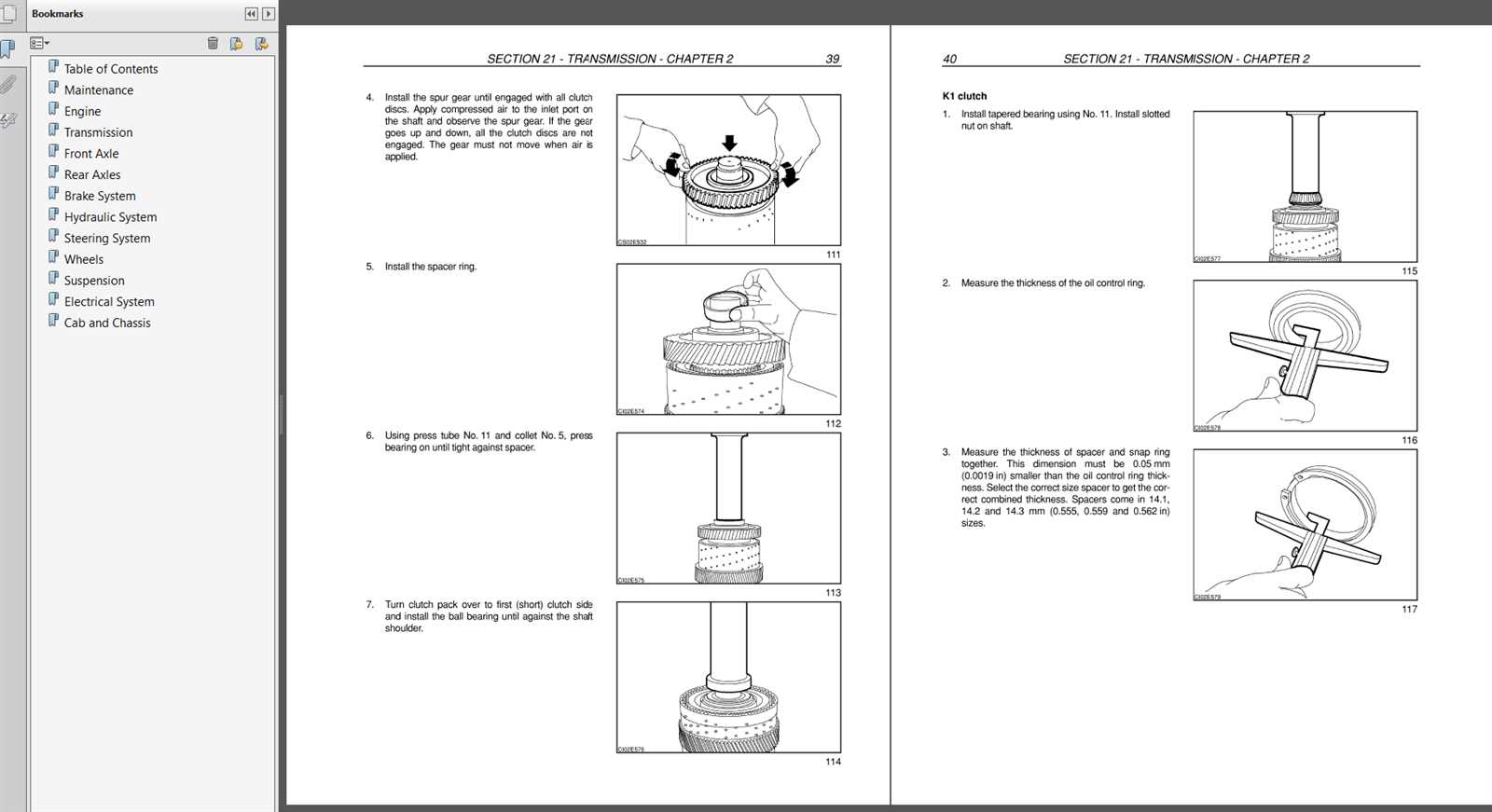

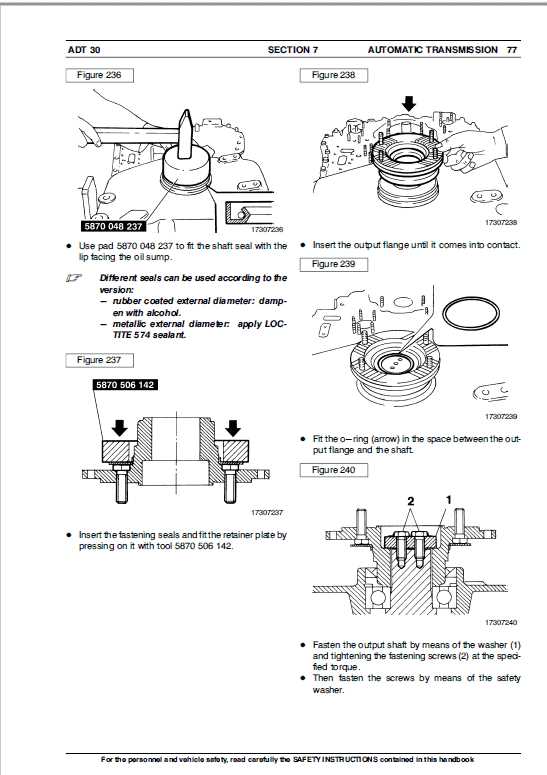

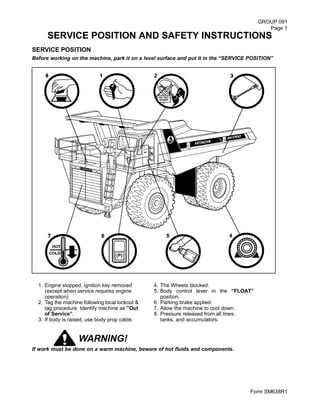

Step-by-Step Repair Procedures

This section outlines the systematic approach to addressing common issues in heavy-duty vehicles. Following a structured method ensures efficient troubleshooting and maintenance, allowing for timely solutions.

Here are the general steps to follow:

- Assessment: Begin by evaluating the condition of the vehicle to identify visible problems.

- Gather Tools: Assemble all necessary tools and parts required for the task.

- Safety Precautions: Implement safety measures to protect yourself and the surrounding environment.

- Disassembly: Carefully take apart the components that need attention, ensuring to document the process.

- Inspection: Examine each part for signs of wear, damage, or malfunction.

- Replacement: If any components are faulty, replace them with suitable alternatives.

- Reassembly: Put everything back together methodically, following the initial disassembly steps.

- Testing: Conduct tests to confirm that the vehicle operates correctly after maintenance.

- Documentation: Record the work done, including parts replaced and any observations made during the process.

By adhering to these outlined procedures, one can effectively maintain functionality and extend the lifespan of the equipment.

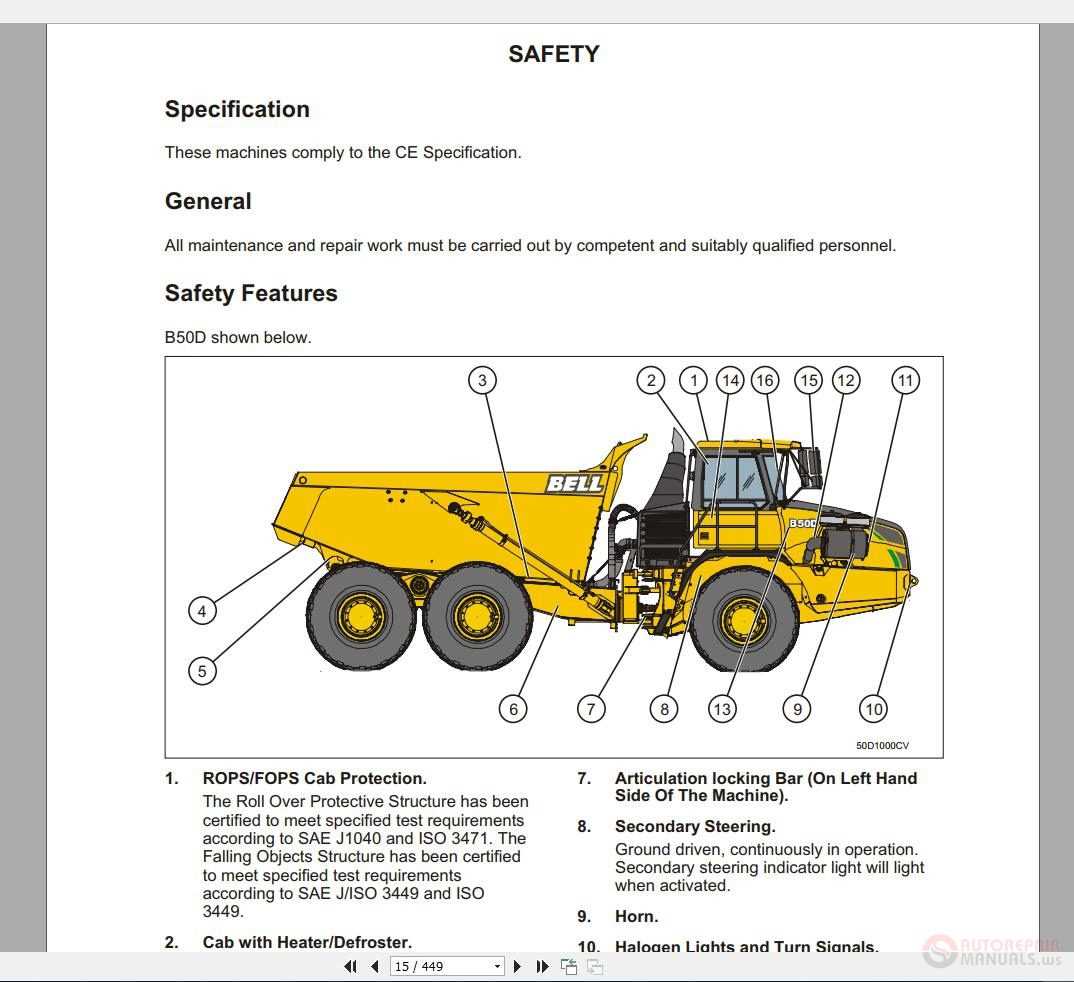

Safety Guidelines for Truck Repairs

Ensuring safety during maintenance activities is crucial for preventing accidents and injuries in the workplace. By adhering to established protocols and employing best practices, workers can minimize risks and enhance overall operational efficiency.

Personal Protective Equipment

Proper use of personal protective equipment (PPE) is essential for safeguarding individuals involved in maintenance tasks. Essential gear includes:

| Equipment | Purpose |

|---|---|

| Hard Hats | Protect against falling objects |

| Gloves | Shield hands from sharp edges and chemicals |

| Safety Glasses | Prevent eye injuries from debris |

| Steel-Toed Boots | Cushion feet from heavy loads |

Work Area Organization

Maintaining an orderly work environment is vital for safe operations. A clutter-free space allows for easier movement and reduces the chance of slips and falls. Additionally, clearly marking hazardous areas and ensuring proper ventilation when working with fumes can further enhance safety.

Parts Replacement: What You Need

Maintaining machinery requires a thorough understanding of its components and when they need to be substituted. Regular assessments ensure that your equipment operates efficiently and safely. Knowing what parts are critical and how to identify wear or damage is essential for optimal performance.

Identifying Worn Components

Before initiating any replacement, it’s crucial to evaluate the condition of each part. Look for signs of wear such as cracks, excessive rust, or unusual noises during operation. Regular inspections can help you determine which elements require immediate attention.

Selecting Quality Parts

When it’s time to replace components, choosing high-quality replacements is vital. Opt for parts that meet or exceed the manufacturer’s specifications to ensure compatibility and durability. Using subpar materials can lead to further issues down the line, jeopardizing overall functionality.

Maintaining Hydraulic Systems Effectively

Ensuring the optimal performance of hydraulic mechanisms is crucial for operational efficiency. Regular upkeep not only extends the lifespan of components but also prevents costly failures. Here are some essential practices to maintain these systems effectively.

- Regular Inspection: Conduct frequent evaluations to identify signs of wear or leakage.

- Fluid Quality: Monitor and replace hydraulic fluid as needed to ensure it meets specified standards.

- Seal Integrity: Check seals and gaskets for deterioration, replacing them promptly to prevent leaks.

- Contamination Control: Implement measures to minimize contaminants entering the system, such as using filters.

- Temperature Regulation: Ensure the system operates within the recommended temperature range to avoid overheating.

Following these guidelines will help maintain hydraulic systems efficiently, leading to enhanced performance and reduced downtime.

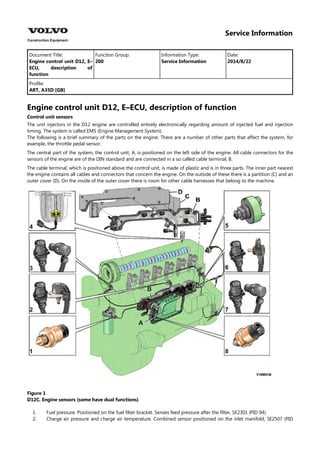

Diagnosing Electrical System Problems

Identifying issues within the electrical framework of heavy machinery requires a systematic approach. Understanding the interplay of various components is essential to accurately assess any malfunctioning parts. This section outlines effective methods for troubleshooting and diagnosing potential electrical failures.

Start by conducting a visual inspection of the wiring and connections. Look for signs of wear, frayed wires, or loose terminals that could disrupt electrical flow. Additionally, utilize diagnostic tools such as multimeters to measure voltage, current, and resistance in circuits, helping to pinpoint discrepancies.

Next, check the fuses and relays, as these components play a crucial role in protecting the system from overloads. A blown fuse or faulty relay can often be the source of electrical failures. Replace any defective parts and retest the system to see if functionality is restored.

Finally, consult schematics and diagrams to understand the specific layout of the electrical system. This knowledge will aid in tracing circuits and isolating problem areas more effectively. Accurate diagnosis is key to implementing timely repairs and ensuring the machinery operates smoothly.

Best Practices for Truck Cleaning

Maintaining cleanliness is essential for enhancing performance and extending the lifespan of heavy vehicles. Regular cleaning not only improves aesthetics but also prevents corrosion and other damage caused by accumulated dirt and debris.

Essential Cleaning Steps

- Start with a thorough inspection to identify areas requiring extra attention.

- Use a gentle water spray to remove loose dirt and grime.

- Apply suitable cleaning agents that are safe for the vehicle’s materials.

- Utilize brushes and cloths designed for automotive surfaces to avoid scratches.

Preventative Maintenance Tips

- Establish a regular cleaning schedule based on usage conditions.

- Protect sensitive areas with wax or sealant after cleaning.

- Inspect and clean undercarriage components to prevent rust.