Understanding the intricacies of small engine upkeep is essential for optimal performance and longevity. This section provides insights into essential practices that ensure your equipment remains functional and efficient over time. With the right knowledge, you can effectively tackle various challenges that may arise during usage.

Key aspects of maintenance involve regular inspections, troubleshooting common issues, and knowing when to seek professional assistance. By familiarizing yourself with these elements, you can enhance your experience and extend the life of your machinery. Proper care not only improves performance but also minimizes potential disruptions in your work.

Equipped with the right guidance, you can confidently address typical concerns, perform necessary adjustments, and make informed decisions. This knowledge empowers you to maintain your equipment with ease, ensuring it serves you well throughout its operational life.

When addressing mechanical issues, having the right instruments at your disposal can make all the difference. A well-equipped toolkit not only simplifies the process but also ensures efficiency and accuracy in every task. Below is a list of fundamental tools that are indispensable for tackling various maintenance challenges.

Basic Hand Tools

- Screwdrivers: A set of both flat and Phillips screwdrivers is essential for loosening and tightening screws.

- Wrenches: Adjustable and socket wrenches are vital for gripping and turning nuts and bolts securely.

- Pliers: Different types of pliers, including needle-nose and slip-joint, are useful for gripping, bending, and cutting wires.

Power Tools and Accessories

- Drill: An electric drill is indispensable for creating holes and driving screws efficiently.

- Impact Wrench: This tool provides the necessary torque for loosening stubborn bolts.

- Toolbox: A sturdy toolbox keeps all your instruments organized and easily accessible.

Investing in quality tools not only enhances your repair capabilities but also ensures that tasks are completed with precision and safety in mind.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues that may arise with your equipment. By following these systematic steps, you can effectively diagnose problems and implement solutions to restore functionality.

1. Identify the Issue: Begin by observing the symptoms. Is there an unusual noise, or is the device not operating as expected? Make a note of any irregularities that could help in the diagnosis.

2. Check the Power Source: Ensure that the power supply is functional. Verify that all connections are secure and inspect for any damage to the cords or plugs.

3. Examine Components: Inspect all parts for signs of wear or damage. Look for loose or corroded connections that might disrupt performance. Replace any faulty components as necessary.

4. Test Functionality: After addressing any visible issues, attempt to operate the equipment again. Observe if the initial problem persists or if new symptoms emerge.

5. Consult Resources: If the problem remains unresolved, refer to available documentation or online resources for further guidance on troubleshooting specific issues related to your equipment.

6. Seek Professional Help: Should the difficulties continue, consider reaching out to a qualified technician who can provide expert assistance and ensure that the equipment is restored to optimal working condition.

Replacing the Engine Components

Maintaining optimal performance in a small engine often requires replacing its essential components. Understanding the process can significantly enhance the engine’s longevity and efficiency. This section outlines the key steps and considerations involved in this procedure.

Preparation Steps

- Gather all necessary tools and replacement parts.

- Ensure the work area is clean and organized.

- Disconnect the spark plug to prevent accidental ignition.

Component Replacement Process

- Remove the engine cover to access internal parts.

- Carefully detach the old components, such as the air filter and carburetor.

- Inspect the surrounding areas for wear or damage.

- Install new components securely, following manufacturer guidelines.

- Reassemble the engine cover and reconnect the spark plug.

Regularly replacing engine components not only enhances performance but also contributes to the overall health of the machine. Following these steps ensures a smooth and efficient replacement process.

Maintenance Tips for Longevity

To ensure the lasting performance of your outdoor equipment, regular upkeep is essential. Simple practices can significantly enhance the lifespan and reliability of your tools, allowing them to function at their best for years to come.

Routine Cleaning: Keeping your machinery clean is fundamental. After each use, remove dirt and debris from surfaces to prevent buildup that can lead to corrosion and mechanical issues. Utilize a soft brush or cloth to reach all areas, especially around moving parts.

Regular Inspections: Conducting frequent checks is crucial for identifying potential problems early. Examine components for wear and tear, ensuring that all parts are functioning properly. Look for any signs of damage or loose connections, and address these issues promptly.

Proper Lubrication: Adequate lubrication of moving parts is vital for reducing friction and preventing premature wear. Use the recommended lubricants and follow the manufacturer’s guidelines for application frequency and amount to maintain optimal performance.

Storage Considerations: When not in use, store your equipment in a dry, sheltered area to protect it from the elements. Covering your tools can also prevent dust accumulation, which may affect functionality. Ensure they are stored in an upright position to avoid any unintended damage.

By following these straightforward maintenance tips, you can extend the operational life of your machinery and enjoy reliable performance throughout its usage. Regular care not only enhances efficiency but also contributes to safer operation.

Understanding Electrical Systems

Electrical systems play a crucial role in the functionality of various machines and equipment. These systems comprise a network of components that work together to ensure efficient operation, powering essential functions and enhancing overall performance.

Key Components of Electrical Systems

To fully grasp the workings of electrical systems, it is important to familiarize yourself with their main elements:

- Power Source: The origin of electrical energy, such as batteries or generators.

- Wiring: Conductors that transport electricity between components.

- Switches: Devices that control the flow of electricity, allowing for on/off functions.

- Load: Components that consume electrical energy, such as motors or lights.

Common Issues in Electrical Systems

Several problems can arise within these systems, impacting performance and efficiency:

- Short Circuits: Occur when unintended paths allow electricity to flow, potentially causing damage.

- Corrosion: Deterioration of connections can lead to poor conductivity.

- Worn Wiring: Aging or damaged wires can result in power loss or safety hazards.

Understanding these systems is vital for troubleshooting and maintenance, ensuring reliable operation and longevity of equipment.

Inspecting the Fuel System

Examining the fuel system is crucial for ensuring optimal performance and longevity of the equipment. A well-maintained fuel system contributes to efficient operation and can prevent various issues that may arise from improper fuel flow or contamination.

Identifying Key Components

Understanding the main parts of the fuel system is essential. Here are the components you should focus on:

- Fuel tank

- Fuel lines

- Fuel filter

- Carburetor

- Fuel pump

Steps for Inspection

Follow these steps to thoroughly inspect the fuel system:

- Check the fuel tank for any signs of leaks or damage.

- Examine fuel lines for cracks or blockages.

- Replace the fuel filter if it appears dirty or clogged.

- Inspect the carburetor for proper functioning and cleanliness.

- Test the fuel pump to ensure it is delivering the right amount of fuel.

Regular inspections can help identify potential issues early and ensure the smooth operation of your equipment.

Blades and Cutting Deck Care

Maintaining the sharpness and functionality of the cutting elements and the deck is essential for optimal performance. Regular upkeep ensures efficient operation and extends the lifespan of the equipment.

Routine Inspection: Frequently examine the blades for any signs of wear, damage, or dullness. It is crucial to address any issues promptly to avoid poor cutting performance.

Sharpening Blades: Keep the cutting edges sharp for clean and precise cutting. Regular sharpening minimizes stress on the motor and enhances the quality of the cut.

Cleaning the Deck: After each use, remove any grass clippings and debris from the deck. A clean deck prevents rust and maintains airflow, which is vital for effective cutting.

Adjusting Blade Height: Ensure the cutting height is set correctly for the type of grass being trimmed. Adjusting the height can improve the quality of the cut and prevent damage to the lawn.

Seasonal Maintenance: At the beginning and end of the cutting season, perform thorough inspections and maintenance tasks. This includes checking for any loose parts and ensuring all components are in good working condition.

Identifying Wear and Tear Signs

Recognizing the signs of deterioration is crucial for maintaining optimal performance and longevity of equipment. Regular inspection can help in detecting subtle changes that may indicate issues requiring attention. Understanding these signs can prevent further damage and enhance the overall functionality.

Common indicators of wear include visible cracks, frayed edges, and unusual noises during operation. Additionally, decreased efficiency or inconsistent performance may suggest that components are reaching the end of their lifespan. Pay close attention to any irregularities that deviate from normal operation.

It is advisable to conduct periodic checks to ensure that all parts are functioning correctly. Early identification of these signs allows for timely interventions, which can save both time and resources in the long run. A proactive approach to maintenance can significantly extend the useful life of the equipment.

Seasonal Maintenance Checklist

Regular upkeep is essential to ensure optimal performance and longevity of your equipment throughout the year. This checklist serves as a guide for routine tasks that should be performed during each season to keep your machine in top condition.

Spring Preparation

As the warmer months approach, it’s important to inspect the unit thoroughly. Focus on the following:

- Oil Change: Replace old oil with fresh lubricant to ensure smooth operation.

- Filter Inspection: Clean or replace air and fuel filters to maintain efficiency.

- Battery Check: Inspect the battery for corrosion and ensure proper connections.

Fall and Winter Readiness

Preparing for colder weather involves specific tasks to protect your equipment:

- Fuel Stabilizer: Add stabilizer to the fuel to prevent deterioration during storage.

- Thorough Cleaning: Clean the exterior and undercarriage to remove debris.

- Storage Preparation: Store the unit in a dry, sheltered location to prevent damage from the elements.

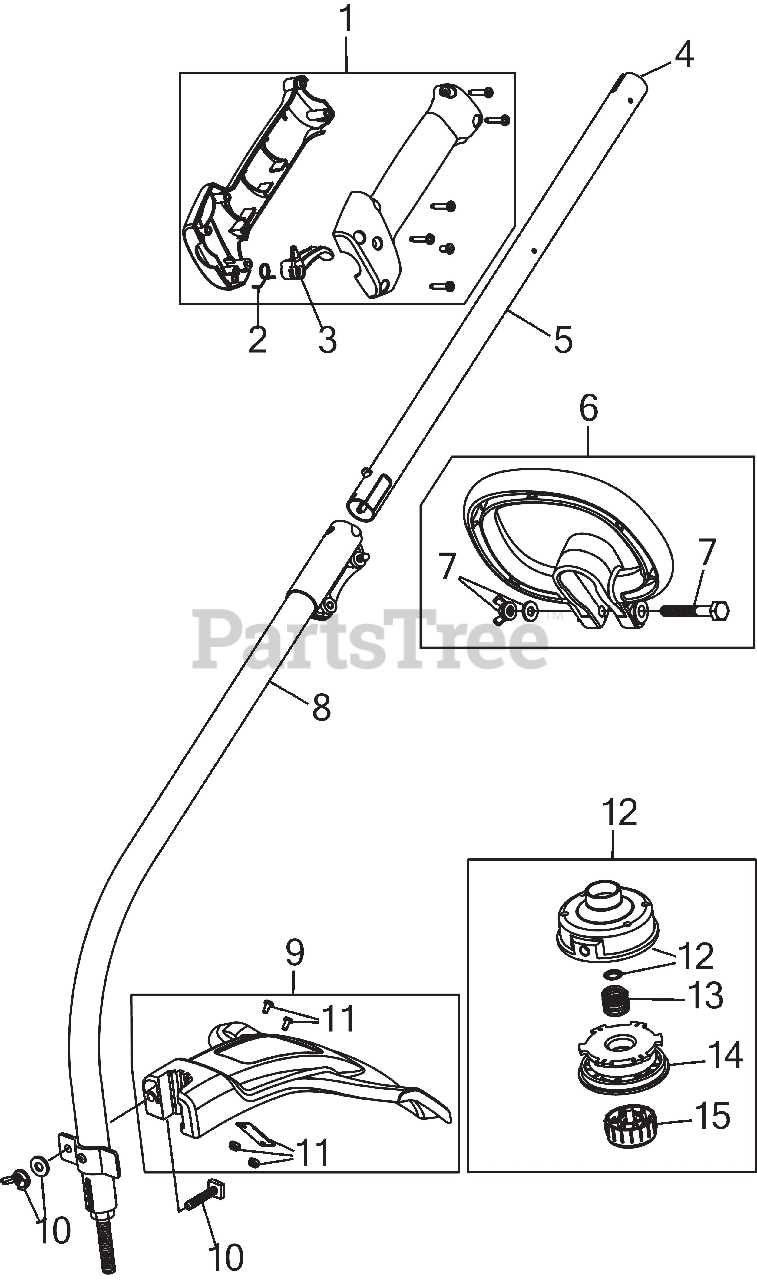

Recommended Replacement Parts

When maintaining outdoor equipment, selecting the right components for replacement is crucial to ensure optimal performance and longevity. This section outlines essential parts that are often needed for various maintenance tasks, helping users keep their machinery running smoothly.

Key Components

Choosing high-quality parts can significantly affect the functionality of your equipment. Here are some vital components to consider:

| Part Name | Description | Compatibility |

|---|---|---|

| Air Filter | Helps keep debris out of the engine. | Compatible with various models. |

| Spark Plug | Ensures efficient ignition of fuel. | Fits multiple engine types. |

| Fuel Filter | Removes impurities from the fuel supply. | Universal fit for many brands. |

| Oil Filter | Maintains clean engine oil circulation. | Suitable for various systems. |

Additional Suggestions

In addition to the primary parts listed, consider inspecting belts and hoses regularly, as these components also play a significant role in the overall operation. Keeping spare parts on hand can minimize downtime during maintenance.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and troubleshooting of outdoor machinery. Understanding these frequently encountered issues can help users efficiently resolve problems and enhance their experience.

- What should I do if the engine won’t start?

Check the fuel level, battery connections, and ensure the safety features are disengaged.

- How can I maintain optimal performance?

Regular cleaning, oil changes, and inspecting the spark plug are essential for keeping the equipment running smoothly.

- What type of fuel is recommended?

Always use the manufacturer-recommended fuel type to avoid damaging the engine.

- How do I troubleshoot unusual noises?

Inspect for loose parts or debris. If the noise persists, consult a professional technician.