Maintaining complex mechanical systems is essential for ensuring their longevity and optimal performance. This section delves into the intricacies of one particular type of system that relies on a sophisticated arrangement of components to facilitate seamless operation. Understanding the nuances of this assembly can significantly enhance your ability to troubleshoot and address issues that may arise during its lifespan.

In the following paragraphs, we will explore various aspects related to the upkeep of these mechanisms. From recognizing common challenges to implementing effective solutions, this guide aims to empower you with the knowledge needed to tackle maintenance tasks confidently. By utilizing practical strategies and insights, you can ensure that your system operates efficiently and remains reliable over time.

Equipping yourself with the right information is the first step towards effective management of your gearbox. As you progress through this guide, you will discover key techniques and tips that will aid you in maintaining the integrity of this crucial assembly.

Let us embark on this journey to gain a deeper understanding of the components and functions involved, paving the way for more informed decisions in the realm of gearbox maintenance.

When tackling complex mechanical systems, having the right equipment is crucial for achieving successful outcomes. A well-equipped workspace not only enhances efficiency but also ensures that each task is completed accurately and safely. Below are key instruments that every technician should have on hand.

- Socket Set: A comprehensive collection of sockets in various sizes is vital for loosening and tightening components.

- Wrenches: Both standard and adjustable wrenches are necessary for accessing hard-to-reach areas and providing a solid grip.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will facilitate the removal of screws from different parts.

- Pliers: These are essential for gripping, twisting, and cutting wires and other small components.

- Torque Wrench: This tool is critical for applying a specific amount of torque to fasteners, ensuring they are securely tightened without over-tightening.

- Multimeter: Used for diagnosing electrical issues, a multimeter helps in measuring voltage, current, and resistance.

- Jack and Stands: A reliable jack and set of stands are necessary for safely elevating and supporting the system during work.

- Fluid Extractor: This tool allows for easy removal of old fluids, aiding in maintenance and servicing.

Equipping oneself with these essential tools can significantly simplify the process of maintaining and restoring mechanical systems, ultimately leading to more effective and reliable results.

Step-by-Step Diagnostic Procedures

Identifying issues within complex systems requires a systematic approach to ensure accurate analysis and effective resolution. This section outlines a structured method for evaluating performance problems, enabling technicians to pinpoint faults with precision.

Begin by gathering all relevant information regarding the symptoms observed. Consultation with the vehicle’s owner can provide valuable insights into the timeline of the issues. Document any unusual behavior, such as irregular shifting patterns or unexpected noises.

Next, conduct a visual inspection of the components involved. Look for signs of wear, leaks, or damaged elements. Ensure that all connections are secure and free from corrosion. This preliminary check can often reveal obvious problems that need addressing.

Following the visual assessment, utilize appropriate diagnostic tools to run tests on the system. Measure fluid levels and assess their condition, as well as evaluate pressure readings where applicable. Employing specialized equipment can yield critical data to assist in the diagnostic process.

Once tests are complete, analyze the collected data against manufacturer specifications. Compare results to determine if they fall within acceptable ranges. If discrepancies are found, further investigation is warranted to understand the underlying causes.

Finally, compile all findings and formulate a comprehensive action plan. Prioritize repairs based on severity and potential impact on overall system functionality. A methodical approach ensures not only accurate problem resolution but also enhances the longevity of the system.

Fluid Types and Maintenance Tips

Ensuring optimal performance in modern vehicles relies heavily on the quality and management of essential liquids. Understanding the various types of fluids available, along with regular maintenance practices, is crucial for longevity and efficiency.

Different formulations serve distinct functions, influencing the overall operation of the vehicle’s systems. Selecting the appropriate type and adhering to maintenance schedules can significantly enhance performance.

| Fluid Type | Description | Maintenance Tips |

|---|---|---|

| Synthetic Blend | Offers improved lubrication and heat resistance. | Change every 30,000 miles or as recommended. |

| Conventional Fluid | Standard option, typically less expensive. | Check levels regularly and replace every 15,000 miles. |

| High-Performance Fluid | Designed for racing or high-stress conditions. | Monitor usage closely and replace frequently. |

Regular checks and timely replacements not only ensure smooth operation but also prevent potential damage, thereby extending the life of the vehicle. Implementing these practices will lead to better performance and reduced costs over time.

Disassembly and Inspection Techniques

Understanding the proper methods for disassembly and evaluation is crucial in ensuring optimal performance of gear systems. This section outlines effective strategies to carefully separate components while assessing their condition, enabling informed decisions for maintenance or replacement.

Preparation Steps

- Gather necessary tools and equipment.

- Establish a clean and organized workspace.

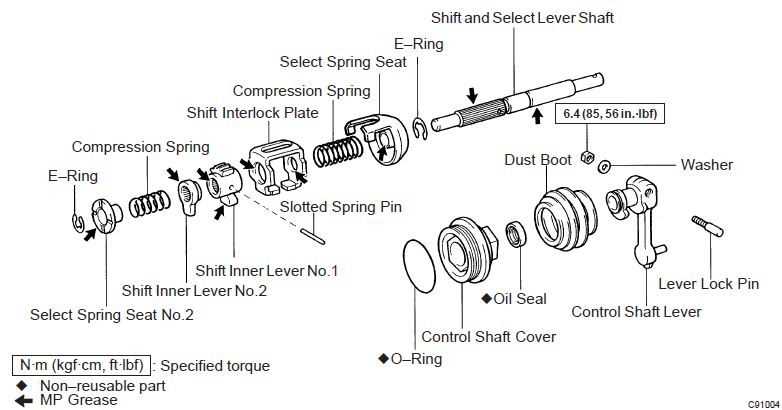

- Review schematic diagrams to familiarize yourself with the assembly.

Disassembly Process

- Begin by removing external covers and shields.

- Carefully disconnect any electrical or hydraulic connections.

- Use appropriate tools to unscrew or unclip internal parts.

- Store disassembled components in labeled containers for easy reassembly.

Regular inspection of individual pieces allows for early detection of wear and damage, ensuring longevity and reliability in future operations.

Replacing Key Components

When it comes to maintaining the efficiency of a vehicle’s drivetrain, understanding the process of substituting essential parts is crucial. This section delves into the fundamental aspects involved in the replacement of critical elements that contribute to optimal functionality.

Identifying components that may require attention is the first step in this process. Signs of wear and tear can manifest in various forms, such as unusual noises, shifting difficulties, or fluid leaks. Regular inspections can help pinpoint these issues early, allowing for timely intervention.

Once a component has been selected for replacement, proper disassembly techniques are necessary to avoid damage to surrounding parts. It is advisable to consult detailed guidelines that outline the steps to safely remove the outdated element. Additionally, utilizing high-quality replacements ensures longevity and reliable performance.

After installing the new component, it is essential to conduct thorough checks to confirm proper functionality. Testing the system under various conditions can provide insights into the effectiveness of the replacement and help identify any further adjustments needed.

Reassembly Guidelines and Best Practices

Reassembling complex mechanical systems requires precision and attention to detail. Following a systematic approach can enhance the likelihood of successful restoration and optimal performance. This section outlines essential strategies and recommended practices to ensure a seamless reassembly process.

Essential Tools and Equipment

Having the right tools is crucial for efficient reassembly. Below is a list of recommended items:

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures proper fastening of components |

| Socket Set | Facilitates removal and installation of fasteners |

| Gasket Scraper | Removes old gaskets without damaging surfaces |

| Magnetic Tray | Holds small parts securely during assembly |

Step-by-Step Reassembly Process

Following a structured process can help avoid mistakes. Here are key steps to consider:

- Clean all components thoroughly before starting.

- Inspect parts for wear or damage and replace as necessary.

- Lubricate moving components to ensure smooth operation.

- Carefully follow the sequence of assembly as outlined in your reference materials.

- Double-check the alignment of all parts before fastening.

Testing and Calibration Processes

Ensuring optimal performance of complex mechanisms involves systematic evaluation and fine-tuning. This section outlines essential methodologies for verifying functionality and achieving precision in various components. Through rigorous assessment, technicians can identify inconsistencies and implement necessary adjustments to enhance efficiency.

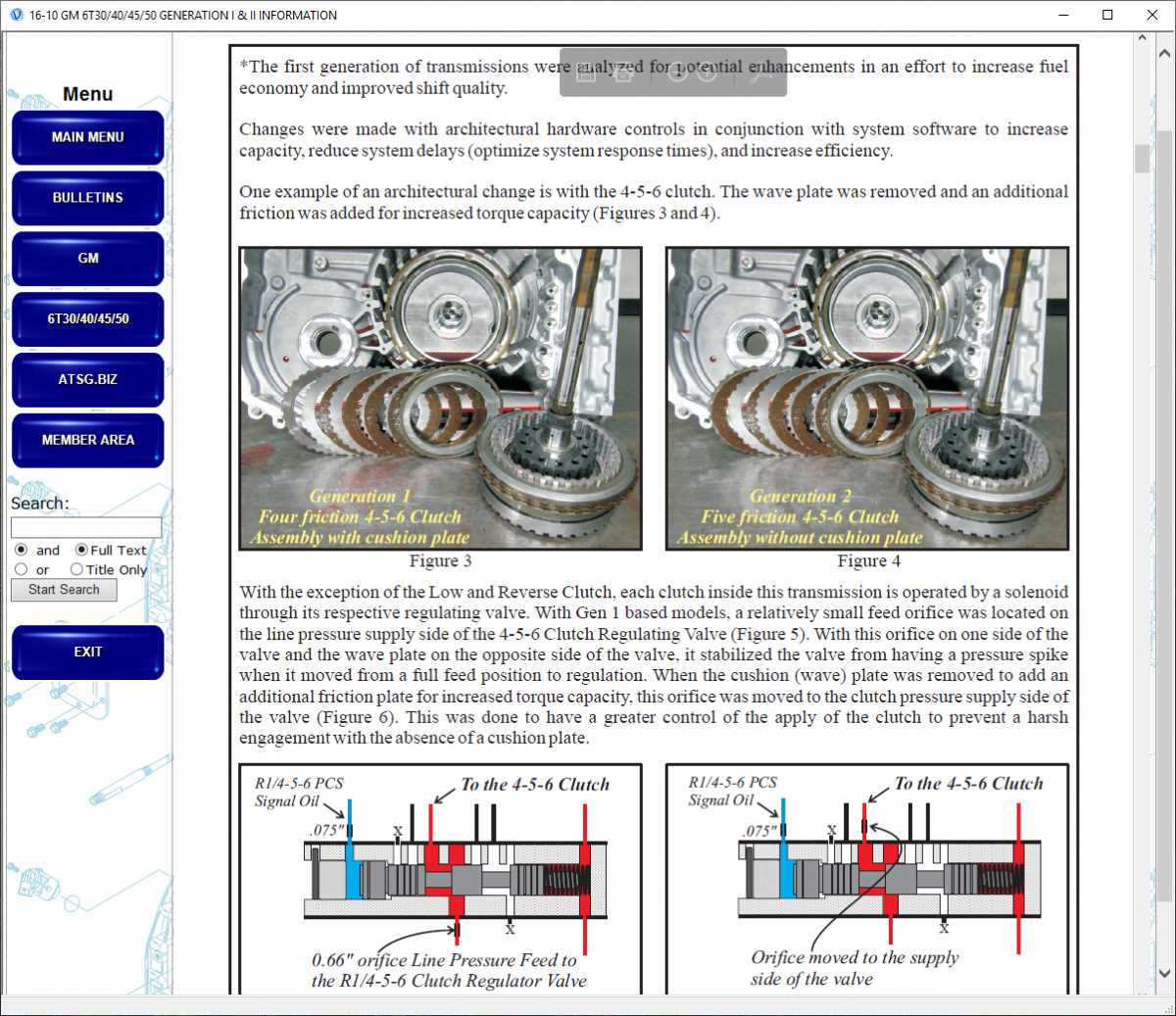

Initial Assessment plays a crucial role in detecting anomalies. Utilizing specialized tools, professionals evaluate operational parameters to establish a baseline for performance. This step is vital for understanding the current state before any modifications.

Calibration Procedures follow the assessment phase, focusing on aligning components to manufacturer specifications. This process may involve adjusting settings, replacing worn elements, or updating software interfaces. Accurate calibration ensures seamless interaction between parts, significantly improving overall system reliability.

Regular testing is recommended to maintain the longevity and functionality of the system. Establishing a routine schedule for evaluations allows technicians to anticipate potential issues, thus preventing costly breakdowns and ensuring consistent performance.

Preventive Measures for Longevity

Ensuring the extended lifespan of complex mechanical systems requires proactive care and attention. Implementing a series of preventive strategies can significantly reduce the risk of premature failures and enhance overall performance. By adopting a disciplined maintenance routine, users can avoid costly interventions and maintain optimal functionality.

Regular Fluid Checks: Monitoring and changing the lubricants at recommended intervals is essential. Clean fluids facilitate smooth operation and prevent wear on critical components.

Temperature Management: Keeping operating temperatures within safe limits is vital. Overheating can lead to detrimental effects on performance, so using cooling systems effectively can mitigate this risk.

Component Inspections: Conducting periodic examinations of critical parts allows for the early detection of wear and tear. Addressing minor issues before they escalate can save time and resources in the long run.

Driving Habits: Encouraging smooth driving techniques, such as gradual acceleration and deceleration, can lessen stress on mechanical systems. Avoiding harsh maneuvers contributes to longevity and reliability.

Professional Servicing: Engaging qualified technicians for routine maintenance ensures that any potential issues are addressed by experts. Their knowledge and experience are invaluable for preserving system integrity.

Resources for Further Learning

Expanding your knowledge in the field of vehicle systems requires access to a variety of educational materials. This section highlights valuable resources that can enhance your understanding and skills related to complex vehicle mechanisms.

Online Courses and Webinars

- Coursera: Offers courses from universities covering various aspects of automotive technology.

- edX: Features programs focused on automotive engineering and related subjects.

- Webinars: Numerous industry experts provide free online seminars to discuss recent advancements and techniques.

Books and Guides

- Automotive Engineering by Michael J. Neall: A comprehensive guide covering fundamental principles and modern practices.

- Understanding Vehicle Systems by John Doe: An informative resource for grasping essential concepts in vehicle mechanics.

- Practical Handbook for Technicians by Jane Smith: A useful manual for hands-on practices and troubleshooting methods.