Ensuring the optimal functioning of a vehicle’s gear selection system is crucial for a smooth driving experience. Over time, this essential component may exhibit signs of wear and tear, impacting performance and responsiveness. Addressing these issues promptly can prevent more significant complications and enhance the overall efficiency of the vehicle.

The process of restoring the functionality of the gear engagement system involves various techniques and tools. Understanding the underlying mechanics is vital for effectively diagnosing problems. This guide will explore common issues, solutions, and the steps necessary to bring the mechanism back to its optimal state.

By maintaining this aspect of your vehicle, you not only improve its performance but also extend its lifespan. Regular inspections and timely interventions can save drivers from costly repairs in the long run. Embracing a proactive approach to vehicle maintenance ensures a more enjoyable and reliable driving experience.

Understanding Manual Transmission Linkage

The system that connects the gear shifter to the mechanism responsible for engaging and disengaging the gears plays a crucial role in vehicle operation. This intricate assembly ensures smooth shifting and optimal performance of the vehicle. Understanding how this setup functions is essential for diagnosing issues and ensuring seamless gear changes.

Components of the Shifting System

The primary elements involved in this assembly include rods, cables, and pivot points. These components work together to translate the driver’s input from the gear lever into mechanical movements that affect gear selection. Proper alignment and condition of each part are vital for maintaining the efficiency of the overall system.

Common Issues and Solutions

Common problems within this assembly may arise from wear, misalignment, or damaged components. Symptoms such as difficulty in shifting gears or unusual noises can indicate underlying issues. Regular inspection and maintenance are key to addressing these challenges, ensuring that the system remains functional and responsive.

Common Issues in Linkage Systems

Linkage systems can encounter various challenges that affect their performance and functionality. Understanding these problems is crucial for maintaining a smooth operation. Below are some frequent issues that may arise within these systems.

Wear and Tear of Components

Over time, parts can experience significant degradation due to regular use. This wear can lead to misalignment and difficulty in shifting. Regular inspections are essential to identify worn components early and ensure they are replaced before they cause further complications.

Improper Adjustments

Incorrect setup can result in poor responsiveness. If the components are not properly calibrated, it may lead to inconsistent shifting and a frustrating driving experience. Ensuring that all elements are correctly adjusted can help mitigate this issue.

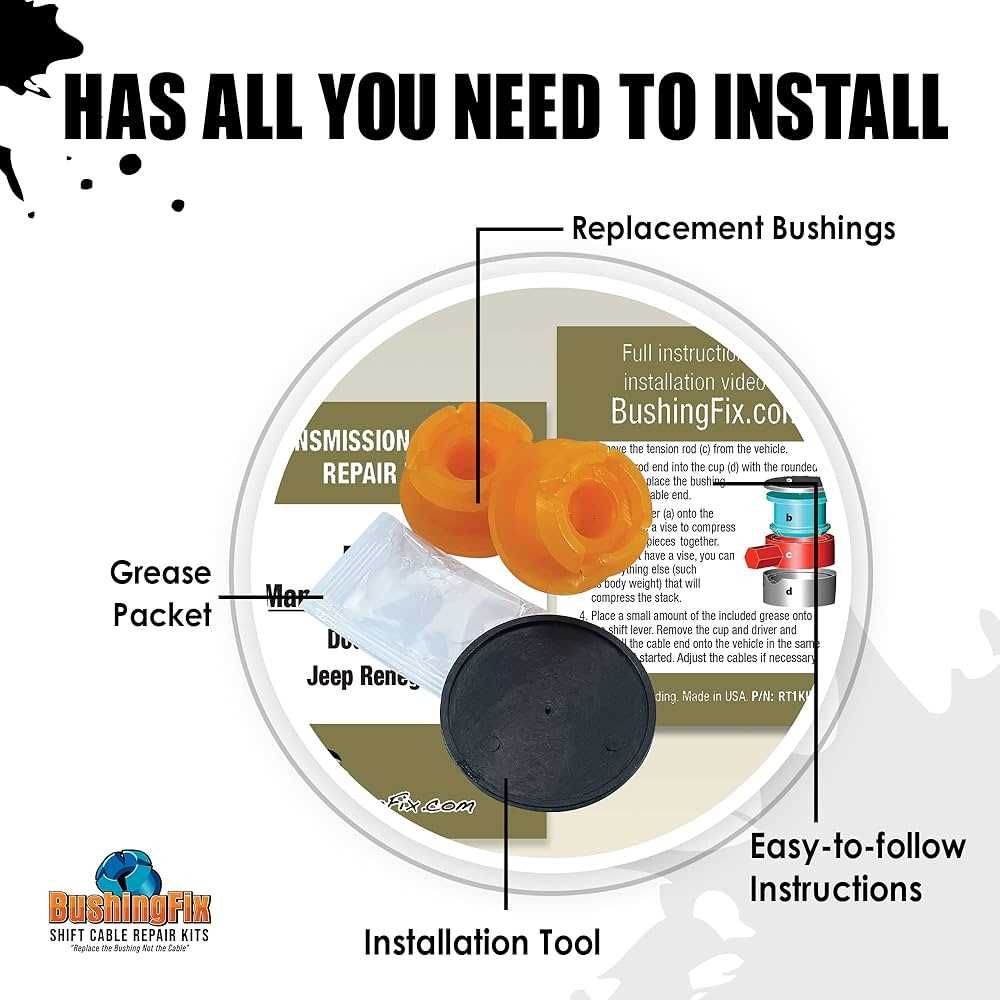

Tools Needed for Repairs

When addressing issues related to vehicle shifting mechanisms, having the right equipment is crucial for effective resolution. A well-prepared toolkit not only facilitates the process but also ensures that each component is handled with care.

Essential tools typically include various wrenches and sockets, which help in loosening and tightening fasteners. Additionally, pliers and screwdrivers of different sizes are important for removing and installing components with precision.

In many cases, a gear puller may be necessary to detach specific parts without causing damage. Furthermore, a reliable torque wrench ensures that all fastenings are secured to the manufacturer’s specifications, enhancing the longevity of the system.

Other valuable items may include a work light for improved visibility in tight spaces and a multimeter for checking electrical connections. With the right assortment of tools, the process of addressing these mechanical challenges becomes more manageable and efficient.

Identifying Symptoms of Malfunction

Recognizing the signs of a failing gear-shifting system is crucial for maintaining vehicle performance. Various indicators can suggest that something is amiss, and being aware of these can help in addressing issues promptly.

Common Indicators

Drivers may experience difficulty in changing gears, which can manifest as grinding noises or a lack of response when shifting. Unusual vibrations or stiffness in the gear lever can also signal underlying problems. Additionally, unexpected noises during operation often point to wear or damage within the mechanism.

Visual and Auditory Clues

Inspecting for fluid leaks or worn components can provide visual confirmation of issues. Listening for abnormal sounds when engaging gears can further assist in diagnosing potential failures. Addressing these symptoms early can prevent more extensive damage and costly interventions down the line.

Step-by-Step Repair Process

This section outlines the detailed procedure for addressing issues related to the gear shifting system in vehicles. Following a systematic approach ensures effective resolution and enhances the overall performance of the mechanism.

1. Preparation: Begin by gathering the necessary tools and equipment. Ensure the workspace is clean and organized to facilitate the process.

2. Inspection: Carefully examine the components involved in the shifting mechanism. Look for signs of wear, damage, or misalignment that may affect functionality.

3. Disassembly: Once the inspection is complete, proceed to remove the affected parts. Take note of the order of disassembly, as this will aid in reassembly.

4. Replacement: Replace any damaged or worn components with new ones. Ensure that all parts meet the required specifications for optimal performance.

5. Reassembly: Carefully reassemble the mechanism, following the notes taken during disassembly. Verify that all parts are correctly aligned and secured.

6. Testing: Finally, conduct a thorough test to confirm that the system operates smoothly. Pay attention to any unusual sounds or difficulties in shifting, and address them as necessary.

Adjusting Linkage for Smooth Shifting

Ensuring seamless gear changes is crucial for optimal vehicle performance. Proper alignment of the components responsible for engaging the gears can significantly enhance the driving experience. When adjustments are needed, it’s essential to follow a systematic approach to achieve the desired functionality.

Identifying Misalignments

The first step in achieving smooth engagement is to inspect the various elements involved in the shifting process. Look for signs of wear or improper positioning that could hinder movement. Any discrepancies in alignment can lead to difficulty in changing gears, impacting overall efficiency.

Making Necessary Adjustments

Once misalignments are identified, adjustments can be made to ensure the components interact correctly. Fine-tuning the positions can resolve issues with stiffness or unresponsiveness. Regular checks and maintenance will help sustain smooth functionality, preventing potential complications in the future.

Maintaining Linkage Components

Proper upkeep of connecting elements is essential for ensuring smooth operation and longevity. Regular maintenance can prevent potential issues and enhance performance, leading to a more efficient driving experience.

Regular Inspection

Conducting routine checks is vital to identify wear and tear. Look for signs of damage or corrosion that could affect functionality.

- Examine all joints and pivots for signs of wear.

- Check for any rust or buildup that could impede movement.

- Ensure that all components are securely fastened and aligned properly.

Lubrication Practices

Applying the right lubricants to moving parts is crucial for smooth operation. Proper lubrication reduces friction and prevents premature wear.

- Use high-quality grease for joints and pivots.

- Regularly clean components before applying lubricant.

- Avoid over-lubricating, as this can attract dirt and debris.

Testing After Repairs

After completing the necessary adjustments and corrections, it is crucial to evaluate the functionality of the system. This phase ensures that everything operates smoothly and that the vehicle performs as intended. Proper testing helps identify any lingering issues and confirms the effectiveness of the modifications made.

Initial Checks: Begin by performing a visual inspection of the components involved. Look for any signs of wear, misalignment, or loose connections. Ensure that all parts are securely attached and that no foreign objects obstruct movement.

Functional Testing: Next, engage the gear selector and observe its response. Shift through the gears while paying attention to any unusual sounds or resistance. A smooth transition between gears is indicative of successful adjustments.

Road Testing: Finally, take the vehicle for a short drive. Pay close attention to how the system behaves under various driving conditions. Note any difficulties in shifting or unexpected noises, as these may require further attention.

Completing these evaluations not only confirms the integrity of the work done but also enhances overall driving safety and performance.

Upgrading Transmission Linkage

Enhancing the connection system in your vehicle can significantly improve performance and responsiveness. This process involves replacing outdated components with modern alternatives, ensuring a smoother and more reliable interaction between the gear selector and the internal mechanisms.

When considering an upgrade, it’s essential to evaluate various factors that contribute to the overall effectiveness of the system. Below is a comparison of different upgrade options:

| Option | Benefits | Drawbacks |

|---|---|---|

| Aftermarket Kits | Improved performance, customizable | May require professional installation |

| OEM Parts | Direct fit, reliable quality | Higher cost, less customization |

| Polyurethane Bushings | Reduced play, enhanced durability | Stiffer feel, possible noise increase |

Choosing the right components can lead to a more engaging driving experience, providing better control and efficiency. Assess your vehicle’s specific needs to make informed decisions that will enhance its overall functionality.

Preventative Measures for Longevity

To ensure the durability and efficiency of vehicle systems, implementing proactive strategies is essential. Regular maintenance and careful driving habits can significantly extend the lifespan of critical components.

- Regular Inspections: Conduct periodic checks to identify potential issues early. This can prevent minor problems from escalating into major failures.

- Quality Lubrication: Utilize high-quality lubricants to reduce friction and wear. Ensure that all moving parts are adequately greased to facilitate smooth operation.

- Driving Habits: Adopt gentle driving practices. Avoid abrupt starts and stops, which can cause undue stress on the system.

- Cleanliness: Keep the area around the components free from dirt and debris. Regular cleaning can prevent the buildup of contaminants that may affect performance.

- Temperature Management: Monitor and maintain optimal operating temperatures. Excessive heat can lead to accelerated wear and damage.

By adhering to these preventative measures, vehicle owners can promote the longevity of essential systems, ensuring reliable performance over time.

Cost Considerations in Repairs

When addressing issues related to vehicle shifting mechanisms, it’s essential to evaluate various financial aspects involved in the restoration process. Understanding the potential expenses can significantly impact decision-making and budgeting.

Parts and Components: The first factor to consider is the cost of necessary components. Depending on the severity of the issue, parts may range from affordable to quite expensive. Researching quality options can lead to significant savings while ensuring durability.

Labor Costs: Skilled technicians typically handle these tasks, and labor rates can vary significantly based on location and expertise. It’s advisable to obtain quotes from multiple service providers to find a reasonable rate.

Unexpected Expenses: During the process, unforeseen complications may arise, leading to additional costs. Setting aside a contingency budget can help manage these unexpected financial burdens.

Long-Term Savings: Investing in high-quality repairs can lead to long-term savings by preventing recurrent issues and reducing maintenance costs over time. A thorough assessment can help determine the most cost-effective approach.

In conclusion, being mindful of these factors will aid in making informed choices, ensuring a successful outcome while keeping finances in check.

When to Seek Professional Help

Understanding the intricacies of your vehicle’s shifting mechanism is essential, but there are times when enlisting the expertise of a skilled technician is the best course of action. Recognizing the signs that indicate a need for professional intervention can save time and prevent further complications.

Identifying Complex Issues

If you encounter persistent challenges with the gear-changing process, such as unusual noises, difficulty in shifting, or an unexpected lack of responsiveness, it may signal an underlying problem. These symptoms often require a thorough diagnostic to identify the root cause.

When DIY Efforts Fail

Attempting to address issues without the proper tools or knowledge can lead to more significant difficulties. If your attempts at resolution have not yielded positive results, it is advisable to consult an experienced professional who can provide a comprehensive assessment and effective solutions.

Frequently Asked Questions

This section addresses common inquiries related to the restoration of gear-shifting systems, providing valuable insights for enthusiasts and practitioners alike.

Common Issues Encountered

Many individuals experience difficulties when attempting to enhance their gear-shifting mechanisms. Below are some frequent challenges:

| Issue | Possible Causes |

|---|---|

| Difficulty shifting gears | Worn components, misalignment, lack of lubrication |

| Unusual noises during operation | Loose parts, damaged connections, insufficient lubrication |

| Inconsistent gear engagement | Improper adjustments, damaged cables, obstructions |

Tips for Maintenance

Proper upkeep can significantly enhance the functionality of gear-shifting systems. Consider the following recommendations:

- Regularly inspect components for wear and tear.

- Keep all moving parts well-lubricated to ensure smooth operation.

- Adjust alignment as necessary to avoid operational issues.