Understanding the intricacies of a vehicle’s power unit is essential for any automotive enthusiast or professional. This section provides an in-depth exploration of crucial procedures, ensuring optimal performance and longevity of your machine. By mastering these techniques, you empower yourself to tackle challenges that may arise during operation.

From troubleshooting to overhauling various components, the information presented here is tailored to enhance your skills and knowledge. With clear instructions and practical insights, this guide aims to make complex tasks more approachable, allowing for a smoother experience in your maintenance endeavors.

Whether you are a novice or a seasoned mechanic, the details discussed will serve as a valuable resource. As you delve into each topic, you’ll uncover the ultimate strategies for maintaining efficiency and reliability in your vehicle’s operations.

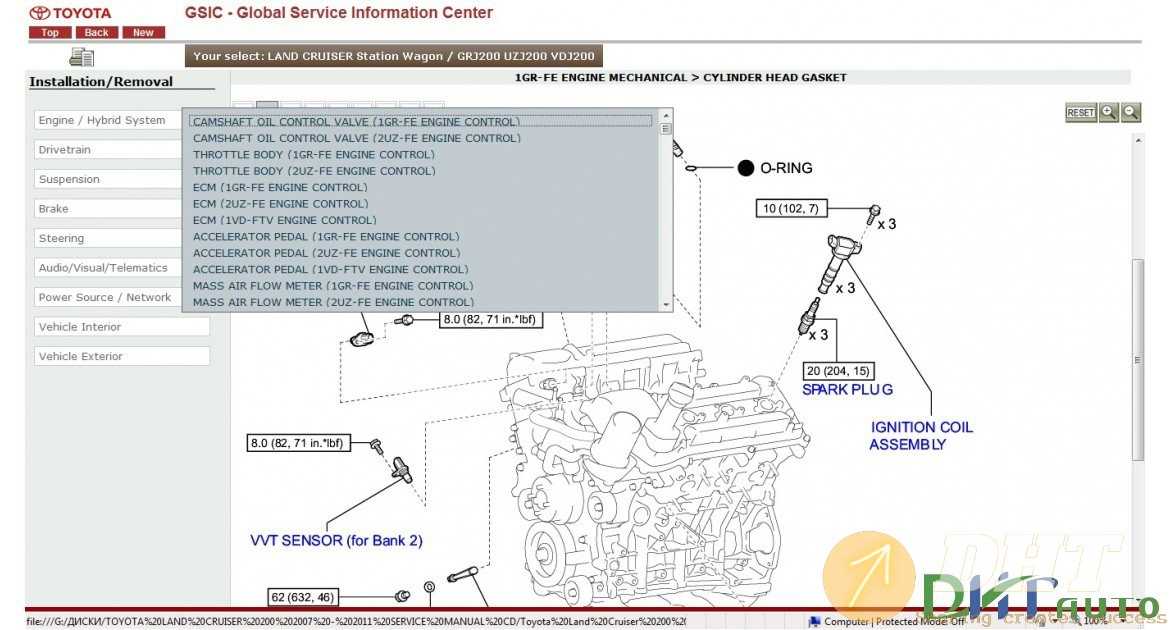

Understanding the 1VD-FTV Engine

This section delves into the intricacies of a robust power unit known for its performance and reliability. It is essential to grasp the fundamental principles behind its design and operation, which contribute to its efficiency and durability in various applications.

Key Features and Specifications

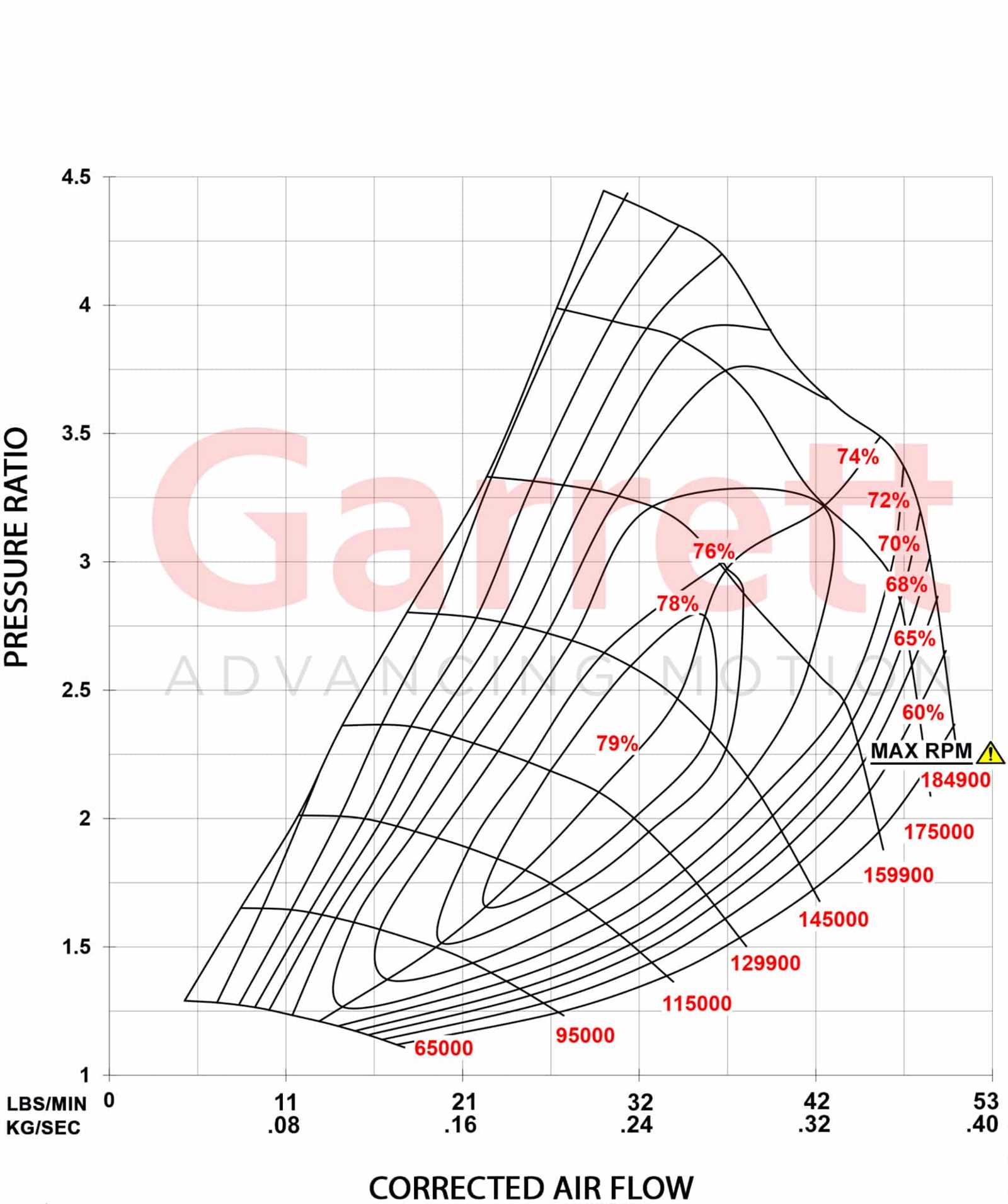

The highlighted power unit boasts advanced technology, featuring a turbocharged configuration that enhances its capability. With a multi-valve system and a high compression ratio, it achieves an optimal balance between power output and fuel consumption. This combination not only elevates performance but also ensures compliance with modern emission standards.

Common Applications

Utilized predominantly in heavy-duty vehicles and specialized machinery, this powerhouse demonstrates exceptional adaptability. Its ability to perform in challenging conditions makes it a preferred choice for both commercial and industrial use. Understanding its versatility aids in appreciating the engineering behind its design and the reasons for its widespread adoption.

Common Issues in 1VD-FTV Engines

Vehicles equipped with this specific power unit can experience a variety of challenges that may affect their performance and reliability. Understanding these common problems is crucial for maintaining optimal functionality and ensuring a long lifespan.

Frequent Challenges

- Oil Leaks: Seals and gaskets may degrade over time, leading to leaks that can compromise performance.

- Overheating: Insufficient coolant circulation or thermostat malfunctions can cause excessive temperatures.

- Fuel Injector Issues: Clogged or malfunctioning injectors can lead to poor combustion and reduced efficiency.

- Electrical Failures: Faulty sensors or wiring can disrupt the ignition process and overall operation.

Symptoms to Watch For

- Check engine light activation.

- Unusual noises during operation.

- Decreased power output.

- Poor fuel economy.

Addressing these concerns promptly can help maintain the vehicle’s performance and prevent more serious complications down the line.

Essential Tools for Engine Repair

When tackling the intricacies of mechanical systems, having the right set of tools is paramount. These instruments not only facilitate the process but also ensure accuracy and efficiency. Understanding the essential equipment can significantly impact the success of any project, making it vital to be well-prepared.

Basic Hand Tools

- Wrenches: A variety of wrenches, including socket and adjustable types, are crucial for loosening and tightening components.

- Screwdrivers: A set of flathead and Phillips screwdrivers is necessary for fastening and removing screws.

- Pliers: Needle-nose and locking pliers provide a secure grip on small parts.

- Hammers: A rubber mallet is useful for gently persuading parts without damaging them.

Specialized Equipment

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Compression Tester: Assesses the health of internal components by measuring cylinder pressure.

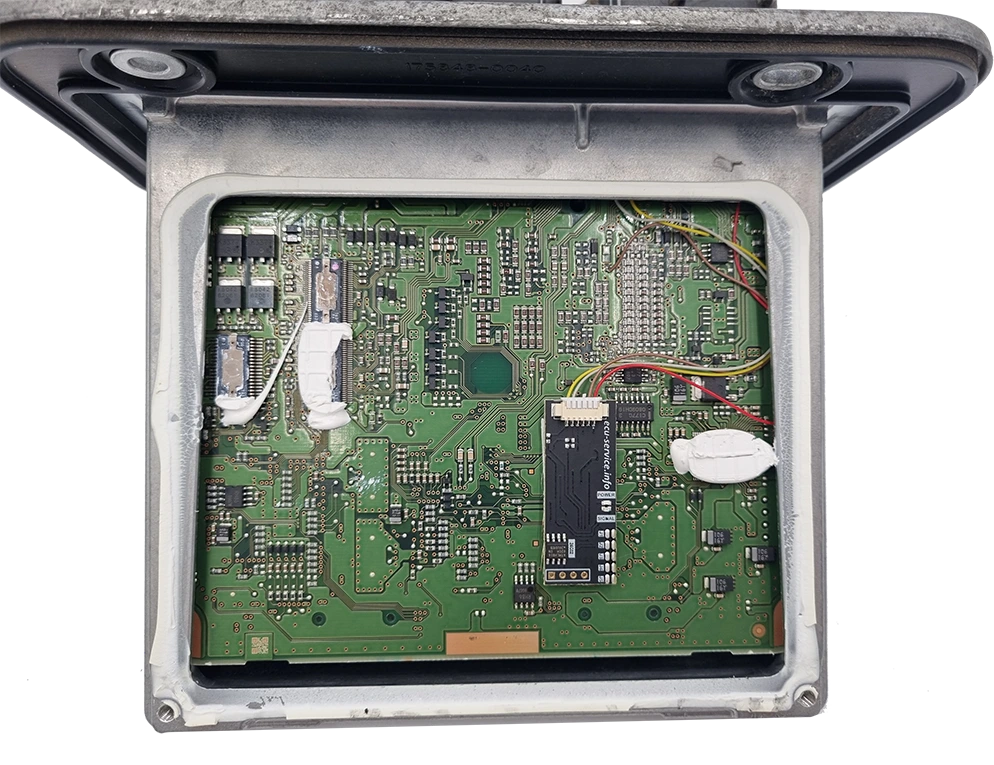

- Diagnostic Scanner: Helps identify electronic issues and provides real-time data.

- Oil Filter Wrench: Simplifies the removal of oil filters during maintenance.

Equipping yourself with these essential tools will empower you to effectively manage various tasks, ultimately leading to enhanced performance and longevity of the mechanical system in question.

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing mechanical issues, ensuring that each phase is clear and manageable. By following these detailed instructions, you can systematically tackle challenges and restore functionality to your system with confidence.

Preparation Phase

Before beginning the work, gather all necessary tools and materials. Make sure to familiarize yourself with the specifications of the unit, as well as any safety protocols. A clean and organized workspace is crucial for efficient progress and to prevent any loss of components during the process.

Execution of Tasks

Start by carefully disassembling the relevant parts, taking note of the order and orientation of each component. Document the condition of each piece, and replace any that show significant wear. Once repairs are complete, reassemble the system meticulously, ensuring that all fasteners are secure and connections are properly aligned. Finally, conduct thorough testing to confirm that everything functions as intended.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of any mechanical system. By adopting a proactive approach, you can minimize the risk of unexpected issues and enhance efficiency. Below are some valuable suggestions to keep in mind.

1. Routine Inspections: Conduct periodic checks to identify any signs of wear or damage. This can include examining belts, hoses, and fluid levels. Early detection can prevent more significant problems down the line.

2. Fluid Maintenance: Ensure that all necessary fluids are topped up and replaced at recommended intervals. This includes coolant, oil, and any other critical substances that keep the system running smoothly.

3. Cleanliness: Keep the area around the machinery free from debris and contaminants. Regular cleaning can prevent blockages and maintain proper airflow, which is vital for performance.

4. Component Checks: Inspect all parts for signs of corrosion or degradation. Replacing worn components before they fail can save time and resources, ensuring reliability during operation.

5. Calibration: Regularly calibrate any sensors or monitoring equipment to guarantee accuracy. Properly functioning gauges provide essential feedback on performance and can alert you to potential issues.

6. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer. This ensures that you are following best practices specific to your system, which can enhance its lifespan.

By implementing these preventive measures, you can effectively prolong the life of your machinery and ensure it operates at peak efficiency. Consistency in maintenance not only enhances performance but also fosters a safer working environment.

Identifying Symptoms of Engine Problems

Recognizing the signs of mechanical issues is crucial for maintaining optimal performance. Unusual behaviors or sounds can indicate underlying complications that need attention. Early detection can prevent more significant damage and costly repairs.

Common Indicators

Owners should be vigilant for specific warning signs such as unusual noises, changes in acceleration, or unexpected vibrations. A persistent knocking sound, for example, may suggest internal wear, while irregular engine performance could point to fuel delivery problems.

Visual and Performance Cues

Additionally, visual checks can reveal leaks, smoke, or abnormal fluid levels. Any increase in exhaust emissions or a decrease in fuel efficiency warrants investigation. Monitoring these aspects closely helps ensure long-lasting functionality and safety.

Replacing Engine Components Effectively

Ensuring optimal performance and longevity of a vehicle often involves the strategic replacement of various internal parts. Understanding the nuances of each component is crucial for achieving the best results, minimizing downtime, and maintaining efficiency. This section focuses on best practices to enhance the replacement process, ensuring a seamless integration of new parts.

Preparation and Planning

Before commencing the task, thorough preparation is essential. Gather all necessary tools and new components, and create a detailed plan that outlines each step. Organizing your workspace can prevent misplacement of parts and tools, streamlining the overall process.

Installation Techniques

When it comes to installation, precision is key. Employ manufacturer specifications for torque settings and alignment to ensure a proper fit. Additionally, using the correct lubricants and sealants can significantly enhance the longevity of the newly installed parts.

Specialized Techniques for 1VD-FTV

This section delves into advanced methodologies tailored for enhancing performance and ensuring longevity in specific power units. By employing unique approaches, mechanics can address common challenges, optimize functionality, and achieve superior results in their maintenance practices.

Precision Diagnostics

Implementing precise diagnostic tools is crucial for identifying underlying issues effectively. Utilizing advanced scanning equipment allows for the accurate detection of anomalies, ensuring that mechanics can address problems before they escalate. Regular updates to diagnostic software enhance reliability, making it easier to interpret data and apply necessary adjustments.

Fluid Management Strategies

Effective management of lubricants and coolants plays a vital role in the overall health of the system. Employing high-quality fluids that meet specific standards can significantly improve performance. Additionally, regular fluid changes and monitoring for contamination ensure optimal operation and extend the lifespan of vital components.

Choosing Quality Replacement Parts

When it comes to maintaining performance and longevity, selecting high-quality components is crucial. The right replacements not only enhance efficiency but also ensure reliability over time. This section will explore the importance of choosing superior parts and offer guidance on how to make informed decisions.

Understanding the Importance of Quality

Opting for premium components can significantly impact functionality and durability. Low-quality parts may lead to frequent failures and higher long-term costs. Investing in reputable brands ensures that the replacements meet specific standards, providing peace of mind and optimal performance.

Tips for Selecting Reliable Components

When searching for suitable replacements, consider the following factors:

- Research: Investigate various brands and read reviews to gauge their reputation.

- Compatibility: Ensure the part fits the specifications required for your particular application.

- Warranty: A solid warranty indicates the manufacturer’s confidence in their product.

- Material Quality: Assess the materials used; higher quality often correlates with better performance.

By prioritizing these aspects, you can make educated choices that will contribute to the overall effectiveness of your machinery.

Testing and Diagnosing Engine Performance

Assessing the functionality and efficiency of a power unit is crucial for maintaining optimal performance. This process involves a systematic approach to identify underlying issues that may hinder the operation. By utilizing various diagnostic tools and techniques, one can gain insights into potential malfunctions and determine the necessary corrective actions.

Common Diagnostic Techniques

Several methods can be employed to evaluate the condition of a power unit. Visual inspections are a fundamental step, allowing one to check for visible signs of wear, leaks, or damage. Additionally, compression tests can provide valuable data regarding the internal state of the system, revealing inconsistencies in pressure that may indicate deeper problems.

Utilizing Advanced Tools

To enhance the diagnostic process, integrating advanced diagnostic tools is beneficial. Devices such as OBD scanners can offer real-time data on performance metrics, while scope analysis can help visualize electrical signals and pinpoint irregularities. Combining these approaches ensures a comprehensive evaluation, leading to more accurate and effective troubleshooting.

DIY vs. Professional Repair Services

When it comes to fixing mechanical issues, individuals often face a choice between tackling the work themselves or enlisting the help of experts. Each approach has its own merits and drawbacks, depending on factors such as complexity, cost, and personal skill level. Understanding the nuances of both methods can aid in making an informed decision.

Engaging in self-repair can be rewarding and cost-effective, allowing enthusiasts to develop skills while saving on labor expenses. However, it requires a certain level of knowledge and access to tools, which can pose challenges for novices. On the other hand, professionals bring expertise and experience, ensuring that the job is done correctly, albeit at a higher financial commitment.

Ultimately, the choice between DIY efforts and professional assistance hinges on individual circumstances, including the specific task at hand and the resources available. Weighing these factors will lead to a more effective resolution of any mechanical challenges faced.

Safety Precautions During Repairs

When performing maintenance tasks, it is essential to prioritize safety to ensure a secure working environment. By following specific guidelines, you can minimize risks and protect yourself from potential hazards. This section outlines vital precautions that should be adhered to during any maintenance activities.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

- Keep the area clean and organized to prevent accidents and injuries.

- Disconnect power sources before beginning any work to avoid electric shocks.

Handling Tools and Equipment

- Inspect all tools before use to ensure they are in good condition.

- Use the right tool for the task to prevent injury or damage.

- Store tools safely after use to avoid tripping hazards.

- Never leave tools unattended, especially in high-traffic areas.

Frequently Asked Questions on Repair

This section addresses common inquiries regarding maintenance and troubleshooting processes. Understanding these aspects can enhance your knowledge and confidence when dealing with mechanical issues.

What are the most common issues that require attention?

Frequent complications include overheating, oil leaks, and performance loss. Identifying these signs early can prevent more significant problems.

How often should routine checks be performed?

It is advisable to conduct inspections regularly, typically every few months or after a set number of miles driven, to ensure optimal functionality.

What tools are essential for basic maintenance tasks?

Basic tasks usually require a set of wrenches, screwdrivers, and diagnostic tools. Having the right equipment makes the process more efficient.

Can I perform maintenance myself, or should I seek professional help?

While some tasks can be completed independently with the proper guidance, complex issues may necessitate professional expertise for safety and accuracy.

How do I find reliable information for troubleshooting?

Consulting credible online resources, community forums, and instructional videos can provide valuable insights and step-by-step guidance for various challenges.