Understanding the intricacies of machinery is essential for effective upkeep and performance enhancement. This section offers comprehensive insights into the processes and techniques that can help enthusiasts and operators alike in their efforts to maintain their equipment.

Here, you will discover valuable resources and tips for addressing common issues and optimizing functionality. Whether you are looking to resolve minor complications or seeking to enhance operational efficiency, this guide aims to provide the knowledge you need.

By following the guidance outlined here, individuals can cultivate a deeper understanding of their tools, leading to more informed decisions and successful outcomes. Empower yourself with the skills necessary to tackle challenges confidently.

Overview of Tecumseh Small Engines

This section provides a comprehensive look at a renowned brand known for its reliable power solutions. These compact machines have been widely utilized in various outdoor equipment, offering durability and performance for numerous applications.

Features and Design are central to understanding these power sources. Engineered with a focus on efficiency, they often incorporate advanced technology that ensures optimal performance while minimizing fuel consumption. The user-friendly design allows for easy maintenance, making them suitable for both novices and experienced users.

Applications of these power units span a diverse range, from lawn care to construction. Their versatility and adaptability to different tasks make them a popular choice among enthusiasts and professionals alike. Overall, their legacy of reliability continues to make them a preferred option in the market.

Common Issues with Small Engines

Understanding typical problems encountered with compact motors can greatly assist in maintaining their performance and longevity. Many individuals face similar challenges, often stemming from neglect or misuse.

Frequent Problems

- Poor starting capabilities

- Inconsistent power output

- Excessive vibration during operation

- Unusual noises while running

Possible Causes

- Dirty or clogged fuel filters

- Worn-out ignition components

- Inadequate lubrication

- Fuel quality issues

Addressing these concerns promptly can prevent further complications and enhance the efficiency of the motor.

Essential Tools for Engine Repair

Having the right set of instruments is crucial for anyone looking to maintain or restore mechanical systems. A well-equipped toolkit not only enhances efficiency but also ensures that tasks are completed safely and effectively. Below are key items that every technician should consider for successful maintenance activities.

Basic Hand Tools

Basic hand tools form the foundation of any toolkit. These include items such as wrenches, screwdrivers, and pliers. Each tool serves a unique purpose, making it essential to have a variety at your disposal. Quality and durability are paramount, as they directly influence performance during intricate tasks.

Specialized Equipment

Beyond the basic tools, specialized equipment can greatly aid in more complex jobs. Items like torque wrenches and compression testers provide precision and reliability when working on intricate components. Investing in high-quality tools in this category ensures accurate measurements and long-lasting functionality.

Step-by-Step Repair Guide

This section offers a comprehensive approach to fixing common issues encountered with various power units. By following a structured process, users can effectively troubleshoot and restore functionality to their machines.

Begin by gathering the necessary tools and materials for the task. Ensure that you have a clean workspace and adequate lighting to facilitate your work. Familiarize yourself with the components and layout of the device you are addressing.

Next, identify the symptoms that indicate a malfunction. Listen for unusual sounds, check for leaks, and observe any irregular performance. Documenting these observations can help streamline the diagnostic process.

Proceed to disassemble the unit carefully, taking note of each step. Use a systematic approach to avoid losing parts. Clean any components that show signs of dirt or corrosion, as this can significantly impact performance.

Once disassembled, inspect each part for wear or damage. Replace any defective components with new or refurbished ones, ensuring they meet compatibility standards. Reassemble the unit by reversing the disassembly steps, being cautious not to force any parts together.

After reassembly, conduct a thorough testing of the device to confirm that the issues have been resolved. Make any necessary adjustments to optimize performance. Finally, ensure proper maintenance practices are in place to prolong the lifespan of your equipment.

Maintaining Your Tecumseh Engine

Proper upkeep of your machine is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents potential issues that could lead to more significant problems down the line. By following a structured approach, you can ensure your equipment operates smoothly and reliably.

Key practices for maintaining your machinery include routine inspections, timely oil changes, and attention to the air intake system. These steps can greatly improve performance and extend the life of the unit.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 25 hours of use | Replace the old oil to prevent sludge buildup and ensure proper lubrication. |

| Air Filter Cleaning | Every 10 hours of use | Remove debris from the air filter to promote efficient airflow. |

| Spark Plug Inspection | Every 50 hours of use | Check the spark plug for wear and replace it if necessary to maintain ignition efficiency. |

| Fuel System Check | Monthly | Inspect the fuel lines for cracks or leaks and ensure the fuel is clean and fresh. |

By adhering to these guidelines, you can maintain the reliability of your machine and enhance its performance over time. Regular attention to these tasks will save you from unexpected breakdowns and costly repairs.

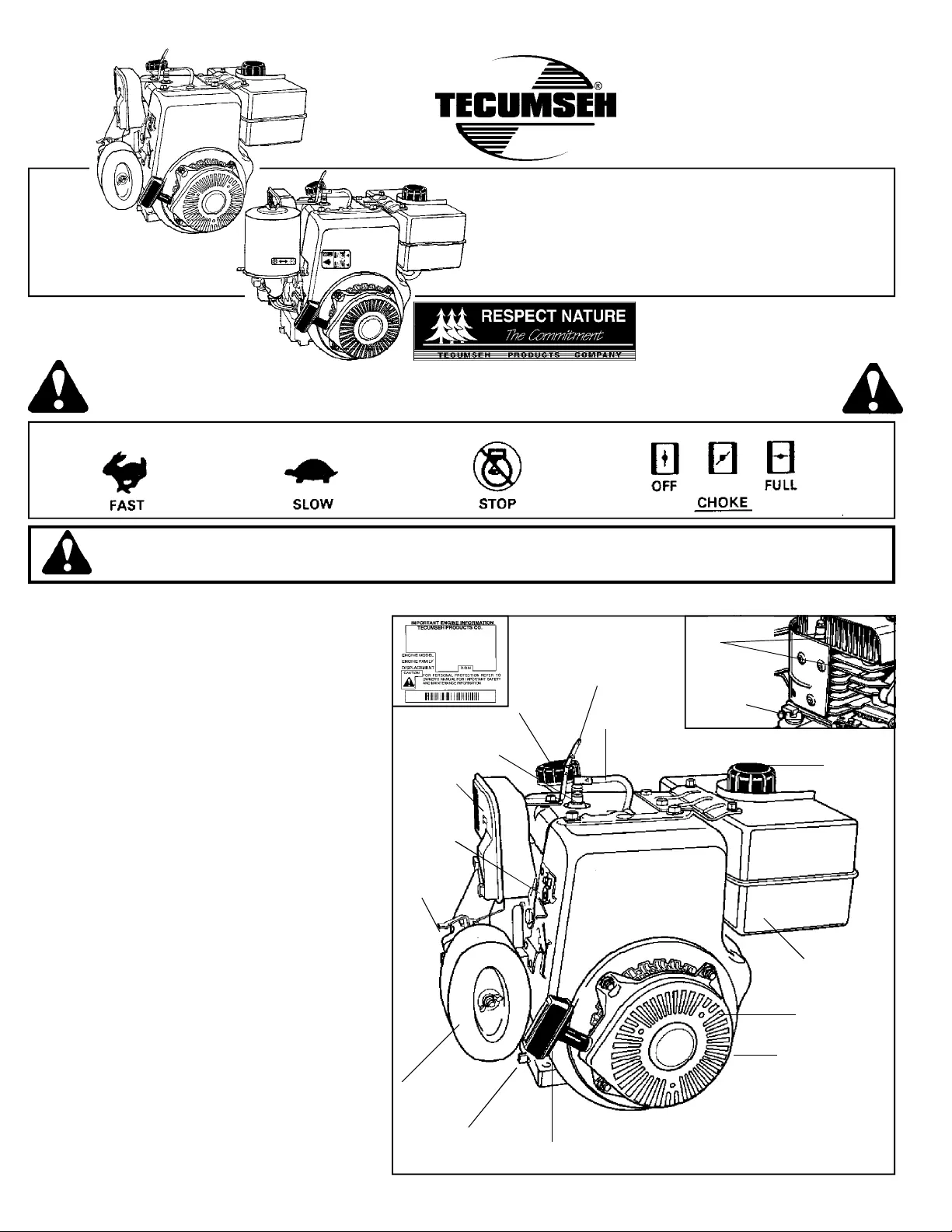

Identifying Engine Components

Understanding the various parts of a power unit is essential for effective maintenance and troubleshooting. Each component plays a significant role in the overall functionality, and recognizing them can enhance your ability to diagnose issues and perform tasks efficiently.

Main Parts Overview

The primary sections of a power unit typically include the combustion chamber, fuel delivery system, and ignition mechanism. Familiarity with these areas allows users to pinpoint potential problems quickly and take appropriate measures to resolve them.

In addition to the main sections, auxiliary elements like the cooling system and exhaust apparatus contribute to optimal performance. Being aware of these components can help in ensuring that the unit operates smoothly and extends its lifespan.

Troubleshooting Engine Performance Problems

Identifying and resolving issues related to performance can significantly enhance the functionality of various power units. Understanding common symptoms and their underlying causes is crucial for effective maintenance.

Here are some frequent issues and their potential solutions:

- Difficulty Starting:

- Check the fuel level and quality.

- Inspect the ignition system for faults.

- Ensure the air intake is not obstructed.

- Unusual Noises:

- Listen for any irregular sounds that may indicate loose components.

- Examine belts and chains for wear and tear.

- Check for any signs of mechanical failure.

- Poor Performance:

- Assess the fuel delivery system for clogs or leaks.

- Evaluate the condition of filters and replace if necessary.

- Monitor exhaust emissions for indications of combustion issues.

- Overheating:

- Inspect the cooling system for blockages or leaks.

- Verify that coolant levels are adequate.

- Ensure the fan and radiator are functioning properly.

By systematically addressing these issues, operators can restore optimal performance and extend the lifespan of their machines.

Understanding Engine Specifications

Grasping the characteristics of power units is essential for effective maintenance and optimal performance. These specifications provide crucial insights into how a unit functions and what requirements it has. They encompass various elements that influence operation, durability, and efficiency.

| Specification | Description |

|---|---|

| Displacement | The total volume of all cylinders, affecting power output. |

| Compression Ratio | The ratio of the maximum to minimum cylinder volume, influencing efficiency. |

| Power Rating | Measured in horsepower or kilowatts, indicating the unit’s output capacity. |

| Fuel Type | The kind of fuel required for operation, affecting performance and compatibility. |

| Starting Method | Indicates whether the unit starts manually or automatically, impacting ease of use. |

Understanding these details helps users make informed decisions about their machinery, ensuring that they select the right type for their specific needs and conditions.

Parts Replacement Process Explained

Understanding the process of component substitution is essential for maintaining optimal performance and longevity of machinery. This involves several systematic steps to ensure that each part is replaced effectively, thereby enhancing the overall functionality.

First, it is crucial to identify the specific component that requires substitution. This can often be done through visual inspection or by observing any operational discrepancies. Once the faulty part is identified, gather the necessary tools and a compatible replacement component.

Next, safely disassemble the unit by following the manufacturer’s guidelines. Take care to remove any screws, bolts, or clips without damaging surrounding parts. As you remove the component, keep track of all hardware to facilitate reassembly.

Once the old part is removed, it’s time to install the new component. Ensure it fits securely in place and connect any wiring or hoses as required. After installation, reassemble the unit carefully, ensuring that all parts are aligned correctly and that no tools or loose items are left inside.

Finally, conduct a thorough test to verify that the replacement was successful and that the unit operates smoothly. Regular maintenance checks after such replacements will further enhance reliability and performance.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and ensure a smooth workflow. Following appropriate guidelines can help protect individuals from potential hazards associated with working on mechanical systems.

Wear Personal Protective Equipment: Always equip yourself with suitable gear such as gloves, goggles, and masks. This protective clothing helps shield against debris, chemicals, and noise that may pose risks during maintenance activities.

Ensure Proper Ventilation: Working in a well-ventilated space is essential, especially when dealing with substances that emit fumes. Adequate airflow reduces the concentration of harmful vapors and promotes a healthier working environment.

Disconnect Power Sources: Before beginning any task, make sure to disconnect any power supply to the equipment. This step minimizes the risk of electrical shock or unintentional activation during the service process.

Organize Your Workspace: Keeping tools and components orderly not only enhances efficiency but also reduces the likelihood of accidents. A clutter-free environment allows for easier navigation and helps prevent misplacing important items.

Follow Manufacturer Guidelines: Always refer to the relevant instructions provided by the manufacturer. Adhering to these specifications ensures that you perform tasks correctly and safely, minimizing the chances of errors or mishaps.

Finding Reliable Replacement Parts

When it comes to maintaining machinery, sourcing dependable components is crucial for ensuring optimal performance. Without the right parts, even the best-maintained systems can falter. Here, we explore strategies to locate trustworthy replacements that meet your needs.

Understanding Quality Standards

Before searching for components, it’s essential to familiarize yourself with quality indicators. Knowing what to look for can help you avoid subpar products. Consider the following:

- Reputation of the manufacturer

- Material specifications and durability

- Compatibility with existing systems

Where to Search for Components

Several avenues exist for acquiring necessary parts. Here are some reliable options to consider:

- Authorized dealers: These suppliers often carry original components that meet manufacturer standards.

- Specialty shops: Stores focusing on specific machinery may provide unique items not found elsewhere.

- Online marketplaces: Reputable websites often list both new and refurbished parts, allowing for comparison shopping.

- Local salvage yards: These can be a goldmine for hard-to-find pieces at a fraction of the cost.

By taking the time to understand quality and explore various sources, you can ensure that the components you obtain will enhance the longevity and efficiency of your equipment.

Repair Manual Resources Online

Accessing reliable documentation for maintenance and troubleshooting is essential for anyone looking to service their machinery. The internet offers a wealth of resources where individuals can find comprehensive guides, instructional videos, and community forums dedicated to various types of equipment. These platforms provide valuable insights that can aid in understanding the intricacies of machinery.

Online Forums and Communities are excellent places to connect with fellow enthusiasts. Users can share experiences, ask questions, and obtain tips from those who have faced similar challenges. Engaging in these communities can lead to discovering innovative solutions and techniques that may not be available in traditional literature.

Video Tutorials on platforms like YouTube offer visual step-by-step instructions that can enhance the learning experience. These resources can be particularly beneficial for visual learners, allowing them to see the processes in action, which may simplify complex tasks.

Manufacturer Websites often have a wealth of resources, including downloadable content and specifications. Even if a specific document isn’t available, these sites can provide crucial information about parts, compatibility, and best practices, ensuring that users have a solid foundation for their projects.

By exploring these online resources, individuals can equip themselves with the knowledge needed to effectively maintain their equipment and extend its lifespan.