Understanding the core aspects of maintaining a watercraft’s propulsion system is essential for ensuring smooth and reliable performance. Regular attention to various operational elements can help extend the lifespan of the equipment and prevent unexpected issues on the water. This guide delves into the crucial steps and best practices for keeping your system in top shape.

In this section, we’ll explore key methods for diagnostics, adjustments, and essential upkeep tasks. By familiarizing yourself with these fundamentals, you’ll be well-equipped to address potential concerns and enhance the overall durability and efficiency of your vessel’s propulsion setup.

Preparation and Tools: Before diving into specific procedures, having the right tools and a clear workspace is important. This part will cover recommended equipment and organizational tips to make the process straightforward and efficient.

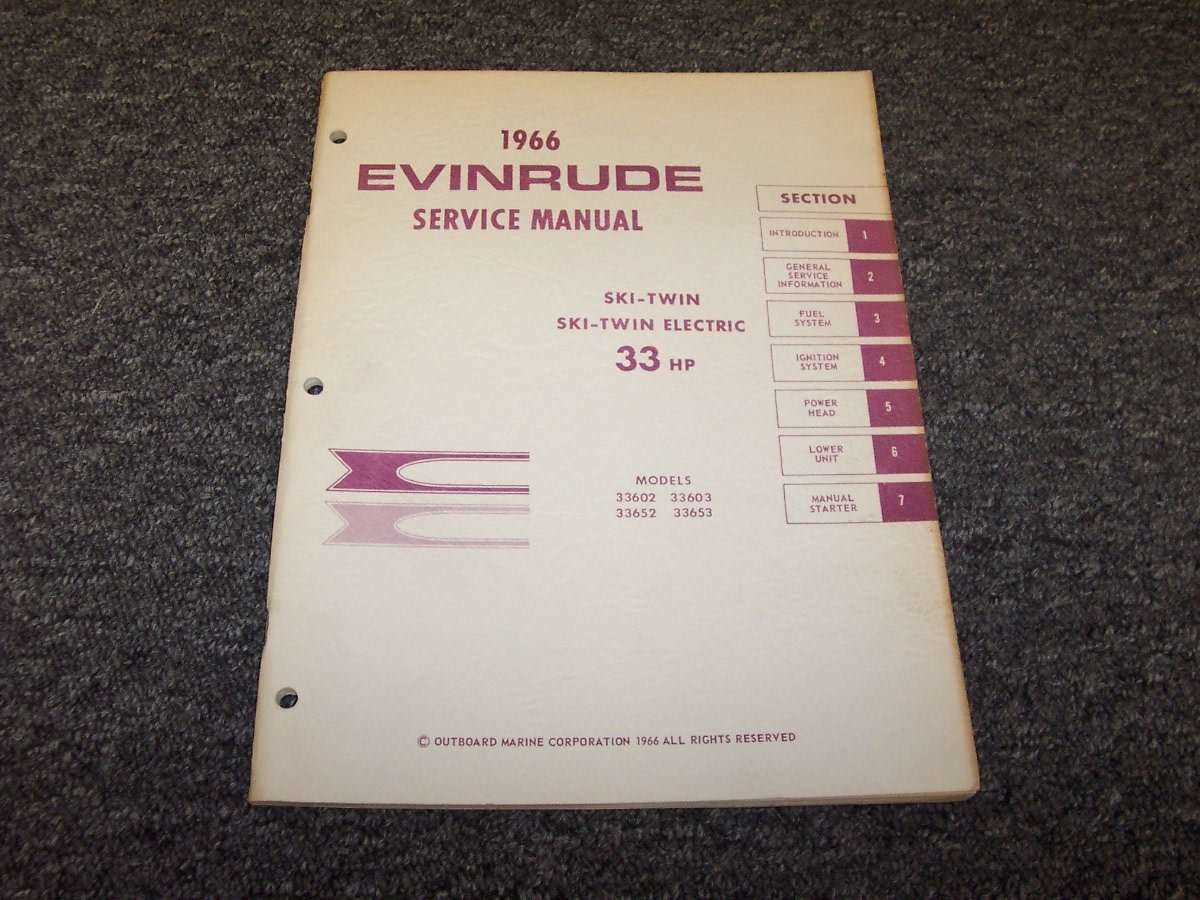

Guide to Evinrude Engine Maintenance

Regular upkeep of marine engines is essential for consistent performance and longevity on the water. This section highlights essential steps and practices to help you maintain your engine in optimal condition, ensuring reliability and preventing unexpected issues during use.

Basic Routine Checks

- Inspect Fuel Lines: Look for any signs of wear or cracking in the fuel lines, and replace them if needed. Ensure all connections are secure to prevent leaks.

- Examine the Propeller: Regularly inspect the propeller for any debris, nicks, or bends. Remove any tangles and replace the propeller if damage is significant.

- Battery Health: Keep the battery clean and check its charge level frequently. Ensure battery connections are tight and free from corrosion.

Essential Seasonal Maintenance

- Lubricate Mo

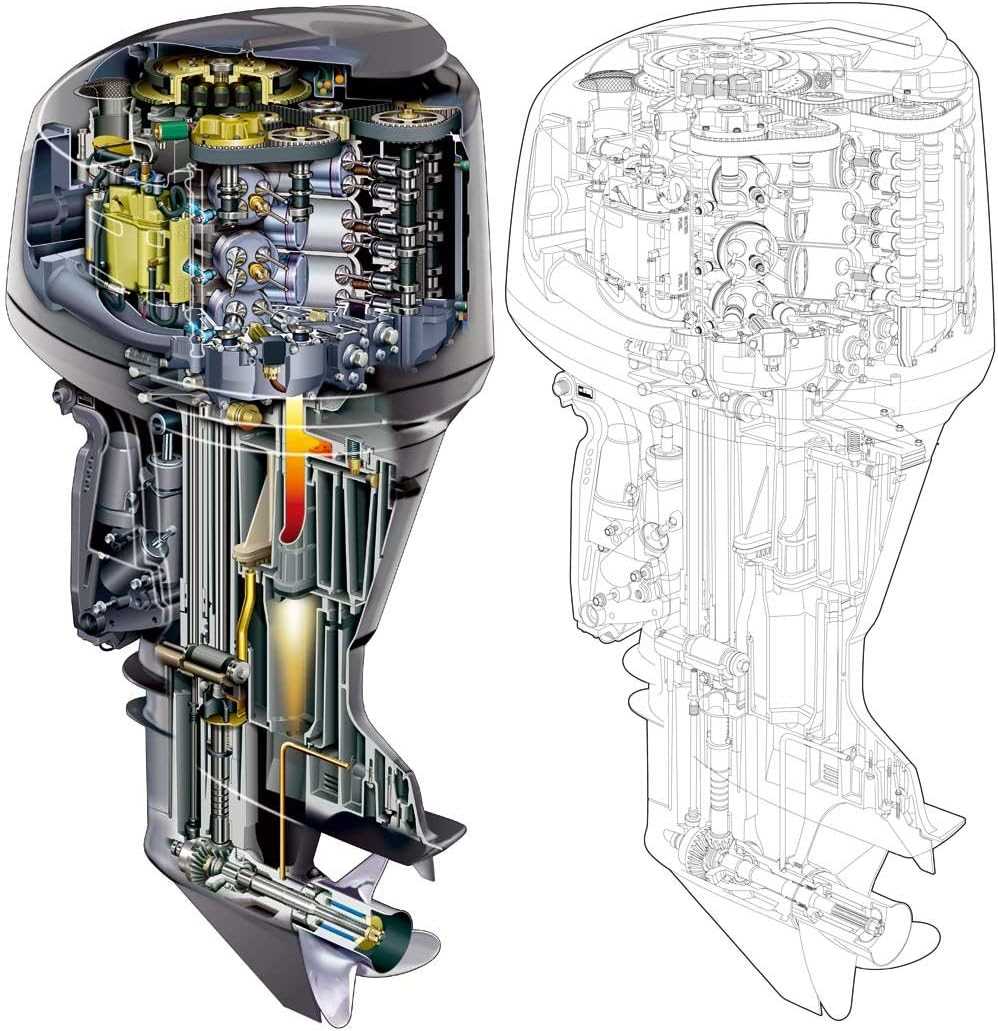

Basic Steps for Motor Inspection

Regular assessment of equipment ensures smooth operation and longevity, preventing potential issues before they escalate. This section highlights fundamental inspection techniques to maintain optimal performance and identify any signs of wear or damage.

Visual Assessment

Begin by conducting a thorough visual check. Examine all external surfaces for cracks, corrosion, or other visible anomalies. Pay special attention to areas where parts join, as these are often more susceptible to wear. Observing these details can help detect issues early and ensure timely intervention.

Fluid and Filter Check

Inspect fluid levels and assess their condition to ensure they are within the recommended range. Clean fluids and well-maintained filters contribute significantly to efficient functionality. Replace any worn or dirty filters as needed to maintain steady operation and avoid potential blockages.

Following these foundational steps helps ensure consistent functionality and reduces the likelihood of unexpected breakdowns. Routine checks also contribute to a

Essential Tools for Evinrude Repairs

Working on high-performance outboard engines requires a well-selected set of tools to ensure accurate and efficient results. Having the right equipment at hand can significantly reduce the time and effort involved, allowing for smoother and more precise maintenance tasks.

Socket Set and Wrenches: A comprehensive socket set and high-quality wrenches are indispensable for handling a variety of bolts and fasteners. Make sure to have both standard and metric sizes to accommodate different components.

Torque Wrench: To avoid over-tightening or under-tightening crucial parts, a reliable torque wrench is essential. It helps maintain the correct tension, ensuring that parts stay securely fastened without risking damage.

Fuel Line Disconnect Tool: Removing fuel lines safely is a delicate task, and a specialized disconnect tool allows for a quick release without causing leaks or damage to fittings.

Compression Tester

Identifying Common Engine Issues

Understanding frequent issues that may affect your engine can simplify troubleshooting and maintenance. Recognizing early symptoms helps in avoiding more serious complications and extends the lifespan of the equipment.

Symptoms of Mechanical Wear

Mechanical parts experience wear over time, which can cause various performance issues. Below are typical signs that indicate a need for inspection:

- Unusual noises or vibrations during operation

- Reduced efficiency or slower response

- Increased fuel consumption

Warning Signs of Ignition Problems

Issues related to ignition systems can result in poor performance or even prevent the engine from starting. Key warning signs include:

- Engine sputtering or failing to start

- Intermittent loss of power

- Misfires under load or idle conditions

Regularly in

Fuel System Troubleshooting Tips

Maintaining a stable and efficient fuel system is crucial for reliable performance. Identifying and resolving issues within this system can help avoid unexpected interruptions and enhance overall functioning.

Key areas to examine when troubleshooting fuel-related issues:

- Fuel Quality: Check for stale or contaminated fuel. Poor-quality fuel can lead to reduced efficiency and possible damage to system components.

- Filter Blockages: Inspect fuel filters for any buildup or obstructions. Replacing clogged filters can improve fuel flow and prevent further issues.

- Fuel Line Integrity: Look over fuel lines for signs of cracks, leaks, or loose fittings. Secure any connections and replace damaged lines as needed.

- Ventilation Check: Ensure that vents are clear, allowing for proper fuel flow. Blocked vents can cause a vacuum effect, disrupting performance.

- Proper Carburetion: Adjust carburetors if necessary, as incorrect settings can lead to improper fuel-air mixture

Regular Lubrication and Oil Checks

Maintaining optimal performance of your watercraft’s engine requires consistent attention to lubrication and fluid levels. Proper upkeep not only enhances efficiency but also prolongs the life of the engine components.

Routine checks of oil and lubrication are crucial for ensuring smooth operation. Regular monitoring helps identify potential issues before they escalate, thus avoiding costly repairs.

- Check oil levels frequently, especially before and after outings.

- Use the recommended type of lubricant to ensure compatibility and effectiveness.

- Inspect for any leaks or signs of deterioration in seals and gaskets.

Implementing a schedule for these checks will foster reliability and optimal performance. Adhering to these guidelines ensures that your equipment remains in peak condition, ready for any adventure.

Cooling System Maintenance Essentials

Maintaining the cooling mechanism is crucial for optimal performance and longevity of your aquatic propulsion unit. Proper care ensures that the system operates efficiently, preventing overheating and associated damages. Regular inspection and maintenance can significantly enhance reliability during use.

Key Components to Inspect

- Water Pump: Check for wear and tear, ensuring it effectively circulates coolant.

- Hoses: Inspect for cracks, leaks, or blockages that may impede fluid flow.

- Thermostat: Ensure it opens and closes at the correct temperatures to regulate coolant flow.

Maintenance Tips

- Flush the cooling system regularly to remove debris and build-up.

- Replace any worn components promptly to prevent further damage.

- Use high-quality coolant recommended for aquatic applications to enhance performance.

Ignition System Repair Guidance

The ignition system is a crucial component in ensuring optimal performance of your watercraft. This section provides essential information and strategies for addressing common issues that may arise within the ignition setup. Understanding the fundamental elements of this system is key to maintaining reliable operation and enhancing the overall functionality of your vessel.

Common Issues and Solutions

Identifying typical problems associated with the ignition system can significantly aid in troubleshooting. Below is a table summarizing frequent concerns and their respective solutions:

Issue Possible Causes Recommended Actions Engine won’t start Faulty spark plug, weak battery Check and replace spark plug, recharge or replace battery Inefficient firing Worn ignition coil, incorrect gap Inspect and replace ignition coil, adjust spark plug gap Intermittent operation Loose connections, damaged wiring Tighten connections, repair or replace damaged wires Maintenance Tips

Regular maintenance is essential for the longevity of the ignition components. Consider the following practices:

- Conduct routine inspections to catch issues early.

- Keep electrical connections clean and secure.

- Follow the manufacturer’s specifications for component replacements.

Electrical System Diagnostics Guide

This section provides essential insights into assessing and troubleshooting the electrical components of your aquatic vehicle. Understanding the functionality and common issues within the electrical framework is crucial for maintaining optimal performance and ensuring safety on the water. This guide aims to equip you with the knowledge necessary to identify and resolve potential electrical discrepancies effectively.

Common Issues and Symptoms

Many users encounter a range of challenges related to electrical systems. These may include intermittent power failures, difficulty starting the unit, or malfunctioning accessories. Recognizing the symptoms early can significantly reduce repair costs and downtime. Pay attention to unusual sounds, dimming lights, or erratic behavior of electronic components.

Troubleshooting Steps

To begin diagnosing electrical issues, start with a visual inspection of the wiring and connectors. Look for signs of wear, corrosion, or loose connections that could impede electrical flow. Utilizing a multimeter can help measure voltage levels and continuity, allowing for more precise identification of faults. Additionally, refer to component specifications to ensure all parts are functioning within their designated parameters.

Propeller and Gearcase Care Tips

Maintaining the propeller and gearcase is crucial for optimal performance and longevity of your aquatic vehicle. Proper care ensures efficiency and minimizes wear, contributing to a smoother experience on the water.

Regular Inspection: Conduct frequent examinations of the propeller and gearcase for any signs of damage or wear. Look for dents, cracks, or corrosion, as these issues can affect performance and safety.

Cleaning: After each outing, rinse the propeller and gearcase with fresh water to remove salt, dirt, and debris. This practice prevents corrosion and buildup that can impair functionality.

Lubrication: Ensure that all moving parts are adequately lubricated. Using the appropriate lubricant not only enhances performance but also protects against rust and wear over time.

Storage Considerations: When not in use, store your vessel in a dry, sheltered location. If possible, remove the propeller to avoid accidental damage during storage.

Professional Assistance: If you notice any significant issues or require maintenance beyond routine care, seek assistance from a qualified technician. Professional evaluation can prevent minor problems from escalating into major repairs.

Winterizing Your Evinrude Motor

Preparing your outboard engine for the colder months is crucial to ensure its longevity and reliable performance. This process involves several key steps that help protect the internal components from damage caused by freezing temperatures and moisture.

Follow these essential steps for proper preparation:

- Flush the Cooling System: Thoroughly rinse the cooling passages with fresh water to remove salt, dirt, and debris. This helps prevent corrosion and blockages.

- Change the Oil: Replace the oil and filter to eliminate contaminants and moisture. This step is vital for maintaining engine health.

- Add Fuel Stabilizer: Incorporate a fuel stabilizer into the fuel tank. This prevents fuel degradation and keeps the system clean during storage.

- Run the Engine: Start the engine and let it run for a few minutes to circulate the oil and stabilizer throughout the system.

- Protect the Electrical System: Disconnect the battery and store it in a dry place. This prevents drainage and damage due to low temperatures.

- Cover the Engine: Use a breathable cover to protect the engine from dust and moisture while in storage.

By following these steps, you can ensure that your outboard engine is ready for a smooth start when the boating season resumes.