Every sewing enthusiast knows the importance of keeping their equipment in top condition. Regular maintenance not only prolongs the life of the machine but also enhances performance and ensures high-quality results in every project. This section delves into the essential aspects of caring for your sewing device, providing guidance to both beginners and seasoned users.

When faced with issues, having a comprehensive guide can be invaluable. It equips users with the knowledge to troubleshoot common problems, adjust settings, and perform necessary upkeep tasks. By familiarizing oneself with the inner workings of the machine, individuals can gain confidence in addressing various challenges that may arise during operation.

Moreover, understanding the intricacies of your sewing companion can transform your crafting experience. It empowers you to execute more complex techniques and unlock the full potential of your creativity. With the right information at hand, any sewing project can turn into a rewarding endeavor.

Understanding the Consew 226 Model

This section delves into the intricacies of a renowned sewing machine known for its durability and versatility. Designed for various textile applications, this device has become a staple in both industrial and domestic settings, appreciated for its efficiency and robust performance.

Key Features

- Sturdy construction for long-lasting use

- High-speed stitching capabilities

- Versatile in handling different types of fabrics

- Adjustable tension settings for optimal results

Common Applications

- Upholstery work

- Leather crafting

- Garment manufacturing

- Quilting and home décor projects

Understanding these aspects will enhance the user experience, ensuring optimal performance and satisfaction with this sewing device.

Common Issues with Consew 226

In the realm of sewing machines, certain challenges frequently arise, impacting performance and efficiency. Understanding these common problems can significantly enhance your experience and prolong the lifespan of your equipment.

Thread Tension Problems

One prevalent issue is inconsistent thread tension, which can lead to poor stitch quality. Adjusting the tension settings can often rectify this, ensuring a balanced stitch.

Feeding Issues

Another common challenge involves the feeding mechanism. If the fabric is not advancing smoothly, it may be necessary to inspect the feed dogs and ensure they are clean and properly adjusted. Regular maintenance is key to preventing such disruptions.

Essential Tools for Repairs

When it comes to maintaining and fixing sewing machines, having the right instruments at your disposal is crucial. These tools not only facilitate the process but also ensure precision and efficiency in your work. Whether you’re tackling minor adjustments or more significant overhauls, a well-equipped toolkit can make all the difference.

1. Screwdrivers: A set of screwdrivers, including both flathead and Phillips, is indispensable. They allow you to easily access and tighten or loosen various components of the machine.

2. Pliers: Needle-nose pliers are particularly useful for reaching into tight spaces and gripping small parts securely. Their versatility makes them a staple in any toolkit.

3. Allen Wrenches: Many machines utilize hex screws, making a set of Allen wrenches essential for adjustments and disassembly.

4. Cleaning Brushes: Keeping your equipment free of dust and lint is vital. A set of brushes can help you maintain cleanliness and prevent operational issues.

5. Oiling Tools: Proper lubrication is key to the longevity of your machine. Having an oil can or dropper ensures that you can easily apply lubricant where needed.

6. Thread and Needle Sets: A variety of needles and threads can help you tackle different projects and resolve issues related to stitching.

Equipped with these fundamental tools, you will be prepared to address various challenges that may arise during your sewing projects, ensuring smooth operation and enhanced performance.

Step-by-Step Repair Process

This section outlines a systematic approach to restoring and maintaining sewing machines, ensuring optimal functionality and longevity. By following these detailed steps, you can effectively troubleshoot common issues and perform necessary adjustments or replacements with confidence.

Preparation

- Gather necessary tools: screwdrivers, pliers, lubricants, and replacement parts.

- Set up a clean and well-lit workspace to ensure accuracy and safety.

- Refer to the manufacturer’s specifications for model-specific guidance.

Execution

- Begin by disconnecting the machine from its power source.

- Inspect for visible damage or wear, focusing on the needle, bobbin area, and threading path.

- Clean any accumulated lint or debris from internal components and exterior surfaces.

- Check the tension settings and adjust as necessary to ensure even stitching.

- Replace any faulty parts, such as the needle or feed dogs, as identified during inspection.

- Reassemble all components, ensuring each part is secured properly.

- Test the machine on scrap fabric to verify functionality and make further adjustments if needed.

By adhering to this comprehensive process, users can enhance the performance of their sewing machines and extend their operational life, ensuring consistent results in future projects.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficient performance of your sewing machine. By following a few simple guidelines, you can enhance its lifespan and reduce the likelihood of issues arising. Regular attention to specific areas will contribute to smoother operation and a more enjoyable sewing experience.

- Regular Cleaning: Dust and lint can accumulate over time, affecting performance. Clean the machine after each project or at least once a week.

- Oil the Moving Parts: Lubricate the essential components according to the manufacturer’s instructions to ensure smooth movement and prevent wear.

- Use Quality Threads: High-quality threads reduce friction and minimize the risk of breakage or damage to the needle and other parts.

- Check Tension Settings: Regularly inspect and adjust the tension settings to avoid fabric puckering or uneven stitching.

In addition to these practices, consider the following tips for optimal performance:

- Avoid Overloading: Do not push the machine beyond its capacity. Sew within the recommended limits to prevent strain.

- Store Properly: When not in use, keep the machine covered to protect it from dust and environmental factors.

- Consult the Documentation: Familiarize yourself with the user guide for specific maintenance requirements and troubleshooting advice.

By incorporating these maintenance practices into your routine, you can ensure your sewing equipment remains in excellent working condition for years to come.

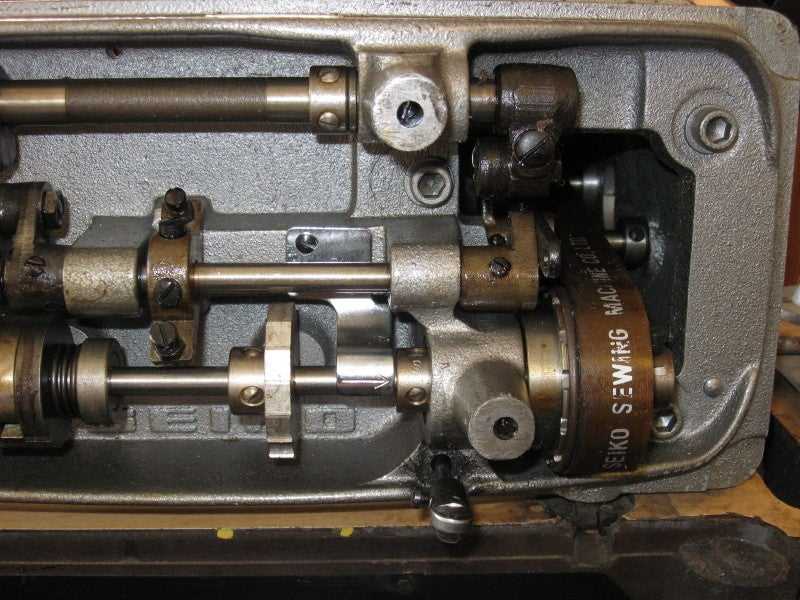

Identifying Parts and Components

Understanding the various elements and mechanisms of a sewing machine is crucial for effective maintenance and operation. Familiarity with these parts enhances the user experience and ensures the longevity of the device. This section will guide you through the identification and function of essential components.

The following are key parts commonly found in sewing machines:

- Needle: A critical component for stitching, available in various sizes and types for different fabrics.

- Bobbin: Holds the lower thread and is essential for creating stitches.

- Presser Foot: Assists in holding the fabric in place during sewing; various types exist for different tasks.

- Feed Dogs: Mechanisms that move the fabric under the needle as you sew.

- Tension Discs: Regulate the thread tension to ensure even stitching.

In addition to these components, understanding their locations and interactions is vital for troubleshooting and performance enhancement. Here are some additional parts to consider:

- Stitch Selector: Allows the user to choose different stitch types for various applications.

- Power Switch: Controls the machine’s operation.

- Foot Pedal: Serves as a control for speed and start/stop functions.

- Thread Guide: Directs the thread from the spool to the needle for smooth operation.

By becoming acquainted with these components, users can better navigate their machines, perform maintenance tasks, and address any issues that may arise during sewing projects.

Adjusting Tension Settings Properly

Properly calibrating the tension settings on your sewing machine is crucial for achieving high-quality stitches. Correct tension ensures that the upper and lower threads interlock perfectly, resulting in smooth and durable seams. Misadjusted tension can lead to various issues, such as puckering, thread breakage, or even fabric damage.

Understanding Tension Mechanics

The tension system involves multiple components that work together to control the tightness of the thread as it passes through the machine. It’s essential to understand how each part functions to make informed adjustments. The upper tension is typically managed by a dial or knob, while the bobbin tension is adjusted through a small screw on the bobbin case.

Steps for Adjusting Tension

To achieve optimal results, start by threading the machine correctly, as improper threading can affect tension. Use a test piece of fabric similar to your project material. Begin with the manufacturer’s recommended settings and gradually make adjustments. If the top thread is too tight, loosen the upper tension by turning the dial counterclockwise. If the bottom thread is loose, tighten the bobbin tension slightly. Always test your settings after each adjustment to ensure balanced tension. Remember, patience and precision are key to perfecting this aspect of your sewing.

Threading the Machine Correctly

Properly threading your sewing device is crucial for achieving optimal performance and preventing issues during operation. This process ensures that the needle and bobbin work in harmony, allowing for smooth stitching and consistent tension. Understanding the steps involved in this task can significantly enhance your sewing experience.

Step-by-Step Guide

Follow these essential steps to correctly thread your machine:

| Step | Description |

|---|---|

| 1 | Start by placing the spool of thread on the spool pin, ensuring it is secure and rotates freely. |

| 2 | Guide the thread through the tension discs and ensure it is properly seated for optimal tension. |

| 3 | Thread the take-up lever by passing the thread through the designated slot and downwards. |

| 4 | Insert the thread through the needle from front to back, ensuring a clean entry. |

| 5 | Finally, pull the thread through the presser foot and leave a tail of several inches to prevent tangling. |

Common Issues and Solutions

If you encounter problems while sewing, consider these common threading issues:

- Thread Breakage: Ensure the thread is correctly seated in the tension discs and that the needle is not damaged.

- Skipped Stitches: Check that the thread is threaded properly through the needle and that the bobbin is inserted correctly.

- Uneven Stitching: Verify that the tension settings are appropriate for the fabric being used.

By following these guidelines, you can ensure that your sewing machine is threaded correctly, leading to a more enjoyable and efficient sewing process.

Cleaning and Lubricating the Mechanism

Maintaining the functionality of sewing machinery is crucial for optimal performance and longevity. Regular cleaning and proper lubrication of the internal components help to prevent wear and tear, ensuring smooth operation and reducing the risk of malfunctions. This process involves both the removal of accumulated debris and the application of suitable oils to facilitate movement.

Step-by-Step Cleaning Process

Begin by disassembling the necessary parts of the machine to gain access to the interior. Use a soft brush or compressed air to eliminate dust and lint. Pay special attention to the feed dogs, needle plate, and bobbin case, as these areas tend to collect the most debris. After cleaning, ensure that all components are completely dry before reassembly.

Lubrication Guidelines

Once the cleaning is complete, it’s time to apply lubricant. Use a high-quality sewing machine oil, which is specifically formulated for such equipment. Apply a few drops to the designated lubrication points, usually outlined in the manufacturer’s guidelines. Avoid over-lubricating, as excess oil can attract dirt and lead to further issues.

| Component | Cleaning Method | Lubrication Points |

|---|---|---|

| Feed Dogs | Brush or Compressed Air | Top and sides |

| Needle Plate | Wipe with a Lint-Free Cloth | None |

| Bobbin Case | Remove and Clean with Brush | Pivot points |

| Gears and Cogs | Clean with a Soft Cloth | Central shaft |

Regular attention to these tasks will not only enhance the performance of the sewing machine but also prolong its operational life, allowing for a more enjoyable and efficient sewing experience.

Upgrading Parts for Better Performance

Enhancing the functionality of your sewing machine can significantly improve its efficiency and output quality. By replacing standard components with high-performance alternatives, you can experience smoother operation, greater durability, and an overall boost in your crafting experience. This section will explore various upgrades that can lead to optimal performance.

Key Components to Consider for Upgrade

- Needles: Upgrading to specialized needles can reduce fabric damage and improve stitch quality.

- Bobbin Cases: A high-quality bobbin case can ensure better thread tension and prevent jamming.

- Presser Feet: Different presser feet for specific tasks can enhance versatility and precision in sewing.

- Motor: A stronger motor can provide faster stitching speeds and increased power for heavier fabrics.

- Belts: Replacing worn belts with upgraded options can enhance machine responsiveness and longevity.

Benefits of Upgrading

- Improved stitch consistency and quality.

- Increased speed and efficiency in sewing tasks.

- Enhanced adaptability for various fabric types.

- Longer machine lifespan and reduced maintenance needs.

- Greater enjoyment and satisfaction during the sewing process.

Investing in these enhancements not only boosts your machine’s capabilities but also elevates your overall sewing experience, allowing you to take on more complex projects with confidence.

Frequently Asked Questions About Repairs

This section aims to address common inquiries regarding maintenance and troubleshooting of sewing machines. Whether you’re facing minor issues or significant challenges, understanding these frequently asked questions can help streamline the process and improve your experience.

| Question | Answer |

|---|---|

| What should I do if my machine won’t start? | Check the power supply and ensure that the machine is properly plugged in. Inspect the foot pedal for any damage and try using a different outlet. |

| How can I resolve thread tension problems? | Adjust the tension settings on the machine, ensuring the upper and lower threads are balanced. Consult the user guide for specific recommendations based on your fabric type. |

| What causes my fabric to bunch up while sewing? | This issue can arise from improper thread tension or an incorrectly installed needle. Make sure the needle is suitable for the fabric and recheck the tension settings. |

| Why is the needle breaking frequently? | Needles can break due to several factors, including using the wrong size for the fabric, sewing through thick layers, or a damaged needle plate. Always use the appropriate needle type and size. |

| How often should I clean my machine? | Regular cleaning is essential for optimal performance. It is recommended to clean your machine after every few sewing projects, or at least once a month if used frequently. |

Resources for Further Assistance

When tackling maintenance and troubleshooting tasks for your sewing equipment, having access to reliable sources of information can significantly enhance your understanding and skills. This section provides various avenues where you can find guidance, support, and additional resources to help you navigate any challenges you might encounter.

| Resource Type | Description |

|---|---|

| Online Forums | Engage with fellow enthusiasts and professionals who share tips, solutions, and experiences related to sewing machinery. |

| YouTube Channels | Discover video tutorials that demonstrate techniques, repairs, and best practices in a visual format. |

| Manufacturer Support | Contact customer service for expert advice or visit the official website for downloadable guides and FAQs. |

| Books and Publications | Explore literature focused on sewing equipment, offering detailed insights and troubleshooting techniques. |

| Local Workshops | Participate in hands-on classes that provide practical experience and direct assistance from knowledgeable instructors. |