Understanding the intricacies of an all-terrain vehicle can significantly enhance its longevity and performance. This section focuses on essential guidance for maintaining and troubleshooting various aspects of the vehicle, ensuring optimal operation and reliability.

For enthusiasts and owners alike, having access to comprehensive instructions and insights can be invaluable. It empowers users to tackle common issues independently, promoting a deeper appreciation for the mechanics involved. By exploring common challenges and their solutions, one can confidently engage in the upkeep of their machine.

Moreover, embracing a systematic approach to maintenance can prevent minor problems from escalating into major repairs. This section aims to equip readers with the knowledge needed to keep their vehicle in peak condition, ensuring countless adventures ahead.

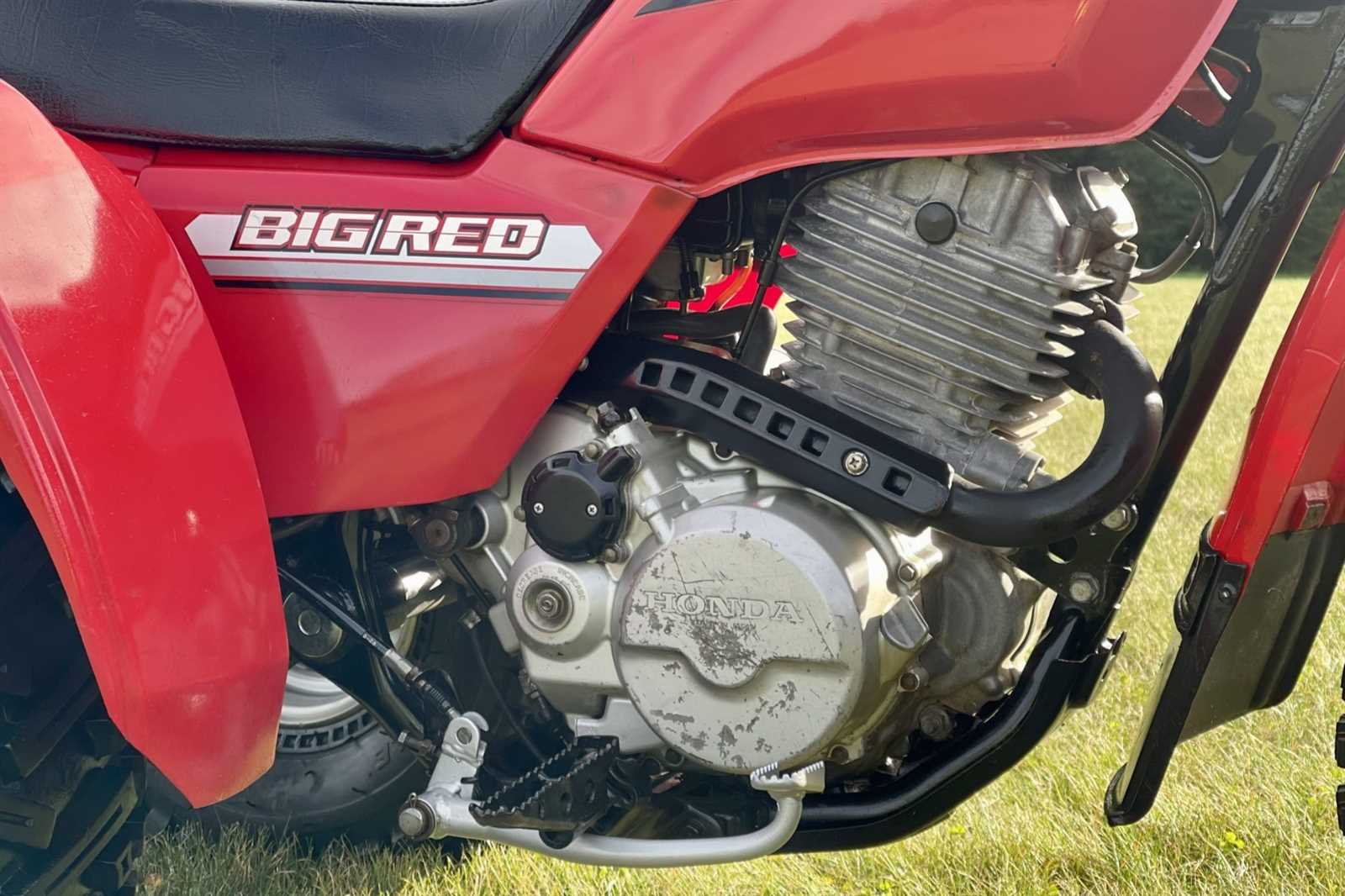

1985 Honda 250ES Big Red Overview

The 1985 model of this utility vehicle is designed for versatility and ruggedness, appealing to outdoor enthusiasts and professionals alike. Known for its robust construction, it provides reliable performance across various terrains, making it an ideal choice for both recreational and work-related tasks.

Featuring a powerful engine and a user-friendly design, this model ensures ease of handling and maneuverability. Its sturdy frame supports a range of attachments and accessories, enhancing functionality and allowing for greater adaptability to different needs. With a focus on durability, this vehicle is built to withstand the rigors of demanding environments, ensuring longevity and sustained performance.

Common Issues with Big Red

Owners of this iconic all-terrain vehicle often encounter a range of typical problems that can affect performance and reliability. Understanding these issues is crucial for maintaining optimal operation and ensuring a smooth riding experience.

One prevalent concern involves the electrical system, where faulty connections or worn-out components may lead to starting difficulties. Additionally, the suspension system can exhibit wear over time, resulting in diminished handling and ride comfort. Another frequent issue is related to the fuel system, where clogged filters or outdated fuel can hinder engine performance.

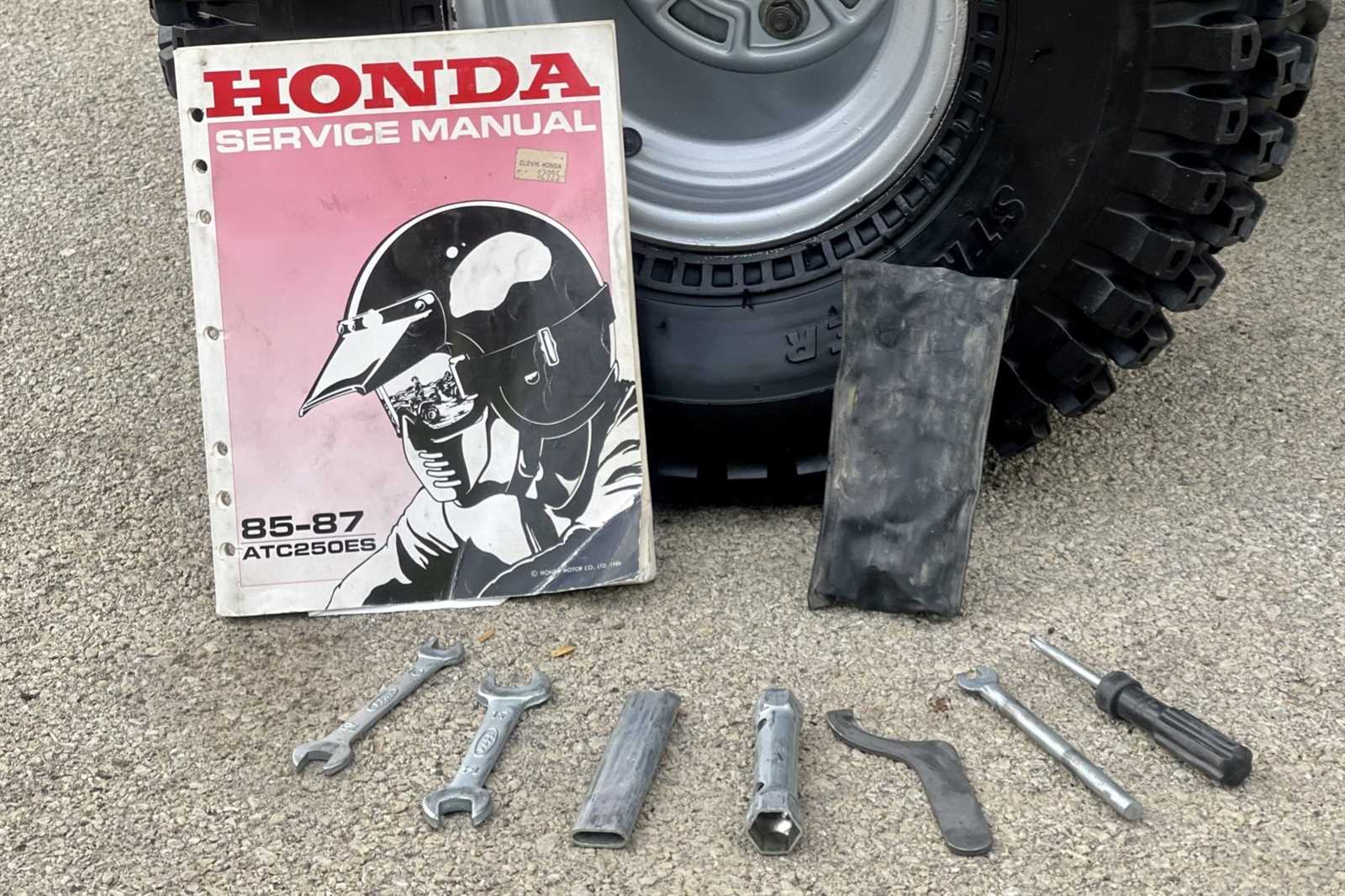

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and restoration tasks. Proper tools not only enhance efficiency but also ensure that each task is completed with precision. Understanding which instruments are necessary can save both time and effort.

Basic Hand Tools: A reliable set of hand tools is fundamental for any maintenance work. Wrenches, pliers, and screwdrivers should be readily available to handle a variety of tasks.

Specialized Equipment: Certain jobs may require specific devices, such as torque wrenches or alignment tools. These specialized instruments can make complex tasks much simpler and more accurate.

Safety Gear: Protecting oneself while working is paramount. Safety glasses, gloves, and appropriate footwear should always be worn to minimize risks during maintenance activities.

By gathering these essential instruments, anyone can approach their tasks with confidence and competence, ensuring a successful outcome every time.

Step-by-Step Maintenance Guide

Proper upkeep of your vehicle is essential for ensuring optimal performance and longevity. This section provides a systematic approach to maintenance tasks that every owner should follow regularly. By adhering to these guidelines, you can enhance the reliability and efficiency of your machine.

Routine Inspection Procedures

Begin with a thorough examination of key components to identify any potential issues early. Regular checks can prevent minor problems from escalating into major repairs.

Fluid Replacement Schedule

Maintaining proper fluid levels is crucial for the smooth operation of your vehicle. Follow the recommended intervals for changing oils and other fluids to ensure maximum efficiency.

| Fluid Type | Recommended Change Interval |

|---|---|

| Engine Oil | Every 3,000 miles |

| Transmission Fluid | Every 12,000 miles |

| Brake Fluid | Every 2 years |

| Coolant | Every 30,000 miles |

Engine Troubleshooting Techniques

Troubleshooting an engine can often seem daunting, but understanding key techniques can simplify the process. By systematically identifying and addressing issues, you can enhance performance and ensure reliability.

Identifying Symptoms is the first step in diagnosing problems. Pay attention to unusual sounds, vibrations, or changes in performance. These indicators can point towards specific issues, such as misfires or overheating.

Next, Visual Inspections are essential. Check for obvious signs of wear or damage, including leaks, loose connections, or corroded components. Regular maintenance and observation can prevent more serious complications.

Finally, Using Diagnostic Tools can greatly aid in pinpointing issues. Instruments such as multimeters or compression testers can provide valuable insights into the engine’s health. By interpreting the data, you can make informed decisions about necessary repairs.

Electrical System Diagnostics

Understanding the intricacies of the electrical system is crucial for ensuring optimal performance and reliability. This section delves into various diagnostic techniques to identify issues within the circuitry, ensuring that all components function harmoniously. Proper assessment can prevent minor faults from escalating into major problems.

Key Diagnostic Tools

Utilizing the right tools is essential for effective troubleshooting. Below is a table outlining the primary instruments used in diagnosing electrical issues:

| Tool | Description |

|---|---|

| Multimeter | Measures voltage, current, and resistance to diagnose electrical integrity. |

| Wiring Diagram | Visual representation of the electrical layout, assisting in identifying circuits. |

| Test Light | Indicates power presence in various points of the system. |

| Oscilloscope | Analyzes the waveform of electrical signals for detailed examination. |

Common Issues and Solutions

Recognizing common faults is vital for efficient repairs. Below are typical electrical problems encountered:

- Battery failure: Check for corrosion and test voltage levels.

- Faulty connections: Inspect connectors for wear and ensure tightness.

- Blown fuses: Replace and investigate underlying causes.

- Wiring shorts: Examine for insulation damage or frayed wires.

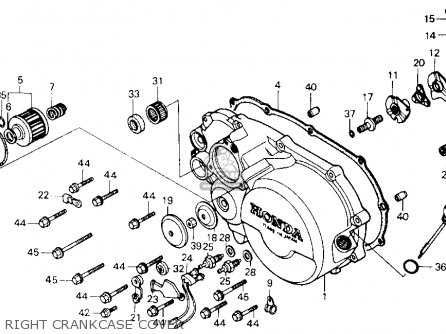

Transmission and Drivetrain Care

Maintaining the components responsible for power transfer and control is essential for optimal performance and longevity. Proper care can prevent common issues and ensure smooth operation during use.

Regular inspection of the drivetrain is crucial. Here are some key areas to focus on:

- Fluid Levels: Check and replenish fluids as needed to keep the system lubricated.

- Wear and Tear: Examine belts and chains for signs of damage or excessive wear.

- Alignment: Ensure that all components are properly aligned to prevent unnecessary strain.

Periodic maintenance tasks include:

- Changing the transmission fluid regularly to maintain optimal viscosity.

- Inspecting seals and gaskets for leaks to avoid fluid loss.

- Cleaning the air filter to prevent dust and debris from entering the system.

By following these guidelines, you can enhance the performance and reliability of the power transmission system, leading to a more enjoyable experience during operation.

Fuel System Maintenance Tips

Ensuring the longevity and efficiency of the fuel delivery system is crucial for optimal performance. Regular upkeep not only enhances the functionality of your vehicle but also prevents potential issues that can arise from neglect.

Here are some essential maintenance tips to keep the fuel system in peak condition:

| Task | Frequency | Description |

|---|---|---|

| Inspect Fuel Lines | Monthly | Check for cracks, leaks, or wear that could compromise fuel flow. |

| Change Fuel Filter | Every 6 Months | Replace to ensure clean fuel reaches the engine, enhancing performance. |

| Check Fuel Quality | Every Filling | Use high-quality fuel and avoid contaminated sources to maintain system health. |

| Clean Fuel Injectors | Annually | Utilize a cleaning solution to remove deposits and improve efficiency. |

By following these guidelines, you can effectively maintain the fuel delivery system, ensuring smooth operation and preventing costly repairs in the future.

Suspension and Wheel Adjustments

Properly configuring the suspension and wheel alignment is essential for maintaining optimal performance and ride quality. This section provides guidance on how to adjust these critical components to enhance stability and comfort during operation.

Suspension Setup

The suspension system plays a vital role in absorbing shocks and providing a smooth ride. Adjustments may include setting the preload on springs and ensuring that dampers are functioning correctly. Regular checks can prevent premature wear and improve handling.

Wheel Alignment Techniques

Accurate wheel alignment is crucial for effective maneuverability and tire longevity. Ensure that both front and rear wheels are correctly aligned to prevent uneven tire wear and to promote safe driving conditions.

| Adjustment Type | Reco

Safety Precautions During RepairsWhen performing maintenance on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions help ensure a secure working environment and contribute to the successful completion of tasks. This section outlines essential guidelines to follow during the service process. Before beginning any work, always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear. This gear minimizes the risk of injury from sharp objects or harmful substances. Additionally, ensure that the workspace is clean and well-lit, reducing the likelihood of accidents due to poor visibility or clutter. Moreover, familiarize yourself with the equipment and its components to avoid mishandling. Disconnect power sources when working on electrical systems and ensure that all tools are in good condition to prevent malfunction during use. By following these safety measures, you can significantly reduce hazards while undertaking maintenance tasks. Resources for Parts and AccessoriesFinding the right components and enhancements for your vehicle can significantly improve its performance and longevity. Numerous resources are available to assist enthusiasts in sourcing quality items tailored to their specific needs. This section will explore various options for acquiring essential elements and supplementary features. Online marketplaces provide a vast selection of components, ranging from original parts to aftermarket alternatives. Websites dedicated to motorsports and outdoor equipment often carry a diverse inventory, allowing users to compare prices and quality easily. Additionally, forums and community groups can be invaluable, connecting you with fellow owners who may offer recommendations or even spare parts. Local retailers specializing in automotive supplies can also be a great resource. These shops often carry popular brands and can provide guidance on compatibility and installation. Furthermore, attending swap meets and trade shows offers opportunities to discover unique items and interact directly with vendors who understand the specific requirements of your vehicle. |

|---|