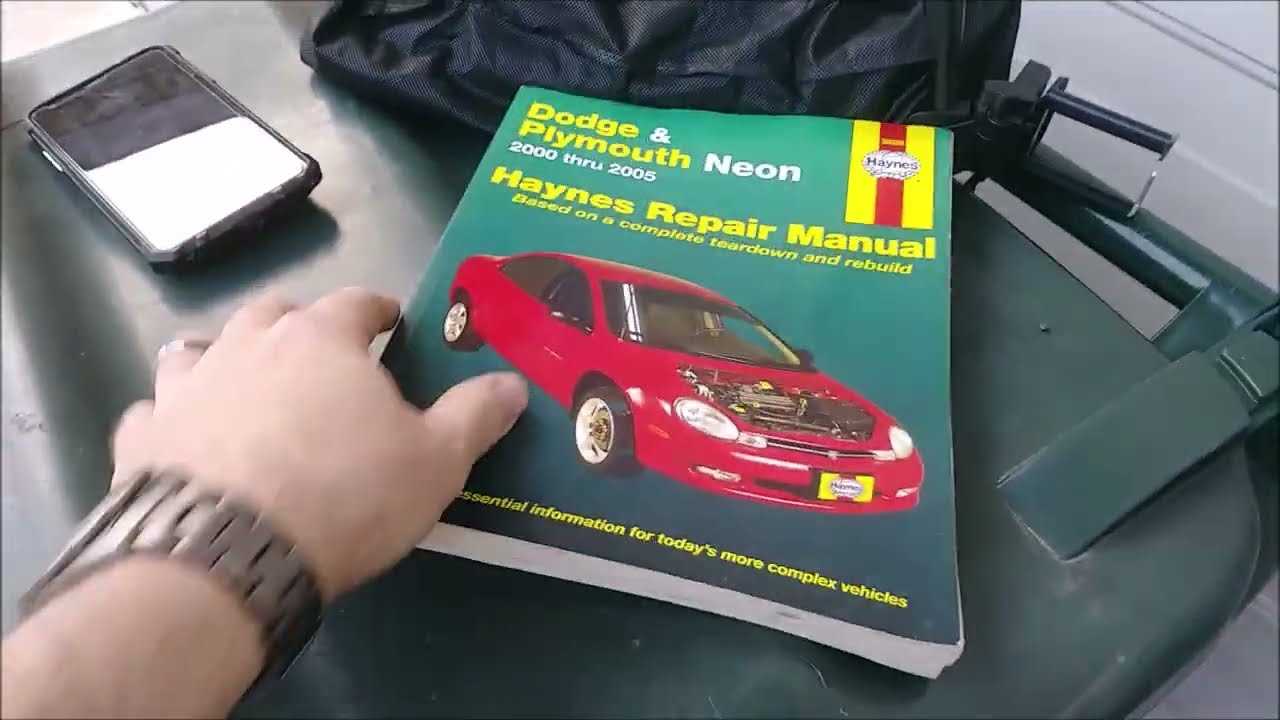

Maintaining a vehicle is essential for ensuring its longevity and optimal performance. A thorough understanding of various components and their functions can empower owners to address issues effectively. This section offers valuable insights into troubleshooting, servicing, and enhancing the overall efficiency of a specific model.

Knowledge is power when it comes to automotive care. Familiarity with the intricacies of your vehicle enables timely interventions, preventing minor concerns from escalating into significant problems. Whether you’re a seasoned enthusiast or a novice, having access to detailed information is crucial for making informed decisions.

With an emphasis on practical solutions, this resource aims to equip you with the necessary tools to navigate common challenges. From routine checks to more complex repairs, understanding the mechanics will not only save time but also provide peace of mind on the road. Explore the essential tips and techniques to keep your automobile running smoothly for years to come.

Overview of the 2000 Plymouth Neon

This section provides a comprehensive look at a compact car known for its efficiency and practicality. Designed for urban commuting and daily driving, this vehicle captures attention with its stylish design and user-friendly features.

Key Features

- Compact and agile structure for easy maneuverability.

- Fuel-efficient engine options that minimize operating costs.

- Comfortable interior with a focus on driver and passenger convenience.

- Variety of trim levels catering to different preferences and budgets.

Performance Highlights

- Responsive handling suitable for city environments.

- Good acceleration for a vehicle in its class.

- Decent cargo space for practicality and versatility.

- Reliable safety features to enhance driver confidence.

This vehicle stands out as a reliable choice for individuals seeking an economical and functional option in the compact segment.

Common Issues with the 2000 Model

Every vehicle has its quirks, and this particular model is no exception. Owners often encounter several prevalent problems that can affect performance and comfort. Understanding these issues is essential for maintaining reliability and ensuring a smooth driving experience.

Electrical Problems: One of the most frequently reported concerns involves the electrical system. Drivers may experience issues with the battery, alternator, or wiring, leading to unexpected breakdowns or difficulties starting the engine.

Engine Performance: Some individuals notice a decrease in engine efficiency over time. Symptoms can include rough idling, stalling, or a lack of power during acceleration. These issues may stem from faulty sensors or issues with the fuel system.

Transmission Troubles: Shifting difficulties are another common complaint. Owners might find that gears hesitate to engage or that the vehicle struggles to move smoothly. Regular maintenance can help mitigate these issues.

Suspension and Steering: Many users report problems related to the suspension and steering systems. Worn-out components can lead to a rough ride, poor handling, and increased tire wear. Keeping these systems in good condition is vital for safety and comfort.

Interior Wear: The interior of this model may show signs of wear and tear faster than expected. Common issues include fraying upholstery, malfunctioning electronics, and fading dashboard materials, which can detract from the overall driving experience.

Essential Tools for Repairs

Having the right equipment is crucial for successful maintenance tasks. A well-equipped workspace not only enhances efficiency but also ensures safety while working on automotive components. Below is a list of essential implements that every enthusiast should consider having on hand.

- Socket Set: A comprehensive socket set is vital for loosening and tightening various fasteners.

- Wrenches: Both adjustable and fixed wrenches are necessary for different sizes of bolts and nuts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will help tackle various screws encountered in vehicles.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Pliers: Needle-nose and standard pliers are essential for gripping, bending, and cutting wires.

- Jack and Stands: A hydraulic jack and jack stands are crucial for safely elevating the vehicle during maintenance.

- Multimeter: Useful for diagnosing electrical issues by measuring voltage, current, and resistance.

- Oil Filter Wrench: This tool simplifies the removal of the oil filter during an oil change.

Investing in quality tools not only makes tasks easier but also extends the lifespan of the equipment itself. Always ensure that tools are maintained and organized for quick access during projects.

Engine Maintenance Tips and Tricks

Proper upkeep of your vehicle’s powertrain is essential for optimal performance and longevity. Regular attention to various components can prevent costly issues down the line and enhance driving experience. Below are several key strategies to help you maintain your engine effectively.

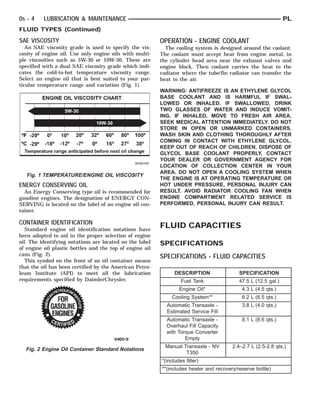

Regular Fluid Checks

Maintaining the right fluid levels is crucial for engine health. Regularly inspect and top off essential fluids such as oil, coolant, and transmission fluid to ensure smooth operation.

| Fluid Type | Recommended Check Interval | Importance |

|---|---|---|

| Engine Oil | Every 3,000 to 5,000 miles | Lubrication and heat dissipation |

| Coolant | Every 6 months | Prevent overheating |

| Transmission Fluid | Every 30,000 miles | Gear shifting efficiency |

Routine Inspections

Conducting regular inspections of engine components can help identify potential problems early. Pay attention to belts, hoses, and filters to ensure they are in good condition. Replace any worn or damaged parts promptly to avoid further complications.

Transmission Troubleshooting Guide

This section aims to assist users in identifying and resolving common issues related to the vehicle’s gear-shifting system. Proper diagnosis is essential for maintaining optimal performance and prolonging the lifespan of the automotive transmission. Understanding potential problems can lead to timely interventions and effective solutions.

Common Symptoms and Possible Causes

| Symptom | Possible Cause |

|---|---|

| Slipping gears | Low fluid levels or contaminated fluid |

| Delayed engagement | Worn clutch plates or low fluid pressure |

| Unusual noises | Worn bearings or gears |

| Fluid leaks | Deteriorated seals or gaskets |

| Warning light on dashboard | Electrical issues or sensor malfunctions |

Troubleshooting Steps

To address transmission-related issues, follow these essential steps:

1. Check the fluid level and condition, adding or replacing as necessary.

2. Inspect for leaks around the transmission casing and components.

3. Test the electrical connections and sensors associated with the transmission.

4. If problems persist, consider seeking professional assessment for deeper mechanical issues.

Electrical System Diagnostics

Effective troubleshooting of the electrical framework in vehicles is essential for maintaining optimal performance and safety. This process involves a systematic approach to identify and resolve issues that may arise within the circuitry, components, and connections. By employing specific techniques and tools, one can diagnose malfunctions and ensure the system operates efficiently.

Understanding the Components is the first step in the diagnostic process. Familiarity with various parts, such as the battery, alternator, wiring harness, and fuses, allows for a more focused examination. Each component plays a crucial role, and any failure can lead to broader system issues.

Utilizing Diagnostic Tools enhances the accuracy of the assessment. Multimeters, oscilloscopes, and circuit testers are invaluable in measuring voltage, current, and resistance. These tools help in pinpointing faults, ensuring that repairs are targeted and effective.

Visual Inspection is another vital aspect of diagnostics. Regularly checking for signs of wear, corrosion, or damage can reveal underlying problems. Inspecting connections and wiring for any signs of fraying or loose fittings is critical for reliable operation.

Finally, documenting findings throughout the process aids in tracking recurring issues and understanding trends over time. This practice not only streamlines future diagnostics but also supports informed decision-making regarding repairs and replacements.

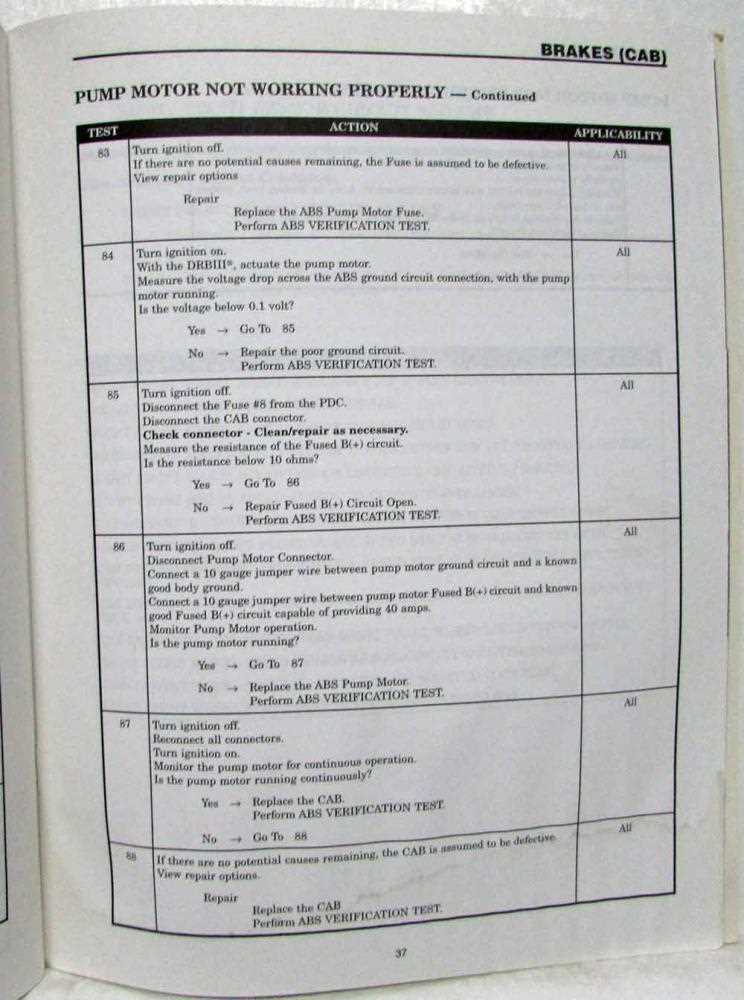

Brake System Inspection Procedures

The proper functioning of the braking system is essential for vehicle safety and performance. Regular examination of the components involved can help identify potential issues before they escalate into serious problems. This section outlines systematic approaches to assess the various elements of the braking mechanism, ensuring optimal operation and longevity.

Visual Inspection: Begin with a thorough visual examination of the brake components. Check for any signs of wear, such as cracks in the brake pads, uneven surface on rotors, or fluid leaks around the calipers and hoses. Ensure that all hardware, including brackets and fasteners, are securely in place.

Brake Pad Thickness: Measure the thickness of the brake pads using a caliper. Typically, a pad thickness below 3 mm indicates the need for replacement. Even if the pads appear to be intact, it’s crucial to assess their condition periodically to prevent brake fade.

Rotor Condition: Inspect the rotors for grooves, scoring, or discoloration. A smooth, even surface is necessary for effective braking. If the rotors show significant wear or warping, resurfacing or replacement may be necessary.

Fluid Level and Quality: Check the brake fluid level in the reservoir and ensure it meets the manufacturer’s specifications. Inspect the fluid for contamination or discoloration, which could indicate moisture absorption or degradation. If the fluid appears dark or murky, a complete flush and replacement may be warranted.

Brake Lines and Hoses: Examine all brake lines and hoses for signs of wear, bulging, or cracking. Any indication of deterioration can lead to brake failure. Ensure that all connections are tight and free from leaks.

Functionality Test: Conduct a functional test by pressing the brake pedal. The pedal should feel firm and responsive. If it feels spongy or sinks to the floor, this could indicate air in the system or a leak that requires immediate attention.

By following these inspection procedures, you can maintain a reliable braking system, enhancing overall safety on the road. Regular assessments help catch issues early and ensure that your vehicle remains in peak condition.

Suspension and Steering Care

Maintaining the integrity of the suspension and steering systems is essential for ensuring a smooth and safe driving experience. Regular attention to these components can enhance vehicle performance and prolong lifespan.

| Component | Maintenance Tips |

|---|---|

| Shock Absorbers | Inspect for leaks and replace every 50,000 miles. |

| Ball Joints | Check for wear and tear; greasing regularly is advisable. |

| Steering Rack | Monitor for fluid leaks and ensure proper alignment. |

| Control Arms | Inspect bushings for damage and replace if necessary. |

By prioritizing these areas, drivers can ensure optimal handling and stability on the road.

Bodywork and Exterior Repairs

This section focuses on the essential techniques and considerations for maintaining and restoring the outer surfaces of your vehicle. Proper attention to bodywork not only enhances aesthetic appeal but also protects against environmental elements and potential damage. Understanding the necessary procedures will enable you to address common issues effectively.

Common Issues and Solutions

Vehicles often encounter various challenges related to their exterior. Here are some typical problems and effective solutions:

| Issue | Solution |

|---|---|

| Dents and Dings | Utilize a hairdryer to heat the area, then apply ice to shrink the metal, or use a specialized dent puller. |

| Scratches | Buff the area with a polishing compound, followed by waxing to restore shine. |

| Rust Spots | Sand down the affected area, treat with a rust inhibitor, and repaint. |

| Chipped Paint | Touch up with matching paint and apply a clear coat for protection. |

Preparation and Materials

Before starting any exterior work, proper preparation is crucial. Gather necessary tools such as sanders, primers, and paints. Ensure the workspace is clean and well-ventilated. This attention to detail will significantly enhance the outcome of your project.

Interior Maintenance and Fixes

Keeping the cabin of your vehicle in optimal condition is essential for both aesthetics and comfort. Regular attention to various components can enhance your driving experience and prolong the lifespan of the interior elements.

Common Issues and Solutions

Identifying and addressing frequent problems can help maintain a pleasant environment inside the vehicle. Here are some typical issues you might encounter:

| Issue | Possible Solution |

|---|---|

| Faded upholstery | Use fabric cleaner or upholstery dye to restore color. |

| Scratched dashboard | Apply a plastic polish or consider replacement if severe. |

| Worn-out floor mats | Replace with new mats for better protection and appearance. |

Preventative Measures

Regular cleaning and protection of surfaces can prevent future deterioration. Utilizing appropriate cleaners and conditioners tailored for different materials will ensure longevity and maintain the vehicle’s overall appeal.

Recommended Fluids and Parts

Maintaining optimal performance in your vehicle requires using the right materials and components. Selecting high-quality fluids and parts is essential for ensuring longevity and reliability. This section highlights the best choices to keep your automobile running smoothly.

Engine Oil: It is crucial to use a high-grade engine lubricant that meets the manufacturer’s specifications. Look for synthetic options that provide excellent protection against wear and enhance fuel efficiency.

Transmission Fluid: Using the correct transmission fluid is vital for smooth gear transitions. Ensure that the fluid is compatible with your transmission type, whether automatic or manual.

Coolant: A reliable coolant prevents overheating and protects the engine from corrosion. Opt for a mixture that suits the climate you drive in, balancing antifreeze and water for optimal performance.

Brake Fluid: The braking system requires a specific type of hydraulic fluid to function effectively. Always use fluid that adheres to the required standards to maintain braking efficiency and safety.

Oil Filter: Replacing the oil filter regularly is as important as changing the oil itself. Choose a filter that can effectively capture contaminants and ensure proper flow.

Air Filter: A clean air filter enhances engine efficiency by improving airflow. Select a high-quality filter to maximize performance and fuel economy.

Fuel Filter: Regularly replacing the fuel filter helps maintain the health of the fuel system by preventing dirt and debris from clogging injectors and fuel lines.

By utilizing these recommended fluids and components, you can significantly improve the performance and durability of your vehicle, ensuring a safer and more enjoyable driving experience.

Safety Precautions During Repairs

Ensuring personal safety is paramount when undertaking maintenance on vehicles. Proper precautions not only protect the individual but also enhance the efficiency of the task at hand. A few key guidelines can significantly reduce risks associated with mechanical work.

Before commencing any task, it is essential to wear appropriate protective gear, such as gloves, goggles, and closed-toe shoes. This minimizes the risk of injury from sharp objects or hazardous materials. Additionally, working in a well-ventilated area is crucial, especially when dealing with chemicals or exhaust fumes, to prevent inhalation of harmful substances.

Always ensure that the vehicle is securely supported on jack stands or ramps to prevent it from falling during work. It is advisable to disconnect the battery to avoid electrical shocks or accidental starts. Keeping a clean workspace free from clutter also contributes to safety, as it reduces the likelihood of slips and trips.

Familiarizing oneself with the tools and materials needed for the task is important. Using the right equipment for the job ensures efficiency and reduces the chances of accidents. If unsure about any procedure, consulting relevant resources or seeking assistance from knowledgeable individuals can provide valuable guidance.