Outdoor lighting equipment, especially those designed for adventure, can face significant wear and tear due to exposure to various elements. Ensuring their longevity and optimal performance requires a keen understanding of their components and how they operate. In this section, you’ll discover essential insights for revitalizing and caring for these essential tools, helping them shine bright during every outing.

Maintaining your lighting gear involves more than just simple upkeep. Recognizing early signs of wear, addressing minor issues, and understanding how different components interact can dramatically extend its lifespan. This guide provides clear and practical steps, detailing everything from regular checks to in-depth restoration techniques, making it straightforward to keep these units operating smoothly.

Step-by-step instructions and hands-on techniques will walk you through each process, giving you confidence to tackle any maintenance task. With the right approach, even complex issues become manageable, allowing you to make the most of your lighting equipment for many adventures to come.

Coleman Lantern Repair Manual

This guide provides insights into maintaining and restoring outdoor lighting equipment, ensuring that your device functions reliably for many future uses. By exploring various techniques, you can effectively address common issues and optimize performance.

Understanding Common Issues

Outdoor lighting devices often encounter a range of operational challenges, from flickering to reduced brightness. Identifying the root causes, such as fuel or component concerns, is crucial. A thorough inspection can reveal areas that need attention, helping to keep your equipment in top condition.

Steps for Safe Maintenance

To ensure long-lasting performance, regular upkeep is essential. Begin by cleaning all surfaces and inspecting connections. Tighten any loose parts and replace worn elements as needed. This routine helps extend the life of your lighting device and ensures safe usage in various environments.

Understanding Common Lantern Issues

Identifying common issues with portable lighting devices can help maintain their performance and extend their lifespan. Many challenges arise due to regular usage, wear, and occasional environmental factors. Recognizing the symptoms of these problems is essential for prompt and effective troubleshooting.

- Inconsistent Light Output: One frequent issue is a flickering or dim light. This can result from buildup in key areas or battery-related factors, causing interruptions in light quality.

- Difficulty Igniting: If starting the device is challenging, it could stem from clogged components or wear in ignition parts. Regular maintenance may help to avoid this issue.

- Fuel-Related Problems: For models using fuel, blockages or leaks in the fuel pathway can disrupt functionality. This may include reduced brightness or unexpected shutdowns.

- Component Wear and Tear: Over time, certain parts may deteriorate, affecting overall performance. Periodic inspection and timely replacements are advisable to ensure proper operation.

Tools Needed for Lantern Repairs

When handling maintenance for lighting equipment, having the right tools is essential to ensure smooth and effective adjustments. Equipping yourself with the correct instruments not only makes the process faster but also reduces the risk of causing further wear to the parts involved. Here’s a breakdown of essential items that can assist in maintaining and refurbishing these devices.

Basic Hand Tools

Basic hand tools, such as screwdrivers and adjustable wrenches, are commonly required for accessing and removing parts. A small, multi-purpose screwdriver set is beneficial for dealing with various screw types, while an adjustable wrench is versatile enough to fit a range of nut sizes. These tools are the foundation for most disassembly and minor adjustments.

Specialized Maintenance Equipment

For more specific tasks, specialized items like needle-nose pliers and a pressure gauge can come in handy. Needle-nose pliers are ideal for reaching into tight spaces and manipulating small components, while a pressure gauge allows for accurate adjustments to any pressurized parts. Having these tools on hand ensures precision and safety during more detailed repair tasks.

Steps to Clean the Lantern Parts

Regular maintenance of your outdoor lighting equipment helps to ensure consistent performance. Keeping all parts clear of dust, soot, and buildup will prolong their lifespan and improve efficiency. Here, we’ll go through effective steps for thorough cleaning of each component.

1. Disassemble Carefully

Begin by gently separating each part of the lighting unit, ensuring not to force or twist any component. Use caution to avoid damaging any sensitive or delicate pieces. Lay out all parts on a clean, soft surface to prevent scratches or other damage.

2. Clean the Glass Cover

Using a soft cloth and mild soapy water, wipe the glass section to remove any grime or residue. Avoid abrasive materials that might scratch or weaken the glass. Rinse and dry thoroughly to prevent streaks.

3. Remove Residue from Metal Components

For metal pieces, a soft brush can help dislodge stubborn debris. Apply a gentle cleaner suitable for metal su

Fixing a Flickering Lantern Light

Sometimes, a flickering light can make outdoor experiences challenging. Restoring steady illumination is essential for a reliable light source, enhancing both visibility and comfort. Here are steps to address and resolve flickering issues effectively.

- Inspect the Power Source: Ensure the power supply is stable. Replace old batteries with new ones or check that the fuel supply is adequate for smooth operation.

- Examine the Connection Points: Look over all contact points within the device. A loose or dirty connection may disrupt the electrical flow, causing inconsistent lighting. Gently clean contacts if needed.

- Adjust the Light Source: Sometimes, the brightness setting or flame control may need minor adjustments to achieve a steady light. Test different levels to find the optimal setting.

- Clean the Components: Residue or dust buildup can affect performance. Carefully clean components such as the bulb or mantles to remove any obstructive particles.

- Replace Damaged Parts: If any part appears worn or broken, consider replacing it with compatible parts to

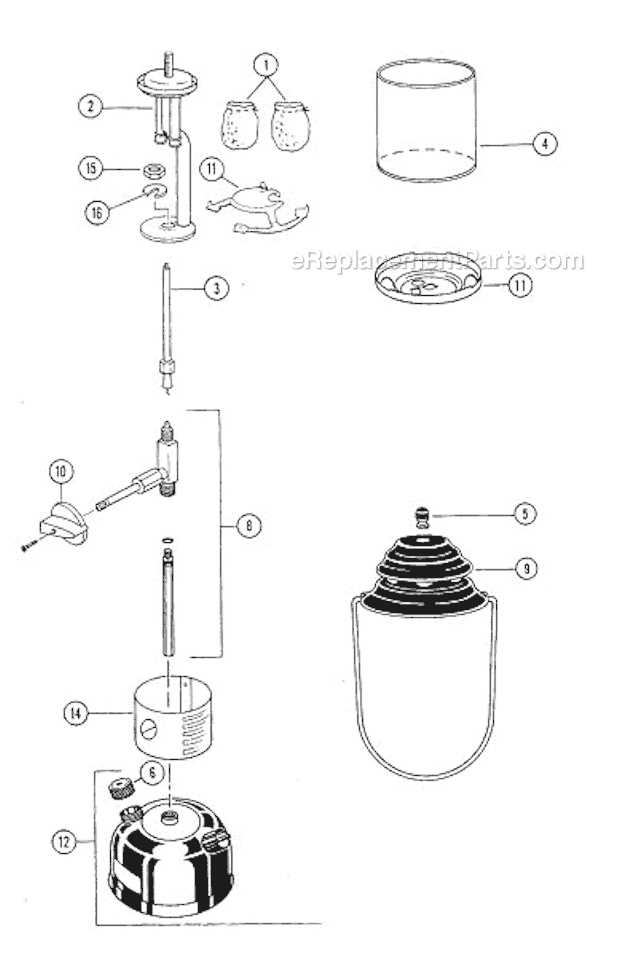

Replacing Worn Out Lantern Components

Over time, certain elements of a light source can become damaged or less effective, impacting its overall functionality. It is essential to identify and replace these worn parts to ensure optimal performance and safety. Regular maintenance and timely upgrades can significantly enhance the longevity of your illuminating device.

When addressing the replacement of these components, it is crucial to follow a systematic approach. Below are some common parts that may require attention:

- Glass Globes: These can crack or become foggy, affecting light output.

- Fuel Tanks: Inspect for leaks or corrosion that may compromise functionality.

- Burners: Ensure these are clean and free from blockages to maintain efficient operation.

- Wicks: Replace when frayed or burnt out to ensure proper fuel consumption.

Before initiating any replacements, gather the necessary tools and new parts. Make sure to consult guidelines specific to your device to facilitate a smooth replacement process. Taking these steps will help restore the functionality and reliability of your light source.

Troubleshooting Ignition Problems

When dealing with issues related to the starting mechanism, it’s essential to identify potential causes that prevent proper functioning. These difficulties can stem from various factors, including fuel supply, electrical connections, or the ignition source itself. By systematically addressing these areas, users can effectively resolve ignition-related challenges.

Common Symptoms

- No response when the ignition button is pressed.

- Flame flickering or inconsistent.

- Difficulty starting after multiple attempts.

Diagnostic Steps

- Check the fuel level to ensure it is adequate.

- Inspect the ignition source for wear or damage.

- Examine the electrical connections for corrosion or loose wires.

- Test the starting mechanism by following the manufacturer’s guidelines.

- Clean any debris or buildup around the ignition area.

Maintaining Fuel Efficiency

Ensuring optimal fuel efficiency is essential for maximizing the performance of your portable illumination device. Proper maintenance and regular checks can significantly enhance the longevity and effectiveness of the fuel source, allowing for extended usage and reducing the need for frequent refills.

Regular Maintenance Practices

Adopting consistent maintenance routines is crucial for preserving fuel efficiency. This includes inspecting the fuel system for leaks, ensuring clean fuel pathways, and replacing any worn components that could impact performance. Keeping the fuel source clean and free of contaminants helps to maintain a steady flow and optimal combustion.

Tips for Efficient Fuel Usage

Implementing specific strategies can further enhance fuel utilization. For instance, operating the device at recommended settings rather than maximum output can lead to more efficient fuel consumption. Additionally, utilizing the device in well-ventilated areas minimizes the buildup of exhaust, allowing for better air circulation and improving overall efficiency.

Practice Description Check for Leaks Regularly inspect the fuel system to identify any potential leaks that may waste fuel. Clean Fuel Pathways Ensure that fuel lines and filters are free from debris to maintain proper fuel flow. Optimal Operating Settings Adjust the device to run at recommended settings for efficient fuel consumption. Ventilation Use the device in well-ventilated spaces to promote better combustion and reduce exhaust buildup. Guidelines for Safe Lantern Use

Ensuring the safe operation of portable illumination devices is essential for a pleasant outdoor experience. Adhering to specific precautions can help prevent accidents and enhance user enjoyment. This section presents crucial recommendations for handling and utilizing these lighting solutions responsibly.

Before utilizing your device, it is vital to inspect it for any signs of wear or damage. Check all components to ensure they are functioning correctly and securely fitted. Proper maintenance not only prolongs the life of the equipment but also guarantees safety during operation.

Safety Tips Description Ventilation Always use in well-ventilated areas to prevent the buildup of harmful gases. Fuel Handling Handle fuel carefully, avoiding spills and keeping it away from open flames. Distance Maintain a safe distance from flammable materials while in use. Supervision Never leave the device unattended while lit to avoid potential hazards. Extinguishing Ensure the device is completely extinguished before storing or refueling. By following these guidelines, users can enjoy the benefits of portable illumination devices while minimizing risks. Always prioritize safety for a more enjoyable and worry-free experience.

Restoring Vintage Coleman Lanterns

Reviving classic illumination devices can be a rewarding endeavor for enthusiasts and collectors. These timeless pieces often hold sentimental value and represent a bygone era of craftsmanship. By dedicating time and effort to their restoration, one can bring back their former glory and ensure they remain functional for years to come.

Assessment and Preparation

The first step in the rejuvenation process is to assess the condition of the device thoroughly. Examine for any visible damage, rust, or deterioration. Gathering the necessary tools and replacement parts ahead of time can streamline the process, ensuring a smoother restoration experience. Clean the exterior to remove grime and prepare the surface for further work.

Functional Restoration

Addressing internal components is crucial for the proper functioning of the device. Carefully inspect the fuel system and replace any worn seals or fittings. It is also essential to check the glass components for cracks and ensure they are securely in place. By meticulously following these steps, one can achieve a successful revival of these cherished artifacts.

Proper Storage to Prevent Damage

Ensuring that your illumination device is stored correctly is essential for maintaining its functionality and longevity. Proper storage techniques can help avoid common issues such as rust, leaks, and other forms of deterioration, which can occur when the equipment is improperly handled or placed in unsuitable environments.

Choosing the Right Environment

When selecting a location for storage, aim for a cool, dry space that is free from extreme temperatures and moisture. Avoid areas that are prone to high humidity, as excessive dampness can lead to corrosion and other damages. A dedicated shelf or cabinet can provide a safe haven for your device, protecting it from physical impacts and environmental factors.

Protective Measures

Utilizing protective covers or bags can further safeguard your equipment. These coverings help shield against dust and scratches while also providing an extra layer of moisture resistance. Additionally, it is advisable to periodically check the stored item for any signs of wear or damage, ensuring that it remains in optimal condition for future use.