This section provides a thorough overview of essential procedures and techniques to ensure the longevity and optimal performance of your automobile. Understanding the intricacies of vehicle upkeep not only enhances reliability but also contributes to safety on the road. A well-maintained car can significantly improve driving experiences while minimizing unexpected issues.

In this guide, you will find detailed insights into various aspects of automotive care, including troubleshooting methods, routine checks, and specialized advice tailored to specific models. Whether you are a seasoned enthusiast or a novice, having access to accurate information empowers you to make informed decisions regarding your vehicle’s condition.

By following the guidelines presented here, you can effectively address common concerns and maintain your vehicle’s efficiency. Knowledge of proper maintenance practices ultimately leads to cost savings and enhances the overall enjoyment of your driving experience.

This section aims to provide a comprehensive introduction to a specific vehicle model, highlighting its key features and characteristics. Understanding the foundational aspects of this automobile is crucial for both current and prospective owners, as it sets the stage for more detailed discussions on maintenance and troubleshooting.

Key Features and Specifications

The vehicle in question is known for its compact design and practicality. It offers various engine options and configurations tailored to meet diverse driving needs. Below is a summary of its essential specifications:

| Feature | Details |

|---|---|

| Engine Type | 4-cylinder |

| Horsepower | 130 hp |

| Transmission | Automatic/Manual |

| Fuel Economy | 25 mpg city / 30 mpg highway |

Target Audience

This vehicle appeals to a wide range of individuals, from young professionals seeking an economical option to families needing reliable transportation. Its affordability and efficiency make it a practical choice in the competitive automotive market.

Common Issues and Troubleshooting Tips

This section provides insights into typical challenges encountered with specific vehicle models and offers practical advice for addressing them. Understanding these common problems can help in maintaining optimal performance and ensuring a smooth driving experience.

Engine Performance Problems

One frequent issue relates to engine performance, which may manifest as decreased power or irregular idling. This can be attributed to several factors, including air filter obstructions, fuel delivery issues, or ignition system failures. Regularly checking these components can aid in preventing performance drops and ensure the engine operates efficiently.

Electrical System Failures

Another common concern involves electrical system malfunctions. Symptoms may include non-functioning lights, erratic dashboard indicators, or starting difficulties. Inspecting the battery, fuses, and wiring connections can often resolve these issues. Keeping the electrical components in good condition is essential for the overall reliability of the vehicle.

Engine Maintenance Procedures Explained

Proper upkeep of the power unit is essential for ensuring optimal performance and longevity of any vehicle. Regular servicing and timely interventions can prevent major issues, enhancing both reliability and efficiency. This section outlines fundamental practices that contribute to the overall health of the engine, focusing on routine tasks that every owner should prioritize.

One of the primary tasks involves regular oil changes, which are crucial for maintaining proper lubrication and preventing wear on moving components. It is advisable to follow a specific interval, often recommended by the manufacturer, to ensure the engine operates smoothly. Additionally, checking and replacing the oil filter during these changes helps to trap contaminants, further protecting the engine.

Another key aspect is monitoring fluid levels, including coolant and transmission fluid. Maintaining adequate levels is vital for avoiding overheating and ensuring smooth operation of the transmission system. It is essential to inspect these fluids periodically and top them off as necessary, as well as to replace them based on the recommended schedule.

Furthermore, examining the air filter regularly is important for ensuring that the engine receives adequate airflow. A clean filter promotes better fuel efficiency and reduces strain on the engine. Replacing the air filter at regular intervals can significantly improve overall performance.

Lastly, keeping an eye on the condition of belts and hoses is imperative. These components can wear out over time and may require replacement to avoid unexpected breakdowns. Regular inspections help identify potential issues early, allowing for timely repairs and maintaining the reliability of the power unit.

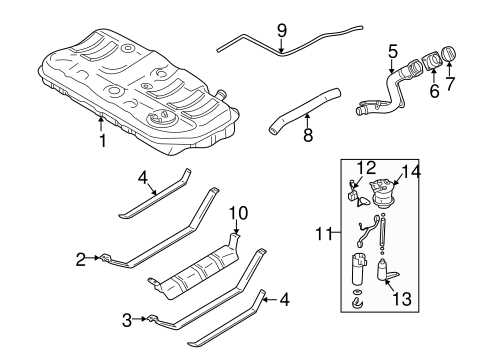

Transmission Fluid Change Instructions

Maintaining the fluid levels in your vehicle’s transmission is crucial for ensuring optimal performance and longevity. Regular changes help prevent potential issues and maintain smooth shifting. Below are detailed steps to effectively replace the transmission fluid.

- Gather necessary materials:

- New transmission fluid

- Transmission filter

- Wrench set

- Drain pan

- Funnel

- Safety gloves

- Rags for cleanup

- Park on a level surface and engage the parking brake.

- Let the engine cool down if it has been running.

- Locate the transmission drain plug and place the drain pan beneath it.

- Carefully remove the drain plug and allow the old fluid to completely drain.

- Remove the old filter from the transmission.

- Install the new filter, ensuring it is securely fitted.

- Replace the drain plug and tighten it securely.

- Using a funnel, pour the new transmission fluid into the designated fill port.

- Check the fluid level with the dipstick and add more if necessary.

- Transfer the drained fluid into a sealed container.

- Take it to a local recycling center or auto shop for proper disposal.

Following these steps will help maintain the efficiency of the transmission system, promoting a smoother driving experience.

Brake System Inspection Guidelines

The braking mechanism is a crucial component of any vehicle, ensuring safety and control during operation. Regular examination of this system helps identify potential issues before they escalate, enhancing overall performance and reliability.

Visual Examination: Begin by conducting a thorough visual inspection of the braking components. Look for signs of wear, damage, or corrosion on the brake pads, rotors, and calipers. Any visible cracks or uneven surfaces should be addressed immediately.

Fluid Check: Inspect the brake fluid level and quality. Ensure the fluid is clear and free from contaminants. Low fluid levels or murky appearance may indicate leaks or the need for replacement.

Functionality Test: Perform a functionality test by engaging the brakes at various speeds. Listen for unusual sounds, such as grinding or squeaking, which may suggest that components require maintenance or replacement.

Wear Indicators: Many brake pads are equipped with wear indicators that emit a high-pitched sound when the pads are worn down. Regularly check for these indicators to ensure timely intervention.

Professional Assessment: If any irregularities are detected during inspection, it is advisable to seek a professional evaluation. Trained technicians can provide comprehensive assessments and necessary repairs to maintain optimal safety.

Cooling System Maintenance Essentials

Maintaining the cooling system of your vehicle is crucial for optimal engine performance and longevity. Regular attention to this component ensures efficient temperature regulation, preventing overheating and potential damage to critical parts.

Inspecting Coolant Levels is the first step in maintaining a healthy cooling system. Regularly check the reservoir to ensure it is filled to the appropriate level. Low coolant can lead to insufficient heat dissipation, causing engine temperatures to rise.

Flushing the System periodically is essential to remove accumulated debris and contaminants. This process enhances the efficiency of the cooling liquid and helps prevent corrosion within the system. It is advisable to follow the manufacturer’s guidelines regarding the frequency of this maintenance task.

Checking Hoses and Connections for wear or leaks is also vital. Cracked or loose hoses can result in coolant loss and subsequent overheating. Ensure that all connections are secure and inspect for any signs of deterioration.

Thermostat Functionality should not be overlooked. A malfunctioning thermostat can disrupt the cooling process, leading to erratic temperature readings. Testing and replacing it as necessary ensures that the engine maintains its ideal operating temperature.

By prioritizing these maintenance tasks, you can safeguard your vehicle’s cooling system, enhancing both performance and reliability over time.

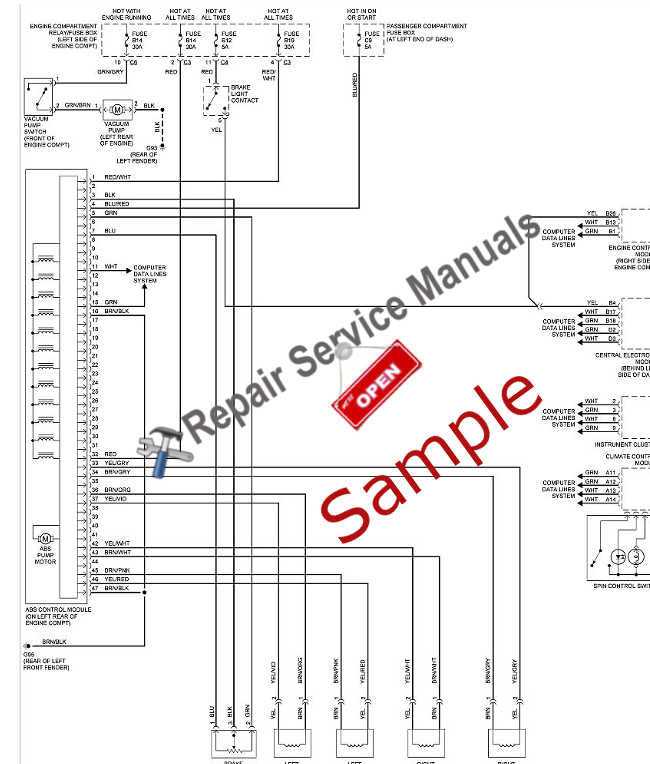

Electrical System Diagnostics and Repair

This section focuses on the evaluation and correction of issues within the vehicle’s electrical framework. Understanding the components and their interrelations is essential for effective troubleshooting and restoring functionality.

Common Electrical Issues

Several frequent problems may arise in the electrical system, often leading to malfunctioning components. Identifying these issues promptly can prevent further complications.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Dead Battery | Engine won’t start, dim lights | Recharge or replace the battery |

| Faulty Alternator | Battery warning light, electrical failures | Test and replace if necessary |

| Wiring Issues | Intermittent failures, short circuits | Inspect, repair, or replace damaged wiring |

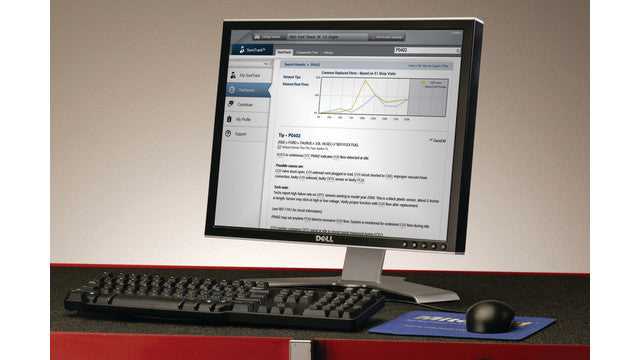

Diagnostic Tools and Techniques

Utilizing the right tools can significantly enhance the accuracy of diagnostics. Multimeters, oscilloscopes, and specialized diagnostic devices allow for precise assessments and effective resolution of electrical challenges.

Suspension and Steering Adjustments

This section focuses on the critical aspects of modifying and fine-tuning the vehicle’s suspension and steering systems. Proper adjustments can enhance ride quality, improve handling, and ensure optimal contact with the road surface.

Suspension Alignment plays a vital role in maintaining the vehicle’s stability and comfort. Regular checks for camber, caster, and toe angles are essential to prevent uneven tire wear and ensure proper handling. Adjustments can be made using specialized tools to achieve the manufacturer’s specifications.

Additionally, steering system calibration is crucial for accurate response and driver control. Periodic inspections for wear in components such as tie rods and ball joints can identify potential issues before they escalate. Ensuring that the steering wheel is centered during driving is also a key adjustment for overall driving satisfaction.

By regularly maintaining and adjusting these systems, one can achieve a harmonious balance between comfort and performance, leading to a safer and more enjoyable driving experience.

Fuel System Cleaning Techniques

Maintaining the cleanliness of the fuel system is essential for optimal engine performance and longevity. Regular cleaning procedures can prevent the buildup of deposits and ensure that fuel flows freely to the engine, ultimately enhancing efficiency and reducing emissions.

Types of Cleaning Methods

There are several approaches to cleansing the fuel system. One common method involves using specialized cleaning solutions that are introduced into the fuel tank. These solutions work by dissolving deposits and contaminants, allowing them to be expelled during normal engine operation. Another effective technique is the application of pressurized cleaning equipment that targets specific components, such as injectors and fuel lines, removing stubborn buildup.

Benefits of Regular Cleaning

Regular maintenance of the fuel system offers multiple benefits. It improves fuel atomization, which enhances combustion efficiency and power output. Additionally, it helps to reduce the likelihood of misfires and rough idling, leading to a smoother driving experience. Emphasizing cleanliness in the fuel system can also prolong the lifespan of vital engine components, saving time and costs associated with extensive repairs.

Exhaust System Troubleshooting Steps

This section outlines essential procedures for diagnosing issues related to the exhaust mechanism of a vehicle. Effective troubleshooting can help identify problems that may affect performance, emissions, and overall safety. Follow these systematic steps to ensure a thorough examination.

| Step | Description |

|---|---|

| 1 | Visual Inspection: Examine the exhaust components for any visible damage, rust, or leaks. Look for hanging parts or unusual positioning. |

| 2 | Listen for Unusual Noises: Start the engine and listen for any rattling or hissing sounds, which may indicate leaks or loose components. |

| 3 | Check Exhaust Fumes: Observe the color of the exhaust gases. Blue smoke may suggest oil burning, while black smoke indicates excessive fuel consumption. |

| 4 | Pressure Test: Use a pressure gauge to measure exhaust pressure at various points. Abnormal readings may indicate blockages or restrictions. |

| 5 | Inspect Oxygen Sensors: Ensure the oxygen sensors are functioning correctly, as faulty sensors can affect fuel mixture and emissions. |

Wheel Alignment and Tire Care

Proper alignment and maintenance of wheels and tires are essential for ensuring optimal vehicle performance and safety. This process not only enhances driving comfort but also extends the lifespan of the tires and improves fuel efficiency. Regular checks can prevent uneven wear and potential handling issues, contributing to a smoother ride.

Importance of Wheel Alignment

Maintaining correct wheel alignment is crucial for vehicle stability and handling. Misalignment can lead to uneven tire wear, affecting traction and increasing the risk of accidents. Frequent inspections and adjustments help in preserving tire integrity and enhancing overall performance. It’s advisable to have the alignment checked periodically, especially after any significant impacts or alterations to suspension components.

Tire Maintenance Tips

Regular tire care is vital for optimal performance. Ensure that tire pressure is monitored and adjusted according to manufacturer specifications. Adequate inflation prevents premature wear and improves fuel economy. Additionally, rotating tires at recommended intervals promotes even wear, while inspecting for damage or foreign objects can help avoid blowouts. Proper storage and maintenance during off-seasons also contribute significantly to longevity.

Scheduled Maintenance Checklist Overview

This section provides a comprehensive guide to the regular upkeep of your vehicle, ensuring optimal performance and longevity. Following a systematic approach to maintenance helps identify potential issues early, enhancing safety and reliability.

Importance of Regular Upkeep

Consistent attention to scheduled tasks not only improves the efficiency of your automobile but also contributes to its overall value. Addressing minor concerns before they escalate can save time and costs in the long run.

Key Maintenance Tasks

Essential tasks include fluid checks, filter replacements, and tire inspections. These actions are crucial in maintaining functionality and preventing breakdowns, fostering a smooth driving experience.