This section provides essential insights into the upkeep and troubleshooting of a specific type of two-wheeled vehicle. Understanding the intricacies of its components is vital for optimal performance and longevity. Knowledge of standard practices will empower enthusiasts and users alike to address common issues effectively.

Moreover, familiarity with the machinery’s functions enhances safety and efficiency. A systematic approach to understanding each part’s role not only aids in resolving problems but also promotes a deeper appreciation of the vehicle’s design and engineering. Emphasizing preventive measures can significantly reduce the likelihood of future malfunctions.

By delving into detailed instructions and guidelines, this resource serves as a valuable tool for both novice and experienced individuals. Whether you’re performing routine maintenance or diagnosing more complex concerns, having access to reliable information is crucial for ensuring a seamless riding experience.

Overview of Maintenance Guide

This section provides a comprehensive outline of the maintenance document designed for a specific off-road motorcycle model. It serves as an essential resource for enthusiasts and mechanics alike, offering valuable insights into the upkeep, troubleshooting, and performance enhancement of the vehicle.

Key Components

The guide typically includes detailed descriptions of various components, such as the engine, transmission, and suspension systems. Each section aims to assist users in understanding the intricate workings of the motorcycle and how to maintain them effectively.

Maintenance Schedule

A well-structured maintenance schedule is crucial for ensuring optimal performance and longevity. Users can find recommendations for regular checks, replacements, and adjustments that keep the motorcycle running smoothly.

| Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 10 hours | Replace with manufacturer-approved oil. |

| Air Filter Check | Every 5 hours | Inspect and clean as needed to ensure proper airflow. |

| Chain Lubrication | After every ride | Apply lubricant to the chain to prevent rust and wear. |

| Tire Inspection | Weekly | Check for wear and proper inflation. |

Engine Maintenance Procedures

Maintaining the engine is crucial for ensuring optimal performance and longevity of the vehicle. Regular checks and procedures can prevent potential issues and enhance reliability. This section outlines essential practices to keep the engine in top condition.

- Regular Oil Changes: Change the engine oil as recommended to maintain lubrication and prevent wear.

- Air Filter Maintenance: Inspect and clean or replace the air filter periodically to ensure proper airflow and engine efficiency.

- Cooling System Checks: Monitor coolant levels and inspect hoses for leaks to prevent overheating.

- Spark Plug Inspection: Check spark plugs for wear and replace them as necessary to maintain efficient combustion.

Following these maintenance procedures will help ensure that the engine operates smoothly and effectively.

Detailed Maintenance Steps

- Change Engine Oil:

- Gather necessary tools and oil.

- Remove the oil drain plug and allow old oil to fully drain.

- Replace the oil filter if applicable.

- Reinstall the drain plug and fill with fresh oil.

- Inspect Air Filter:

- Locate the air filter housing.

- Remove the air filter and clean it with compressed air or replace it if necessary.

- Reassemble the housing securely.

- Check Coolant Levels:

- Open the coolant reservoir.

- Add coolant as needed and check for any visible leaks in hoses.

- Replace Spark Plugs:

- Remove the spark plug wire and use a socket wrench to take out the old spark plug.

- Install a new spark plug and reattach the wire securely.

By adhering to these guidelines, you will significantly enhance the operational efficiency and lifespan of the engine.

Transmission and Clutch Adjustments

Ensuring optimal performance of a motorcycle’s transmission and clutch system is crucial for smooth operation and longevity. Proper adjustments are essential to enhance the vehicle’s responsiveness and to prevent potential mechanical issues. This section outlines the key aspects of adjusting these components, providing insights into the necessary steps and considerations.

To begin with, it’s important to check the clutch cable tension. A properly adjusted cable allows for smooth engagement and disengagement of the clutch plates. To adjust, locate the adjuster near the clutch lever and turn it to achieve the desired tension. A gap of approximately 2-3 mm between the lever and the perch is generally recommended.

Next, examine the clutch assembly for wear and tear. Inspect the friction plates and springs, as worn components can lead to slipping or dragging. If replacement is necessary, ensure to use components that meet the specifications for your specific model.

When adjusting the transmission, focus on the shift linkage. Ensure that the linkage is free of debris and that all connections are secure. Adjust the shift lever height to facilitate comfortable gear changes. The lever should be positioned such that the foot can easily engage it without strain.

Regular maintenance and timely adjustments of the transmission and clutch are vital for preserving performance and reliability. By following these guidelines, riders can ensure a smooth and enjoyable riding experience.

Suspension System Inspection Tips

The suspension system plays a crucial role in ensuring a smooth and controlled ride. Regular inspections are essential to maintain optimal performance and safety. This section provides valuable insights into effectively examining the components of your vehicle’s suspension to prevent issues that could lead to unsafe driving conditions.

Check for Leaks: Start by inspecting the shock absorbers and struts for any signs of fluid leaks. A leaking suspension component can indicate internal damage and reduced effectiveness, compromising the system’s performance.

Examine Bushings: Look closely at the bushings for signs of wear or deterioration. Cracked or brittle bushings can lead to increased vibration and noise, affecting overall handling. Replace any damaged bushings promptly to maintain ride quality.

Inspect Alignment: Misalignment can cause uneven tire wear and affect steering response. Regularly check the alignment of the wheels and suspension components to ensure they are in proper configuration. Adjustments should be made as necessary to enhance stability and control.

Test Shock Absorber Performance: A simple bounce test can help assess the effectiveness of the shock absorbers. Push down on each corner of the vehicle and observe how it rebounds. If it bounces more than once, it may indicate that the shocks need replacement.

Listen for Unusual Noises: Pay attention to any unusual sounds while driving, especially over bumps. Clunks, rattles, or squeaks can be indicative of loose or damaged components within the suspension system. Investigating these noises can help identify underlying issues before they escalate.

Brake System Repair Guidelines

The brake system is a crucial component of any two-wheeled vehicle, ensuring safe stopping and handling. Proper maintenance and timely interventions can significantly enhance performance and longevity. This section provides essential instructions for maintaining and troubleshooting the braking mechanism.

To begin, it is vital to regularly inspect the brake pads for wear. Worn pads can compromise braking efficiency, leading to potential hazards. If the pads are excessively thin, replacing them is necessary to restore optimal function.

Next, ensure that the brake fluid level is adequate. Low fluid can affect the hydraulic pressure within the system, resulting in diminished stopping power. If the fluid appears dark or contaminated, a complete fluid replacement is recommended. Always use the correct type of brake fluid specified for your vehicle.

In addition, check the brake lines for any signs of leakage or damage. Damaged lines can lead to fluid loss and, consequently, brake failure. If any issues are found, replace the affected lines promptly to ensure the integrity of the braking system.

Finally, periodically examine the brake calipers for proper operation. Sticking calipers can cause uneven wear on the brake pads and reduce overall performance. If the calipers do not retract properly, they may need servicing or replacement to restore full functionality.

Electrical System Troubleshooting

This section focuses on diagnosing and resolving issues related to the electrical components of a two-wheeled vehicle. A comprehensive understanding of the electrical system is essential for maintaining optimal performance and ensuring safe operation. Identifying problems early can prevent further damage and costly repairs.

Common Electrical Issues

Electrical malfunctions can arise from various sources. Here are some prevalent problems encountered:

| Issue | Symptoms | Potential Causes |

|---|---|---|

| Battery Not Charging | Dim lights, difficulty starting | Faulty alternator, bad connections |

| Blown Fuses | Non-functional components | Short circuit, overload |

| Starter Problems | Clicking sound, no engine turnover | Weak battery, defective starter motor |

| Wiring Issues | Intermittent power, erratic behavior | Corroded connectors, damaged wires |

Troubleshooting Steps

To effectively address electrical problems, follow these systematic steps:

- Inspect the battery and connections for corrosion or looseness.

- Check all fuses and replace any that are blown.

- Test the alternator output to ensure proper charging.

- Examine wiring for visible damage or frayed ends.

- Utilize a multimeter to diagnose voltage levels at various points.

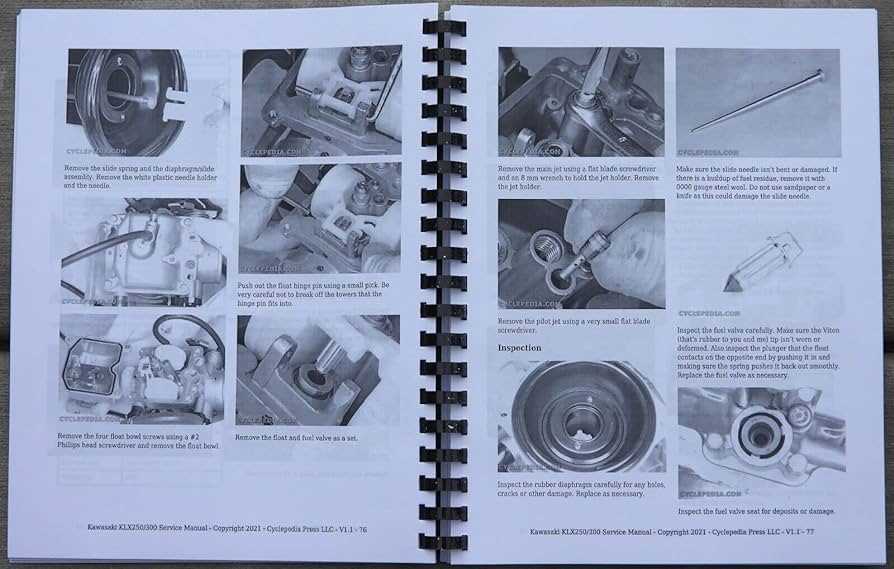

Fuel System Cleaning Techniques

Maintaining the cleanliness of the fuel system is essential for optimal performance and longevity of any two-stroke engine. Over time, fuel residues and impurities can accumulate, leading to various operational issues. Regular cleaning can help ensure efficient fuel delivery and engine responsiveness.

Here are some effective methods for cleaning the fuel system:

- Fuel Additives: Utilizing high-quality fuel additives can help dissolve deposits and prevent future buildup. Look for products specifically designed for cleaning fuel injectors and carburetors.

- Manual Cleaning: For thorough cleaning, disassemble the fuel system components, including the carburetor and fuel lines. Use a soft brush and a suitable solvent to remove grime and debris.

- Ultrasonic Cleaning: This technique uses high-frequency sound waves in a cleaning solution to gently remove contaminants from small parts. It is particularly effective for intricate components.

- Compressed Air: Blowing compressed air through the fuel lines and injectors can help dislodge any stubborn particles and ensure that pathways are clear.

- Regular Maintenance: Incorporating regular checks and cleanings into your maintenance routine can prevent the accumulation of debris and extend the life of the fuel system.

By employing these techniques, you can maintain an efficient fuel system, ensuring your engine operates smoothly and reliably.

Frame and Chassis Adjustments

Proper adjustments to the frame and chassis are crucial for optimal performance and handling of the motorcycle. Ensuring that these components are correctly aligned and set up can significantly enhance stability and rider comfort. This section will guide you through the essential steps for fine-tuning these critical parts.

1. Frame Alignment: Begin by inspecting the frame for any signs of damage or misalignment. A bent frame can lead to handling issues and affect the overall safety of the vehicle. Use a straight edge to check for straightness, and if discrepancies are found, consider professional assistance to correct the alignment.

2. Suspension Setup: The suspension plays a vital role in how the motorcycle reacts to terrain. Adjust the front and rear suspension settings according to the rider’s weight and riding style. Make sure to measure sag and adjust preload settings to achieve the desired ride height and comfort level.

3. Wheel Alignment: Ensuring that the wheels are aligned correctly is essential for even tire wear and handling. Check the alignment by measuring the distance from the rear axle to the front axle on both sides. Adjust as necessary by using the axle adjustment mechanisms.

4. Component Tightening: Regularly check and tighten all bolts and fasteners related to the frame and chassis. Loose components can lead to vibrations and instability while riding. Use a torque wrench to ensure all fittings are tightened to the manufacturer’s specifications.

By following these guidelines, you can ensure that the frame and chassis are in optimal condition, leading to improved handling and overall performance of the motorcycle.

Wheel and Tire Maintenance

Proper care and upkeep of wheels and tires are essential for optimal performance and safety of any off-road vehicle. Regular maintenance not only enhances traction and handling but also prolongs the lifespan of these critical components. This section outlines key practices for ensuring that wheels and tires remain in excellent condition.

Inspection and Cleaning

Routine inspection is vital for identifying any signs of wear or damage. Check for cracks, bubbles, or other deformities in the tire surface. Additionally, assess the tread depth to ensure adequate grip on various terrains. Cleaning the wheels regularly helps prevent dirt and debris buildup, which can lead to corrosion and affect overall functionality. Use a gentle cleaner and a soft brush to remove any accumulated grime.

Air Pressure and Alignment

Maintaining the correct air pressure is crucial for safe operation. Under-inflated or over-inflated tires can result in reduced performance and uneven wear. Always refer to the recommended pressure specifications. Furthermore, proper alignment of wheels is essential to avoid uneven tire wear and to enhance steering response. Regularly check and adjust alignment as necessary to ensure a smooth and safe ride.

Safety Checks Before Riding

Ensuring safety before heading out on a ride is crucial for any motorbike enthusiast. A thorough inspection can prevent accidents and enhance the overall riding experience. Below are essential checks that should be performed every time before starting your journey.

- Tires:

- Check tire pressure and adjust to the recommended levels.

- Inspect for any signs of wear or damage, such as cuts or bulges.

- Ensure proper tread depth for optimal grip.

- Brakes:

- Test both front and rear brakes for responsiveness.

- Check brake fluid levels and look for any leaks in the system.

- Inspect brake pads for wear and replace if necessary.

- Fluids:

- Check engine oil levels and top up if needed.

- Inspect coolant levels and ensure there are no leaks.

- Examine fuel levels to ensure enough for the ride.

- Lights and Signals:

- Test all lights, including headlights, brake lights, and turn signals.

- Ensure reflectors are clean and visible for safety.

- Controls:

- Check throttle and clutch operation for smooth movement.

- Inspect the kill switch and ensure it is functioning properly.

- Test the horn for adequate sound output.

- Body and Frame:

- Examine the body for any loose parts or damage.

- Ensure that all bolts and screws are tightened.

- Inspect the frame for any cracks or signs of stress.

Conducting these checks regularly will help maintain the vehicle’s performance and ensure a safer ride every time you hit the road.

Common Issues and Solutions

This section addresses frequent challenges encountered with this type of off-road vehicle and offers practical solutions to enhance its performance and longevity. Understanding these common problems can significantly improve your riding experience and reduce the likelihood of breakdowns.

One prevalent issue is difficulty in starting the engine, often caused by a weak battery or clogged fuel lines. To resolve this, check the battery’s charge and ensure that fuel is reaching the carburetor without any blockages. Regular maintenance of the fuel system can prevent this problem.

Another common concern is overheating, which can result from low coolant levels or a malfunctioning radiator. It’s essential to regularly inspect the coolant and ensure that the radiator is clean and free from debris. Flushing the cooling system periodically can also help maintain optimal operating temperatures.

Additionally, riders may experience handling issues, such as wobbling or instability. This can stem from improper tire pressure or misaligned wheels. Ensuring that tires are inflated to the recommended pressure and regularly checking wheel alignment can greatly improve stability on various terrains.

Lastly, unusual noises while operating the vehicle may indicate wear in the engine or drivetrain components. Regularly inspecting these parts and replacing worn bearings or gears can mitigate this issue and prevent further damage.

Upgrading Parts for Performance

Enhancing the capabilities of your two-wheeler involves selecting components that improve speed, handling, and overall efficiency. Upgrading specific parts can lead to significant improvements in performance, allowing riders to achieve their desired outcomes on various terrains.

Engine modifications are among the most impactful changes. By installing a high-performance exhaust system, for instance, you can reduce back pressure and enhance airflow, which often results in a noticeable boost in power. Additionally, considering aftermarket air filters can increase air intake, promoting better combustion and further enhancing engine performance.

Another area worth exploring is the suspension system. Upgrading forks and shock absorbers can drastically improve handling and stability, especially during rough rides. High-quality suspension components provide better damping and responsiveness, ensuring a smoother and more controlled ride.

Finally, attention should be given to the braking system. Upgrading to high-performance brake pads and rotors can greatly enhance stopping power, providing greater confidence and safety while riding. These upgrades, combined with regular maintenance, will ensure your machine performs at its best.

Essential Tools for Repair Work

Having the right equipment is crucial for any maintenance task. A well-stocked toolkit not only streamlines the process but also ensures that tasks are completed efficiently and effectively. Below are some indispensable items that every enthusiast should consider for their maintenance endeavors.

Basic Hand Tools

Hand tools are the foundation of any maintenance kit. They are versatile and can be used for a variety of tasks, from tightening screws to adjusting components. Here is a list of essential hand tools:

| Tool | Purpose |

|---|---|

| Screwdrivers | Used for tightening or loosening screws. |

| Wrenches | Ideal for gripping and turning nuts and bolts. |

| Pliers | Useful for gripping, twisting, and cutting. |

| Hex Keys | Essential for adjusting hexagonal bolts. |

Power Tools

Power tools can significantly enhance productivity and precision. These tools are designed for heavier tasks that require more strength and speed. Common power tools include:

| Tool | Purpose |

|---|---|

| Drill | For creating holes and driving screws quickly. |

| Angle Grinder | Used for cutting, grinding, and polishing materials. |

| Impact Wrench | Great for loosening or tightening stubborn bolts. |

| Sanders | Perfect for smoothing surfaces and removing old paint. |