Ensuring the longevity and efficiency of your agricultural machinery is crucial for optimal performance. This section focuses on essential practices and guidelines that aid in keeping your equipment in prime condition. From regular upkeep to addressing common issues, having the right knowledge can significantly impact productivity.

Understanding the intricacies of your machinery will empower you to perform necessary adjustments and repairs with confidence. Familiarizing yourself with the components and their functions will enhance your ability to diagnose problems effectively. This knowledge not only saves time but also reduces potential downtime during critical farming operations.

As you delve into the specifics of maintenance protocols, you will discover various techniques and recommendations tailored to enhance functionality. Whether it’s routine checks or troubleshooting common faults, following these guidelines will help ensure that your machinery operates smoothly and reliably.

This section addresses frequent challenges encountered with various machinery and provides effective solutions to resolve them. Understanding these common problems can help users maintain optimal functionality and avoid unnecessary downtime.

Mechanical Failures

Mechanical components may experience wear and tear over time, leading to operational issues. Regular inspections and timely maintenance can prevent most failures. Here are some common mechanical problems:

| Issue | Solution |

|---|---|

| Engine not starting | Check fuel levels, battery charge, and connections. |

| Unusual noises during operation | Inspect for loose parts or lack of lubrication. |

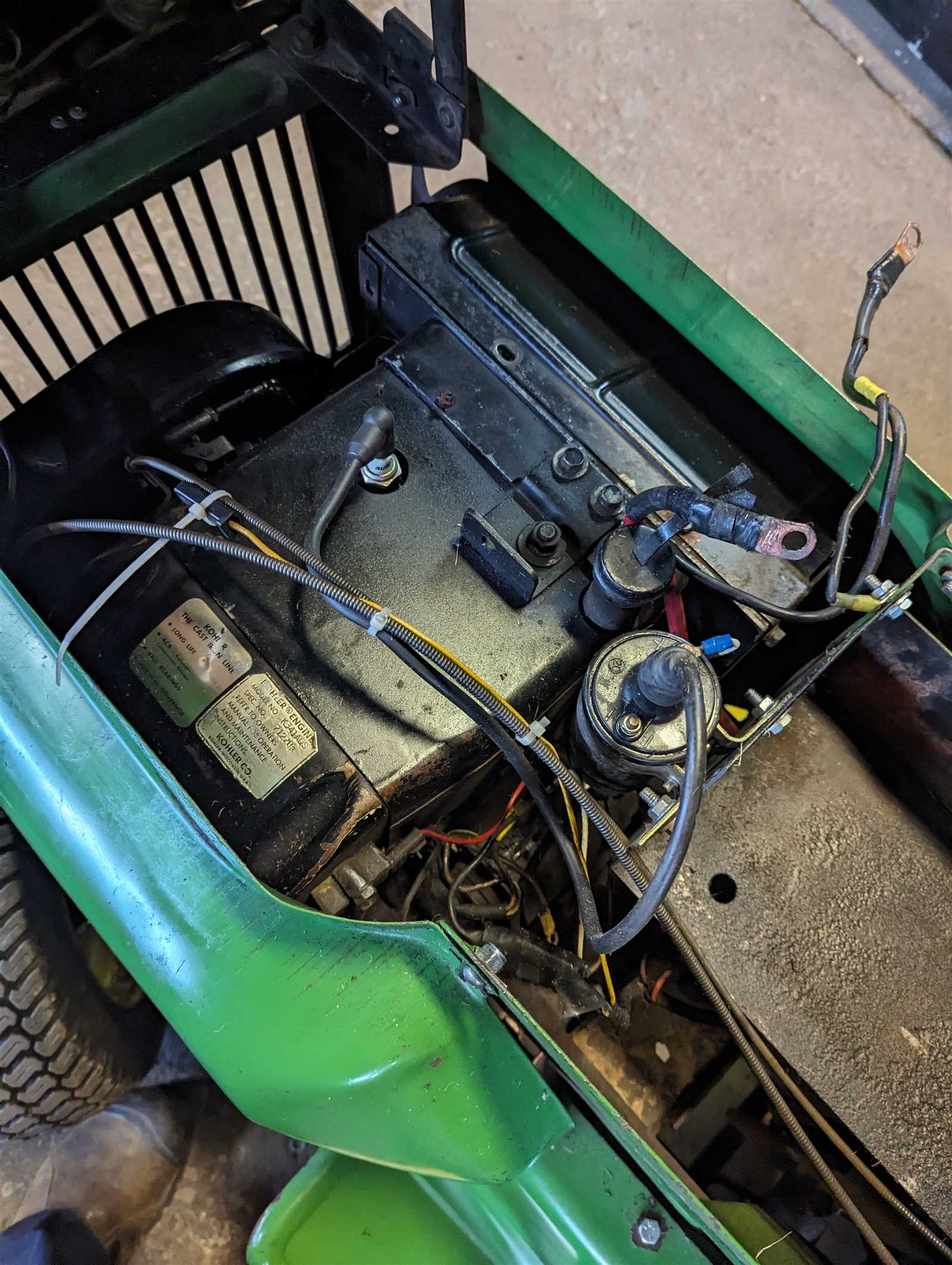

Electrical Concerns

Electrical systems can also pose challenges. Issues such as faulty wiring or dead batteries are common. Implementing proper diagnostic procedures can assist in identifying the root cause:

| Issue | Solution |

|---|---|

| Lights not functioning | Examine fuses and wiring connections. |

| Inconsistent power supply | Test the battery and charging system. |

Maintenance Tips for Longevity

Ensuring the extended life of your machinery requires consistent care and attention. By following a few essential practices, you can significantly enhance performance and durability.

- Regular Inspections: Frequently check all components for signs of wear or damage.

- Proper Lubrication: Ensure all moving parts are adequately lubricated to prevent friction and overheating.

- Clean Filters: Keep air and fuel filters clean to maintain optimal engine performance.

- Battery Maintenance: Regularly inspect and clean battery terminals to prevent corrosion.

- Fluid Levels: Regularly monitor and top off engine oil, coolant, and hydraulic fluids as needed.

Implementing these tips will not only extend the lifespan of your equipment but also improve its efficiency and reliability in various tasks.

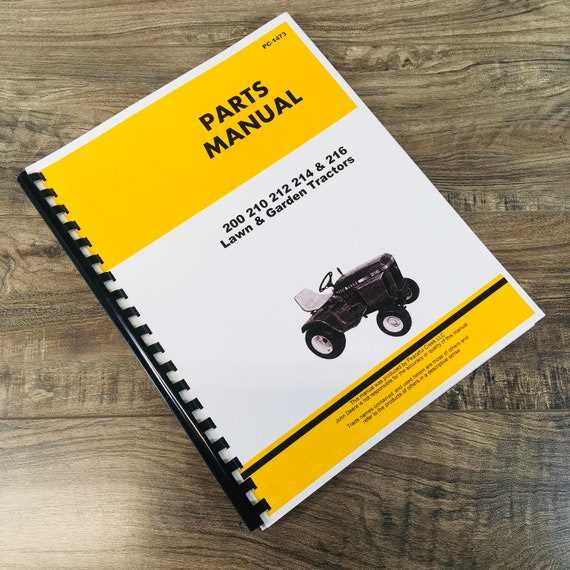

Parts Replacement Guide

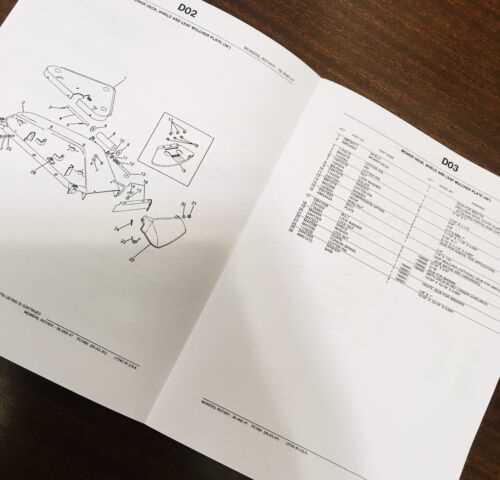

This section provides essential information for effectively replacing components in your machinery. Understanding the process of part substitution is crucial for maintaining optimal performance and ensuring longevity. Whether you’re addressing wear and tear or upgrading for enhanced functionality, following proper guidelines is key.

Identification of Components: Before proceeding with any replacements, it’s vital to accurately identify the parts that require attention. Refer to your documentation for specifications and compatibility to avoid mismatches.

Steps for Replacement: Begin by gathering the necessary tools and new components. Always ensure the machinery is powered down and secure before starting work. Carefully remove the old part, taking note of its orientation and connection points for proper installation of the new one.

Testing: After installation, conduct thorough testing to confirm that the new part functions correctly. Look for any signs of improper installation or issues that may arise. Regular checks and maintenance can prevent future complications.

In summary, staying informed about component replacement will not only enhance the efficiency of your equipment but also prolong its operational life.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is essential for achieving optimal results. Proper tools not only facilitate the process but also enhance safety and efficiency. This section outlines the key instruments that are indispensable for successful servicing of your machinery.

Essential Hand Tools

Wrenches and screwdrivers are fundamental for loosening and tightening various components. A set of ratchet sockets can significantly speed up the process, allowing for quick adjustments and repairs. Additionally, pliers and cutting tools may be required for specific tasks.

Specialized Equipment

In some cases, specialized instruments like diagnostic tools or torque wrenches are necessary to ensure that all parts function correctly and meet safety standards. Investing in quality equipment can prevent complications during maintenance and prolong the lifespan of your machinery.

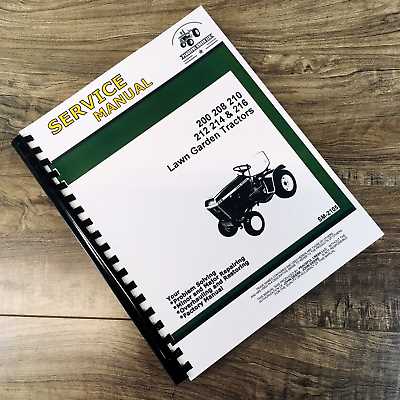

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing common issues encountered with agricultural machinery. By following systematic methods, users can effectively diagnose and resolve various operational challenges, ensuring optimal performance and longevity of the equipment.

Diagnosis and Preparation

Before initiating any maintenance tasks, it is essential to thoroughly inspect the machinery for visible signs of wear or malfunction. Gather the necessary tools and parts, and ensure a clean workspace to facilitate efficient handling. Document any observed symptoms to assist in troubleshooting.

Executing Repairs

Once the initial assessment is complete, proceed with the repairs by following the established procedures. Take care to adhere to safety guidelines throughout the process. After completing the necessary adjustments or replacements, conduct a final inspection to verify that all functions are restored to expected standards.

Safety Precautions During Repairs

When performing maintenance tasks on machinery, it is essential to prioritize safety to prevent accidents and injuries. Understanding the potential hazards and taking proactive measures can create a safer work environment.

Before starting any work, ensure that you are equipped with the proper personal protective equipment (PPE). This includes gloves, safety goggles, and appropriate footwear to minimize the risk of injury. Additionally, a well-organized workspace helps reduce the likelihood of accidents.

Always disconnect power sources and follow lockout/tagout procedures. This step is crucial to prevent unintentional machinery activation. Familiarizing yourself with the equipment’s operational manual will also provide insights into specific safety measures pertinent to the model being serviced.

Maintaining a clean work area is vital; clutter can lead to slips and falls. Regularly check tools and equipment for defects, and replace any that show signs of wear. Following these guidelines will enhance safety and efficiency during maintenance activities.

Troubleshooting Electrical Problems

Addressing electrical issues is crucial for ensuring the optimal performance of machinery. Identifying the source of faults can help maintain efficiency and prevent further complications. This section outlines key steps to diagnose and resolve common electrical malfunctions.

- Check the Battery: Ensure that the battery is fully charged and connections are secure. Look for any signs of corrosion on terminals.

- Inspect Wiring: Examine all wiring for wear, fraying, or disconnections. Ensure that connections are tight and free of debris.

- Test Fuses: Verify that all fuses are intact. Replace any blown fuses with ones of the appropriate rating.

- Examine Switches: Test all electrical switches for functionality. If a switch is faulty, it may need to be replaced.

- Utilize a Multimeter: Use a multimeter to check for continuity and voltage in various components. This tool can help pinpoint the source of an electrical problem.

By following these steps, users can effectively troubleshoot and resolve many electrical challenges, ensuring their equipment remains operational and efficient.

Engine Maintenance and Care

Proper upkeep of the power unit is essential for optimal performance and longevity. Regular attention to key components ensures smooth operation and minimizes the risk of breakdowns.

To maintain peak efficiency, it’s important to follow a routine that includes checking fluids, inspecting filters, and addressing any wear and tear. A well-maintained engine not only enhances productivity but also contributes to overall reliability.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check oil levels | Weekly | Top up if necessary, change oil as recommended. |

| Inspect air filter | Monthly | Clean or replace as needed to ensure airflow. |

| Examine fuel lines | Quarterly | Look for leaks or wear; replace if damaged. |

| Clean cooling system | Annually | Flush and refill to prevent overheating. |

By adhering to these maintenance practices, operators can extend the life of the power unit and improve its overall efficiency.

Hydraulic System Overview

The hydraulic system is a critical component that facilitates the efficient operation of various machinery. By utilizing fluid under pressure, this system enables the transmission of force, allowing for smooth movement and precise control of different parts. Understanding its functioning is essential for optimal performance and maintenance.

Key Components

Several integral parts constitute the hydraulic system. These include the hydraulic pump, which generates pressure, the valves that control the flow of fluid, and the cylinders that convert hydraulic energy into mechanical force. Each component plays a vital role in ensuring the system operates seamlessly.

Functionality and Maintenance

Proper functionality of the hydraulic system is paramount for operational efficiency. Regular inspection and maintenance are necessary to prevent issues such as leaks or pressure loss. Adhering to maintenance schedules not only enhances the system’s longevity but also ensures consistent performance during usage.

Transmission Service Recommendations

Ensuring the optimal performance of the transmission system is crucial for enhancing the longevity and reliability of the equipment. Regular maintenance and timely servicing can prevent common issues, ensuring smooth operation and minimizing downtime.

Routine Inspection

Regular checks should be performed to identify any potential leaks or irregularities. Inspecting the transmission fluid levels and condition is essential, as this can indicate the need for replacement or additional servicing. It is advisable to monitor the color and texture of the fluid; a burnt smell or dark color may signal problems.

Fluid Replacement Guidelines

It is important to follow the manufacturer’s recommendations for fluid replacement intervals. Generally, replacing the transmission fluid every 1,500 to 2,500 hours of operation is advised. This practice helps maintain the integrity of the system and ensures that all components operate effectively.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and troubleshooting of agricultural machinery. Below are some of the most frequently posed questions by users seeking guidance.

- What are the common issues faced with this equipment?

Users often report problems such as difficulty starting, unusual noises, and hydraulic failures.

- How can I perform regular maintenance?

Regular upkeep includes checking fluid levels, replacing filters, and inspecting belts and hoses.

- What tools do I need for basic servicing?

A basic toolkit typically includes wrenches, screwdrivers, pliers, and a socket set.

- Where can I find troubleshooting guides?

Numerous online resources and community forums offer step-by-step instructions and tips.

- When should I seek professional assistance?

If issues persist despite troubleshooting, it is advisable to consult a qualified technician.