Ensuring optimal performance of snow clearing machinery is essential for efficient winter operations. Understanding the intricacies of these machines can significantly enhance their longevity and reliability. Proper upkeep not only facilitates smooth functionality but also prevents costly breakdowns, ensuring that the equipment is always ready for action.

In this comprehensive guide, we will delve into various aspects of troubleshooting and maintenance for a specific model of snow blower. From routine inspections to more detailed technical procedures, the focus will be on empowering users with the knowledge to tackle common issues and perform essential tasks effectively.

With a blend of practical advice and detailed information, this resource aims to equip operators with the tools necessary to maintain their equipment in peak condition. Whether you are a seasoned user or a newcomer to snow removal, understanding these principles will enhance your ability to manage winter challenges with confidence.

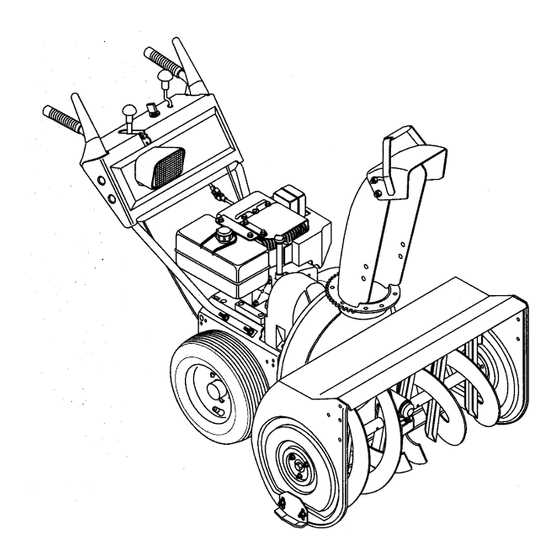

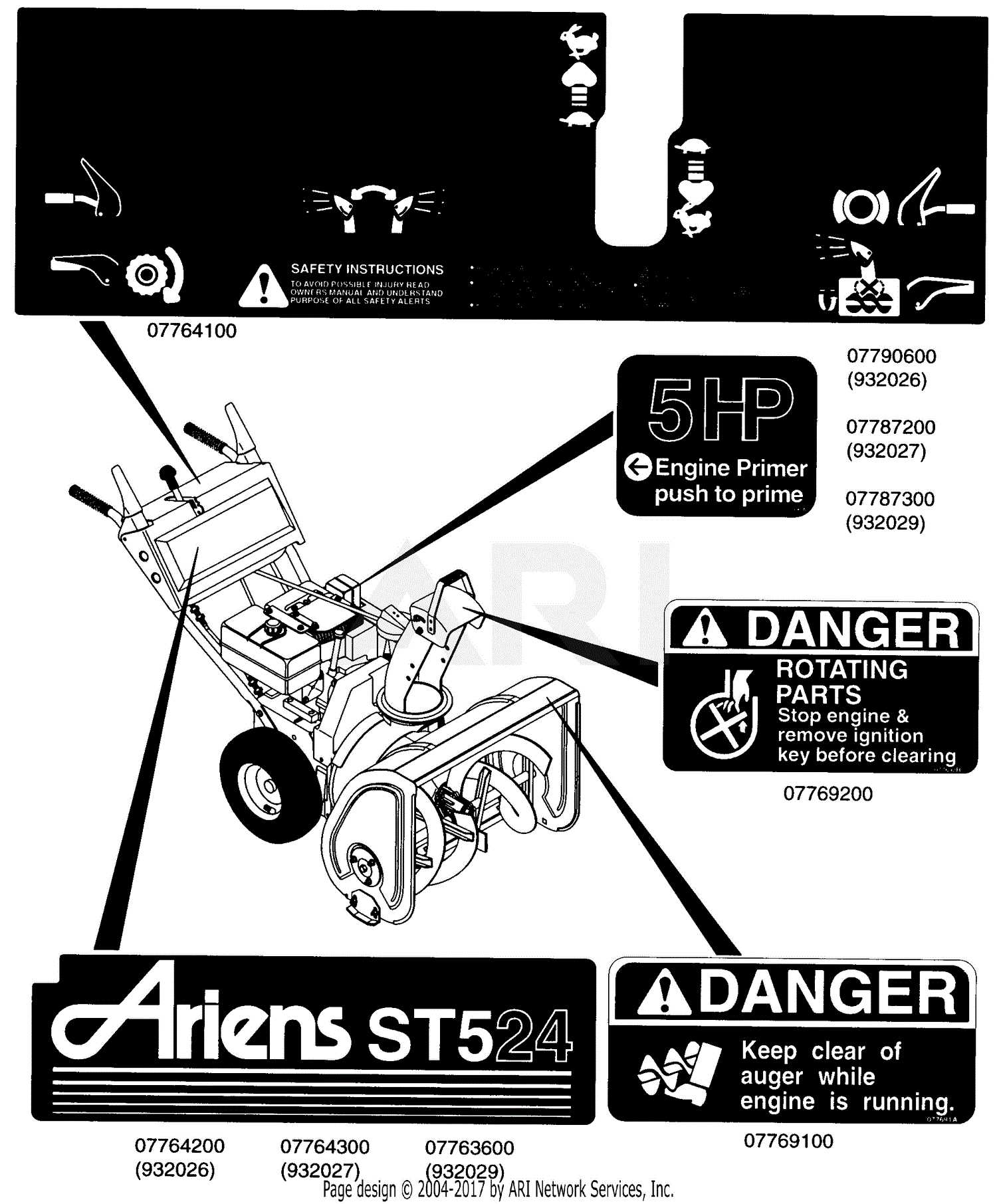

Ariens ST824 Overview

This section provides a comprehensive look at a particular snow-clearing machine known for its efficiency and durability. Designed for tackling harsh winter conditions, this equipment offers reliable performance to homeowners and professionals alike.

The model features a robust engine, ensuring powerful operation and the ability to handle heavy snow loads. Its innovative design includes a wide clearing width, allowing for swift and effective removal of snow from driveways and walkways.

In addition to its strength, the machine is equipped with user-friendly controls, making it accessible for operators of varying skill levels. The intuitive interface and adjustable settings provide a tailored experience, ensuring that users can adapt the machine to different snow conditions.

Maintenance is simplified with readily accessible components, promoting longevity and sustained performance over time. The combination of thoughtful engineering and high-quality materials contributes to its reputation as a dependable choice for winter weather challenges.

Ultimately, this snow-clearing equipment stands out for its blend of power, ease of use, and durability, making it a popular option for those looking to efficiently manage snowfall in their area.

Common Issues with Ariens ST824

Snow clearing machines can encounter various challenges during operation. Understanding these common problems can help users effectively maintain their equipment and ensure optimal performance throughout the winter months.

Here are some frequent issues faced by users:

- Starting Difficulties: Many operators experience trouble getting their machine to start. This can often be attributed to fuel issues or electrical malfunctions.

- Insufficient Snow Throwing: When the snow isn’t being thrown effectively, it may indicate a clogged chute or worn paddles that need attention.

- Unusual Noises: Strange sounds during operation may signal loose components or mechanical wear that requires immediate inspection.

- Stalling: If the machine stalls frequently, it could be due to fuel flow problems or engine overload.

- Control Malfunctions: Difficulty in managing speed or direction often points to issues with the control cables or gearbox.

Addressing these problems promptly can extend the lifespan of the equipment and enhance its performance during harsh winter conditions.

Essential Tools for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right equipment can make all the difference. The appropriate tools not only facilitate the process but also ensure safety and efficiency. This guide outlines the fundamental instruments needed to tackle common issues effectively.

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening and loosening nuts and bolts. |

| Screwdriver Set | Essential for handling various screws in the machinery. |

| Pliers | Useful for gripping, twisting, and cutting wires. |

| Jack Stand | Provides stability while working under the equipment. |

| Multimeter | Helps in diagnosing electrical issues. |

| Oil Can | For lubrication of moving parts to ensure smooth operation. |

| Safety Goggles | Protects eyes from debris and potential hazards. |

Having these tools on hand can greatly enhance the ability to perform necessary tasks effectively, ensuring your equipment remains in top condition.

Step-by-Step Maintenance Guide

This guide provides a comprehensive approach to ensuring the optimal performance of your snow-clearing machine. Regular upkeep not only extends the lifespan of the equipment but also enhances its efficiency, allowing you to tackle winter challenges with ease.

Begin by inspecting the exterior for any signs of wear or damage. Check for loose screws and tighten them as necessary. Ensure that the discharge chute is clear of any debris to facilitate smooth operation.

Next, focus on the engine. Change the oil according to the manufacturer’s recommendations, typically at the end of the season or after a certain number of hours of use. Replace the oil filter to keep the engine running cleanly.

Cleaning the air filter is essential for maintaining proper airflow. Remove the filter and clean it according to the instructions, replacing it if it’s excessively dirty or damaged.

Examine the spark plug for wear and replace it if it shows signs of corrosion or if the electrode is worn down. This will ensure reliable starting and efficient fuel consumption.

Lastly, inspect the belts and cables for any fraying or signs of wear. Replace them as needed to maintain safe and effective operation. Following these steps will help you keep your equipment in prime condition, ready for whatever winter throws your way.

Engine Troubleshooting Techniques

When facing issues with an engine, identifying the root cause is essential for effective resolution. By employing systematic methods and techniques, one can diagnose problems efficiently and take appropriate action. Understanding common symptoms and their potential origins can simplify the troubleshooting process.

- Visual Inspection:

- Check for visible damage or leaks in hoses and components.

- Look for loose connections and worn-out parts.

- Listening for Unusual Noises:

- Identify any abnormal sounds that may indicate mechanical issues.

- Pay attention to changes in noise patterns during operation.

- Monitoring Performance:

- Observe the engine’s performance, noting any decrease in power or efficiency.

- Assess whether it starts easily or requires multiple attempts.

- Checking Fluids:

- Inspect oil levels and quality for signs of contamination.

- Ensure coolant levels are adequate and free of debris.

- Testing Electrical Systems:

- Examine the battery for corrosion and charge status.

- Test ignition components and wiring for continuity.

By following these techniques, one can systematically approach engine issues, ultimately leading to effective solutions and improved functionality. Understanding the symptoms and applying a methodical approach is key to successful troubleshooting.

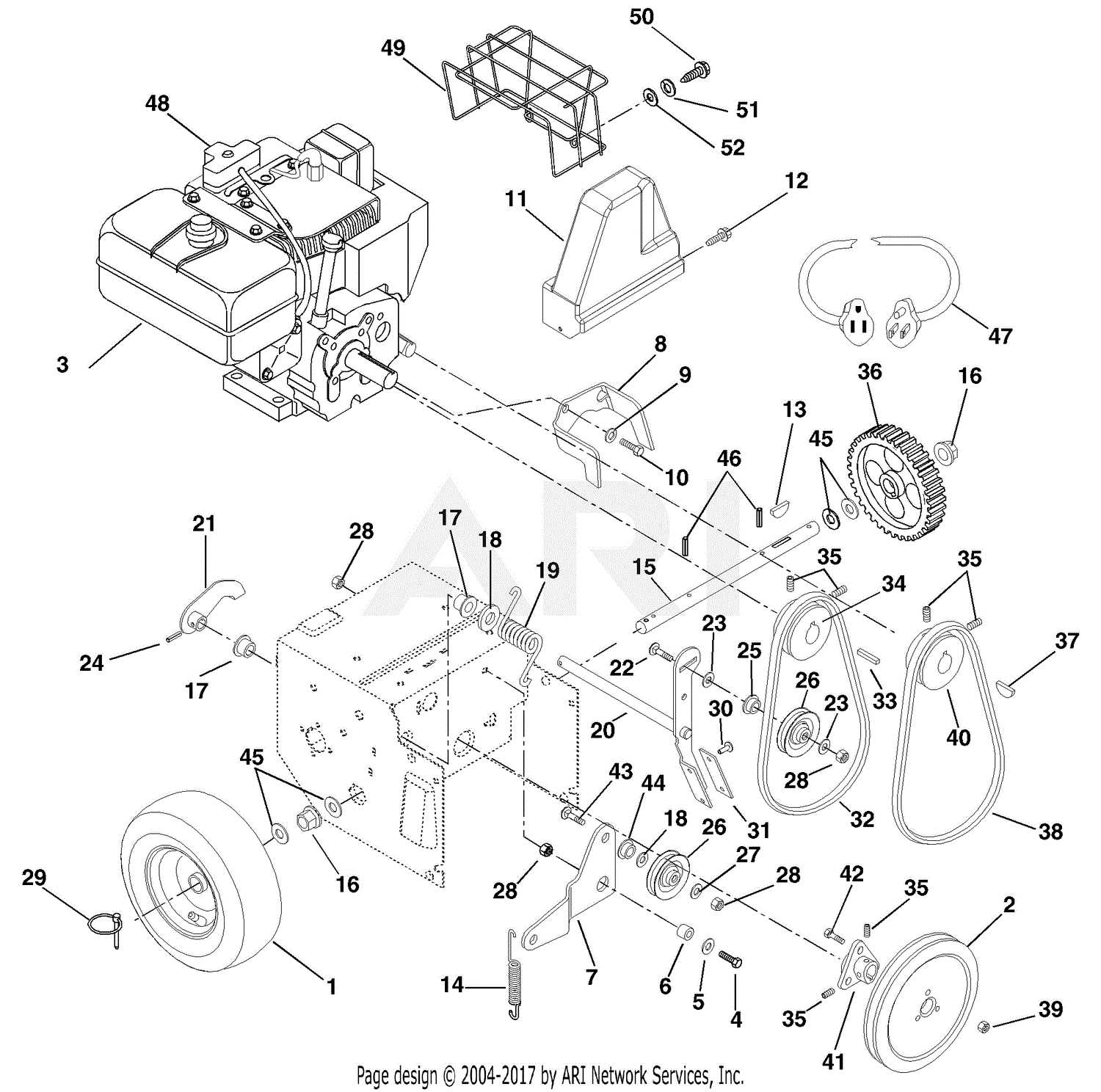

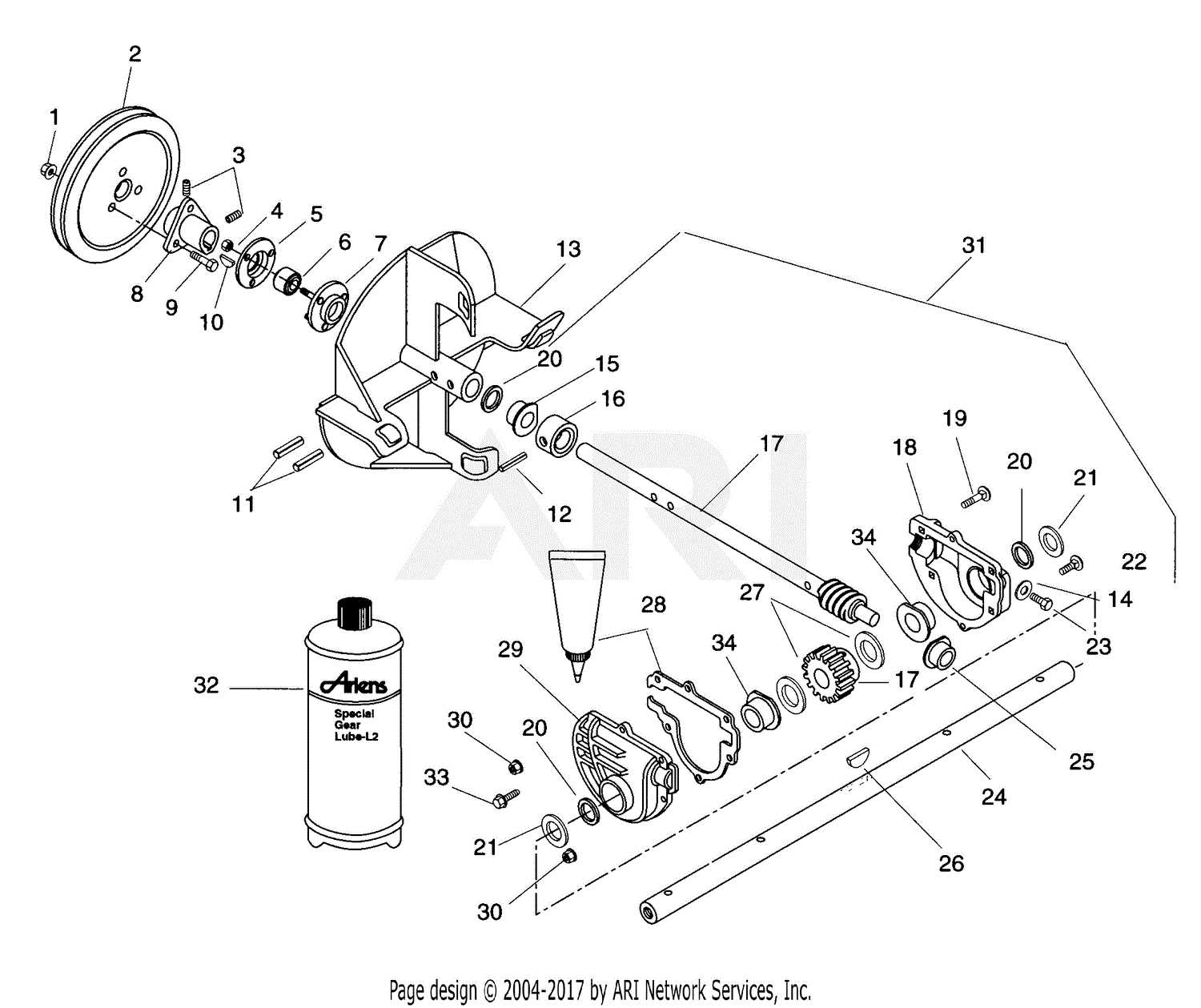

Snow Thrower Belt Replacement Process

Replacing the drive belt on a snow-clearing machine is a crucial maintenance task that ensures optimal performance during winter conditions. A worn or damaged belt can lead to decreased efficiency and potential breakdowns. This guide outlines the essential steps for a successful belt replacement, helping users restore their equipment to peak functionality.

Tools and Materials Needed

Before starting the replacement, gather the necessary tools and materials. You will need a new belt compatible with your snow thrower, basic hand tools such as wrenches and screwdrivers, and safety gloves. Having everything ready will streamline the process and enhance safety.

Step-by-Step Instructions

1. Prepare the Machine: Begin by ensuring the snow thrower is on a stable surface. Disconnect the spark plug wire to prevent accidental starting. This step is vital for your safety.

2. Remove the Belt Cover: Locate and unscrew the belt cover, which protects the internal components. Carefully set the cover aside, ensuring not to lose any screws.

3. Take Out the Old Belt: Examine the existing belt and note its routing path. Remove it from the pulleys, taking care to note how it is positioned for easier installation of the new one.

4. Install the New Belt: Position the new belt according to the notes made earlier. Ensure it sits correctly on all pulleys to avoid operational issues. Double-check the alignment.

5. Reattach the Belt Cover: Once the new belt is in place, replace the cover and secure it with screws. This protects the internal mechanisms and maintains the machine’s integrity.

6. Final Checks: Reconnect the spark plug wire. Start the machine and observe the belt in operation to ensure proper movement and function. Listen for any unusual sounds that may indicate misalignment.

By following these steps, users can efficiently replace the belt and keep their snow-clearing equipment running smoothly throughout the winter season.

How to Adjust the Skid Shoes

Proper adjustment of the skid shoes is essential for optimal performance during snow clearing operations. These components help maintain the ideal distance between the machine and the ground, ensuring efficient operation while protecting surfaces from damage. Follow these steps to effectively adjust the skid shoes for better functionality.

| Step | Description |

|---|---|

| 1 | Ensure the machine is turned off and safely positioned on a flat surface to prevent any accidents during the adjustment process. |

| 2 | Locate the skid shoes, typically found on either side of the machine’s base. Inspect them for wear and tear before making any adjustments. |

| 3 | Use a suitable wrench to loosen the bolts that secure the skid shoes in place. This will allow for easy repositioning. |

| 4 | Adjust the height of each skid shoe according to the surface conditions. For uneven or icy terrains, a lower setting may be beneficial. |

| 5 | Once adjusted, tighten the bolts securely to ensure the skid shoes remain in place during operation. |

| 6 | Perform a test run to check the effectiveness of the adjustment. Monitor how the machine interacts with the ground and make further tweaks if necessary. |

Regular maintenance and adjustment of the skid shoes contribute significantly to the longevity of your equipment and improve overall performance. Make it a habit to inspect and adjust them as needed for the best results.

Checking and Changing Oil

Regular maintenance of the lubrication system is essential for the longevity and optimal performance of any machinery. Monitoring and replacing the oil not only ensures smooth operation but also prevents damage to internal components. This section provides guidance on how to effectively check and change the oil to maintain your equipment in top condition.

How to Check Oil Levels

Begin by locating the dipstick or oil fill cap. Clean the dipstick before inserting it back into the tube to get an accurate reading. Pull it out and inspect the oil level against the marked indicators. If the level is below the recommended range, it’s time to add oil. Additionally, observe the oil’s color and consistency; dark or gritty oil may indicate the need for a complete change.

Steps to Change Oil

To change the lubricant, first, warm up the machine for a few minutes to help the oil drain out smoothly. Then, turn off the engine and place a container underneath the drain plug. Remove the plug and allow the used oil to flow completely into the container. After draining, replace the drain plug securely. Next, refill with fresh oil using a funnel, ensuring you do not exceed the maximum level. Finally, run the machine for a short period and recheck the oil level to confirm it is within the appropriate range.

Electric Start System Diagnostics

The electric start mechanism is essential for the efficient operation of many outdoor power equipment models. Properly diagnosing issues within this system can prevent unnecessary downtime and ensure smooth functionality. Understanding the components involved and common failure points is crucial for effective troubleshooting.

Common Issues and Symptoms

Several factors can lead to malfunction in the starting system. A weak battery is often the primary culprit, as it may fail to provide sufficient power to initiate the engine. Signs of battery problems include slow cranking speeds or complete failure to start. Additionally, issues with the starter motor, solenoid, or wiring can disrupt the flow of electricity, causing similar symptoms. Observing these signs early can facilitate timely repairs.

Diagnostic Steps

To accurately assess the electric start system, follow a systematic approach. Begin by checking the battery voltage using a multimeter; a reading below 12.4 volts indicates a potential problem. Next, inspect the connections for corrosion or loose wiring, as these can impede current flow. If the battery appears functional, test the starter motor and solenoid to ensure they are operational. Applying direct power to the starter can help determine if it is working correctly. Document any anomalies encountered during these checks to guide further troubleshooting.

Reconditioning the Carburetor

Revitalizing the fuel delivery system is essential for optimal engine performance. This process ensures that the air-fuel mixture is correctly regulated, promoting efficiency and longevity of the machinery. A well-maintained carburetor can significantly enhance the overall functionality of your equipment.

Before diving into the reconditioning process, it’s important to gather the necessary tools and materials:

- Screwdrivers (flathead and Phillips)

- Wrenches

- Carburetor cleaner

- Compressed air

- New gaskets and seals

- Safety gloves and goggles

Follow these steps to effectively recondition the carburetor:

- Disassembly: Carefully detach the carburetor from the engine, taking note of the position of all components.

- Inspection: Examine all parts for wear or damage. Look for signs of corrosion or blockages that could impede function.

- Cleaning: Use carburetor cleaner to eliminate dirt and residue. Pay special attention to jets and passages, ensuring they are free of obstructions.

- Blow out passages: Utilize compressed air to clear any remaining debris from small openings.

- Replace components: Install new gaskets and seals to prevent leaks and ensure a tight fit.

- Reassembly: Carefully put the carburetor back together, ensuring all parts are aligned correctly.

- Reinstallation: Attach the reconditioned carburetor back to the engine, following the original configuration.

By reconditioning the fuel delivery system, you can restore its performance and extend the lifespan of your equipment. Regular maintenance will keep your machinery running smoothly and efficiently.

Winter Preparation Tips

As the cold season approaches, ensuring that your outdoor equipment is ready for the challenges of winter is essential. Proper maintenance and preparation can enhance performance and extend the lifespan of your tools, allowing you to tackle the harsh elements with confidence.

Check and Maintain Your Equipment

Before the snow begins to fall, inspect all components of your machinery. Make sure to clean any debris, check for fuel leaks, and replace worn parts. A well-maintained device will perform at its ultimate efficiency when you need it most.

Store Properly

When not in use, store your equipment in a dry, sheltered area to protect it from moisture and rust. Consider using a cover or tarp for added protection. Keeping your tools in optimal conditions will prevent unnecessary damage and ensure they are ready for action.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance work is crucial. Adhering to specific guidelines minimizes risks and promotes a secure atmosphere for both the technician and the equipment. Understanding the importance of safety measures can lead to a more efficient and effective workflow.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection.

- Ensure the workspace is well-lit and free from clutter.

- Keep a first aid kit readily available in case of emergencies.

- Disconnect power sources before beginning any disassembly or adjustments.

- Use tools that are in good condition and appropriate for the task at hand.

Handling Hazardous Materials

- Identify any fluids or chemicals involved and handle them according to safety data sheets (SDS).

- Store hazardous materials in labeled containers away from heat sources.

- Dispose of waste materials according to local regulations to prevent environmental harm.

- Wash hands thoroughly after handling any potentially harmful substances.

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward process if you know where to look. With the right resources and strategies, you can ensure that your machinery operates efficiently without unnecessary delays. This guide will provide you with effective tips to simplify your search for replacement items.

Begin by identifying the specific parts you need. This may involve referencing your equipment’s documentation or online resources that detail specifications. Once you have this information, consider using the following methods to find what you require:

| Method | Description |

|---|---|

| Online Retailers | Explore e-commerce platforms that specialize in outdoor machinery to find a wide range of components. |

| Local Dealers | Visit authorized local distributors who can provide genuine parts and valuable advice. |

| Forums and Communities | Engage with online forums where enthusiasts share experiences and tips on sourcing parts. |

| Manufacturer’s Website | Check the official website for a parts catalog that lists compatible components. |

By utilizing these strategies, you can efficiently track down the necessary components and ensure your equipment is maintained in optimal condition.