When it comes to preserving the functionality of a cherished sewing device, understanding its intricacies is essential. This section aims to provide valuable insights into the upkeep and troubleshooting of a specific vintage model that has captured the hearts of many enthusiasts.

The following information delves into various aspects of ensuring optimal performance. From basic adjustments to common issues faced by users, mastering these techniques can enhance the longevity of your beloved machine.

Embracing a hands-on approach will empower you to tackle challenges confidently. By familiarizing yourself with the mechanisms and components, you will be better equipped to maintain its exquisite craftsmanship and reliability.

To effectively address issues with a specific sewing machine model, having the right tools is essential. Proper equipment not only simplifies the process but also ensures that adjustments and fixes are carried out correctly.

- Screwdrivers: A set of flathead and Phillips screwdrivers in various sizes is crucial for accessing different components.

- Wrenches: Adjustable wrenches or socket sets help in loosening and tightening nuts and bolts.

- Pliers: Needle-nose pliers can be particularly useful for gripping small parts.

- Lubricant: A good-quality sewing machine oil is necessary to keep moving parts functioning smoothly.

- Cleaning tools: Brushes and lint removers assist in maintaining cleanliness and preventing dust accumulation.

- Replacement parts: Keeping a stock of essential spare parts can save time during maintenance tasks.

Having these items readily available can significantly improve the efficiency and effectiveness of the maintenance process.

Step-by-Step Maintenance Guide

This section offers a comprehensive approach to ensuring the longevity and optimal performance of your sewing machine. By following these detailed instructions, you can easily maintain and enhance its functionality, ultimately resulting in a smoother sewing experience.

Essential Tools Needed

Before starting the maintenance process, gather the following tools:

| Tool | Purpose |

|---|---|

| Screwdriver | For loosening and tightening screws |

| Brush | For cleaning dust and lint |

| Oiling Can | For applying lubricant |

| Needle Set | For replacing worn needles |

Maintenance Steps

Follow these steps to keep your machine in peak condition:

- Unplug the machine and remove any attachments.

- Clean the exterior and interior parts using a soft brush to eliminate dust and lint.

- Check the needle and replace it if it’s dull or damaged.

- Apply lubricant to the moving parts according to the manufacturer’s recommendations.

- Reassemble the machine and perform a test run to ensure everything functions smoothly.

Troubleshooting Stitching Problems

When facing issues with thread formation and fabric tension, it’s essential to diagnose the underlying causes effectively. Common complications can arise from a variety of factors, including the choice of materials, settings on the device, and even environmental conditions. Understanding these aspects can help restore optimal performance.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Skipped Stitches | Incorrect needle type, dull needle, or improper threading | Replace with a suitable needle, rethread the machine correctly |

| Loose Stitches | Poor tension settings or incorrect bobbin placement | Adjust tension settings, check bobbin insertion |

| Bunching Threads | Incorrect thread type or tangled threads | Use recommended thread type, untangle and rethread |

| Uneven Stitching | Incorrect feed settings or fabric feed issues | Adjust feed settings, ensure fabric is feeding smoothly |

Lubrication Tips for Longevity

Proper maintenance of your sewing device is essential for ensuring its durability and optimal performance. Regular lubrication helps to reduce friction, prevent wear, and maintain smooth operation. Here are some valuable tips to enhance the lifespan of your machine.

Choosing the Right Lubricant

Select a lubricant specifically designed for sewing machines. These products are formulated to withstand the unique conditions of sewing, providing long-lasting protection without attracting dust and debris. Avoid using household oils, as they can lead to build-up and potential damage.

Application Techniques

When applying lubricant, focus on moving parts such as gears, levers, and needle bars. Use a few drops and avoid over-lubricating, as excess oil can create a mess and attract lint. Regularly inspect and clean these areas to ensure optimal performance.

Replacing Worn Parts Safely

Ensuring the longevity and optimal performance of your sewing machine often requires the timely replacement of worn components. By addressing these issues promptly, you can maintain efficiency and prevent further damage. Understanding the correct procedures for safely swapping out these parts is crucial for both novice and experienced users.

Before beginning the replacement process, gather all necessary tools and components. Ensure that the workspace is clean and well-lit to avoid any mishaps. Always disconnect the power source to prevent accidental activation while working on the machine.

| Part | Signs of Wear | Replacement Tips |

|---|---|---|

| Needle | Fraying fabric, skipped stitches | Replace regularly, use the correct size for your project |

| Belt | Squeaking noise, slipping | Check tension, replace if cracked or frayed |

| Bobbin Case | Uneven stitching, thread jams | Ensure proper seating, clean regularly |

After replacing the necessary components, conduct a test run to ensure everything functions smoothly. If any issues persist, reevaluate your installation process or consult additional resources for guidance.

Adjusting Tension Settings

Proper adjustment of thread tension is essential for achieving flawless stitching results. When the tension is correctly set, the upper and lower threads interlock seamlessly, preventing puckering or skipped stitches. This section provides insights into how to effectively modify the tension settings on your sewing device.

Identifying Tension Issues

Before making adjustments, it’s crucial to recognize the signs of incorrect tension. Look for the following symptoms:

- Puckering on the fabric surface

- Visible loops on the underside

- Skipped stitches or uneven seams

Making Adjustments

To achieve the desired tension, follow these steps:

- Begin by threading the machine correctly, ensuring that the thread passes through all tension discs.

- Start with the tension dial set to the manufacturer’s recommended value.

- Test the stitch on a scrap piece of fabric, observing the results.

- If issues persist, gradually adjust the tension dial in small increments, testing after each change.

- Continue until the upper and lower threads interlock neatly without any visible problems.

Regularly checking and adjusting tension settings will enhance your sewing experience and ensure professional-quality results.

Cleaning Your Featherweight Machine

Maintaining the cleanliness of your sewing device is essential for its optimal performance and longevity. Regular cleaning prevents dust and lint buildup, ensuring smooth operation and high-quality results.

Start by gathering the necessary supplies: a soft brush, lint-free cloth, and a mild cleaning solution. These tools will help you effectively remove debris without damaging any components.

Begin the cleaning process: Disconnect the machine from the power source. Use the soft brush to gently sweep away any dust and fibers from the exterior and around the needle area. Pay attention to crevices where lint may accumulate.

Next, wipe the surfaces with a damp cloth, ensuring no moisture enters the internal parts. For deeper cleaning, consult the guidelines specific to your model, as they may provide insights into accessing hard-to-reach areas.

After cleaning, reassemble any components: Make sure everything is dry and secure. Regular maintenance not only enhances functionality but also contributes to a pleasant sewing experience.

Electrical Components and Safety

This section focuses on the essential elements of electrical systems and the importance of maintaining safety during their use. Understanding these components is crucial for ensuring proper functionality and preventing hazards.

Key electrical components include:

- Wiring: Responsible for transmitting power and signals.

- Switches: Control the flow of electricity, allowing devices to be turned on or off.

- Fuses: Protect the circuit from overloads by breaking the connection when excessive current flows.

- Connectors: Facilitate secure connections between wires and components.

To ensure safety while working with electrical systems, follow these guidelines:

- Always disconnect power before performing any maintenance.

- Use insulated tools to minimize the risk of shock.

- Inspect wires regularly for damage or wear.

- Replace any faulty components immediately to prevent further issues.

By adhering to these practices, users can effectively manage electrical systems while ensuring a safe working environment.

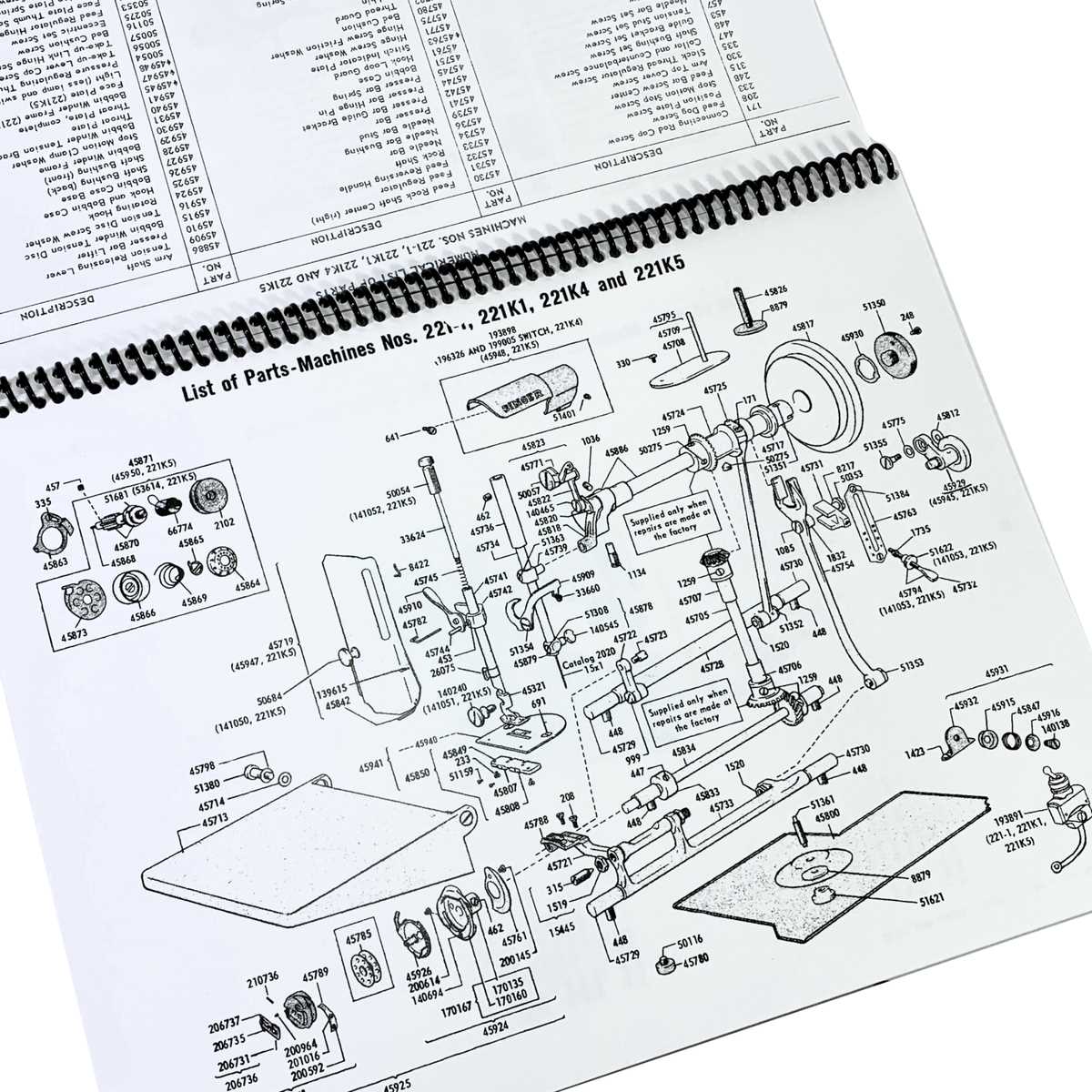

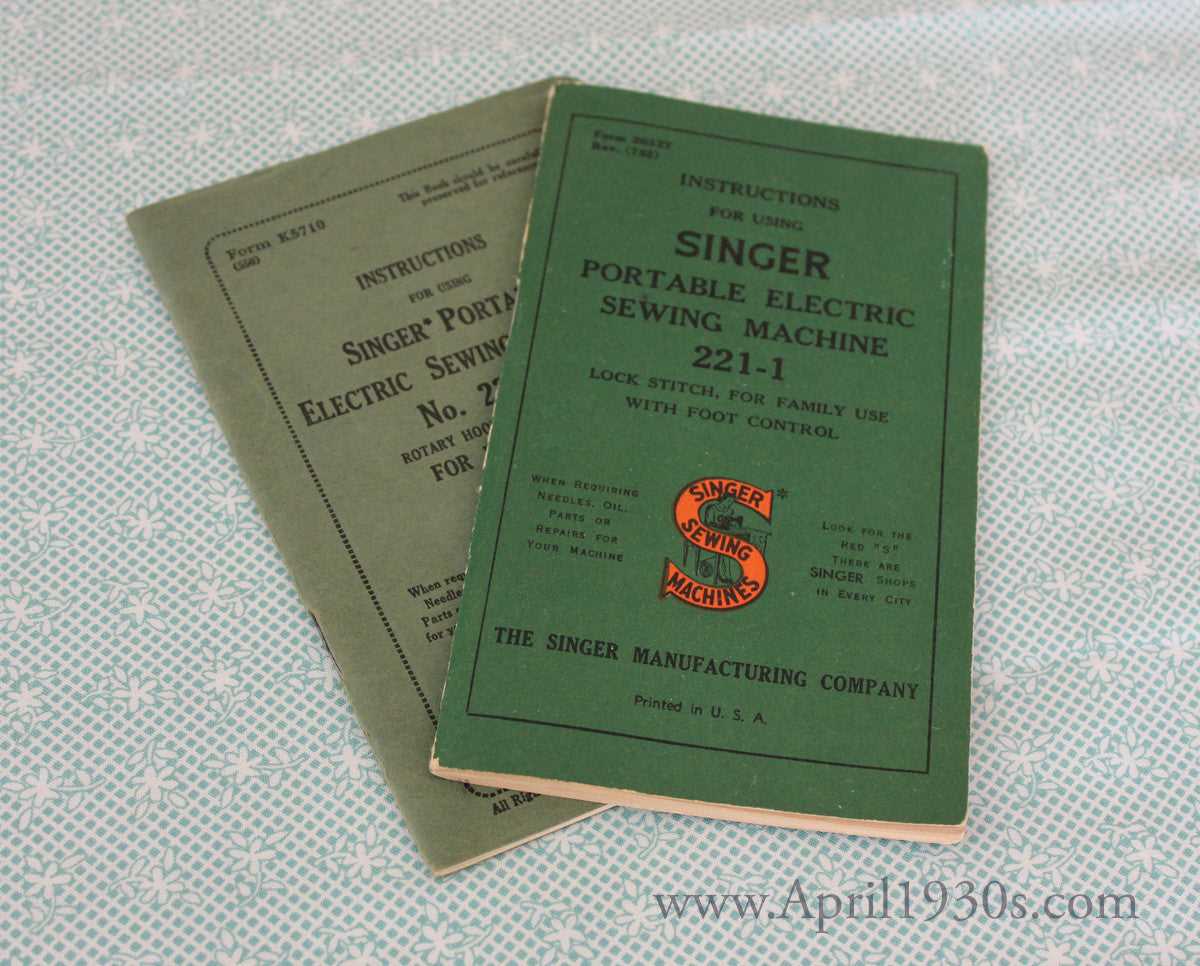

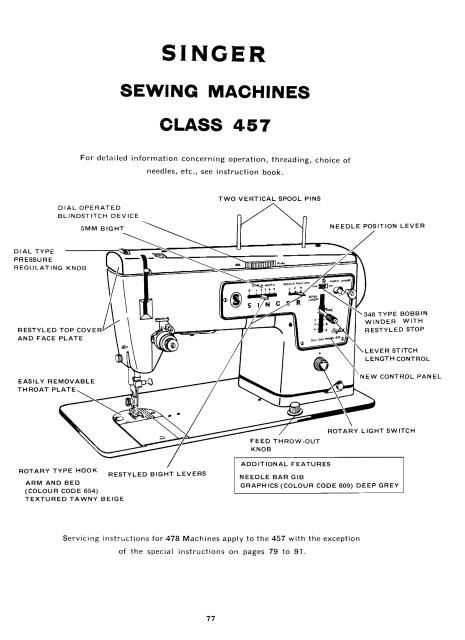

Identifying Vintage Models

Recognizing classic sewing machines requires an understanding of their distinctive features and characteristics. These machines often exhibit unique designs that reflect their era of production, making them a fascinating subject for collectors and enthusiasts alike.

To effectively identify vintage models, consider the following aspects:

- Serial Numbers: Check for the machine’s serial number, which can provide valuable information about its production date and model type.

- Design Elements: Observe the aesthetics, including the materials used, color schemes, and overall craftsmanship. Each era tends to favor different styles.

- Functional Features: Familiarize yourself with the operational components. Older machines may have manual controls, while newer variants could incorporate more automated features.

- Accessories: Note any accompanying tools or attachments, as these can also indicate the model’s vintage and functionality.

By paying attention to these details, you can better appreciate and categorize classic sewing machines in your collection.

Resources for Further Assistance

For those seeking additional support and guidance, various avenues are available to enhance your knowledge and troubleshooting skills. Utilizing these resources can greatly aid in resolving issues and improving your understanding of the subject.

Online Communities: Engaging with forums and social media groups dedicated to enthusiasts can provide valuable insights. Members often share their experiences, tips, and solutions to common challenges.

Instructional Videos: Numerous platforms offer visual tutorials that can simplify complex processes. Watching demonstrations can clarify techniques and foster greater confidence in handling your equipment.

Books and Guides: Comprehensive literature can serve as a beneficial reference. Look for titles that cover various aspects, from basic maintenance to advanced techniques, ensuring you have a well-rounded resource at your disposal.

Local Workshops: Participating in hands-on workshops or classes can enhance your practical skills. Learning from experienced individuals in a structured environment can provide direct feedback and support.