When the cold season arrives, ensuring your outdoor equipment remains functional is crucial. Proper upkeep of these machines can extend their lifespan and enhance performance, allowing you to tackle winter challenges effectively. Understanding how to troubleshoot and service your equipment is essential for any owner.

In this section, we delve into practical techniques and strategies for maintaining your winter machinery. From diagnosing common issues to executing simple fixes, our aim is to empower you with the knowledge needed to handle various situations that may arise during use. With a bit of guidance, even complex tasks can become manageable.

By familiarizing yourself with the components and operation of your equipment, you can prevent minor problems from escalating. Emphasizing routine checks and maintenance not only saves time but also ensures that your machinery operates smoothly throughout the frosty months. Let’s explore the essentials of keeping your winter gear in top shape.

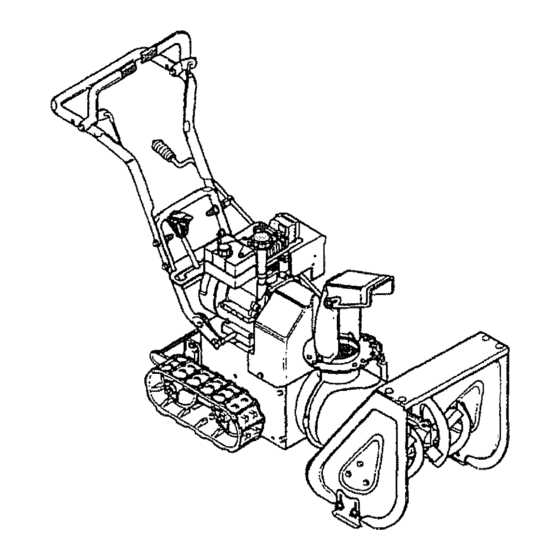

Understanding Your Craftsman Snow Thrower

Familiarizing yourself with your outdoor equipment can significantly enhance its performance and longevity. Knowing the various components and their functions allows for better maintenance and operation, ensuring efficiency during winter tasks. This section aims to provide insights into the essential features and workings of your machine, empowering you to handle it with confidence.

Firstly, it is crucial to recognize the core elements that contribute to the overall functionality. Each part, from the engine to the chute, plays a vital role in how effectively your device operates. Understanding how these components interact can help you identify any issues that may arise and facilitate timely interventions.

Additionally, being aware of the operational controls can make your experience smoother. Familiarizing yourself with the throttle, steering mechanism, and auger control can enhance maneuverability and responsiveness in various conditions. This knowledge will not only improve your efficiency but also ensure safety while in use.

Lastly, regular upkeep is key to maintaining peak performance. Knowing the maintenance schedule and the tasks required–such as oil changes, spark plug replacements, and clearing debris–will keep your equipment running reliably. Taking the time to understand these aspects will pay off in the long run, allowing you to tackle any winter challenges with ease.

Common Problems with Snow Throwers

When it comes to winter equipment, various issues can arise that affect performance and efficiency. Understanding these challenges can help owners maintain their devices and ensure they operate smoothly during the colder months. Below are some frequent complications faced by users.

1. Difficulty Starting

One of the most frustrating problems is when the equipment fails to start. This can be caused by several factors, including:

- Fuel Quality: Using old or contaminated fuel can lead to starting issues.

- Battery Problems: A weak or dead battery can prevent ignition.

- Clogged Fuel Lines: Blockages can impede the flow of necessary fluids.

2. Ineffective Clearing

Another common issue is the inability to clear snow effectively. This may be attributed to:

- Worn Blades: Dull or damaged blades can significantly reduce performance.

- Improper Settings: Incorrect adjustments can hinder the equipment’s ability to function efficiently.

- Snow Buildup: Accumulation of ice or snow can restrict movement and functionality.

Essential Tools for Repairing Snow Throwers

When it comes to maintaining and fixing winter equipment, having the right instruments is crucial for achieving optimal performance. The right set of tools not only simplifies the task at hand but also ensures that the machinery operates efficiently and lasts longer.

1. Socket Set: A comprehensive socket set is indispensable for loosening and tightening various bolts and nuts. It allows for quick access to hard-to-reach areas, making disassembly and assembly more manageable.

2. Wrenches: Both adjustable and fixed wrenches are essential for gripping and turning fasteners. They provide the leverage needed to tackle stubborn components effectively.

3. Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are necessary for handling different types of screws. Their versatility makes them a staple in any toolkit.

4. Pliers: Pliers, particularly needle-nose and slip-joint types, are useful for gripping, twisting, and cutting wires or small parts, adding flexibility to your repair tasks.

5. Torque Wrench: To ensure that components are tightened to the manufacturer’s specifications, a torque wrench is essential. This tool prevents over-tightening, which can lead to damage.

6. Multimeter: For diagnosing electrical issues, a multimeter is a must. It helps measure voltage, current, and resistance, allowing you to troubleshoot effectively.

7. Cleaning Supplies: Keeping your equipment clean is vital for longevity. Brushes, rags, and appropriate solvents should be on hand to remove debris and grime.

8. Safety Gear: Always prioritize safety by using gloves, goggles, and hearing protection when working on machinery. This gear protects you from potential hazards during the repair process.

By equipping yourself with these essential tools, you can tackle any challenges that arise while maintaining your winter machinery, ensuring reliable performance when it matters most.

Step-by-Step Maintenance Procedures

Regular upkeep of your outdoor equipment is crucial to ensure optimal performance and longevity. Following a systematic approach can help you identify potential issues early and keep your machinery in top shape. This section outlines essential practices that will guide you through the maintenance process effectively.

1. Pre-Season Check

Before the onset of the season, it is vital to conduct a thorough inspection. Start by checking the oil level and quality. Replace any old or contaminated oil to maintain engine efficiency. Additionally, inspect the fuel system for leaks or blockages. Ensure that all connections are secure, and clean or replace the fuel filter if necessary.

2. Cleaning and Inspection

After the initial check, focus on cleaning the equipment. Remove any debris or buildup from critical components. Pay special attention to the auger and housing. Use a brush or compressed air to eliminate dirt and grime. This will not only improve performance but also prevent corrosion. Once cleaned, examine belts and cables for wear and tear, replacing any damaged parts promptly.

Identifying Engine Issues in Snow Throwers

Recognizing potential problems with the power unit is crucial for maintaining optimal performance during winter operations. Various signs can indicate malfunctions, and understanding these can help prevent more severe complications. This section outlines common symptoms and diagnostic approaches to identify engine-related issues effectively.

Common Symptoms of Engine Problems

- Difficulty Starting: The machine may struggle to turn over or fail to start altogether.

- Unusual Noises: Grinding, knocking, or excessive rattling can indicate internal issues.

- Excessive Smoke: Blue or black smoke could signify oil leaks or fuel-related problems.

- Reduced Power: The unit may operate sluggishly or fail to throw material effectively.

- Vibrations: Unsteady operation may point to misalignment or worn components.

Diagnostic Steps

- Check the fuel level and quality, ensuring it meets specifications.

- Inspect the air filter for clogs or dirt that may restrict airflow.

- Examine spark plugs for wear or fouling, which can hinder ignition.

- Listen for irregular sounds while the engine is running, noting any changes in pitch or volume.

- Monitor exhaust emissions for abnormal smoke colors and intensity.

Addressing these issues promptly can extend the lifespan of the equipment and ensure reliable operation during challenging conditions.

Replacing the Auger Assembly

When it comes to ensuring optimal performance of your outdoor equipment, addressing issues with the auger component is essential. This section outlines the process of substituting the auger assembly, helping you restore functionality and efficiency to your machine.

Tools and Materials Needed

Before you begin, gather the following tools and materials: a socket wrench set, a flathead screwdriver, a replacement auger assembly, and safety gloves. Having everything on hand will streamline the process and minimize downtime.

Step-by-Step Instructions

1. Disconnect Power: Always ensure the unit is powered off and unplugged to prevent any accidents during the procedure.

2. Remove the Housing: Using the socket wrench, carefully detach the housing cover. This will give you access to the internal components.

3. Detach the Old Auger: Locate the auger assembly and unscrew any fasteners holding it in place. Gently pull it out, taking care not to damage surrounding parts.

4. Install the New Auger: Position the new auger assembly into the designated area. Secure it using the previously removed fasteners, ensuring everything is tightened appropriately.

5. Reattach the Housing: Once the new assembly is in place, reattach the housing cover and secure it with the screws.

6. Test the Equipment: Finally, plug the unit back in and perform a brief test to confirm that the new auger functions correctly.

By following these steps, you can successfully replace the auger assembly, ensuring your equipment operates smoothly for all your outdoor tasks.

Troubleshooting Electrical Components

Understanding the functionality of electrical systems is crucial for maintaining optimal performance in any machine. This section provides guidance on identifying and resolving common issues associated with electrical parts, ensuring reliable operation and longevity of your equipment.

Common Electrical Issues

- Battery failure

- Faulty wiring connections

- Defective switches

- Malfunctioning sensors

Troubleshooting Steps

- Check the battery voltage using a multimeter to ensure it is adequately charged.

- Inspect all wiring for signs of wear, corrosion, or loose connections.

- Test switches by using a continuity tester to verify their operation.

- Examine sensors for any physical damage or misalignment.

Following these steps can help pinpoint the source of electrical malfunctions and facilitate prompt repairs, ensuring the equipment operates efficiently.

Winter Preparation Tips for Snow Throwers

As the chilly season approaches, ensuring your equipment is in optimal condition is crucial for effective performance. Proper maintenance and readiness can save time and effort when dealing with harsh weather conditions. Here are some essential tips to prepare your machine for winter.

Essential Maintenance Tasks

- Check the fuel system: Use fresh fuel to prevent clogs and ensure efficient operation.

- Inspect belts and cables: Look for wear and tear, and replace any damaged components.

- Sharpen or replace the blades: Ensure cutting edges are sharp for efficient snow removal.

- Clean the machine: Remove any dirt or debris to maintain optimal airflow and performance.

Pre-Season Testing

- Start the engine: Ensure it runs smoothly and listen for any unusual noises.

- Test all controls: Make sure all levers and buttons function properly.

- Run the equipment: Perform a test run on a small area to ensure everything is working as it should.

By following these tips, you’ll ensure your equipment is ready to handle the challenges of winter, providing you with a reliable ally in clearing your path.

Cleaning and Care for Longevity

Proper maintenance is essential for ensuring the durability and efficiency of your equipment. Regular cleaning and attentive care can significantly extend its lifespan and improve performance. By following a few straightforward practices, you can keep your machine in optimal condition, ready to tackle any task.

Regular Cleaning: After each use, it is important to remove debris, dirt, and moisture from the unit. A simple rinse with water and a gentle scrub can prevent buildup that might hinder functionality. Pay special attention to hard-to-reach areas where residue tends to accumulate.

Inspecting Components: Routine inspections of parts such as belts, blades, and filters can help identify wear and tear early. Replacing worn components promptly ensures your equipment operates efficiently and reduces the risk of more significant damage.

Storage Practices: Proper storage is vital for longevity. Store the machine in a dry, sheltered area to protect it from harsh weather conditions. If possible, cover it to prevent dust accumulation and moisture exposure, which can lead to rust and other issues.

Lubrication: Regularly lubricating moving parts is crucial for smooth operation. Use the appropriate lubricant as recommended by the manufacturer, applying it to joints and pivots to reduce friction and prevent premature wear.

By implementing these simple yet effective care practices, you can enhance the performance and extend the life of your equipment, ensuring it remains a reliable tool for years to come.

How to Adjust the Skid Shoes

Properly adjusting the guiding components is essential for optimal performance and longevity of your outdoor equipment. These elements play a crucial role in controlling the height at which the machine operates, ensuring that it effectively interacts with the surface while minimizing wear. This section outlines the steps needed to achieve the ideal setting for these components.

Tools Required

Before starting the adjustment process, gather the necessary tools. Typically, you will need a socket set or wrench, a screwdriver, and possibly a measuring tool to ensure accuracy in height settings.

Adjustment Steps

Begin by locating the attachment points of the guiding components on the underside of the equipment. Loosen the bolts securing them in place, allowing for movement. Adjust the height according to your preference or the surface conditions, ensuring both sides are even for balanced operation. Once the desired height is achieved, retighten the bolts securely to prevent any shifting during use. Regularly checking and adjusting these components will enhance efficiency and prevent unnecessary damage.

Safety Guidelines for Operation

Ensuring safety during the use of outdoor equipment is paramount to prevent accidents and injuries. Proper knowledge of safety practices not only protects the operator but also preserves the integrity of the machinery and the surrounding environment. This section outlines essential precautions that should be adhered to while using such equipment.

General Safety Precautions

Before operating the equipment, it is crucial to familiarize oneself with the manufacturer’s recommendations and local regulations. Below are key guidelines to follow:

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear such as gloves, goggles, and sturdy footwear to safeguard against potential hazards. |

| Check Equipment | Inspect the machine for any damage or wear before each use. Ensure all parts are functioning properly to avoid malfunctions. |

| Clear Work Area | Remove any obstacles or debris from the operating area to prevent accidents and ensure a smooth workflow. |

| Fuel Safety | Handle fuel with care. Avoid overfilling and ensure that the engine is off before refueling. |

| Stay Alert | Maintain focus while operating. Avoid distractions and do not operate under the influence of alcohol or drugs. |

Emergency Procedures

In case of an emergency, it is vital to act swiftly and effectively. Familiarize yourself with the following procedures:

| Emergency | Action |

|---|---|

| Accidental Injury | Stop the equipment immediately and seek medical attention if necessary. Report the incident to a supervisor. |

| Equipment Malfunction | Shut down the machine and disconnect the power source. Do not attempt repairs unless qualified. |

| Fire Hazard | In the event of a fire, evacuate the area and use a fire extinguisher if trained. Call emergency services immediately. |

When to Seek Professional Help

Understanding when to call in an expert can save time and prevent further damage to your equipment. While many issues can be tackled with basic tools and knowledge, some problems require specialized skills and experience. Recognizing these situations is crucial for effective maintenance.

Consider seeking professional assistance in the following scenarios:

- Complex Mechanical Failures: If your unit is experiencing unusual noises or malfunctions that you cannot diagnose.

- Electrical Issues: When there are problems with wiring, circuits, or other electrical components.

- Severe Damage: If you notice significant wear and tear or structural damage that may compromise functionality.

- Persistent Problems: When a recurring issue continues despite your attempts to resolve it.

- Safety Concerns: If you feel unsure about the safety of operating your equipment.

In these situations, turning to a trained technician can ensure proper handling and restore your machinery to optimal performance. Investing in expert help not only resolves current issues but can also extend the life of your equipment.