In the world of construction and heavy-duty tasks, the longevity and efficiency of equipment play a pivotal role. Proper upkeep not only enhances performance but also ensures safety during operation. This section aims to provide essential insights into maintaining a specific power tool that professionals rely on for their daily challenges.

Understanding the intricacies of your device can significantly impact its lifespan. Regular checks and timely interventions can prevent minor issues from escalating into major failures. Here, we delve into key practices that will empower users to keep their tools in optimal condition, ensuring they remain reliable assets on the job site.

From troubleshooting common problems to learning effective techniques for upkeep, this guide serves as a valuable resource. Whether you are an experienced tradesperson or a newcomer to the field, the knowledge shared here will facilitate a deeper connection with your equipment, ultimately leading to improved productivity and satisfaction.

Overview of Hilti TE 72

This section provides a comprehensive look at a powerful tool designed for heavy-duty applications. Its robust construction and advanced features make it an essential choice for professionals in the construction industry.

Key features include enhanced performance capabilities, allowing for efficient operation in demanding environments. The tool is equipped with ergonomic design elements, ensuring user comfort during extended use.

With a focus on durability and reliability, this equipment is built to withstand the rigors of daily tasks. Users can expect superior results thanks to its innovative technology, which enhances productivity and minimizes downtime.

Key Features of the TE 72

The TE 72 stands out in the world of construction tools due to its advanced capabilities and robust design. This tool is engineered to enhance productivity, ensuring that users can tackle a variety of tasks with efficiency and precision.

Powerful Performance

Equipped with a high-performance motor, the TE 72 delivers exceptional power, allowing for effective operation in demanding environments. Its ability to handle various materials makes it a versatile choice for professionals.

User-Friendly Design

The ergonomic structure of the TE 72 minimizes user fatigue during prolonged use. Lightweight yet durable, it is designed to provide maximum control and comfort. Additionally, integrated safety features ensure secure operation, making it suitable for both novice and experienced users.

Common Issues and Solutions

In the realm of power tools, users often encounter a variety of challenges that can hinder performance and efficiency. Understanding these frequent problems and their corresponding solutions is essential for maintaining optimal functionality. This section highlights some common difficulties faced by operators and offers practical resolutions to enhance tool longevity and effectiveness.

Electrical Problems

One of the most prevalent issues involves electrical malfunctions, which can arise from various factors such as power supply inconsistencies or internal wiring failures. Identifying the root cause is crucial for effective troubleshooting.

| Issue | Solution |

|---|---|

| Tool does not start | Check power source, inspect cords for damage, and test the switch functionality. |

| Intermittent power loss | Examine connections and replace any worn-out components. |

Mechanical Failures

Another common category of challenges involves mechanical components, which can wear down or become obstructed over time. Regular maintenance is vital to prevent these issues from escalating.

| Issue | Solution |

|---|---|

| Unusual noises during operation | Inspect for foreign objects and lubricate moving parts as needed. |

| Reduced performance | Clean filters and check for any blockages in the tool’s mechanism. |

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues encountered with your tool. By following these systematic instructions, you can enhance its performance and prolong its lifespan. Each step is designed to be clear and concise, ensuring that you can confidently navigate the process.

Step 1: Begin by gathering all necessary tools and materials. This preparation will save you time and effort as you proceed.

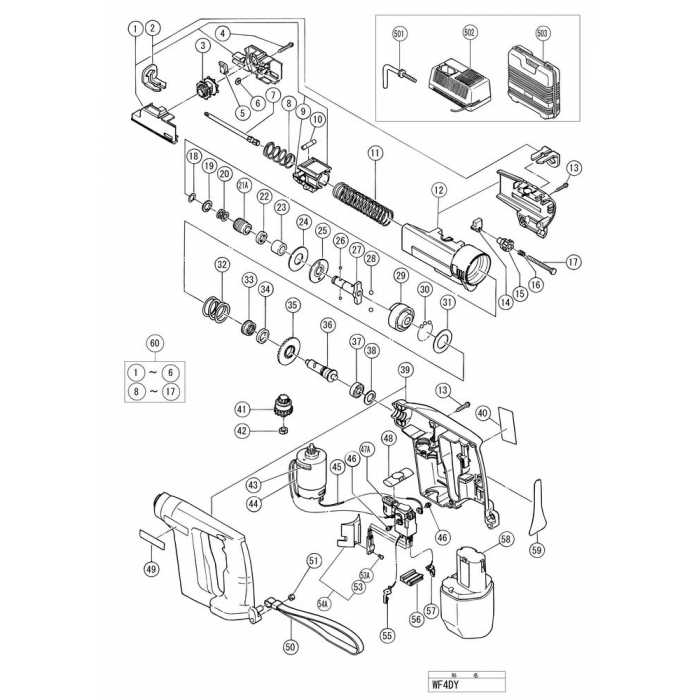

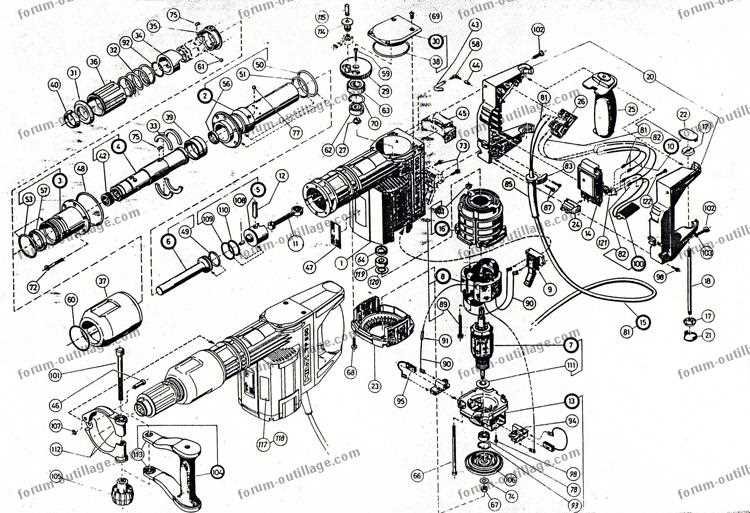

Step 2: Carefully disassemble the unit, taking note of each component’s position. Using a designated container for screws and small parts can help prevent loss.

Step 3: Inspect each piece for wear and damage. Look for cracks, corrosion, or any signs of malfunction that could impact functionality.

Step 4: Clean all components thoroughly using appropriate cleaning agents. Removing debris and residue is crucial for optimal operation.

Step 5: Replace any faulty parts with new ones, ensuring they are compatible with your specific model. Refer to the specifications if needed.

Step 6: Reassemble the unit in the reverse order of disassembly. Be cautious to secure all screws and fittings properly to maintain stability.

Step 7: Conduct a final inspection to confirm everything is in place. Testing the tool in a safe environment will ensure it operates correctly before regular use.

By adhering to these steps, you can effectively address issues and restore functionality, ensuring your equipment serves you well for years to come.

Essential Tools for Repairing TE 72

When maintaining and servicing a powerful tool like the TE 72, having the right equipment at your disposal is crucial for achieving optimal performance. A well-equipped workspace not only enhances efficiency but also ensures safety throughout the process. Below, we outline the key instruments needed to effectively address any issues that may arise.

1. Screwdrivers: A variety of screwdrivers, including Phillips and flathead, are necessary for loosening and tightening various screws within the device. Ensure that they are of high quality to prevent stripping the screws.

2. Pliers: Pliers, particularly needle-nose and slip-joint types, are invaluable for gripping, twisting, and cutting wire or other components. They offer precision and control in tight spaces.

3. Wrenches: A set of adjustable wrenches or socket sets is essential for loosening or tightening nuts and bolts. Ensure they fit snugly to avoid damaging the hardware.

4. Cleaning Tools: Brushes and cloths for removing dust and debris from the tool’s exterior and internal components help maintain its functionality and prolong its lifespan.

5. Lubricants: High-quality lubricants are important for ensuring smooth operation. Regular application can help reduce friction and wear on moving parts.

6. Multimeter: This device is crucial for diagnosing electrical issues. A multimeter allows you to test voltage, current, and resistance, aiding in the troubleshooting process.

7. Safety Gear: Don’t forget protective equipment, such as safety glasses and gloves. They are vital for ensuring your safety while working on any tool.

Equipping yourself with these essential instruments will significantly enhance your ability to maintain and enhance the performance of the TE 72, ensuring it operates smoothly for years to come.

Maintenance Tips for Longevity

Proper upkeep of your equipment is crucial for extending its lifespan and ensuring optimal performance. By following some fundamental care practices, you can significantly reduce the risk of breakdowns and enhance overall efficiency.

Regular Cleaning

Dust and debris can accumulate and cause wear over time. It is essential to regularly clean the exterior and accessible components. Use a soft brush or cloth to remove particles, and ensure that air vents are unobstructed to promote effective cooling.

Inspection and Lubrication

Routine checks for wear and tear can help identify potential issues before they escalate. Pay close attention to moving parts and apply lubricant as necessary to prevent friction and prolong functionality. A proactive approach can save time and resources in the long run.

| Maintenance Task | Frequency |

|---|---|

| Clean exterior and components | Weekly |

| Inspect for wear and tear | Monthly |

| Lubricate moving parts | Every 3 months |

| Check power cords and connections | Monthly |

Parts Replacement Process Explained

Understanding the procedure for substituting components in your equipment is essential for maintaining its performance and longevity. This process not only enhances the efficiency of your tool but also ensures safety during operation. Below, we outline the key steps involved in replacing parts effectively.

Identifying the Component

The first step involves accurately determining which part needs to be exchanged. This may require inspecting the device for any signs of wear or malfunction. Careful observation can help pinpoint the issue, ensuring that you focus on the correct area during the replacement process.

Executing the Replacement

Once the component has been identified, proceed with the removal of the old part. This typically involves loosening screws or fasteners. Utilize appropriate tools to avoid damaging surrounding areas. After the old part is detached, install the new component by following the reverse procedure, ensuring everything is securely fastened. Finally, conduct a functionality test to verify that the new part operates as intended.

Understanding the User Manual

A well-crafted guide serves as an essential resource for users, offering insights into the operation and maintenance of tools. It provides crucial information that helps individuals maximize the functionality and longevity of their equipment. Familiarizing oneself with the contents can enhance safety and efficiency during usage.

Key Sections to Explore

Effective Utilization of the Guide

Troubleshooting Electrical Problems

Electrical issues can significantly impact the performance of your tools. Identifying and addressing these concerns promptly is essential to maintain efficiency and prevent further damage. This section aims to provide guidance on diagnosing common electrical faults, enabling you to take appropriate action.

Check Power Supply: The first step in troubleshooting is to verify that the power source is functioning. Ensure the outlet is working by testing it with another device. If the outlet is faulty, you may need to consult a professional electrician.

Inspect Cords and Connectors: Examine all cables and connectors for visible signs of wear, fraying, or damage. Any compromised insulation or broken connections can lead to electrical failures. If you notice issues, replace the damaged components immediately.

Test the Switch: If the tool does not turn on, the switch may be defective. Use a multimeter to test for continuity. If there is no continuity when the switch is activated, replacement is necessary.

Examine Internal Components: If external checks do not reveal issues, consider inspecting the internal wiring and components. Loose connections, burnt-out fuses, or damaged circuit boards can lead to malfunctions. Ensure all internal parts are secure and replace any faulty components as needed.

Consult the Documentation: Always refer to the product documentation for specific troubleshooting steps tailored to your device. This can provide additional insights and help you resolve issues more effectively.

By following these steps, you can systematically address electrical problems, ensuring your equipment operates at its best. Regular maintenance and vigilance will further enhance performance and longevity.

Safety Precautions During Repairs

Ensuring a secure environment is crucial when undertaking maintenance tasks. Proper precautions not only protect individuals but also enhance the effectiveness of the work being performed. Adhering to safety protocols minimizes risks associated with tools and equipment.

Essential Safety Gear

- Wear protective eyewear to shield against debris.

- Utilize gloves to prevent hand injuries.

- Don suitable footwear to provide stability and protection.

Work Environment Considerations

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

- Keep the area organized and free from clutter to prevent accidents.

- Verify that all tools are in good condition before use.

FAQs About Hilti TE 72

This section addresses common inquiries regarding a popular tool designed for heavy-duty applications. Whether you’re a novice or an experienced user, understanding the key features and maintenance tips can enhance your experience and efficiency.

Common Questions

- What types of tasks can this tool perform?

- How can I ensure optimal performance during operation?

- What safety precautions should I take while using it?

Maintenance and Care

- How often should I clean the device?

- What is the recommended procedure for checking parts for wear?

- Where can I find replacement components if needed?

Addressing these questions can provide clarity and help users make the most of their equipment.

Where to Find Replacement Parts

Finding the right components for your tool can enhance its performance and longevity. Various options are available to locate the necessary parts, ensuring your equipment remains in optimal condition.

- Official Distributors: Check with authorized vendors that specialize in your tool brand. They often have a comprehensive inventory of parts.

- Online Retailers: Many e-commerce websites provide a wide selection of components. Ensure you verify the specifications to match your requirements.

- Local Hardware Stores: Some neighborhood shops may stock essential parts or be able to order them for you.

- Manufacturer’s Website: Visit the official site for a dedicated section on parts. It typically includes diagrams and lists of compatible items.

- Second-hand Markets: Platforms for used goods can sometimes offer good deals on parts that are still in working condition.

By exploring these avenues, you can efficiently track down the pieces you need to maintain your tool’s functionality.

Professional Repair Services Overview

In the realm of power tools and machinery, ensuring optimal performance is essential for efficiency and safety. Engaging with specialized service providers can significantly enhance the longevity and functionality of equipment. These experts offer a range of solutions tailored to address various technical issues, providing peace of mind to users who rely on these essential devices in their daily operations.

Expertise and Quality Assurance

Specialized service centers employ highly trained technicians who possess in-depth knowledge of various tool systems. Their expertise allows them to diagnose problems accurately and implement effective solutions. Utilizing state-of-the-art equipment, these professionals ensure that all tasks are completed to the highest standards. Regular maintenance and timely interventions not only prolong the life of tools but also improve their overall performance.

Comprehensive Service Offerings

Providers typically offer a wide array of services, including routine maintenance, component replacements, and troubleshooting assistance. Each service is designed to cater to specific needs, ensuring that clients receive personalized attention. By employing genuine parts and adhering to manufacturer guidelines, these professionals help maintain the integrity of the equipment, allowing users to operate with confidence.