In the world of automotive care, having a detailed resource at your fingertips can make all the difference. Whether you are a seasoned technician or a dedicated enthusiast, understanding the intricacies of vehicle upkeep is essential for ensuring longevity and optimal performance. This guide serves as a crucial tool, providing insights into the various aspects of maintenance, troubleshooting, and component replacement.

From routine inspections to more complex repairs, knowing how to navigate potential issues is vital. This resource not only outlines step-by-step procedures but also emphasizes the importance of safety and proper techniques. With this knowledge, you can confidently address challenges that arise, minimizing downtime and enhancing your driving experience.

Additionally, the guide highlights common pitfalls and offers tips to prevent them, ensuring that you are well-equipped to handle any situation. Whether it’s minor adjustments or significant repairs, a comprehensive understanding of your vehicle’s mechanics will empower you to take charge of its maintenance and care.

Toyota Dyna Overview

This section provides a comprehensive look at a popular line of light commercial vehicles known for their durability and versatility. These vehicles are often utilized in various industries, offering practical solutions for transporting goods and performing a wide range of tasks. Their design emphasizes efficiency and reliability, making them a favored choice among businesses.

The series has garnered attention for its robust performance and adaptability, featuring multiple configurations to cater to different needs. With a focus on user-friendly features and maintenance accessibility, these vehicles are engineered to ensure that operators can easily manage their upkeep.

| Model | Engine Type | Payload Capacity | Year Introduced |

|---|---|---|---|

| Standard Model | Diesel | 3,500 kg | 2002 |

| Long Wheelbase | Diesel | 4,000 kg | 2005 |

| Chassis Cab | Gasoline | 3,200 kg | 2010 |

Known for their longevity and low operational costs, these vehicles have become a staple in commercial transportation. Their reputation for reliability contributes to their enduring popularity among fleet operators and small businesses alike.

Common Issues and Solutions

In the realm of vehicle maintenance, certain challenges frequently arise that can impact performance and reliability. Understanding these common problems and their respective solutions is essential for keeping your vehicle in optimal condition.

Engine Overheating: One prevalent issue is engine overheating, often caused by coolant leaks or a malfunctioning thermostat. To address this, regularly check coolant levels and inspect hoses for wear. Replacing a faulty thermostat can also prevent this issue from recurring.

Brake System Failure: Another critical area is the braking system, where worn pads or low fluid levels can lead to diminished stopping power. It’s advisable to replace brake pads at the first signs of wear and ensure that brake fluid is topped up to maintain effective braking performance.

Electrical Problems: Electrical malfunctions can manifest as issues with lights or the ignition system. A thorough examination of the battery and wiring connections is necessary to identify loose connections or corrosion. Replacing a weak battery can also resolve many electrical concerns.

Transmission Issues: Transmission difficulties, such as slipping gears or delayed shifting, can occur due to low fluid levels or contamination. Regularly checking and replacing transmission fluid can help avoid severe damage and ensure smooth operation.

By proactively addressing these common challenges, vehicle owners can significantly enhance the longevity and functionality of their machinery.

Essential Tools for Repairs

Having the right instruments is crucial for any maintenance task. A well-equipped workspace not only enhances efficiency but also ensures safety and quality in the work performed. Below is a comprehensive list of must-have tools that facilitate various tasks and contribute to a smoother workflow.

Basic Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Hammer

- Socket set

Specialized Equipment

- Torque wrench

- Multimeter

- Oil filter wrench

- Diagnostic scanner

- Jack and jack stands

Equipping yourself with these tools will prepare you for most tasks, ensuring that you can address issues effectively and maintain peak performance.

Engine Maintenance Guidelines

Proper upkeep of your vehicle’s powertrain is crucial for optimal performance and longevity. Regular attention to various components can prevent costly repairs and enhance driving experience. Below are essential practices to ensure your engine remains in peak condition.

Routine Checks

- Monitor oil levels frequently and change the oil according to the manufacturer’s recommendations.

- Inspect coolant levels and ensure the cooling system is functioning properly.

- Check the air filter regularly, replacing it as needed to maintain efficient airflow.

- Examine belts and hoses for signs of wear or damage, replacing them if any issues are detected.

Scheduled Maintenance

- Change the spark plugs at the interval specified in the vehicle’s specifications to ensure optimal ignition.

- Flush and replace the coolant every couple of years to prevent corrosion and overheating.

- Have the fuel system cleaned periodically to remove deposits and maintain fuel efficiency.

- Perform regular inspections of the exhaust system for leaks or blockages.

By adhering to these guidelines, you can extend the life of your engine and ensure a smooth and reliable ride. Always refer to your vehicle’s specific instructions for any additional recommendations.

Transmission Troubleshooting Tips

Identifying issues within the shifting mechanism of your vehicle can be a complex task. However, by following a systematic approach, you can effectively pinpoint the root cause of the problem and determine the necessary steps for resolution. This section provides practical advice for diagnosing common transmission difficulties.

Common Symptoms and Potential Causes

Understanding the symptoms of transmission issues is crucial for effective troubleshooting. Below is a table that outlines some frequent signs and their corresponding potential causes.

| Symptom | Possible Cause |

|---|---|

| Slipping Gears | Low fluid levels or worn clutch components |

| Unusual Noises | Loose components or insufficient lubrication |

| Delayed Shifting | Faulty solenoid or clogged filter |

| Fluid Leaks | Damaged seals or gaskets |

| Warning Lights | Electronic issues or sensor malfunctions |

Step-by-Step Diagnostic Process

Once symptoms are identified, follow these steps for a thorough diagnosis:

- Check fluid levels and condition.

- Inspect for leaks under the vehicle.

- Examine the transmission filter for clogs.

- Test the electrical components for proper function.

- Consider professional assistance if issues persist.

By systematically addressing each symptom and following these diagnostic steps, you can enhance your understanding of transmission problems and work towards effective solutions.

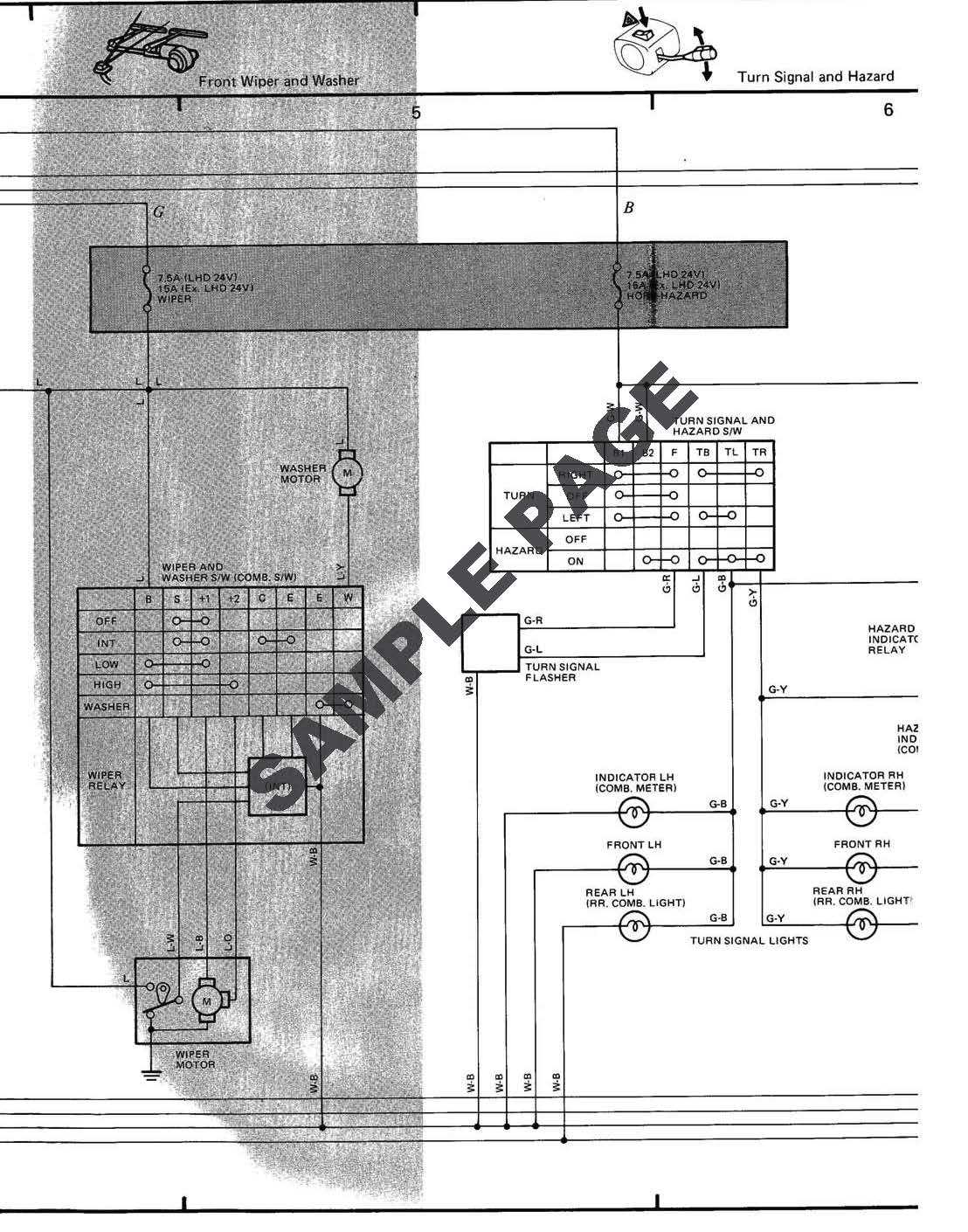

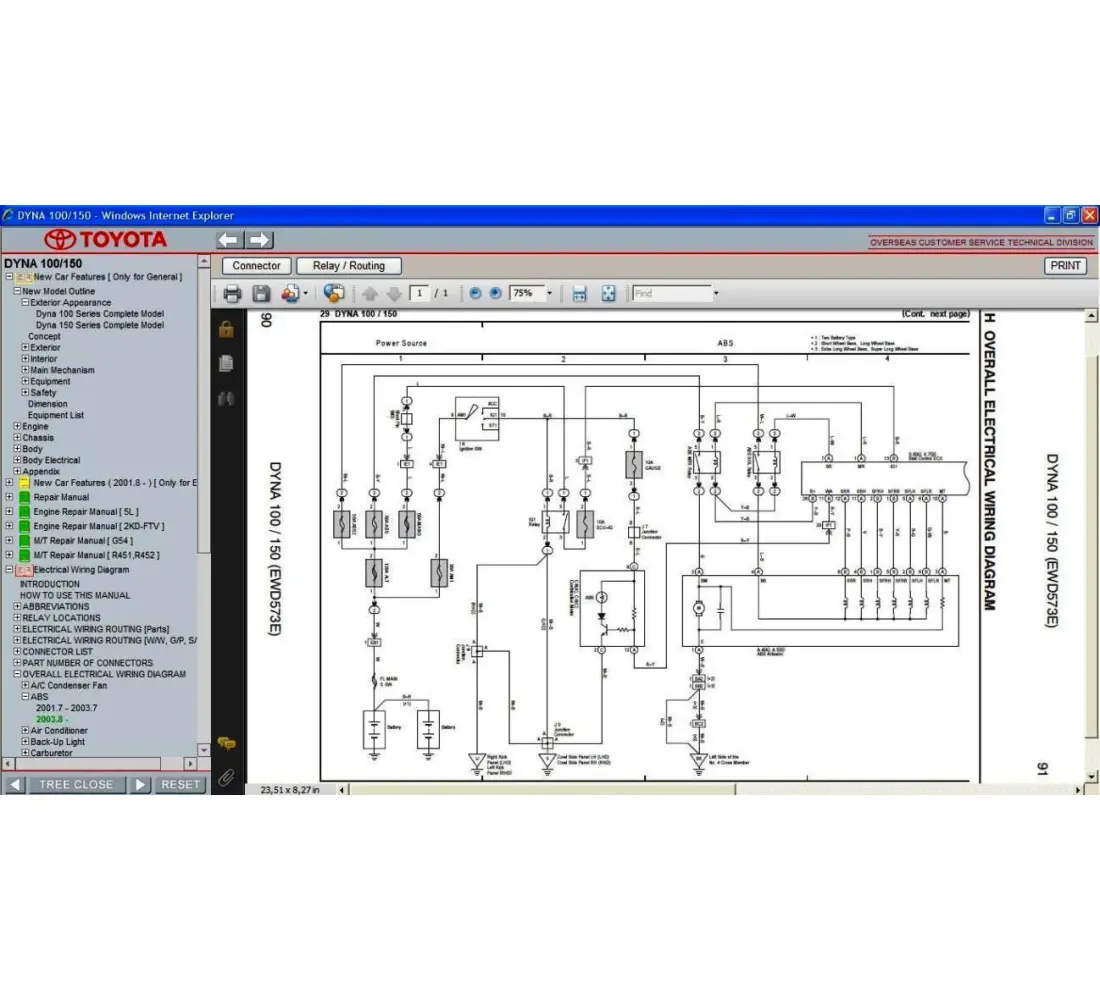

Electrical System Diagnostics

The assessment of an automotive electrical system is crucial for ensuring optimal performance and reliability. By systematically identifying and troubleshooting issues, one can enhance the overall functionality of the vehicle. This section outlines the fundamental approaches and tools necessary for effective diagnostics in the electrical framework of a vehicle.

Common Electrical Issues

Several typical problems may arise within the electrical system. Awareness of these issues is the first step toward efficient troubleshooting:

- Battery failure or insufficient charge

- Faulty wiring or loose connections

- Malfunctioning fuses

- Defective sensors or actuators

- Issues with the alternator or starter motor

Diagnostic Tools and Techniques

Utilizing the right tools and methods is essential for accurate diagnostics. Here are some recommended tools and their applications:

- Multimeter: Used to measure voltage, current, and resistance, helping to pinpoint electrical faults.

- OBD-II Scanner: A device that reads trouble codes from the vehicle’s computer, providing insights into malfunctions.

- Wiring Diagrams: Visual aids that illustrate the electrical layout, facilitating easier identification of components and connections.

- Test Lights: Simple tools for checking the presence of voltage in various circuits.

By systematically applying these techniques, one can effectively diagnose and rectify issues within the electrical system, ultimately leading to enhanced vehicle reliability and safety.

Bodywork Repair Techniques

When it comes to restoring vehicle exteriors, various methods can be employed to ensure a seamless finish and structural integrity. Understanding these approaches is essential for both amateurs and professionals looking to achieve high-quality results. The techniques vary in complexity, addressing issues such as dents, scratches, and rust damage.

Panel Beating is a fundamental technique that involves reshaping metal panels to their original form. This process requires specialized tools and a keen eye for detail, allowing the technician to remove dents and bends effectively. The skillful application of this method ensures that the surface remains smooth and even.

Painting and Finishing play crucial roles in bodywork restoration. After any structural repairs, applying the right paint type is vital for aesthetic appeal and protection against environmental factors. Techniques such as spray painting and touch-up methods are commonly used to achieve a flawless finish, blending seamlessly with the vehicle’s existing color.

Rust Treatment is another important aspect of bodywork care. Addressing rust early can prevent further deterioration. Methods include sanding down affected areas, applying rust inhibitors, and using high-quality primers and paints to seal the metal.

Lastly, Panel Replacement may be necessary for severely damaged sections. This process involves removing the compromised part and fitting a new panel, which requires precision and proper alignment to maintain the vehicle’s overall integrity. Adhering to best practices in each of these techniques ensures a durable and visually appealing outcome.

Suspension System Insights

The suspension framework of a vehicle plays a crucial role in ensuring a smooth and stable ride. This system is designed to absorb shocks from uneven surfaces, maintain tire contact with the road, and enhance overall handling. Understanding the intricacies of this system can significantly contribute to the longevity and performance of any automobile.

Key Components

The primary elements of the suspension system include springs, dampers, and control arms. Each component works synergistically to provide optimal support and comfort. Springs are responsible for absorbing energy from bumps, while dampers control the oscillation of these springs, ensuring stability. Control arms connect the wheels to the vehicle’s frame, allowing for controlled movement and alignment.

Importance of Maintenance

Regular inspection and upkeep of the suspension system are vital for safety and performance. Worn or damaged components can lead to poor handling and increased tire wear. Signs of issues may include excessive bouncing, uneven tire wear, or a noticeable decrease in ride quality. Addressing these problems promptly can prevent more extensive repairs and enhance driving comfort.

Braking System Essentials

The braking system is a crucial component in any vehicle, responsible for ensuring safe and efficient deceleration. Understanding its parts and functioning can greatly enhance maintenance and performance. This section covers the fundamentals of braking systems, their components, and the importance of regular checks.

Key Components

- Brake Pads: These friction materials press against the rotors to create stopping power.

- Rotors: Metal discs that the brake pads clamp onto to slow down or stop the vehicle.

- Calipers: The devices that house the brake pads and exert pressure on them.

- Brake Lines: Tubes that carry hydraulic fluid from the master cylinder to the brakes.

- Master Cylinder: A component that converts the force from the brake pedal into hydraulic pressure.

Importance of Maintenance

- Regular inspection of brake pads and rotors for wear and tear.

- Ensuring brake fluid levels are adequate and free from contamination.

- Listening for unusual noises during braking, which may indicate issues.

- Checking for leaks in the brake lines and connections.

- Testing the brake response periodically to ensure optimal performance.

By keeping the braking system in good condition, drivers can ensure not only their safety but also the longevity of their vehicle.

Regular Maintenance Checklists

Consistent upkeep is crucial for ensuring the longevity and optimal performance of any vehicle. A systematic approach to routine inspections can prevent minor issues from escalating into significant problems. This section outlines essential tasks that should be included in a comprehensive maintenance schedule, allowing owners to keep their vehicles in top condition.

Daily Checks

Performing daily inspections can help identify any immediate concerns. Key tasks include checking fluid levels such as oil, coolant, and brake fluid. Additionally, inspect tire pressure and condition, ensuring they are free from any damage or excessive wear. A quick visual assessment of lights and signals can also enhance safety on the road.

Weekly and Monthly Maintenance

Weekly and monthly tasks provide a more in-depth look at the vehicle’s overall health. Weekly checks might involve cleaning air filters and inspecting belts for signs of wear. Monthly, it’s advisable to rotate tires, inspect the brake system, and examine the battery for corrosion. Keeping track of these maintenance items can extend the vehicle’s lifespan and improve performance.

Finding Genuine Replacement Parts

When it comes to maintaining the longevity and performance of your vehicle, sourcing authentic components is crucial. Genuine parts ensure optimal functionality and compatibility, ultimately extending the life of your automobile.

Here are some key reasons to prioritize original components:

- Quality Assurance: Authentic parts meet strict manufacturing standards.

- Perfect Fit: Designed specifically for your model, ensuring seamless installation.

- Warranty Protection: Using genuine items often helps maintain any existing warranties.

- Enhanced Performance: Original parts work efficiently with the vehicle’s systems, improving overall performance.

To locate these authentic items, consider the following strategies:

- Authorized Dealers: Visit certified dealerships for a wide selection of genuine parts.

- Manufacturer Websites: Browse official sites for parts catalogs and ordering options.

- Reputable Online Retailers: Purchase from trusted platforms that specialize in authentic components.

- Local Auto Parts Stores: Many carry genuine parts or can order them for you.

By taking the time to find genuine components, you contribute to the durability and reliability of your vehicle, ensuring a smoother driving experience for years to come.

DIY Repair vs. Professional Help

When faced with the need to fix a vehicle, individuals often grapple with the decision of whether to tackle the task themselves or seek assistance from an expert. Both options come with their own set of advantages and challenges, influencing the final outcome and overall experience. Understanding these differences can help vehicle owners make informed choices that best suit their needs and skills.

| Aspect | DIY Approach | Professional Service |

|---|---|---|

| Cost | Generally lower, as it eliminates labor fees. | Typically higher, due to service charges and parts markup. |

| Time | Can take longer, especially for inexperienced individuals. | Usually faster, benefiting from experience and specialized tools. |

| Skill Level | Requires a certain level of knowledge and hands-on ability. | Performed by trained technicians with expertise in the field. |

| Satisfaction | Often brings a sense of accomplishment upon completion. | Provides peace of mind, knowing the job is done correctly. |

| Quality | Results may vary based on individual skill and experience. | Generally consistent and reliable, backed by warranties. |

Ultimately, the decision between self-service and hiring a professional hinges on personal circumstances, including expertise, available resources, and the complexity of the task at hand. Weighing these factors will lead to a more satisfying resolution for any vehicle-related issues.