Maintaining outdoor machinery is essential for optimal performance and longevity. Understanding how to address common issues and perform routine tasks can greatly enhance the usability and lifespan of your equipment. This section aims to provide invaluable insights into the maintenance and troubleshooting processes of your outdoor gear.

In the world of garden tools, knowing the intricacies of your machine can make a significant difference. From regular upkeep to handling unexpected challenges, having a clear understanding of operational elements will empower you to tackle any situation effectively. By exploring various techniques and solutions, you can ensure your equipment remains in peak condition.

With the right knowledge at your fingertips, you can confidently engage with your outdoor machinery. This resource will guide you through essential steps, helping you become proficient in handling your equipment with ease. Whether you’re a novice or a seasoned user, the information provided here will prove to be an indispensable asset in your maintenance endeavors.

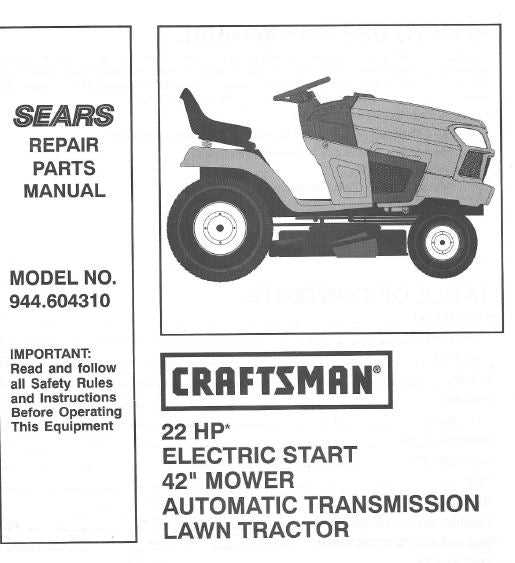

This section aims to provide insights into identifying and understanding various types of grass-cutting equipment. Knowing the specifics of your machine can enhance its performance and longevity.

Understanding your equipment model involves several key aspects:

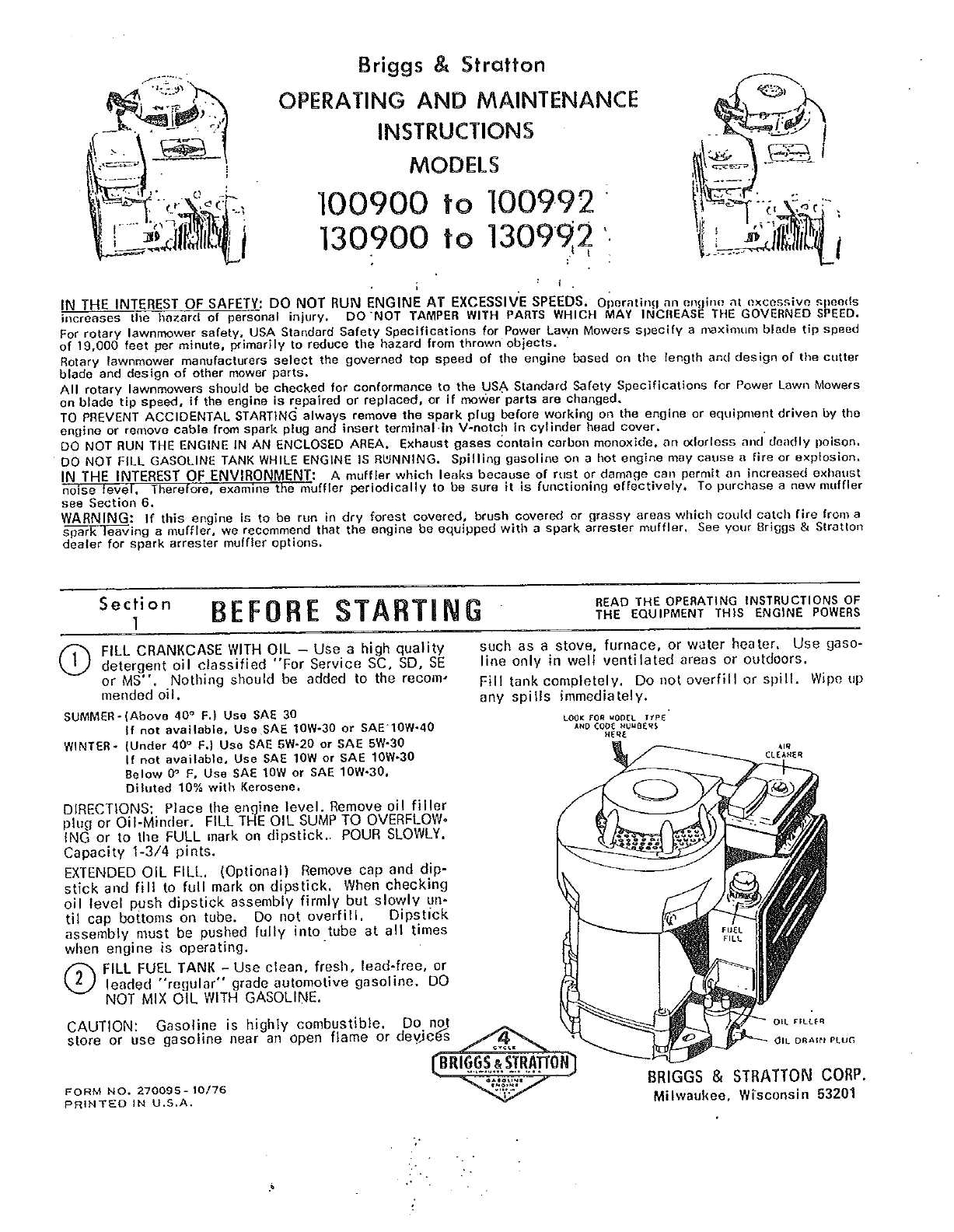

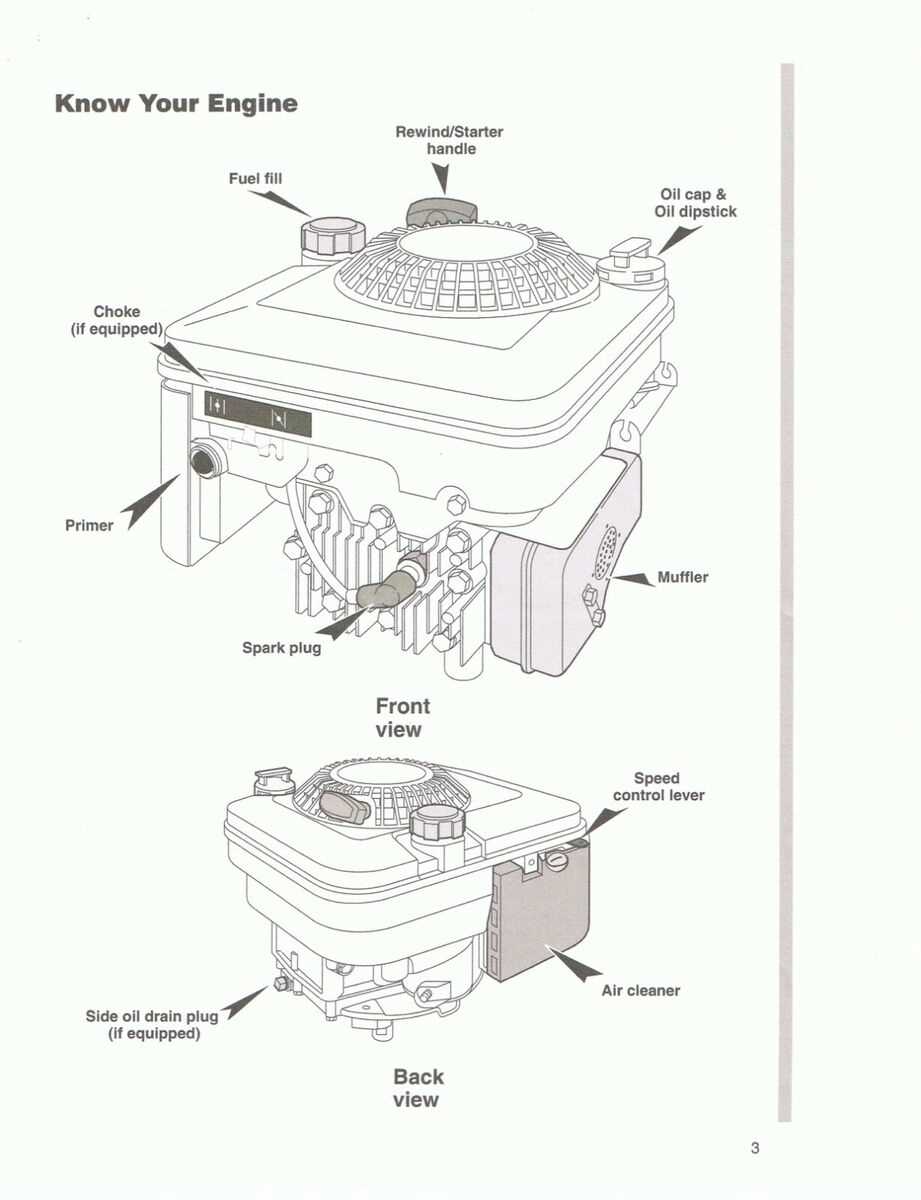

- Model Identification: Locate the model number on the machine. This can typically be found on a label or tag attached to the frame.

- Specifications Overview: Familiarize yourself with the features and specifications that define your device’s capabilities, such as engine power and cutting width.

- Usage Instructions: Review guidelines on how to operate your equipment effectively, including starting procedures and safety measures.

- Maintenance Requirements: Learn about regular upkeep tasks that can prevent issues, such as cleaning, oil changes, and blade sharpening.

By understanding these elements, users can ensure optimal operation and address any potential issues proactively.

Common Issues with Lawn Mowers

Maintaining a grass cutting machine involves understanding various complications that may arise during operation. Identifying these common problems can lead to more efficient usage and longevity of the equipment.

- Starting Difficulties: Many users encounter challenges when trying to ignite their equipment, often due to fuel issues or battery problems.

- Uneven Cutting: If the grass is not cut uniformly, it may indicate dull blades or incorrect height settings.

- Strange Noises: Unusual sounds during operation can suggest loose parts or mechanical failure.

- Vibrations: Excessive shaking may stem from unbalanced components or worn-out elements.

- Overheating: Machines that run too hot often need oil checks or air filter replacements.

By recognizing these issues early, users can take appropriate steps to ensure their equipment operates smoothly.

Tools Needed for Repairs

Having the right instruments is essential for effective maintenance of outdoor equipment. Proper tools not only facilitate the process but also ensure that each task is performed accurately and safely.

Essential Instruments

- Socket set

- Wrench set

- Screwdrivers (flathead and Phillips)

- Torque wrench

- Pliers (needle-nose and regular)

Additional Items

- Oil filter wrench

- Fuel line clamp

- Safety goggles

- Gloves

- Cleaning brushes

Gathering these tools in advance will streamline the process and help achieve optimal results. Regular checks of your toolkit will also ensure you are always prepared for any maintenance task.

Step-by-Step Maintenance Guide

This section offers a comprehensive approach to keeping your outdoor cutting equipment in optimal condition. Regular upkeep is essential for ensuring longevity and performance, allowing you to enjoy a well-groomed yard with minimal effort.

1. Gather Necessary Tools

Before starting, collect essential tools such as wrenches, screwdrivers, and cleaning supplies. Having everything on hand streamlines the process and prevents interruptions.

2. Check the Fuel System

Inspect the fuel system for any leaks or damage. Replace old fuel with fresh gasoline to ensure proper operation. If your equipment uses a filter, consider replacing it to maintain efficiency.

3. Examine the Blades

Regularly inspect the cutting blades for sharpness and wear. Sharpen or replace them as needed to achieve a clean cut. Dull blades can cause damage to grass and reduce the overall performance.

4. Clean the Exterior

Remove debris and grass clippings from the exterior components. A clean surface prevents rust and maintains the appearance of your equipment. Use a brush or cloth to wipe down surfaces, ensuring all dirt is removed.

5. Check the Air Filter

Inspect the air filter for dirt and blockages. A clean filter allows for optimal airflow, improving performance. Replace it if it appears heavily soiled.

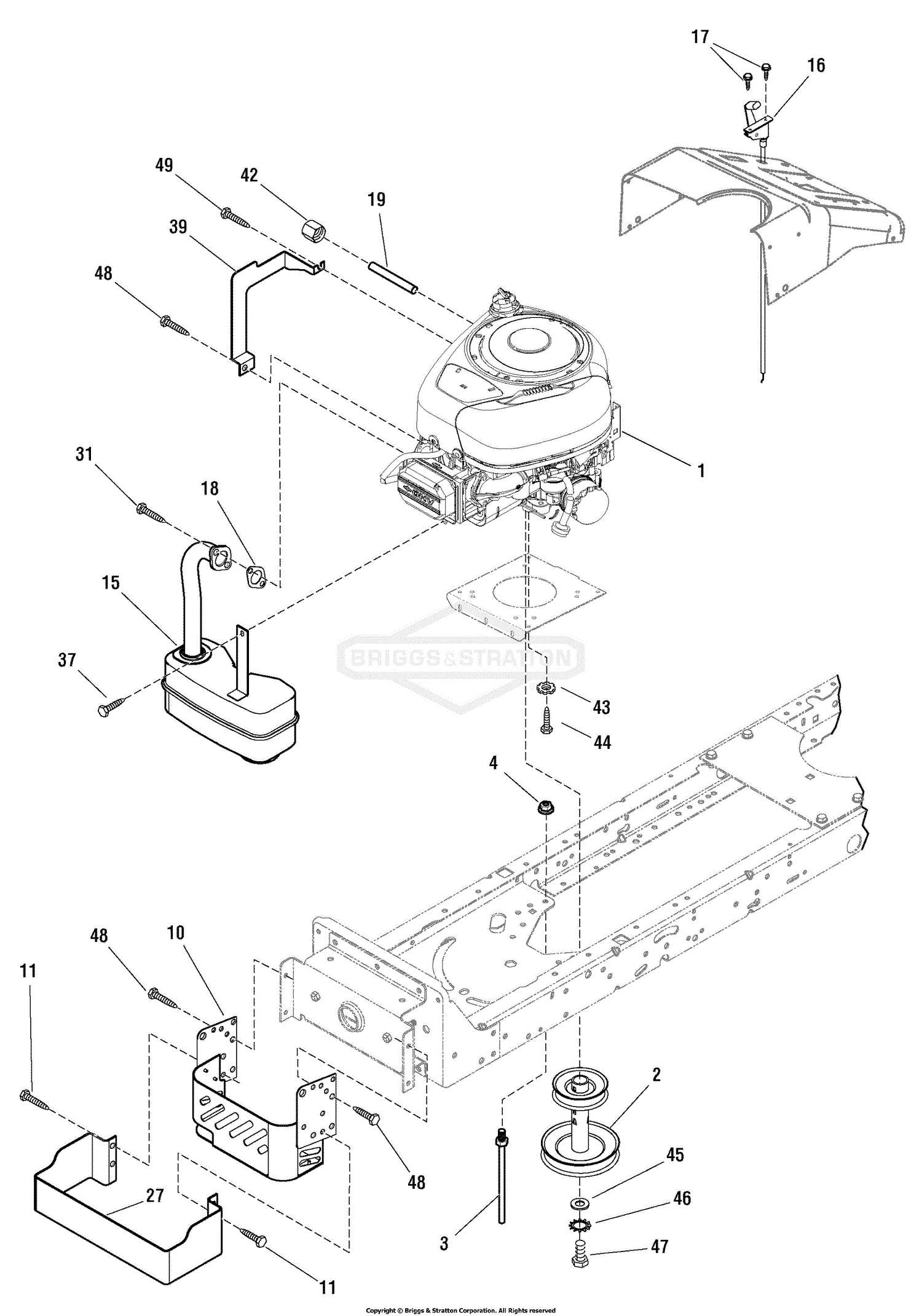

6. Inspect the Cables and Belts

Examine all cables and belts for signs of wear or damage. Properly functioning cables and belts are crucial for smooth operation. Replace any worn components to avoid potential breakdowns.

7. Perform Regular Oil Changes

Change the oil as recommended by the manufacturer. Fresh oil lubricates internal components, reducing friction and extending the life of your equipment.

8. Store Properly

After maintenance, store your equipment in a dry, sheltered area. Protecting it from the elements helps prevent rust and damage, ensuring it’s ready for the next use.

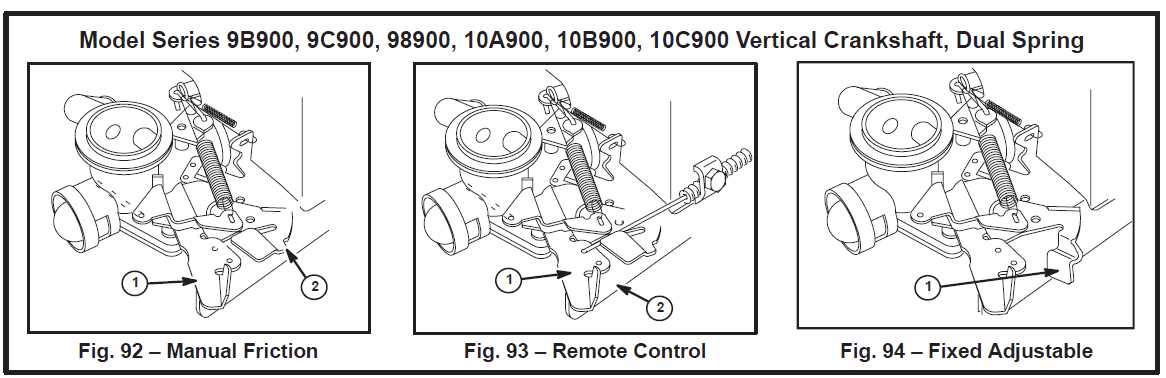

Diagnosing Engine Problems

Identifying issues with your small engine can be crucial for maintaining its efficiency and performance. Recognizing the symptoms early can save time and resources. This section outlines common problems and how to systematically approach diagnosing them.

Start by observing the engine’s behavior during operation. Common indicators of trouble include unusual noises, difficulty starting, or irregular power output. Below is a table that categorizes various symptoms and potential causes.

| Symptoms | Possible Causes |

|---|---|

| Engine won’t start | Fuel supply issue, spark plug malfunction, battery failure |

| Engine runs rough | Clogged air filter, improper fuel mixture, worn components |

| Overheating | Low oil levels, blocked cooling fins, faulty thermostat |

| Excessive smoke | Oil leak, fuel flooding, worn piston rings |

By systematically evaluating these indicators, you can pinpoint the underlying issues and take appropriate steps towards resolving them.

Replacing the Blades Safely

Maintaining sharp cutting edges is essential for optimal performance and efficiency. This process requires careful attention to ensure safety and effectiveness. Understanding the necessary precautions can make the task straightforward and secure.

Before starting the procedure, gather all required tools and materials. Always ensure the power source is disconnected to prevent accidental activation. Wearing appropriate personal protective equipment, such as gloves and safety goggles, is crucial to safeguard against injuries.

Once prepared, locate the securing mechanisms for the cutting components. Loosen these fasteners gently to avoid damaging them. It is advisable to clean the area before proceeding, as debris can interfere with both the installation and removal processes.

After removing the old edges, inspect the mounting points for wear or damage. Installing the new blades should follow the manufacturer’s guidelines, ensuring they are oriented correctly. Tighten all fasteners securely, but take care not to overtighten, as this may lead to breakage.

Finally, reconnect the power source and perform a brief test run. Monitor for any unusual vibrations or noises that may indicate improper installation. Regular checks and maintenance can significantly extend the lifespan of the equipment.

Fuel System Troubleshooting Tips

Ensuring optimal performance in any small engine requires a thorough understanding of its fuel delivery components. Common issues can often arise from a variety of sources, affecting efficiency and functionality. Addressing these concerns systematically can lead to quick resolutions and improved operation.

Identifying Fuel Flow Problems

Begin by checking the fuel supply for any blockages or restrictions. Inspect fuel lines for leaks or cracks that may hinder the flow. Additionally, ensure that the fuel filter is clean and unobstructed. Replacing a dirty filter can often restore proper fuel delivery.

Examining Fuel Quality

Stale or contaminated fuel can severely impact engine performance. Always use fresh fuel that meets the required specifications. If the fuel appears cloudy or has an unusual odor, it is advisable to drain the tank and replace it with new, high-quality fuel to prevent further complications.

Electrical System Diagnostics

Evaluating the functionality of the electrical components is essential for ensuring optimal performance. This section focuses on methods to assess and troubleshoot the system effectively, allowing for the identification of issues that may hinder operation.

Begin by inspecting the battery for any signs of damage or corrosion. A multimeter can be used to measure voltage and ensure it is within the required range. Check all connections to confirm they are secure and free from rust or dirt. If any anomalies are detected, further testing of the components may be necessary.

| Component | Test Procedure | Expected Outcome |

|---|---|---|

| Battery | Measure voltage with a multimeter | 12.6V or higher |

| Fuse | Visual inspection and continuity test | No breaks in filament |

| Starter Motor | Check for operational response when energized | Motor should engage and spin |

| Wiring Harness | Inspect for frays or shorts | All wires intact with no exposed conductors |

Following these procedures will help in diagnosing issues effectively. If problems persist, consider consulting a professional for advanced troubleshooting.

Cleaning and Care Techniques

Maintaining your outdoor equipment in optimal condition is essential for its longevity and efficiency. Regular attention to cleanliness and proper upkeep can prevent performance issues and extend the lifespan of your machinery. This section highlights effective methods to ensure your device remains in peak shape.

Regular Cleaning Practices

Keeping the exterior and components free from dirt and debris is crucial. After each use, take a moment to wipe down surfaces with a damp cloth. For stubborn grime, a gentle scrub with soapy water can be effective. Ensure to rinse thoroughly and dry the parts to avoid rusting.

Lubrication and Component Care

Periodic lubrication of moving parts is vital for smooth operation. Use a suitable lubricant on joints and pivot points to reduce friction. Additionally, inspect the air filter regularly, as a clean filter enhances performance. Replacing or cleaning it as needed can significantly impact efficiency.

Upgrading Lawn Mower Components

Enhancing the efficiency and performance of your outdoor equipment can significantly improve its longevity and functionality. By focusing on specific elements, you can achieve better results and elevate the overall user experience.

First, consider the engine. Upgrading to a more powerful version can provide improved torque and speed, making it easier to tackle tough tasks. Additionally, investing in a quality air filter can enhance airflow, contributing to better combustion and overall performance.

Next, examine the cutting system. High-quality blades not only provide a cleaner cut but also reduce strain on the engine. Opting for sharp, durable materials can ensure precision and effectiveness in the task.

Lastly, pay attention to the wheel assembly. Upgrading to larger wheels can improve maneuverability, especially on uneven terrain. Enhanced suspension components can also provide a smoother ride, making the operation more enjoyable.

Overall, strategic enhancements can lead to a more efficient and enjoyable experience with your equipment.

When to Seek Professional Help

Knowing when to enlist the expertise of a specialist can be crucial for maintaining optimal performance of your equipment. There are instances when issues arise that require more than basic troubleshooting or DIY efforts.

If you encounter persistent difficulties that hinder functionality, it may be time to consider professional assistance. Unusual noises, smoke, or leaks are signs that warrant immediate attention. Additionally, if your attempts at maintenance yield no improvement, seeking expert guidance can prevent further complications.

For complex issues involving the engine or electrical systems, professionals possess the necessary skills and tools to address these challenges effectively. Investing in expert support not only saves time but also ensures that your equipment operates safely and efficiently.