Maintaining outdoor machinery is essential for optimal performance and longevity. Whether you are a professional landscaper or a dedicated homeowner, understanding how to care for your tools can save time and money. This guide will explore essential techniques and best practices to ensure your equipment runs smoothly.

Regular upkeep not only enhances efficiency but also prevents potential issues before they arise. By familiarizing yourself with the components and functions of your device, you can address common problems effectively. This resource provides step-by-step instructions tailored for different maintenance tasks, helping you to keep your machinery in top condition.

From troubleshooting minor faults to performing more extensive servicing, having a reliable reference is invaluable. Here, you will find detailed insights into specific procedures, along with tips to streamline the maintenance process. Empower yourself with the knowledge to enhance the reliability and performance of your outdoor tools.

Overview of Husqvarna 223L

This section provides a comprehensive insight into a popular outdoor power tool designed for versatility and efficiency. Renowned for its reliable performance, this device is an essential companion for both homeowners and landscaping professionals. Its lightweight design combined with powerful features makes it suitable for various tasks, from trimming grass to tackling tougher vegetation.

Key Features

Equipped with a robust engine, this equipment delivers excellent power-to-weight ratio, ensuring ease of handling during extended use. The ergonomic design promotes comfort, reducing operator fatigue. Additionally, features such as easy start mechanisms and low vibration technology enhance user experience and safety.

Applications

This tool is ideal for a wide range of applications, including residential gardening, commercial landscaping, and maintenance of large properties. Its adaptability allows users to switch between different attachments, making it a versatile solution for tackling various outdoor tasks efficiently.

Common Issues with Trimmer

String trimmers are essential tools for maintaining a tidy lawn, but they can encounter various problems that hinder their performance. Understanding these common issues can help users troubleshoot effectively and keep their equipment running smoothly.

Starting Difficulties

One frequent problem is difficulty in starting the engine. This can stem from several factors, including fuel quality, a clogged air filter, or issues with the ignition system. Ensuring that the fuel is fresh and that the filter is clean can often resolve these issues quickly.

Line Feed Problems

Another common concern is the improper feeding of the cutting line. Users may experience tangling or snapping of the line, which can disrupt work and increase frustration. Regular maintenance, such as checking the spool and ensuring it is correctly wound, can help prevent these occurrences.

Essential Tools for Repairs

Having the right instruments is crucial for effective maintenance and troubleshooting of outdoor equipment. The correct tools not only enhance efficiency but also ensure that tasks are completed safely and accurately.

Basic Hand Tools

- Screwdrivers (flathead and Phillips)

- Wrenches (adjustable and socket)

- Pliers (needle-nose and regular)

- Allen keys

Specialized Equipment

- Torque wrench

- Fuel mixing jug

- Diagnostic tools

- Cleaning brushes

Step-by-Step Repair Instructions

This section provides a detailed approach to resolving common issues encountered with your equipment. By following the outlined procedures, you can efficiently address problems, ensuring optimal performance and longevity of the machine. Each step is designed to be straightforward, allowing even novice users to navigate the process with ease.

Preparation

Before you begin, gather the necessary tools and materials. Make sure the machine is powered off and disconnected from any power source. Wear appropriate safety gear, such as gloves and goggles, to protect yourself during the process. Organizing your workspace will help streamline the steps that follow.

Troubleshooting Steps

Start by identifying the specific issue. Is it related to the engine, the cutting mechanism, or perhaps the fuel system? Consult the equipment’s specifications to understand common malfunctions. Proceed to disassemble the relevant components carefully, keeping track of screws and parts to avoid losing them. Clean any debris from the areas of concern, as buildup can often lead to operational problems.

Once you have inspected the components, replace any damaged parts with suitable replacements. Reassemble the machine in the reverse order of disassembly, ensuring everything is securely tightened. Finally, conduct a test run to verify that the issues have been resolved. Regular maintenance will help prevent future complications.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your outdoor power equipment. By following a few straightforward practices, you can ensure that your tools operate efficiently and remain in excellent condition for years to come.

- Regular Cleaning: After each use, clean the exterior and components to prevent dirt and debris buildup. This helps avoid unnecessary wear and tear.

- Inspect Components: Frequently check parts such as the air filter, spark plug, and cutting attachment for any signs of damage or wear. Replacing worn parts promptly can prevent further issues.

- Proper Fuel Usage: Use fresh fuel and the correct fuel-to-oil ratio. Stale fuel can lead to performance problems and engine damage.

- Lubrication: Keep moving parts well-lubricated to reduce friction and prevent rust. Follow the manufacturer’s guidelines for lubrication intervals.

By adhering to these maintenance practices, you can significantly improve the reliability and durability of your equipment, ensuring that it remains ready for any task you undertake.

Identifying Spare Parts Needed

Determining the necessary components for maintenance or restoration tasks is essential for ensuring optimal performance of your equipment. Proper identification of these parts can significantly reduce downtime and enhance efficiency. This section outlines key strategies for recognizing which components may require replacement or servicing.

Assessing Wear and Damage

Start by thoroughly inspecting the unit for signs of wear, corrosion, or physical damage. Look for frayed wires, cracked casings, or any unusual sounds during operation. Regular checks can help in spotting issues early, allowing for timely replacement of affected components.

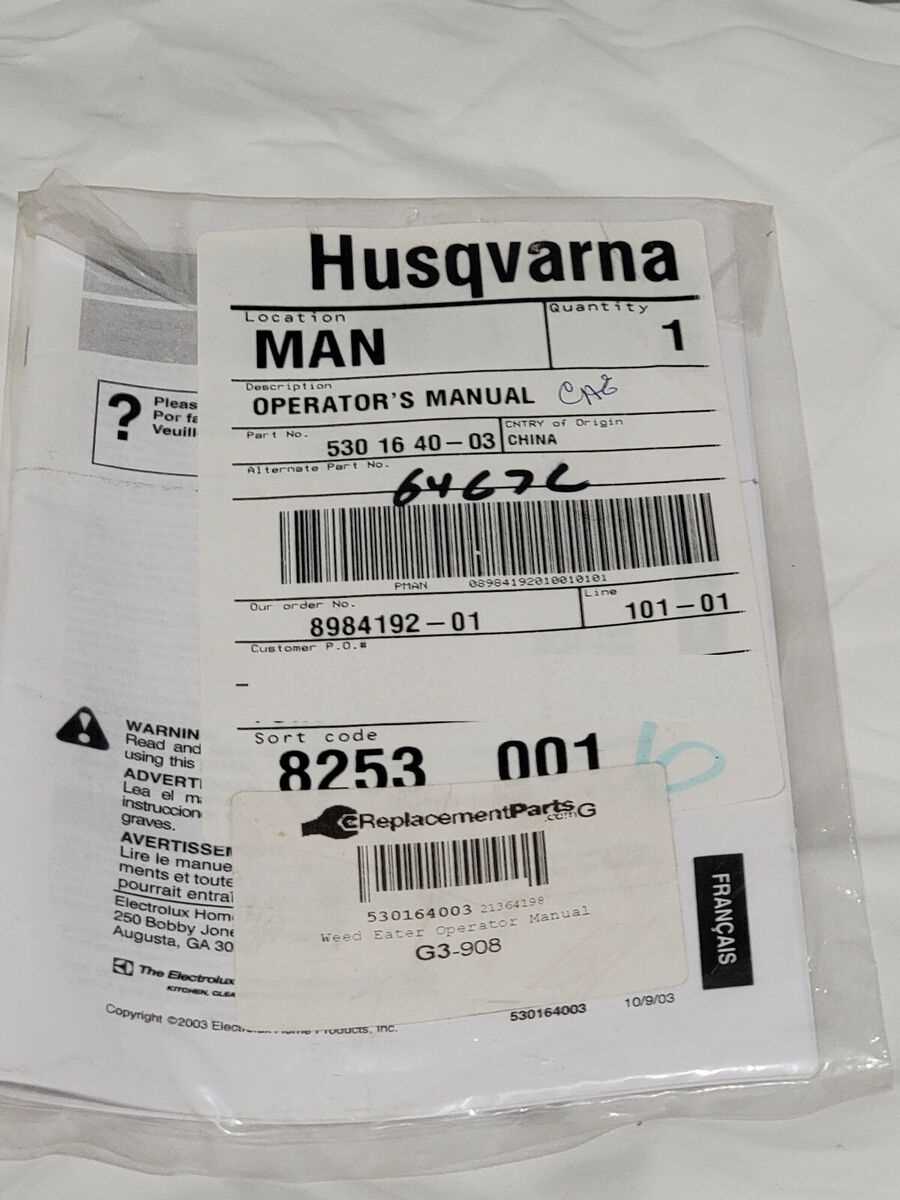

Consulting Manufacturer Documentation

Referring to official documentation or component lists can provide invaluable information regarding part specifications and compatibility. This can aid in pinpointing exact replacements and ensuring that all necessary items are acquired for a comprehensive servicing.

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of small outdoor equipment is crucial for ensuring optimal performance. Understanding the components and their interactions can aid in identifying faults, allowing for efficient resolutions.

Common Symptoms of Electrical Issues

- Equipment fails to start or respond.

- Intermittent power loss during operation.

- Unusual noises or sparks from electrical connections.

- Battery not charging or holding a charge.

Troubleshooting Steps

- Inspect Connections: Check all wiring and connectors for signs of wear, corrosion, or loose fittings.

- Test the Battery: Use a multimeter to measure voltage and ensure the battery is functioning correctly.

- Examine the Switch: Verify that the ignition or power switch is operational and not stuck or damaged.

- Check Fuses: Inspect fuses for continuity and replace any that are blown.

- Inspect Components: Examine components such as coils, relays, and sensors for signs of damage or malfunction.

Following these steps systematically can help pinpoint electrical problems and restore functionality effectively.

Engine Performance Enhancement Tips

Maximizing engine efficiency is essential for optimal performance and longevity. Implementing a few strategic adjustments can lead to noticeable improvements in power output and fuel consumption. Here are some valuable tips to enhance the overall functionality of your engine.

- Regular Maintenance: Consistent upkeep is crucial. Change the oil and air filters according to the manufacturer’s schedule to ensure smooth operation.

- Fuel Quality: Use high-quality fuel to prevent carbon buildup and ensure complete combustion, which improves efficiency.

- Proper Tuning: Regularly check and adjust the ignition timing and carburetor settings to maintain optimal performance.

Additionally, consider the following techniques:

- Upgrade Exhaust System: A performance exhaust can reduce back pressure, allowing for better airflow and improved engine efficiency.

- Install a High-Performance Air Filter: An upgraded air filter increases airflow and enhances combustion, leading to better acceleration.

- Weight Reduction: Minimizing excess weight can significantly improve acceleration and overall engine responsiveness.

By following these guidelines, you can achieve a noticeable boost in performance, making your engine more responsive and efficient in its operation.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also preserve the integrity of the equipment being serviced. By following a set of guidelines, one can create a safer environment for any hands-on activity.

Essential Safety Gear

- Gloves: Always wear appropriate gloves to protect your hands from sharp edges and hazardous materials.

- Eye Protection: Use safety goggles to shield your eyes from debris and chemical splashes.

- Footwear: Sturdy, closed-toe shoes are recommended to guard against heavy objects and slips.

- Hearing Protection: Consider earplugs or earmuffs when working with loud machinery.

Work Environment

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

- Keep the area clean and organized to minimize tripping hazards.

- Have a first-aid kit readily accessible in case of emergencies.

- Disconnect power sources before beginning any maintenance to prevent accidental starts.

Cleaning and Care Procedures

Proper maintenance is essential for the longevity and optimal performance of your outdoor equipment. Regular cleaning and care routines not only enhance functionality but also prevent premature wear and tear. This section outlines effective practices to keep your machine in top condition.

Routine Cleaning

After each use, it’s advisable to remove debris and dirt from the exterior components. Utilize a soft brush or cloth to clean surfaces, ensuring that any clippings or residue do not accumulate. Pay special attention to air intakes and cooling vents, as obstructions can lead to overheating. Additionally, periodically check and clean the filter to maintain proper airflow.

Periodic Maintenance

In addition to routine cleaning, more thorough inspections should be conducted regularly. This includes examining the cutting equipment for signs of wear and replacing any dull or damaged blades. Lubrication of moving parts is crucial to reduce friction and prevent rust. Always refer to the manufacturer’s recommendations for specific maintenance intervals and product suggestions.

Expert Advice for Beginners

Starting a new venture in maintenance and repair can be both exciting and daunting. For novices, understanding the basics is crucial for building confidence and competence. This section aims to provide essential tips that will help you navigate your initial experiences with equipment handling and upkeep.

Understand Your Equipment

Familiarity with your tools is key. Take the time to learn about the different components and how they function together. This knowledge will aid you in troubleshooting and performing routine maintenance.

- Read the user guidelines thoroughly.

- Familiarize yourself with the parts and their purposes.

- Observe how others operate similar machinery.

Safety First

Prioritizing safety cannot be overstated. Ensuring that you are equipped with the right protective gear will significantly reduce the risk of accidents.

- Always wear appropriate eyewear and gloves.

- Ensure your workspace is clean and free of hazards.

- Disconnect the power source before performing any maintenance.

By following these foundational tips, beginners can approach their tasks with greater assurance, ultimately leading to more successful outcomes in their repair efforts.

When to Seek Professional Help

Understanding when to turn to an expert can save time and prevent further damage to your equipment. Some situations demand specialized knowledge or tools that may be beyond the capabilities of a casual user.

Signs That Indicate a Need for Expertise

- Persistent operational issues despite basic troubleshooting.

- Unusual sounds or vibrations that weren’t present before.

- Visible wear or damage to critical components.

- Leaks or other fluid issues that could pose safety risks.

Benefits of Consulting a Professional

- Access to specialized tools and techniques that ensure proper repairs.

- Expert diagnosis that can pinpoint underlying problems.

- Time efficiency, allowing you to avoid prolonged downtime.

- Warranty considerations that may be affected by unauthorized repairs.