Understanding the intricacies of household appliances is essential for ensuring their longevity and optimal performance. This section provides valuable insights into the common issues encountered by users, along with effective strategies to address them. By familiarizing yourself with the essential components and their functions, you can tackle minor challenges confidently.

When appliances exhibit unusual behavior, it often indicates the need for attention. This guide aims to equip users with the knowledge necessary to identify problems and implement solutions. Whether it’s a simple malfunction or a more complex issue, having the right information can make a significant difference in the repair process.

Additionally, the importance of regular maintenance cannot be overstated. By incorporating routine checks and preventive measures, users can significantly reduce the likelihood of future complications. This proactive approach not only saves time and money but also enhances the overall efficiency of your appliances.

Understanding the Whirlpool Cabrio Model

The innovative laundry appliance in focus combines modern technology with user-friendly features, designed to enhance the washing experience. This unit stands out for its efficiency and adaptability, catering to various fabric types while ensuring optimal cleaning results.

Key Features and Benefits

One of the notable attributes of this model is its advanced wash cycles, which are tailored to meet diverse laundering needs. The inclusion of multiple settings allows users to customize their washing process, ensuring that even delicate items are treated with care. Additionally, the energy-saving capabilities contribute to reduced utility bills, making it an eco-conscious choice for households.

Maintenance Considerations

Regular upkeep is essential to prolong the lifespan of this appliance. Routine checks on components such as seals and filters can prevent potential issues and maintain performance. Understanding the operational aspects and taking preventive measures ensures that the machine continues to function efficiently over time.

Common Issues and Solutions

This section highlights frequent problems encountered with certain home appliances, along with effective strategies for resolution. Understanding these common challenges can help users maintain optimal performance and extend the lifespan of their devices.

Typical Problems

| Issue | Description | Suggested Solution |

|---|---|---|

| Unusual Noise | Devices may produce unexpected sounds during operation. | Inspect for foreign objects and ensure all components are secure. |

| Inadequate Cleaning | Some cycles fail to clean effectively. | Check the detergent dispenser and ensure proper loading. |

| Leaking Water | Water may leak from hoses or seals. | Examine all connections for wear and replace damaged parts. |

| Power Issues | The appliance may not turn on or respond. | Verify the power source and reset any tripped circuit breakers. |

Preventative Measures

Regular maintenance can help mitigate many of the issues mentioned. Ensuring cleanliness, inspecting hoses, and adhering to usage guidelines contribute significantly to appliance longevity and efficiency.

Tools Needed for Repairs

When tackling maintenance tasks on modern appliances, having the right equipment is essential. The proper tools not only streamline the process but also ensure safety and efficiency while addressing any issues. Below is a comprehensive list of instruments that will facilitate various service actions.

Essential Hand Tools

Basic hand tools are fundamental for most tasks. Items such as screwdrivers, wrenches, and pliers are crucial for disassembling components and securing parts in place. A multimeter is also invaluable for diagnosing electrical problems, allowing for accurate readings and assessments.

Specialized Equipment

In addition to standard tools, certain specialized instruments can enhance the effectiveness of the maintenance process. A socket set provides versatility for various fasteners, while a torque wrench ensures that connections are tightened to the manufacturer’s specifications. For specific issues, replacement parts may be necessary, so having a reliable source for components is advisable.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues with your appliance. Following these steps can help you pinpoint the problem and implement effective solutions, ensuring smooth operation and longevity.

Identifying Symptoms

Begin by observing any unusual behavior from the unit. Take note of specific indicators such as strange noises, failure to start, or leaks. Documenting these symptoms will assist in the next steps of the diagnostic process.

Conducting Basic Checks

After identifying the symptoms, proceed with basic checks. Ensure that the appliance is properly plugged in and that the power source is functioning. Check for any visible obstructions or issues such as damaged hoses or loose connections. These initial evaluations can often reveal simple solutions.

Cleaning and Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your appliance. Implementing effective cleaning routines not only enhances functionality but also prevents potential issues down the line. Following these suggestions can help keep your unit in excellent condition.

Routine Cleaning

Establish a consistent cleaning schedule to remove dirt and residue. Focus on key areas that accumulate grime and ensure that all components are functioning properly.

| Area | Cleaning Method | Frequency |

|---|---|---|

| Drum | Use a mild detergent and soft cloth | Monthly |

| Exterior | Wipe with a damp cloth | Weekly |

| Filters | Rinse and clean | Every 3 months |

Preventive Measures

Incorporate preventive strategies to minimize wear and tear. Ensuring proper loading and avoiding overuse can significantly extend the life of your appliance.

Replacing the Drive Belt

Replacing the drive belt is an essential maintenance task that ensures optimal performance of your appliance. Over time, the belt can wear out, leading to issues such as noise, reduced efficiency, or even malfunction. Addressing this promptly can save you from more extensive repairs down the line.

Tools and Materials Needed

Before starting the replacement process, gather the following tools and materials:

| Item | Purpose |

|---|---|

| Screwdriver | To remove access panels |

| Wrench set | For loosening and tightening bolts |

| Replacement drive belt | To replace the old, worn belt |

| Lubricant | To ensure smooth operation |

Step-by-Step Procedure

Follow these steps to successfully replace the drive belt:

- Disconnect the appliance from the power source to ensure safety.

- Remove the necessary access panels using a screwdriver.

- Locate the existing drive belt and assess its condition.

- Carefully detach the old belt from the pulleys.

- Install the new drive belt, ensuring it is properly aligned on the pulleys.

- Reassemble any panels that were removed.

- Reconnect the power and test the appliance to ensure it operates smoothly.

Dealing with Error Codes

When a home appliance displays error notifications, it can be frustrating for users. Understanding these indicators is essential for efficient troubleshooting and restoring normal functionality. Each code typically corresponds to a specific issue, guiding users towards the appropriate solutions.

Common Error Codes

- Code F1: Indicates a problem with the control board.

- Code E2: Suggests a malfunction in the temperature sensor.

- Code E3: Points to drainage issues within the system.

- Code F5: Signals a door lock malfunction.

Troubleshooting Steps

- Consult the appliance’s documentation to identify the meaning of the code.

- Perform basic checks, such as ensuring power supply and verifying door closure.

- If applicable, reset the machine by unplugging it for a few minutes.

- Inspect relevant components, such as sensors or hoses, for any visible damage.

- If the issue persists, consider contacting a professional technician for further assistance.

Inspecting Electrical Components

Evaluating the functionality of electrical parts is crucial for maintaining proper operation in appliances. This process ensures that all elements are performing optimally, preventing potential issues that could arise from faulty connections or damaged components.

Common Components to Inspect

During the inspection, focus on several key elements that typically require attention. These include connectors, fuses, and wiring. Each of these components plays a significant role in the overall performance and reliability of the system.

| Component | Function | Inspection Tips |

|---|---|---|

| Connectors | Facilitate electrical connections between parts | Check for corrosion or loose connections |

| Fuses | Protect circuits from overload | Test continuity; replace if blown |

| Wiring | Transmit electrical current | Look for frays or breaks in insulation |

Safety Precautions

Always ensure safety before conducting any inspections. Disconnect power sources and use appropriate personal protective equipment. By adhering to these guidelines, you can prevent accidents and work more effectively.

Water Drainage Problems Explained

Effective removal of water is crucial for the proper functioning of any washing appliance. Issues related to drainage can lead to a variety of complications, including extended cycle times, unpleasant odors, and potential damage to the unit. Understanding the common causes of these challenges can assist users in troubleshooting and resolving the situation efficiently.

One frequent cause of drainage issues is a blocked or kinked hose. Over time, debris can accumulate within the hose, obstructing the flow of water. It is essential to inspect the hose regularly for any signs of wear or blockage. Additionally, the positioning of the hose should be checked to ensure it is not bent or twisted, which can impede drainage.

Another factor to consider is the pump’s functionality. If the pump is malfunctioning or has become clogged with lint or other materials, it may fail to expel water effectively. Listening for unusual noises during the drainage cycle can help identify pump-related issues. Routine maintenance, such as cleaning the filter, can prevent these problems from arising.

Finally, issues with the drainage system within the home can also impact the appliance. A backed-up sink or drain can create a situation where the water cannot exit the machine properly. Ensuring that the home’s plumbing system is functioning correctly is an essential step in addressing drainage concerns.

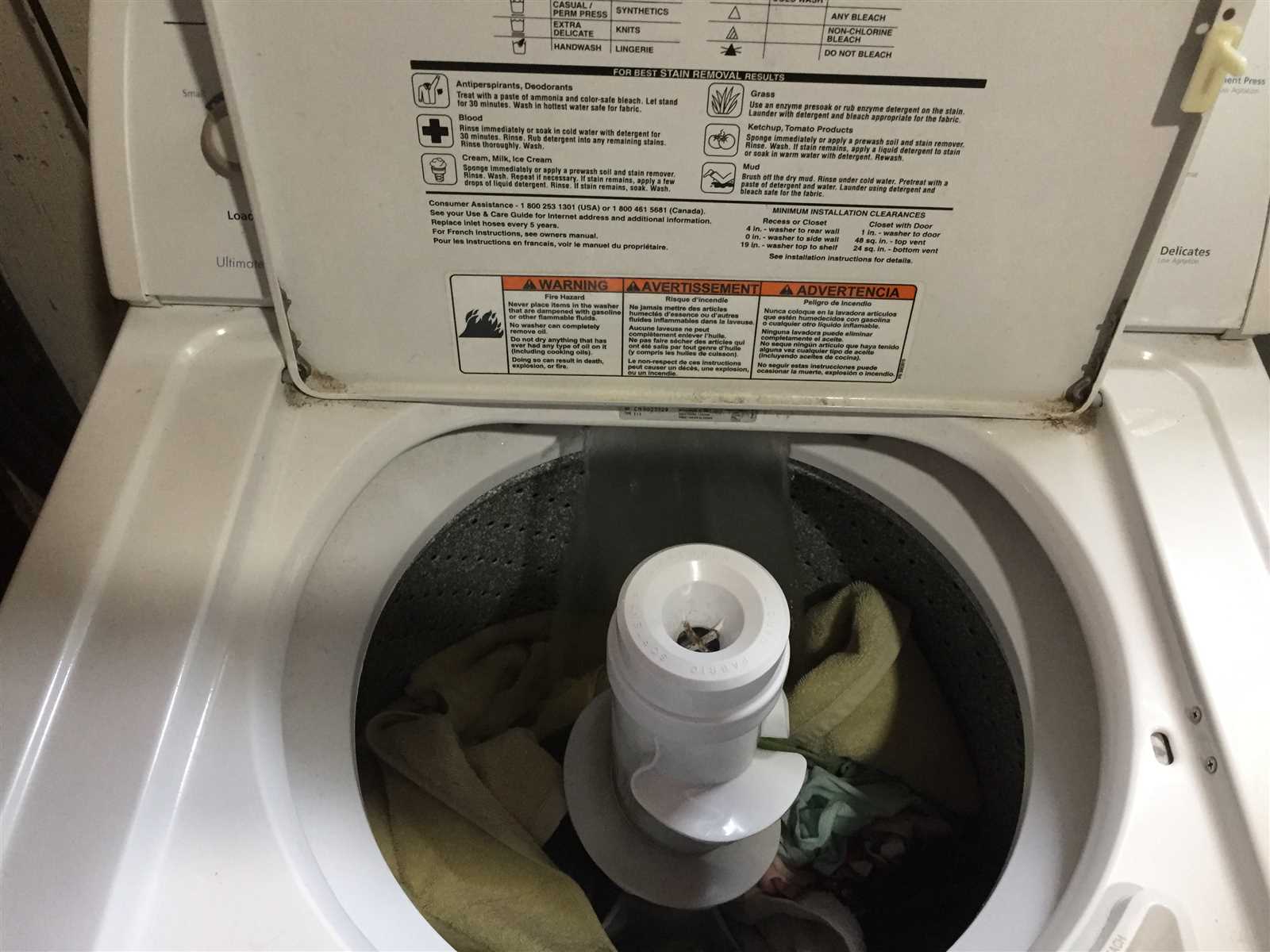

Replacing the Lid Switch

When a laundry appliance fails to operate properly, one common issue could be the malfunction of a specific component responsible for activating the cycle. Replacing this part can restore functionality and ensure that the device runs efficiently. This guide outlines the necessary steps to carry out the replacement process safely and effectively.

Tools and Materials Needed

Before starting the replacement, gather the following tools and materials:

- Screwdriver – for removing screws securing the panel.

- Replacement Switch – ensure compatibility with your model.

- Wire Strippers – for handling electrical connections.

Steps for Replacement

Begin by unplugging the appliance to ensure safety. Next, access the component by removing the top panel, typically secured with screws at the back. Once the panel is off, locate the switch, which is usually positioned near the lid hinge. Disconnect the wires attached to the old switch, noting their arrangement for reconnection.

Install the new switch by connecting the wires as per your notes. Ensure all connections are secure, and then replace the top panel by reversing the initial steps. Finally, plug the appliance back in and test its functionality to confirm that the issue has been resolved.

Maintaining Optimal Performance

Ensuring that your appliance operates efficiently requires regular attention and proper care. By following a few essential practices, you can enhance its functionality and prolong its lifespan. These simple yet effective maintenance strategies will help you achieve the best results.

- Regular Cleaning: Keep the exterior and interior surfaces free of dust and debris. Use appropriate cleaning agents to avoid damage.

- Check Hoses and Connections: Inspect all hoses and connections for signs of wear or leaks. Replace any damaged components promptly.

- Monitor Settings: Ensure that all settings are configured correctly based on the type of load. Adjust as necessary for optimal results.

In addition to these practices, it’s essential to periodically assess the overall condition of your unit. If you notice any unusual noises or performance issues, it may indicate a need for further examination.

- Inspect Filters: Clean or replace filters regularly to maintain proper airflow and efficiency.

- Perform Calibration: Periodically check the calibration of settings to ensure accurate performance.

- Schedule Professional Maintenance: Consider having a technician conduct routine inspections and repairs as needed.

By implementing these strategies, you can maintain peak performance and enjoy a reliable and efficient appliance for years to come.

Safety Precautions During Repair

Ensuring safety during maintenance activities is essential to protect both the individual performing the tasks and the equipment involved. Adhering to safety measures minimizes risks and enhances efficiency while handling various components.

Here are key guidelines to consider:

- Disconnect Power: Always unplug the appliance or turn off the power supply before starting any work to prevent electrical shocks.

- Use Personal Protective Equipment (PPE): Wear appropriate gear, such as gloves and safety glasses, to safeguard against injuries.

- Work in a Well-Lit Area: Ensure that the workspace is adequately illuminated to see clearly and avoid accidents.

- Follow Manufacturer Instructions: Refer to documentation for specific guidelines and precautions related to the equipment.

- Keep Tools Organized: Store tools in a designated area to prevent tripping hazards and ensure quick access when needed.

By prioritizing these precautions, individuals can effectively reduce the likelihood of accidents and ensure a safer working environment while conducting maintenance tasks.

When to Call a Professional

Understanding when to seek expert assistance can significantly enhance the longevity and performance of your appliance. While many issues can be resolved through basic troubleshooting and DIY efforts, some situations warrant the expertise of a trained technician.

Signs of Major Malfunctions

If you notice unusual noises, persistent leaks, or failure to operate, these may indicate serious underlying problems. Attempting to fix these issues without proper knowledge can lead to further damage, resulting in more costly repairs. In such cases, contacting a specialist is advisable to prevent exacerbating the situation.

Lack of Knowledge or Tools

When you find yourself facing a complex issue that requires specialized tools or knowledge beyond your capabilities, it’s wise to reach out for professional help. Trying to tackle advanced repairs without the right equipment can not only be ineffective but also hazardous. Relying on an expert ensures that the problem is addressed safely and effectively.