Outdoor equipment is an essential tool for those who care for green spaces, from large fields to modest gardens. Knowing how to maintain and troubleshoot these machines ensures they continue to function effectively for years. This guide focuses on helping users understand key upkeep techniques, empowering them to handle common performance issues and prevent unexpected breakdowns.

Each section of this guide covers vital aspects of maintenance, from routine care to more complex adjustments and replacements. By understanding the mechanisms and upkeep needs, users can ensure the longevity of their equipment while saving on repair costs. Essential insights into the system’s structure and parts make it easier to identify wear and tear before it affects performance.

Whether it’s regular seasonal maintenance or addressing specific operational issues, this guide serves as a reliable resource for efficient, cost-effective solutions. With this comprehensive approach, users can enhance their expertise,

Poulan Pro Lawn Mower Repair Manual

This guide provides essential steps for maintaining and servicing your grass-cutting equipment, ensuring its smooth operation and longevity. With regular care, your machine can tackle various yard tasks more efficiently and with fewer interruptions.

Common Maintenance Tasks

- Blade Sharpening: Dull blades reduce cutting effectiveness and stress the machine. Regular sharpening ensures cleaner cuts and reduces wear on the motor.

- Oil Change: Periodic oil changes prevent engine wear and improve performance. Refer to your model’s specifications to choose the right type and frequency of replacement.

- Air Filter Cleaning: A clogged filter decreases airflow, causing overheating and reduced power. Clean or replace the filter as per usage to keep the engine breathing freely.

Step-by-Step Troubleshooting

- Inspect the

Understanding the Basics of Poulan Pro Mowers

To effectively maintain and utilize outdoor power tools, it is essential to understand their primary components, operational principles, and unique features. This knowledge can empower users to achieve greater efficiency and longevity from their equipment while minimizing potential issues.

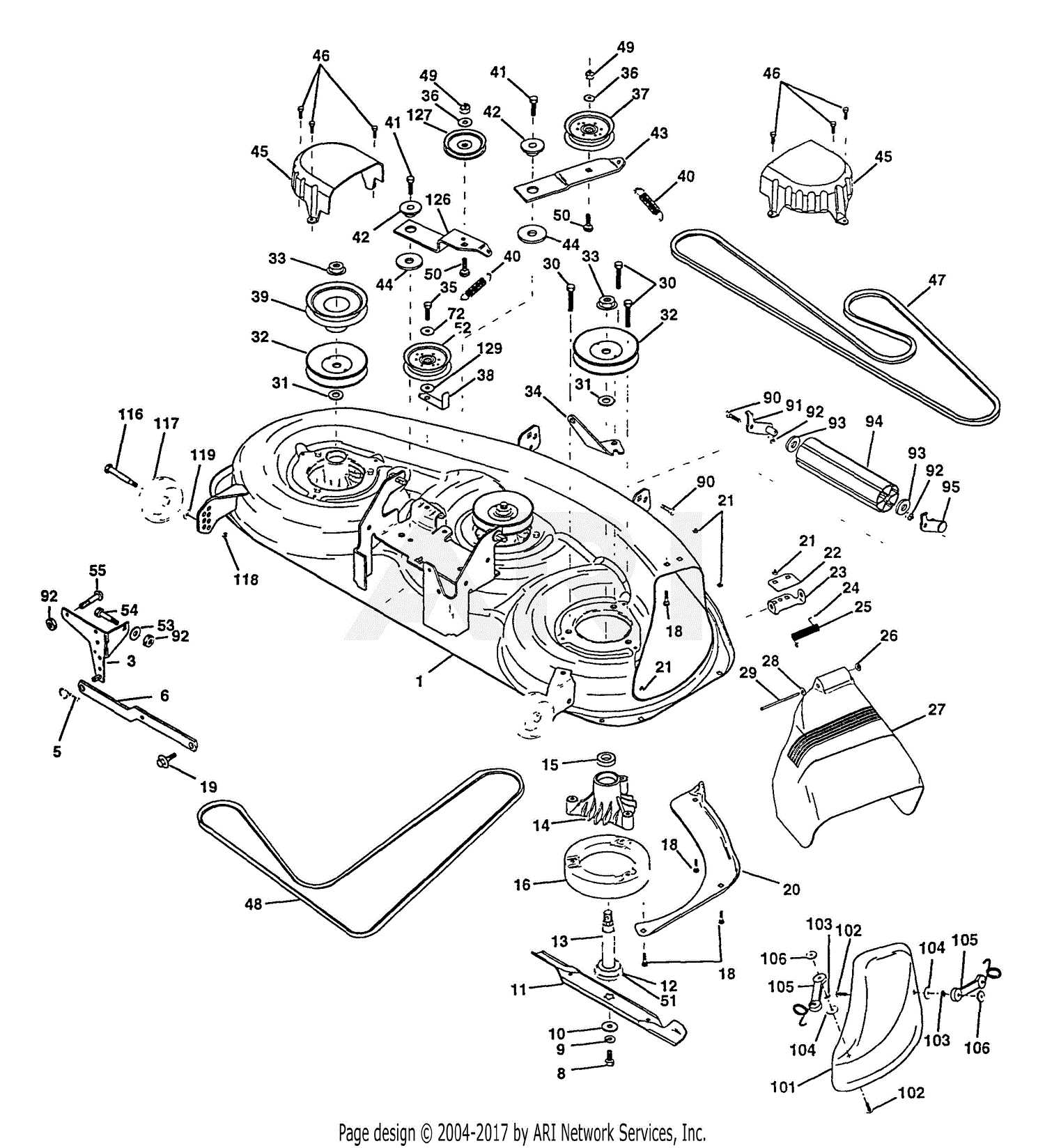

Key Components and Their Functions

Outdoor power tools are built with various parts that work together to provide optimal performance. Below is a breakdown of the main elements found in these machines:

- Engine: Provides the power needed for the cutting mechanism. Available in different power ratings for diverse tasks.

- Deck: The structure that houses the blade, designed to protect the user and direct grass clippings.

- Wheels: Varying sizes and materials impact maneuverability across different terrains.

- Essential Tools for Lawn Mower Repairs

Working on outdoor power equipment requires a selection of key tools to ensure safe, efficient maintenance and repairs. Having the right tools on hand will not only streamline the process but also improve the performance and lifespan of your equipment.

Tool Purpose Socket Set Essential for loosening and tightening various bolts and nuts, particularly on engine parts and handles. Wrenches Used for handling fasteners that hold the machine’s components together, such as wheels and blade attachments. Screwdrivers Flathead and Phillips screwdrivers are essential for tasks like removing screws on housing or adjusting carburetors. Diagnosing Common Mower Issues

Understanding how to identify and resolve frequent problems with outdoor equipment is essential for smooth operation and longevity. Many issues arise from regular use or environmental factors, and early detection can prevent larger repairs down the line. Here we explore effective methods to diagnose typical equipment issues, guiding you through key signs and practical troubleshooting steps.

Starting Problems

If the machine is difficult to start or doesn’t start at all, the cause might be related to fuel or ignition. Begin by checking the fuel quality–old or contaminated fuel can affect performance. Additionally, inspect the spark plug for wear, dirt, or damage, as this component is crucial for ignition. Replacing or cleaning the spark plug may restore normal function.

Uneven Cutting

Uneven cutting patterns are often a result of dull or damaged blades. A quick inspection of the cutting blade’s condition can reveal nicks, wear, or a dull edge. Sharpening or replacing the blade may

How to Replace a Lawn Mower Blade

Keeping your cutting tool sharp is essential for an even trim and to maintain the health of your grass. Dull or damaged blades tear rather than cut, leading to a less attractive result and potential grass damage. Replacing the blade is a straightforward task that can enhance cutting efficiency and extend the life of your equipment.

Step 1: Prepare Your Equipment

Before starting, disconnect the power source to ensure safety. For gas-powered machines, remove the spark plug to avoid accidental ignition. Make sure you’re working on a stable, level surface for easy access to the underside.

Step 2: Access the Blade

Tilt the device carefully to reveal the blade area. Use a block of wood or a sturdy wedge to prevent the blade from rotating. This step makes it easier to loosen and remove the blade safely.

Step 3: Remove the Blade

Using a wrench or socket, loosen the bolt

Fixing Engine Starting Problems

Experiencing difficulties when trying to ignite the engine can be frustrating. Various factors can contribute to these issues, and understanding them is crucial for effective troubleshooting. This section outlines common causes and provides solutions to help restore functionality to your equipment.

Common Causes of Starting Issues

- Insufficient fuel supply

- Faulty spark plug

- Clogged air filter

- Weak battery

- Incorrect choke setting

Troubleshooting Steps

- Check the Fuel: Ensure that there is adequate fuel in the tank and that it is fresh. Old or contaminated fuel can hinder performance.

- Inspect the Spark Plug: Remove the spark plug and examine it for wear or carbon buildup. Replace it if necessary to ensure a strong spark.

- Examine the Air Filter: A blocked air filter can restrict airflow, affecting combustion. Clean or replace it to improve airflow.

- Test the Battery: If the engine turns over slowly or not at all, the battery may be weak. Charge or replace the battery as needed.

- Adjust the Choke: Ensure that the choke is set correctly according to the engine’s requirements. A closed choke can prevent starting in warm conditions.

By following these steps, you can effectively address starting issues and enhance the performance of your equipment.

Maintaining the Mower’s Fuel System

Proper upkeep of the fuel system is essential for ensuring optimal performance and longevity of your outdoor power equipment. A clean and well-functioning fuel system not only enhances the efficiency of the engine but also prevents common issues such as starting difficulties and power loss. Regular maintenance practices can help you avoid costly repairs and ensure that your equipment operates smoothly throughout the season.

Cleaning the Fuel Filter

Over time, the fuel filter can become clogged with debris and contaminants, leading to restricted fuel flow. It is crucial to inspect and clean the filter regularly. Disconnect the filter from the fuel lines, and use a suitable solvent to remove any buildup. If the filter is excessively dirty or damaged, it is advisable to replace it to maintain optimal fuel delivery.

Inspecting Fuel Lines

Check the fuel lines for any signs of wear, cracks, or leaks. Damaged fuel lines can lead to leaks and affect the performance of the engine. Ensure that all connections are tight and free from obstructions. If you notice any issues, replace the affected sections to prevent fuel loss and ensure safe operation.

Steps for Carburetor Cleaning and Adjustment

Maintaining optimal performance in your outdoor power equipment often involves thorough cleaning and precise tuning of the carburetor. This process ensures that the engine operates smoothly and efficiently, leading to better fuel economy and improved overall functionality. Below are the essential steps to effectively clean and adjust the carburetor, enhancing the reliability of your device.

Step Description 1. Gather Necessary Tools Collect essential tools including a screwdriver, a socket set, a cleaning brush, and a carburetor cleaner spray. 2. Disconnect the Power Source Ensure safety by disconnecting the spark plug wire to prevent accidental starts while servicing. 3. Remove the Carburetor Loosen the bolts securing the carburetor to the engine and carefully detach it from its mount. 4. Disassemble the Carburetor Take apart the carburetor components, noting their arrangement for accurate reassembly. 5. Clean the Components Use a suitable cleaner and a brush to remove any debris, varnish, or deposits from all parts. 6. Check the Gaskets Inspect gaskets for wear or damage; replace them if necessary to ensure a proper seal. 7. Reassemble the Carburetor Carefully put the carburetor back together, ensuring all parts are correctly positioned. 8. Adjust the Mixture Settings Set the air-fuel mixture screws according to manufacturer specifications for optimal performance. 9. Reattach the Carburetor Secure the carburetor back to the engine and ensure all connections are tight and leak-free. 10. Test the Equipment Reconnect the spark plug and start the engine, checking for smooth operation and making any necessary adjustments. Repairing a Broken Pull Cord

A malfunctioning starting cord can significantly hinder the operation of outdoor equipment. Understanding the components involved and the steps to rectify the issue can restore functionality efficiently. This section outlines the essential procedures for addressing a faulty pull cord, ensuring your equipment is ready for use once again.

Begin by ensuring the device is turned off and safely positioned. Examine the casing for any visible damage or wear that may have contributed to the cord’s malfunction. Carefully remove the cover to access the recoil assembly, which houses the cord mechanism.

Once exposed, inspect the cord for frays or breaks. If the cord is intact but not retracting properly, check the spring mechanism within the recoil assembly. A broken or dislodged spring can prevent the cord from functioning as intended. In such cases, replacing or re-seating the spring may resolve the issue.

If the cord has snapped, measure a new length of cord suitable for your equipment. Thread it through the housing, ensuring it wraps correctly around the spool. Secure it in place, allowing for adequate tension to facilitate smooth operation. Finally, reattach the casing and perform a test to confirm proper functionality.

Replacing the Spark Plug Efficiently

Replacing the ignition component is a crucial task that can significantly enhance the performance of your equipment. This process ensures that the engine operates smoothly and starts without hassle. A well-maintained spark plug contributes to fuel efficiency and reduces emissions, making it an essential part of routine maintenance.

To begin, gather the necessary tools, including a spark plug socket, a ratchet wrench, and a gap gauge. First, ensure that the machine is completely cool to avoid burns. Disconnect the power source for safety, then locate the ignition component, which is typically situated near the engine.

Using the spark plug socket, carefully remove the old component by turning it counterclockwise. Inspect the old part for any signs of wear or damage, such as carbon buildup or corrosion. These indicators can help determine if the engine has underlying issues that need addressing.

Once the old ignition element is removed, check the gap using the gauge. Adjust it according to the manufacturer’s specifications, as the correct gap is vital for optimal ignition. Insert the new part into the socket, ensuring it is seated properly before tightening it by turning clockwise. Avoid over-tightening, as this can cause damage.

After securing the new ignition component, reconnect the power source and test the equipment to ensure it starts smoothly. Regularly checking and replacing this part will keep your machine running efficiently, prolonging its lifespan and enhancing performance.

How to Adjust Mower Cutting Height

Achieving the perfect trimming height is essential for maintaining a healthy and attractive yard. Proper adjustment ensures that your equipment can effectively manage grass length, promoting optimal growth while preventing damage to the grass or machinery. This section outlines the steps to adjust the cutting height of your equipment for the best results.

Before you begin, gather the necessary tools, such as a ruler or tape measure, to ensure accurate height settings. Follow these guidelines to make the adjustments:

- Ensure the equipment is turned off and positioned on a flat, level surface.

- Locate the height adjustment mechanism, usually found near the wheels or on the body.

- If your model features a lever or knob, adjust it to raise or lower the blades. Some models may require you to adjust each wheel individually.

- Use a ruler or tape measure to verify the height setting by measuring from the ground to the blade’s edge. Adjust as necessary until you reach the desired height.

- Once set, test the equipment on a small section of grass to ensure the height is appropriate and provides a clean cut.

Regularly check the cutting height, especially during different seasons, to adapt to varying growth patterns. Proper maintenance will enhance the performance and longevity of your equipment.

Sharpening the Mower Blade Properly

Maintaining a sharp cutting tool is essential for achieving a clean and precise cut. A well-honed edge not only enhances the performance of the equipment but also contributes to the health of the grass by reducing stress on the blades. Regularly ensuring the sharpness of the edge can prevent damage to the turf and promote a lush, vibrant lawn.

Before beginning the sharpening process, ensure that the equipment is turned off and disconnected from any power source. Use appropriate protective gear such as gloves and safety goggles to safeguard against injuries. Begin by removing the cutting implement from the machine, following the manufacturer’s guidelines for safe disassembly.

Once detached, inspect the edge for any visible damage or dullness. Utilize a file or sharpening stone to carefully hone the cutting edge. Maintain a consistent angle while working on the edge to ensure uniformity. Remember to sharpen both sides evenly, as an imbalance can affect the cutting quality.

After achieving the desired sharpness, clean the blade thoroughly to remove any debris or metal shavings. Reattach the cutting implement securely to the machine, ensuring all components are properly aligned. Finally, test the equipment on a small section of grass to confirm that the sharpening has improved its performance.

Troubleshooting Mower Electrical Issues

Addressing electrical complications in outdoor equipment can be challenging yet essential for optimal performance. Understanding potential faults and their symptoms can aid in efficient diagnosis and resolution of issues. This section outlines common electrical problems and effective methods to troubleshoot them, ensuring your equipment operates smoothly.

Begin by inspecting the power source. A faulty battery or poor connections can lead to performance issues. It’s vital to check for corrosion or loose wires. If the equipment fails to start, these areas are often the first to investigate.

Issue Symptoms Potential Solutions Equipment won’t start No response when ignition is engaged Check battery charge and connections. Replace if necessary. Inconsistent operation Equipment starts and stops unexpectedly Inspect for loose wiring or faulty ignition switch. Electrical sparks Visible sparks from wiring Immediately disconnect power. Replace damaged wires or components. Lights not functioning Indicator lights are off Check fuse and wiring; replace blown fuses or damaged connectors. By systematically evaluating these common electrical issues, you can efficiently troubleshoot and resolve problems. Always prioritize safety and ensure the power is disconnected before performing any inspections or repairs.