In the world of automotive enthusiasts, the pursuit of knowledge about vehicle upkeep is essential. Understanding the intricacies of your car can enhance performance and longevity, making the driving experience more enjoyable. This resource aims to equip you with essential information for effective maintenance and troubleshooting.

Mastering the Art of Vehicle Care involves delving into the specifics of your model, including engine components, electrical systems, and suspension setups. By familiarizing yourself with these aspects, you empower yourself to tackle issues proactively, ensuring your vehicle remains in optimal condition.

Whether you’re a seasoned mechanic or a passionate owner eager to learn, this guide serves as a valuable companion. It provides detailed instructions, helpful tips, and insights that will transform your approach to automotive maintenance, enabling you to confidently manage repairs and enhancements.

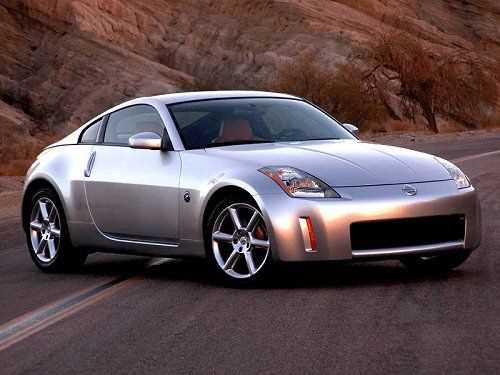

Nissan 350Z Overview

This section provides a comprehensive introduction to a high-performance sports coupe that has captured the hearts of enthusiasts around the globe. Renowned for its sleek design, agile handling, and powerful engine, this vehicle exemplifies the perfect blend of style and performance. It is a true representation of modern engineering, designed for those who appreciate the thrill of driving.

Design and Performance

The exterior showcases bold lines and an aerodynamic profile, emphasizing its sporty character. Under the hood lies a robust powertrain that delivers an exhilarating driving experience, allowing for quick acceleration and sharp cornering. This combination makes it a favorite among those who crave excitement on the road.

Interior Features

Essential Tools for Repairs

When tackling automotive maintenance and restoration, having the right instruments is crucial for effective and efficient work. A well-equipped toolkit not only enhances the repair process but also ensures safety and precision. This section highlights the fundamental instruments that every enthusiast or professional should consider for their projects.

Basic Hand Tools

At the foundation of any toolkit are the basic hand instruments. These include wrenches, screwdrivers, and pliers, which are indispensable for loosening or tightening components. A comprehensive set should cover various sizes to accommodate different fasteners. Additionally, a ratchet and socket set can significantly speed up the process, especially in confined spaces.

Specialized Equipment

Beyond the essentials, certain specialized tools can make complex tasks more manageable. For instance, torque wrenches are vital for ensuring that bolts are tightened to the manufacturer’s specifications, preventing damage or failure. Similarly, diagnostic scanners can help identify issues quickly, allowing for informed decision-making during repairs. Investing in quality equipment will pay off in the long run by enhancing the overall experience and outcomes of your automotive projects.

Common Issues with the 350Z

This section addresses frequent challenges encountered by enthusiasts of this iconic sports car. Understanding these concerns can enhance the ownership experience and facilitate proactive maintenance. Below are some prevalent issues that drivers should be aware of.

Engine Concerns

- Oil Consumption: Many owners report excessive oil usage, which can lead to the need for frequent top-ups.

- Overheating: Problems with the cooling system can cause the engine to run hotter than normal, risking damage.

- Timing Chain Issues: Wear and tear on the timing chain can result in significant performance problems if not addressed promptly.

Transmission Troubles

- Clutch Wear: Premature clutch wear is a common complaint, particularly in models with a manual transmission.

- Transmission Fluid Leaks: Fluid leaks can occur, leading to shifting difficulties and potential transmission failure.

- Synchro Issues: Problems with synchronization can result in grinding noises during gear changes.

Awareness of these common issues allows owners to take timely action and enjoy their vehicles without unexpected interruptions.

Step-by-Step Maintenance Guide

Proper upkeep of your vehicle is essential to ensure longevity and optimal performance. This guide outlines the fundamental procedures to help you maintain your car effectively. Following these steps will not only enhance the driving experience but also prevent costly repairs in the future.

Essential Checks

- Fluid Levels: Regularly inspect and top off engine oil, coolant, brake fluid, and transmission fluid.

- Tire Maintenance: Check tire pressure monthly and inspect tread depth for safety.

- Battery Condition: Examine battery terminals for corrosion and ensure connections are secure.

Scheduled Services

- Oil Change: Replace engine oil and filter every 5,000 to 7,500 miles.

- Air Filter Replacement: Change the engine air filter every 15,000 to 30,000 miles to maintain optimal airflow.

- Brake Inspection: Check brake pads and rotors at least once a year for wear and tear.

- Fluid Flushes: Perform coolant and brake fluid flushes as per the manufacturer’s recommendations.

Engine Specifications and Repair Tips

This section provides essential insights into the performance characteristics and maintenance suggestions for a specific sports vehicle. Understanding the technical specifications of the powertrain is crucial for ensuring optimal functionality and longevity. Below, you’ll find key details and useful advice for tackling common issues.

Key Specifications

The engine in question features a V6 configuration with a displacement of approximately 3.5 liters. It is designed to produce around 300 horsepower, delivering a thrilling driving experience. Key elements include:

- Compression Ratio: 10.6:1

- Fuel System: Multi-point fuel injection

- Max Torque: 260 lb-ft at 4800 RPM

Maintenance and Troubleshooting Tips

Regular upkeep is vital for maintaining performance. Here are some practical tips:

- Ensure the engine oil is changed every 5,000 to 7,500 miles to prevent wear and tear.

- Check the coolant levels and radiator condition to avoid overheating issues.

- Monitor the condition of the air filter; a clean filter enhances airflow and engine efficiency.

- Be attentive to any unusual sounds or vibrations, as these could indicate underlying problems.

By following these guidelines, you can enhance the performance and reliability of your vehicle’s engine, ensuring a thrilling yet dependable driving experience.

Transmission Troubleshooting Techniques

When dealing with transmission issues, a systematic approach can make the diagnosis process more effective. Understanding the symptoms and using appropriate techniques can help identify the root cause of the problem, leading to timely and efficient resolutions.

Common Symptoms of Transmission Problems

- Slipping gears or difficulty shifting

- Unusual noises, such as grinding or whining

- Fluid leaks under the vehicle

- Warning lights on the dashboard

- Unresponsive transmission during acceleration

Troubleshooting Steps

- Check Fluid Levels: Ensure the transmission fluid is at the recommended level. Low fluid can lead to overheating and shifting problems.

- Inspect Fluid Condition: Look for discoloration or a burnt smell, indicating contamination or the need for a fluid change.

- Examine Electrical Connections: Inspect the wiring and connectors for signs of damage or corrosion that could affect transmission performance.

- Test the Transmission Control Module: Use a diagnostic scanner to check for error codes that may point to specific malfunctions.

- Conduct Road Tests: Take the vehicle for a test drive to replicate the issue and observe the transmission’s behavior under various conditions.

Suspension System Inspection Process

The suspension system plays a crucial role in ensuring vehicle stability, comfort, and handling performance. Regular assessment of this system is essential to identify potential issues that could affect driving safety and overall functionality. This section outlines a systematic approach to evaluating the suspension components, focusing on both visual inspections and practical checks.

Initial Visual Inspection

Begin with a thorough visual examination of the suspension elements. Look for signs of wear, damage, or corrosion on components such as shocks, struts, and sway bars. Check for any fluid leaks around the shocks and struts, as this can indicate internal failure. Additionally, inspect bushings and mounts for signs of deterioration or cracking.

Component Movement Check

Next, conduct a movement check by pushing down on the vehicle’s corners. Observe how the suspension reacts; it should return to its original position without excessive bouncing. If the vehicle continues to bounce, this may signal worn shock absorbers or struts that require attention.

Tire Condition Assessment

Examine the tires for uneven wear patterns, which can suggest misalignment or suspension issues. Ensure that the tire pressure is consistent and within the recommended specifications, as incorrect pressure can also affect suspension performance.

Alignment and Height Verification

Finally, verify the vehicle’s alignment and ride height. Incorrect alignment can lead to premature wear on suspension components and tires. Use alignment tools or consult a professional service if discrepancies are observed. Additionally, check the ride height to ensure it meets the manufacturer’s specifications, as sagging or uneven height can indicate underlying suspension problems.

Electrical System Diagnostics Explained

Understanding the intricacies of a vehicle’s electrical framework is essential for maintaining optimal performance and resolving issues effectively. This section delves into the systematic approach to diagnosing electrical problems, enabling enthusiasts and professionals alike to identify and rectify faults efficiently.

Key Components to Examine

When conducting diagnostics, several critical elements should be evaluated:

- Batteries: Check for charge levels and physical integrity.

- Fuses: Inspect for blown fuses that may disrupt circuits.

- Wiring: Look for frayed or damaged wires that could lead to shorts.

- Connectors: Ensure all connectors are secure and free from corrosion.

Diagnostic Tools and Techniques

Employing the right tools is vital for effective diagnostics. Consider the following:

- Multimeter: Use to measure voltage, current, and resistance.

- OBD-II Scanner: Essential for retrieving error codes from the vehicle’s computer.

- Test Lights: Helpful for checking circuit continuity.

- Wire Trace Tool: Useful for identifying wiring issues and tracking signal paths.

By systematically analyzing these components and employing the right diagnostic tools, one can uncover and resolve electrical malfunctions efficiently, ensuring the vehicle operates smoothly and reliably.

Brake System Maintenance and Repair

The braking mechanism is crucial for the safety and performance of any vehicle. Regular upkeep ensures reliable stopping power and extends the lifespan of components. Understanding how to effectively manage this system can prevent costly issues and enhance driving experience.

Inspection is the first step in maintaining the braking system. Regularly checking pads, rotors, and fluid levels can identify potential problems before they escalate. Look for signs of wear, such as uneven surfaces or reduced thickness of brake pads. Visual assessments should be part of a routine check, ideally performed every few months.

Fluid replacement is another critical aspect. Brake fluid absorbs moisture over time, leading to reduced performance. It’s advisable to replace the fluid according to the manufacturer’s recommendations, generally every two years. Ensure the fluid is at the proper level and free from contaminants.

Component Replacement may be necessary when wear is evident. Brake pads and rotors should be changed if they fall below specified thickness levels. When replacing pads, always ensure the new components are compatible with existing parts to maintain system integrity.

When performing any maintenance, always consult the specific guidelines relevant to the vehicle in question. If unsure about any procedure, seeking professional assistance is wise to ensure safety and effectiveness.

Cooling System Functionality and Fixes

The cooling system plays a vital role in maintaining optimal engine temperature and preventing overheating. It circulates coolant through the engine, absorbing heat and dissipating it through the radiator. Understanding how this system operates and recognizing potential issues can help ensure longevity and performance.

Components of the Cooling System include the radiator, water pump, thermostat, and hoses. Each part must function correctly to maintain effective temperature control. If any component fails, it can lead to serious engine damage.

Common Issues often arise from leaks in hoses or the radiator, thermostat failures, or a malfunctioning water pump. Regular inspections can help identify these problems early. Look for signs such as coolant puddles, fluctuating temperature gauges, or steam from the engine bay.

Troubleshooting begins with visual checks for leaks and ensuring all connections are secure. If overheating occurs, start by examining the thermostat and radiator. Replacing worn components promptly can prevent further damage and costly repairs.

Maintenance Tips include regularly checking coolant levels and replacing the coolant as recommended. Flushing the system periodically removes contaminants, helping maintain efficiency. Keeping the radiator and hoses free of debris also contributes to effective cooling.

By understanding the functionality of the cooling system and addressing issues proactively, vehicle owners can enhance reliability and performance, ensuring a smoother driving experience.

Upgrading Parts: What to Consider

Enhancing vehicle components can significantly impact performance, aesthetics, and overall driving experience. However, before making any modifications, it is essential to evaluate various factors to ensure that upgrades align with personal preferences and technical requirements. Each decision can influence not only functionality but also safety and reliability.

Firstly, compatibility with existing systems should be a primary concern. New components must integrate seamlessly with current setups to avoid conflicts and ensure optimal performance. Researching manufacturer specifications and recommendations can provide valuable insights into suitable options.

Next, consider the intended purpose of the upgrades. Whether aiming for improved speed, better handling, or enhanced visual appeal, the selected parts should reflect these goals. It’s crucial to prioritize modifications that complement each other and contribute to a cohesive overall enhancement.

Additionally, budget plays a significant role in the decision-making process. Upgrading can range from minor adjustments to comprehensive overhauls, and understanding the financial implications is vital. It’s advisable to factor in potential installation costs and future maintenance when planning upgrades.

Lastly, consulting with experienced professionals can help navigate the complexities of modifications. Their expertise can provide guidance on the most effective and reliable components, ensuring that choices made lead to satisfactory outcomes in terms of performance and durability.

Safety Precautions During Repairs

Ensuring safety during vehicle maintenance is essential for both the individual performing the work and the surrounding environment. Adhering to specific guidelines can minimize risks and prevent accidents, making the process smoother and more efficient.

Essential Safety Gear

- Wear protective eyewear to shield against debris.

- Utilize gloves to protect hands from sharp edges and chemicals.

- Use sturdy footwear to prevent injuries from heavy tools or components.

- Consider a face mask when working with dust or fumes.

Workspace Considerations

- Ensure the workspace is well-ventilated to disperse harmful vapors.

- Keep the area organized to avoid tripping hazards.

- Use appropriate jacks and stands to support the vehicle securely.

- Store tools properly to prevent accidents when reaching for them.

By following these precautions, individuals can significantly reduce the likelihood of accidents and injuries during automotive service tasks.

Finding Quality Replacement Parts

When it comes to maintaining and enhancing your vehicle, sourcing high-quality components is essential. Reliable parts not only ensure optimal performance but also contribute to the longevity of your automobile. This section explores effective strategies for locating premium replacements that meet or exceed original specifications.

Where to Search for Components

There are several avenues to consider when looking for superior automotive parts. From online platforms to local shops, each option has its own advantages.

| Source | Advantages | Considerations |

|---|---|---|

| Online Retailers | Wide selection, competitive pricing | Check reviews and return policies |

| Local Auto Parts Stores | Immediate availability, personalized service | Limited inventory compared to online |

| Salvage Yards | Cost-effective, unique finds | Condition of parts varies |

| Authorized Dealers | Genuine parts, warranty options | Higher prices, limited selection |

Evaluating Quality

Once you identify potential sources, assessing the quality of the components is crucial. Look for indicators such as brand reputation, materials used, and warranties offered. Reading customer feedback can provide insights into the reliability and performance of the parts.