When it comes to ensuring the longevity and performance of your automobile, having access to comprehensive resources is essential. A thorough guide can empower owners to tackle various challenges that may arise during the life of their vehicle. Understanding the intricacies of maintenance, troubleshooting, and repair can enhance your driving experience and contribute to safety on the road.

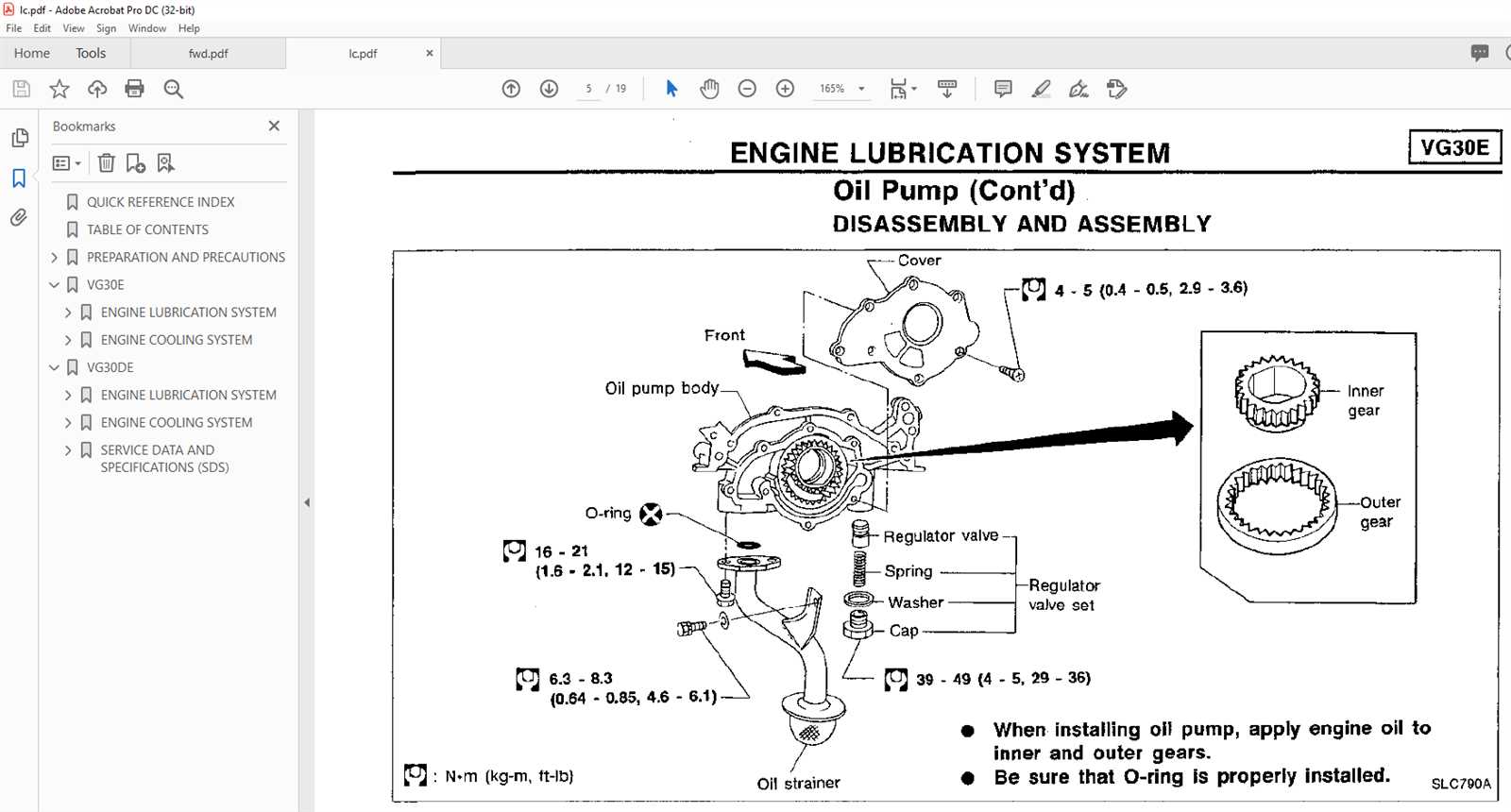

Such a resource typically covers a wide array of topics, from routine upkeep to detailed troubleshooting procedures. It provides valuable insights into the functioning of various components, helping enthusiasts and everyday drivers alike to grasp how to maintain optimal performance. Moreover, detailed diagrams and step-by-step instructions can simplify complex tasks, making them manageable for individuals with varying skill levels.

By utilizing these resources, vehicle owners can develop a deeper understanding of their automobile’s mechanics. This knowledge not only aids in addressing immediate issues but also fosters a proactive approach to maintenance, potentially saving time and costs in the long run. Ultimately, equipping yourself with the right information ensures that your vehicle remains reliable and efficient throughout its service life.

This section provides an overview of a specific vehicle model, highlighting its key features, specifications, and overall performance. Understanding the characteristics of this vehicle is essential for effective maintenance and troubleshooting.

Key aspects to consider include:

- Engine specifications and performance metrics

- Transmission types and handling capabilities

- Interior features and comfort options

- Exterior design and aesthetic appeal

- Safety ratings and essential technology

In this article, we will explore various sections, including:

- Introduction to the vehicle’s history

- Detailed description of engine options

- Transmission and drivetrain information

- Comprehensive interior and exterior features

- Safety and technology advancements

- Common issues and troubleshooting tips

- Regular maintenance recommendations

- Parts replacement guidelines

- Performance enhancements and upgrades

- Owner reviews and experiences

- Technical specifications summary

- Resources for further information

Common Issues with Nissan Maxima

Owners of this particular vehicle often encounter a range of recurring challenges that can affect performance and overall driving experience. Understanding these issues is crucial for maintaining optimal functionality and ensuring longevity.

Frequent Electrical Problems

Electrical malfunctions are commonly reported, impacting various systems within the automobile. These problems can lead to difficulties with the ignition system, dashboard indicators, and power accessories. Timely identification and resolution are essential to prevent further complications.

Transmission Concerns

Another prevalent issue involves the transmission, which may exhibit signs of slipping or delayed shifting. Such symptoms can stem from fluid leaks, worn components, or software glitches in newer models. Addressing these concerns promptly can help avoid costly repairs.

| Issue Type | Description | Potential Solutions |

|---|---|---|

| Electrical Failures | Problems with dashboard lights and power features | Inspect wiring, replace fuses, or update software |

| Transmission Slipping | Delayed gear shifting or slipping while driving | Check fluid levels, inspect for leaks, or perform software updates |

| Brake Wear | Unusual noises or reduced responsiveness | Replace brake pads and inspect rotors |

Engine Specifications and Maintenance

This section outlines essential details regarding the powertrain, including crucial specifications and upkeep practices. Understanding these elements is vital for ensuring optimal performance and longevity of the vehicle’s engine.

Key specifications include:

- Engine Type: V6

- Displacement: 3.5 liters

- Horsepower: Approximately 290 hp

- Torque: About 261 lb-ft

- Fuel System: Electronic fuel injection

To maintain the engine’s efficiency and reliability, follow these recommended practices:

- Regular Oil Changes: Replace engine oil every 5,000 to 7,500 miles to ensure proper lubrication.

- Inspect Air Filter: Check the air filter periodically and replace it as needed to maintain airflow.

- Monitor Coolant Levels: Keep an eye on coolant levels and check for leaks to prevent overheating.

- Check Belts and Hoses: Inspect belts and hoses for signs of wear or damage and replace them promptly.

- Schedule Routine Inspections: Conduct regular inspections and diagnostics to identify potential issues early.

By adhering to these specifications and maintenance practices, you can enhance the engine’s performance and extend its lifespan.

Transmission Repair Guidelines

This section provides essential recommendations for addressing issues related to the vehicle’s transmission system. Proper handling of transmission components is crucial for ensuring optimal performance and longevity. Follow these guidelines to effectively diagnose and rectify common transmission problems.

Common Symptoms of Transmission Issues

- Unusual noises during shifting

- Slipping gears or unexpected changes

- Fluid leaks under the vehicle

- Warning lights on the dashboard

- Delayed engagement when shifting into gear

Steps for Addressing Transmission Problems

- Identify the issue by performing a thorough diagnostic check.

- Inspect the transmission fluid for proper levels and quality.

- Examine the components for signs of wear or damage.

- Replace any faulty parts as needed.

- Test drive the vehicle to ensure the problem is resolved.

Following these procedures will aid in maintaining a reliable transmission system and prevent further complications.

Braking System Troubleshooting

Understanding issues within the braking system is crucial for maintaining vehicle safety and performance. Identifying common symptoms can help in diagnosing problems effectively. Regular inspection and prompt attention to any irregularities are essential steps in ensuring the braking system operates efficiently.

Common Symptoms of Brake Issues

Drivers may notice various signs indicating potential problems with the braking system. Unusual noises such as squeaking or grinding may suggest worn brake pads. Additionally, a soft or spongy brake pedal can signal air in the brake lines or low fluid levels. Vibrations while braking often indicate issues with the rotors.

Troubleshooting Steps

To address braking issues, start by examining the brake fluid level and inspecting for leaks. Next, check the condition of the brake pads and rotors for wear and damage. If the pedal feels abnormal, bleeding the brake lines may be necessary to remove trapped air. Always prioritize safety by ensuring the braking system is in optimal condition.

Electrical System Diagnostics

This section focuses on evaluating the electrical components of the vehicle, ensuring their optimal performance and reliability. Proper assessment of the electrical system is crucial for maintaining functionality and addressing potential issues effectively.

Regular diagnostics can help identify problems early, allowing for timely repairs and preventing further complications. Various tools and methods are utilized to analyze the system’s integrity, helping technicians locate faults and verify the proper operation of electrical circuits.

| Diagnostic Tool | Purpose | Common Issues Detected |

|---|---|---|

| Multimeter | Measures voltage, current, and resistance | Battery issues, faulty connections |

| Scan Tool | Reads trouble codes from the system | Sensor malfunctions, communication errors |

| Oscilloscope | Analyzes waveform patterns | Electrical noise, signal integrity issues |

By utilizing these diagnostic instruments, technicians can ensure the vehicle’s electrical system operates smoothly, enhancing overall performance and safety.

Cooling System Maintenance Tips

Proper upkeep of the cooling system is essential for optimal engine performance and longevity. Regular checks and maintenance can help prevent overheating and costly repairs, ensuring that your vehicle operates smoothly. Below are some key strategies for maintaining an efficient cooling system.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect Coolant Level | Monthly | Check the coolant reservoir to ensure the fluid is at the recommended level, adding more if necessary. |

| Flush Cooling System | Every 2 years | Replace old coolant with fresh fluid to prevent corrosion and buildup within the system. |

| Check Hoses and Belts | Every 6 months | Inspect hoses for cracks or leaks and ensure belts are tight and free from wear. |

| Examine Thermostat | Annually | Test the thermostat to ensure it opens and closes at the correct temperatures. |

| Inspect Radiator | Every 6 months | Check for any debris or damage that might hinder airflow and cooling efficiency. |

Adhering to these maintenance tips will significantly enhance the performance and reliability of the engine’s cooling system, ultimately prolonging the lifespan of the vehicle.

Suspension and Steering Repairs

The effectiveness of a vehicle’s handling and comfort is largely dependent on its suspension and steering systems. Proper maintenance and timely interventions are essential to ensure a smooth driving experience and to avoid more significant issues in the long run.

Key components involved in these systems include:

- Shock absorbers and struts

- Control arms and bushings

- Steering rack and pinion

- Ball joints

- Stabilizer bars

When addressing issues related to suspension and steering, consider the following steps:

- Conduct a thorough inspection of all components for signs of wear or damage.

- Replace any worn-out parts to maintain proper alignment and handling.

- Check fluid levels in the power steering system and replenish as needed.

- Ensure that all fasteners are tightened to the manufacturer’s specifications.

- Perform alignment checks regularly to enhance tire longevity and vehicle performance.

Maintaining the suspension and steering systems not only improves driving comfort but also enhances safety on the road. Regular check-ups and proactive maintenance can prevent costly repairs in the future.

Fuel System Service Procedures

The fuel system is a critical component of vehicle performance, requiring regular maintenance to ensure optimal functionality. Proper service procedures not only enhance efficiency but also extend the lifespan of various elements within the system. This section outlines essential steps for maintaining and troubleshooting the fuel system effectively.

Inspection and Maintenance

Regular inspection of the fuel delivery system is vital. Begin by examining fuel lines for signs of leaks, cracks, or wear. Ensure that all connections are secure and free of corrosion. Additionally, the fuel filter should be checked and replaced according to manufacturer recommendations to prevent contaminants from entering the engine.

Fuel Pump Testing

Testing the fuel pump is crucial for maintaining adequate fuel pressure. Use a pressure gauge to verify that the pump operates within specified parameters. If pressure readings are low, consider checking the electrical connections and relays associated with the pump. Replacing a malfunctioning pump promptly is essential for optimal engine performance.

Body and Interior Repair Techniques

This section focuses on effective methods for restoring and enhancing the external and internal elements of a vehicle. Understanding the various techniques involved can significantly improve the overall appearance and functionality of the automobile, ensuring it remains in excellent condition for years to come.

Exterior Restoration Methods

To maintain the aesthetics of a vehicle’s body, several procedures can be implemented. These include paint correction, dent removal, and surface refinishing. Each technique requires specific tools and expertise to address imperfections, restore shine, and protect against environmental factors. Regular upkeep not only elevates visual appeal but also contributes to the vehicle’s longevity.

Interior Enhancement Practices

The interior of a vehicle plays a crucial role in user experience. Techniques such as upholstery cleaning, dashboard restoration, and installation of modern accessories can transform the cabin space. Employing appropriate cleaning agents and materials ensures that surfaces remain intact while improving comfort and functionality. These enhancements provide a refreshed atmosphere for drivers and passengers alike.

Recommended Tools for Repairs

Having the right instruments is crucial for effective maintenance and troubleshooting. Whether tackling minor adjustments or significant overhauls, a well-equipped toolkit can enhance efficiency and ensure that tasks are completed accurately. Below is a selection of essential tools that are beneficial for various tasks related to vehicle servicing.

Essential Hand Tools

A comprehensive set of hand tools forms the foundation of any maintenance endeavor. Items such as wrenches, screwdrivers, and pliers are indispensable for loosening or tightening components. Additionally, a torque wrench is vital for achieving proper specifications when fastening critical parts.

Diagnostic Equipment

Utilizing diagnostic tools can simplify identifying underlying issues. An OBD-II scanner allows for reading error codes, providing valuable insights into system malfunctions. Furthermore, a multimeter is essential for testing electrical circuits, ensuring components are functioning correctly.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks on vehicles is crucial for both the individual conducting the work and the integrity of the automobile. Following essential guidelines minimizes risks associated with mechanical tasks, protecting against accidents and injuries.

Before commencing any service, it is vital to prepare adequately. This involves gathering the necessary tools and understanding the specific components involved in the task at hand. Proper planning not only streamlines the process but also enhances safety.

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear gloves, goggles, and appropriate footwear to protect against potential hazards. |

| Secure Work Area | Ensure the workspace is clean and organized to prevent tripping or falling. |

| Disconnect Battery | Always disconnect the battery before starting any electrical work to prevent shocks or shorts. |

| Use Proper Lifting Equipment | When lifting the vehicle, use jack stands to secure it and prevent accidental falls. |

| Read Documentation | Consult relevant guidelines or specifications to familiarize yourself with the procedures. |

Adhering to these precautions will significantly reduce the risk of accidents and ensure a safer working environment. Remember that safety should always be the top priority in any automotive undertaking.