Maintaining a lawn care machine is essential for ensuring its longevity and optimal performance. Understanding the various components and their functions can greatly enhance the efficiency of these machines. Regular upkeep not only prevents potential breakdowns but also contributes to a healthier and more vibrant lawn.

In this guide, we will explore the key aspects of servicing your grass-cutting equipment. From routine inspections to troubleshooting common issues, gaining insight into the maintenance process will empower you to tackle challenges with confidence. With the right knowledge, you can ensure your equipment remains in top shape throughout the mowing season.

Equipped with step-by-step instructions and practical tips, this resource aims to demystify the servicing process. Whether you’re a seasoned gardener or a newcomer to lawn care, the information provided here will help you navigate the intricacies of your machine effectively. Embrace the journey of caring for your equipment, and enjoy the benefits of a well-maintained tool in your gardening arsenal.

Overview of John Deere L120

This section provides a comprehensive look at a popular model known for its efficiency and durability in lawn care. Designed for homeowners, this machine offers a combination of power and functionality, making it a favored choice for maintaining residential lawns.

Key Features

- Robust engine performance ensuring reliable operation.

- Wide cutting deck for faster mowing, covering more ground in less time.

- Ergonomic seating for comfort during extended use.

- Easy-to-use controls for enhanced user experience.

- Durable construction to withstand various outdoor conditions.

Benefits

- Improved efficiency in lawn maintenance tasks.

- Enhanced maneuverability in tight spaces.

- Cost-effective solution for homeowners seeking quality.

- Low maintenance requirements with proper care.

- Versatile attachments available for year-round use.

Common Issues with L120 Mowers

Every machine can encounter difficulties over time, and lawn mowers are no exception. Understanding the typical problems that arise can help users maintain their equipment effectively and ensure a smooth mowing experience.

- Engine Troubles:

- Starting issues, often caused by fuel problems or spark plug failures.

- Overheating, which may result from insufficient oil or blocked cooling vents.

- Cutting Problems:

- Uneven cuts due to dull blades or incorrect height settings.

- Grass clumping under the deck, often caused by wet conditions or a clogged discharge chute.

- Transmission Difficulties:

- Slipping gears, which can occur from low fluid levels or worn belts.

- Difficulty in shifting speeds, possibly due to cable adjustments needing attention.

- Electrical Failures:

- Battery issues, such as poor connections or old batteries that need replacement.

- Faulty wiring or blown fuses leading to malfunctions in lights or the starter.

By being aware of these common concerns, operators can take proactive steps to prevent them and enjoy a more efficient mowing experience.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and restoration tasks. Proper tools not only enhance efficiency but also ensure safety and precision while working. Whether you are performing routine checks or addressing specific issues, a well-equipped toolbox makes a significant difference.

Basic Tools

- Wrenches: A set of adjustable wrenches will help in loosening or tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips screwdrivers are essential for various fastening needs.

- Pliers: Needle-nose and standard pliers are useful for gripping and bending components.

- Socket Set: This provides versatility for various sizes of nuts and bolts.

Specialized Tools

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Vital for diagnosing electrical issues within the system.

- Jack and Stands: Necessary for safely elevating the machine during maintenance tasks.

- Cleaning Supplies: Brushes, rags, and solvents are important for keeping components clean and functional.

Equipping yourself with these essential tools will facilitate smoother operations and contribute to the longevity of your machinery.

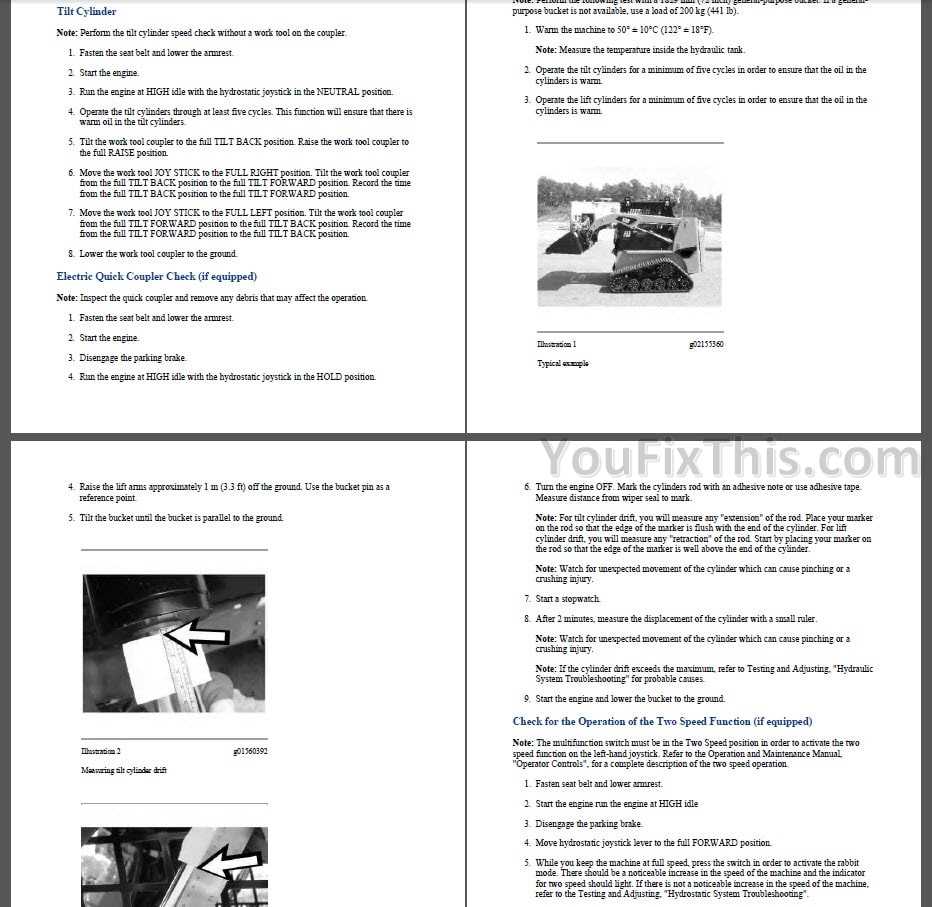

Step-by-Step Maintenance Guide

Regular upkeep of your lawn care equipment is essential to ensure optimal performance and longevity. This guide provides a comprehensive approach to maintaining your machine, covering all critical aspects to keep it running smoothly throughout the seasons.

1. Routine Checks

Begin by inspecting key components such as the air filter, spark plug, and fuel system. Clean or replace the air filter regularly to promote efficient airflow. Check the spark plug for wear and replace it if necessary. Ensure that the fuel is fresh and free from contaminants, as this will enhance engine performance.

2. Lubrication and Cleaning

Proper lubrication of moving parts is crucial. Use suitable lubricants on the drivetrain and other pivot points to minimize wear. Additionally, keep the exterior clean by removing grass clippings and debris, which can cause rust and other issues over time. Regularly wash the undercarriage to prevent build-up and maintain optimal operation.

Replacing the Blades Effectively

Maintaining optimal performance of your lawn equipment involves periodic replacement of cutting components. This process not only ensures a clean cut but also enhances the overall efficiency of the machine. Understanding the right techniques for swapping out these essential parts can make a significant difference in both the quality of your work and the lifespan of your equipment.

Tools and Preparation

Before starting the replacement process, gather the necessary tools, such as wrenches, sockets, and safety gloves. Ensure the equipment is turned off and cooled down to avoid any accidents. Additionally, elevate the machine securely, using jack stands if needed, to provide easy access to the blades. Proper preparation is crucial to facilitate a smooth and safe replacement.

Step-by-Step Replacement Process

Begin by carefully removing the old blades, taking note of their orientation for proper installation of the new ones. Clean the mounting area to eliminate debris that could affect the performance of the new blades. Position the new blades correctly and secure them tightly using the appropriate fasteners. Finally, double-check the alignment and ensure everything is securely in place before lowering the equipment and testing its functionality.

Fuel System Troubleshooting Tips

Diagnosing issues within the fuel system is essential for maintaining optimal engine performance. A variety of factors can contribute to fuel delivery problems, and understanding these can help in identifying the root cause of the malfunction.

Common symptoms of fuel system issues include engine stalling, difficulty starting, and irregular acceleration. When troubleshooting, consider the following tips to effectively address these concerns:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | Empty fuel tank | Refill tank with appropriate fuel |

| Engine stutters during acceleration | Clogged fuel filter | Replace the fuel filter |

| Excessive fuel consumption | Faulty injector | Inspect and clean or replace injector |

| Engine misfires | Poor fuel quality | Use high-quality fuel and consider additives |

| Black smoke from exhaust | Rich fuel mixture | Check and adjust air-fuel ratio |

By systematically addressing these potential issues, you can ensure that the fuel system operates efficiently, leading to improved engine performance and longevity.

Electrical Components and Diagnostics

This section focuses on understanding the various electrical parts of your machine and the methods to troubleshoot issues effectively. Mastering the intricacies of these components is essential for ensuring optimal performance and longevity of your equipment.

Key Electrical Components

Familiarity with the fundamental electrical components will aid in diagnosing problems more accurately. Below are some critical elements:

| Component | Function |

|---|---|

| Battery | Stores electrical energy to start the engine and power accessories. |

| Starter Motor | Engages the engine to begin the combustion process. |

| Alternator | Generates electricity to recharge the battery and power the electrical system. |

| Ignition Coil | Transforms battery voltage into a high voltage for spark plug ignition. |

| Fuse | Protects the electrical system from overloads by breaking the circuit. |

Diagnostic Techniques

Accurate diagnostics can save time and resources. Employ the following techniques to identify issues:

- Visual Inspection: Check for frayed wires, loose connections, and corrosion.

- Multimeter Testing: Measure voltage, continuity, and resistance to assess component functionality.

- Observation of Symptoms: Note any irregularities such as dim lights or intermittent starting issues.

Implementing these practices will enhance your ability to maintain and troubleshoot electrical systems effectively.

Transmissions: Repair and Maintenance

Effective performance of any machinery relies heavily on its transmission system. This component is crucial for converting engine power into movement, ensuring smooth operation and optimal efficiency. Proper care and timely interventions can greatly extend the lifespan of this system, ultimately leading to better functionality and reduced costs over time.

Common Issues

Several problems can arise within the transmission, affecting overall performance. Recognizing these issues early is essential for maintaining functionality. Common concerns include:

- Fluid leaks

- Strange noises during operation

- Difficulty in shifting gears

- Unresponsive controls

Maintenance Tips

Regular upkeep is key to preventing significant issues. Here are some important maintenance practices:

- Check fluid levels frequently and top up as necessary.

- Inspect for leaks and address them promptly.

- Replace filters according to the manufacturer’s guidelines.

- Conduct routine inspections for wear and tear on components.

- Keep the transmission clean to prevent debris accumulation.

By adhering to these maintenance strategies, operators can ensure that the transmission system operates smoothly and efficiently for years to come.

Seasonal Care for Lawn Equipment

Maintaining outdoor machinery is essential for optimal performance throughout the year. Seasonal care ensures that your tools are ready to tackle various tasks, enhancing their longevity and efficiency. Regular upkeep not only improves functionality but also prevents costly repairs in the long run.

Spring Preparation

- Inspect and clean all equipment.

- Sharpen blades to ensure a clean cut.

- Check fuel systems and replace old fuel.

- Examine belts and cables for wear and tear.

Fall Maintenance

- Thoroughly clean the machines to remove debris.

- Change oil and replace filters.

- Store equipment in a dry, protected space.

- Perform any necessary repairs before storage.

When to Seek Professional Help

Determining when to consult an expert can be crucial for maintaining your equipment effectively. While many issues can be addressed with a bit of knowledge and the right tools, some problems require specialized skills and experience. Recognizing the signs that indicate the need for professional assistance can save time, money, and prevent further complications.

Signs That Indicate Professional Assistance is Needed

- Persistent issues that do not resolve after basic troubleshooting.

- Unusual noises or vibrations during operation that were not present before.

- Frequent breakdowns despite regular maintenance.

- Difficulty in understanding the cause of a malfunction.

- Complex systems or components that require specialized knowledge.

Benefits of Consulting an Expert

- Access to advanced diagnostic tools that can identify problems accurately.

- Expertise in handling intricate repairs that may be outside your skill set.

- Potential to extend the lifespan of your equipment through proper care.

- Peace of mind knowing that repairs are conducted correctly.

Resources for DIY Enthusiasts

For those who enjoy tackling projects on their own, a wealth of materials and platforms exists to enhance skills and knowledge. Whether it’s maintenance or upgrades, the right tools and information can empower individuals to achieve satisfying results.

Online Platforms

- YouTube Tutorials

- Dedicated DIY Forums

- Instructional Websites

Books and Guides

- Comprehensive Guides on Equipment Maintenance

- Handbooks for Seasonal Upkeep

- Resourceful DIY Manuals