The longevity and performance of a beloved chainsaw can significantly depend on its upkeep and servicing. This article delves into essential practices and insights to ensure that your trusted cutting tool remains in peak condition. Understanding the intricacies of its design and functionality is crucial for any owner looking to maintain optimal efficiency.

Within these guidelines, you’ll find a comprehensive overview of troubleshooting common issues, conducting routine inspections, and performing necessary adjustments. Whether you’re an experienced operator or a newcomer, familiarizing yourself with these procedures will empower you to address problems confidently and enhance the overall lifespan of your equipment.

By following the outlined steps, you will not only enhance the performance of your machine but also cultivate a deeper appreciation for its mechanics. Embracing regular maintenance can lead to a safer and more enjoyable cutting experience, ultimately making your outdoor projects more efficient and rewarding.

Understanding Stihl 045 AV Chainsaw

The chainsaw in question is a powerful and reliable tool, known for its durability and efficiency. This model is designed for both professional users and enthusiasts, making it a versatile option for a range of cutting tasks. Understanding its components and functionalities is essential for optimal performance and longevity.

Key Features and Benefits

This cutting instrument boasts an impressive engine that provides substantial power, enabling users to tackle tough jobs with ease. The lightweight design enhances maneuverability, while the advanced vibration-damping system ensures comfort during extended use. Such features contribute to improved safety and overall user experience.

Maintenance Essentials

Regular upkeep is crucial for maintaining peak performance. Users should familiarize themselves with essential care routines, such as cleaning the air filter and checking the chain tension. Proper lubrication of moving parts is also vital to prevent wear and tear. By adhering to these guidelines, users can extend the lifespan of their tool significantly.

In conclusion, gaining a comprehensive understanding of this chainsaw’s features and maintenance needs is fundamental for anyone looking to maximize its capabilities and enjoy a seamless cutting experience.

Common Issues with Stihl 045 AV

When it comes to outdoor power tools, certain problems frequently arise that can hinder performance. Understanding these common malfunctions is crucial for maintenance and longevity, ensuring that users can efficiently manage their tasks without interruption.

Engine Difficulties

One prevalent concern is engine starting issues. Factors such as fuel quality, spark plug condition, and carburetor settings often contribute to difficulties. Regular checks and timely replacements can mitigate these troubles.

Chain and Bar Problems

Another common area for malfunction lies within the cutting mechanism. Chain derailment or dullness can drastically affect cutting efficiency. It is essential to maintain proper tension and sharpness for optimal performance.

Tools Required for Repair

When tackling maintenance tasks for outdoor power equipment, having the right set of instruments is essential for achieving efficient and effective results. Proper tools not only facilitate the process but also ensure safety and precision during disassembly and reassembly.

For most tasks, a basic tool kit will suffice. This typically includes items such as screwdrivers (both flat and Phillips), wrenches, and pliers. Additionally, a socket set can be invaluable for reaching hard-to-access fasteners.

Some more specialized jobs may require specific equipment. For example, torque wrenches are crucial for ensuring that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening. Furthermore, a fuel line tool may be necessary for working with fuel systems.

Lastly, don’t forget the importance of cleaning supplies. A good brush set, compressed air, and cleaning solvents will help maintain components in optimal condition, extending the lifespan of the machinery.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring your equipment operates smoothly and efficiently. Regular upkeep not only extends the lifespan of your tool but also enhances its performance.

Essential Tools Needed

- Wrench set

- Screwdriver

- Fuel mixture

- Cleaning brush

- Protective gloves

Maintenance Steps

- Begin by disconnecting the spark plug to ensure safety.

- Clean the exterior using a brush to remove debris.

- Inspect the air filter and replace if necessary.

- Check the fuel lines for leaks or wear.

- Replace the spark plug if it shows signs of damage.

- Ensure the chain is properly tensioned and lubricated.

- Test the tool by reconnecting the spark plug and running it briefly.

Replacing the Chainsaw Chain

Changing the chain on a cutting tool is an essential maintenance task that ensures optimal performance and safety. Over time, chains can wear out or become damaged, affecting the efficiency of the machine. Regularly inspecting and replacing the chain not only enhances cutting precision but also prolongs the lifespan of the equipment.

Tools Needed

Before beginning the replacement process, gather the necessary tools. You will typically need a wrench for loosening bolts, a chain tensioning tool, and safety gloves to protect your hands. Having these items on hand will facilitate a smooth and efficient replacement procedure.

Steps to Replace the Chain

Start by ensuring the tool is powered off and disconnecting the spark plug for safety. Next, locate the chain tensioning mechanism and loosen it to relieve tension on the current chain. Carefully remove the old chain from the guide bar, making sure to note its orientation for the new chain. Position the new chain around the bar, ensuring it fits properly in the sprocket. Finally, adjust the tension according to the manufacturer’s specifications and securely fasten all components before testing the tool for functionality.

How to Clean the Air Filter

Maintaining optimal performance of your power equipment requires regular attention to its components. One crucial aspect of upkeep is ensuring the air filtration system remains free of debris and obstructions. A clean air filter promotes efficient engine operation and prolongs the lifespan of your machinery.

Steps for Cleaning the Air Filter

Begin by gathering the necessary tools: a clean cloth, a brush with soft bristles, and mild detergent. First, remove the air filter from its housing, taking care to note its orientation for reinstallation. Gently tap the filter to dislodge any loose dirt and debris. For a more thorough clean, use the brush to sweep away particles, ensuring that you do not damage the filter material.

Once the bulk of the dirt is removed, wash the filter in warm, soapy water. Rinse thoroughly to eliminate any detergent residue. Allow the filter to air dry completely before reassembling it in its designated place. Regular cleaning of the air filter can significantly enhance the efficiency of your engine.

When to Replace the Air Filter

While cleaning can extend the life of your air filter, it is important to recognize when replacement is necessary. If the filter shows signs of excessive wear, such as tears or significant discoloration, it is time to invest in a new one. Regular inspection and timely replacement will help maintain the performance and reliability of your equipment.

Fuel System Troubleshooting Tips

Ensuring optimal performance of your equipment requires a thorough understanding of its fuel system. Issues related to fuel delivery can lead to operational inefficiencies and decreased reliability. This section provides valuable insights to identify and resolve common fuel-related problems, enhancing the overall functionality of your machinery.

Identifying Common Symptoms

Start by observing the behavior of the engine. If it experiences difficulty starting, stalling, or uneven acceleration, these may indicate fuel flow issues. Inspect the fuel lines for any signs of cracks, blockages, or leaks that could disrupt the flow. Additionally, consider the condition of the fuel itself; old or contaminated fuel can significantly impact performance.

Testing Fuel Components

Once you have identified potential symptoms, focus on the individual components of the fuel system. Check the fuel filter for clogs and replace it if necessary. Next, examine the fuel pump to ensure it is operating correctly; listen for unusual sounds that could signal malfunction. Finally, evaluate the carburetor for any deposits or obstructions that could hinder fuel delivery. Regular maintenance and inspection of these components are crucial for preventing future issues.

Inspecting and Replacing the Spark Plug

Regular examination and substitution of the ignition component are essential for optimal engine performance. This part plays a crucial role in initiating combustion, ensuring that your equipment runs smoothly and efficiently. Over time, wear and deposits can hinder its functionality, leading to poor starting and irregular operation.

To begin, gather the necessary tools: a socket wrench, gap gauge, and a replacement component if needed. First, disconnect the spark plug wire to prevent accidental ignition. Next, use the socket wrench to carefully remove the component from the engine. Inspect it for signs of damage or excessive wear, such as carbon buildup or a worn electrode. A healthy part typically shows a clean appearance with minimal deposits.

If the inspection reveals significant deterioration, it’s time for a replacement. Choose a component that matches the specified type for your engine. Before installation, check the gap using the gap gauge; adjust it if necessary to ensure proper ignition timing. Once prepared, install the new component securely and reconnect the wire. This simple maintenance task can significantly enhance engine reliability and performance.

Adjusting Carburetor Settings

Proper tuning of the fuel-air mixture is essential for optimal engine performance. This process involves fine-tuning the carburetor to ensure that the engine receives the correct amount of fuel relative to the air intake. Achieving the right balance not only enhances efficiency but also prolongs the life of the engine components.

Understanding the Adjustment Screws

Typically, there are three main screws that govern the operation of the carburetor: the idle, low-speed, and high-speed adjustment screws. The idle screw controls the engine’s idle speed, while the low-speed screw affects performance at lower RPMs. The high-speed screw plays a critical role in engine performance at full throttle. Adjusting these screws correctly is crucial for smooth operation.

Steps for Adjustment

To begin the adjustment process, ensure the engine is warm. Start with the idle screw; turn it clockwise to increase the idle speed and counterclockwise to decrease it. Once the idle speed is set, proceed to the low-speed screw, making small adjustments while listening for any changes in engine behavior. Finally, adjust the high-speed screw while the engine is under load, ensuring optimal power without stalling.

Regular maintenance and careful adjustments can significantly enhance performance and reliability. Always refer to specific guidelines to ensure proper tuning and to avoid potential damage.

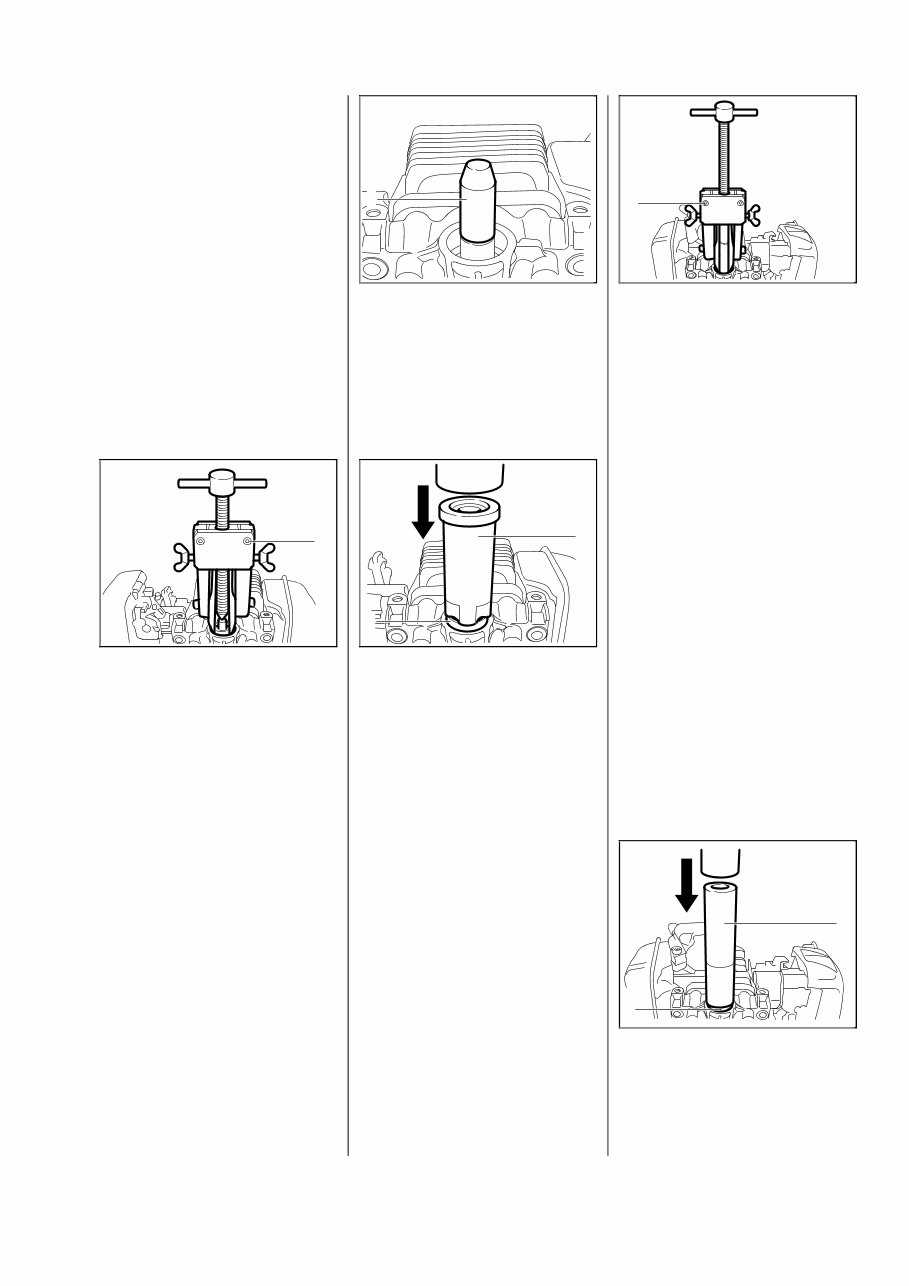

Repairing the Starting Mechanism

The starting system is a crucial component that ensures your equipment functions smoothly. Issues with this mechanism can lead to frustrating experiences during operation. Understanding how to troubleshoot and fix these problems can enhance performance and longevity.

Identifying Common Issues

Common problems include difficulty in pulling the starter cord, a malfunctioning rewind spring, or a worn-out pulley. Begin by inspecting the components for any signs of wear or damage. Ensure that the cord is not frayed and that the recoil assembly is properly aligned. Identifying the root cause is essential before proceeding with any fixes.

Step-by-Step Restoration

To restore the functionality, start by disassembling the starting unit carefully. Clean all parts thoroughly to remove debris. Replace any damaged components, ensuring they fit correctly. Reassemble the unit, making sure the spring tension is appropriate and the cord retracts smoothly. Testing the mechanism before final assembly can save time and ensure reliability.

Understanding Safety Features

When operating powerful machinery, awareness of safety mechanisms is crucial. These features are designed to protect users from potential hazards and ensure a safer working environment. By understanding how these elements function, users can minimize risks and enhance their overall experience.

Safety mechanisms often include protective barriers, automatic shut-off systems, and ergonomic designs that reduce strain. Each of these components plays a vital role in preventing accidents and injuries, providing a layer of security that is essential for effective operation.

Moreover, user education about safety features enhances confidence and competence. Familiarity with operational guidelines and emergency protocols ensures that individuals can react appropriately in critical situations, making the use of such equipment not only efficient but also safe.

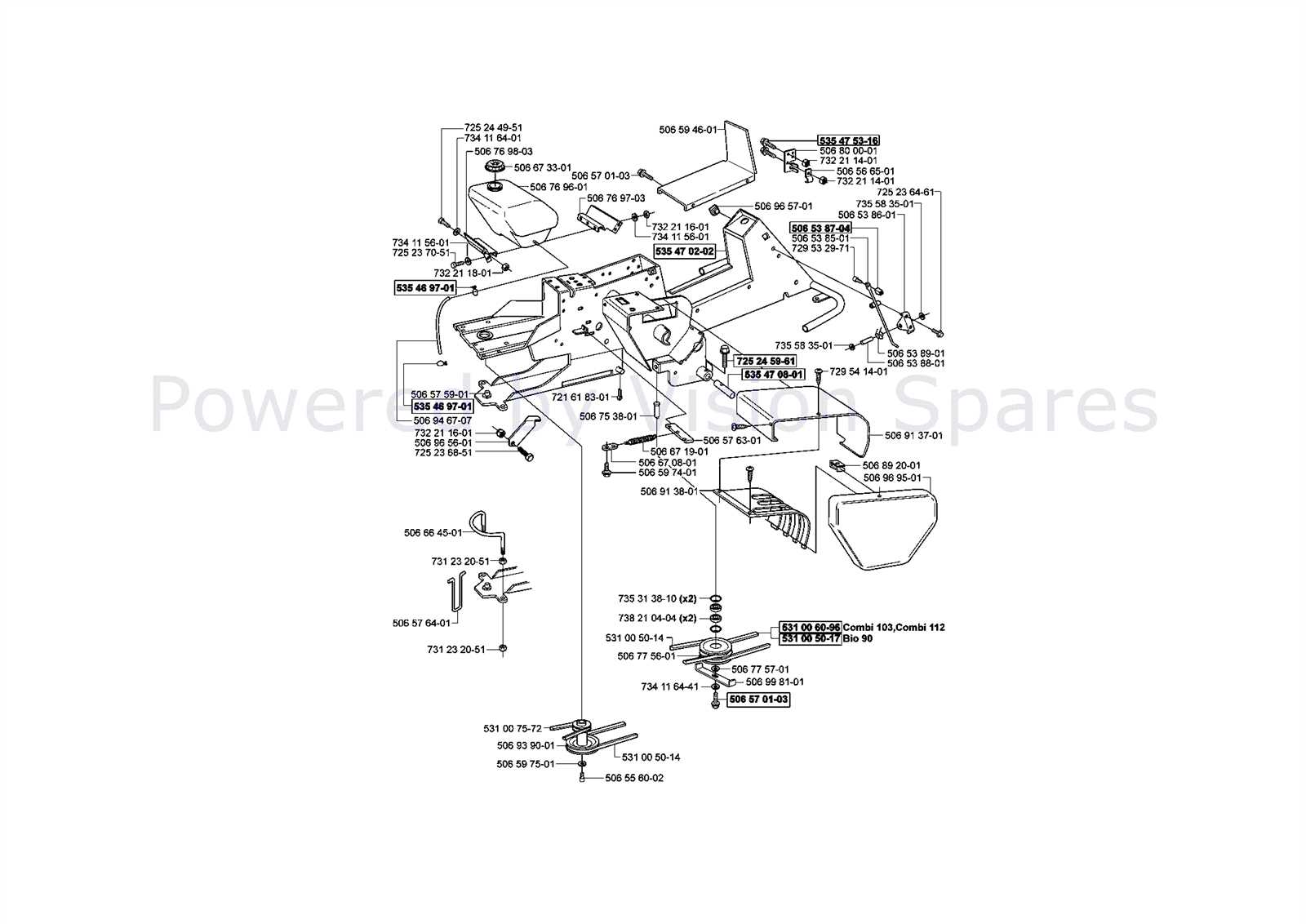

Where to Find Replacement Parts

Finding suitable components for your equipment can greatly enhance its performance and longevity. Whether you are a professional or a DIY enthusiast, knowing where to source these items is crucial for effective maintenance. This guide will highlight various options available for acquiring the necessary pieces.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers offer genuine components, ensuring compatibility and reliability for your equipment. |

| Online Marketplaces | Websites like eBay and Amazon provide a vast selection of parts, often at competitive prices, allowing for convenient shopping from home. |

| Local Repair Shops | Local mechanics or repair facilities may have parts in stock or can order them for you, often with the added benefit of expert advice. |

| Aftermarket Suppliers | These companies produce compatible components that may offer a cost-effective alternative, though quality can vary. |

| Online Forums and Communities | Engaging with other users in forums can provide insights on sourcing rare parts and recommendations for reliable sellers. |