When it comes to maintaining outdoor power tools, understanding their intricate workings can greatly enhance longevity and performance. This section serves as an invaluable resource for those seeking to keep their machinery in top condition, ensuring that they operate smoothly and efficiently.

Regular upkeep not only prevents common issues but also helps in identifying potential problems before they escalate. This guide provides essential insights into the disassembly and assembly processes, as well as troubleshooting techniques that can be applied with confidence.

Moreover, having a thorough understanding of your equipment can save both time and money. Whether you are a seasoned professional or a weekend warrior, the knowledge contained herein will empower you to tackle various challenges and maintain optimal functionality.

Overview of Stihl 066 Chainsaw

This powerful tool is designed for heavy-duty cutting tasks, making it a popular choice among professionals and enthusiasts alike. With its robust construction and advanced features, it offers reliable performance in various woodcutting applications. Users appreciate its efficiency, allowing for quicker and cleaner cuts, even in dense materials.

Key Features

Equipped with a high-capacity engine, this device delivers impressive power while maintaining fuel efficiency. The ergonomic design ensures comfort during prolonged use, reducing fatigue. Additionally, the easy-access air filter and simplified maintenance procedures contribute to its appeal, allowing users to focus more on their tasks and less on upkeep.

Applications

This chainsaw excels in a variety of environments, from logging and tree trimming to land clearing. Its versatility enables it to handle different types of cutting, whether it’s felling large trees or pruning smaller branches. As a result, it has become a trusted tool for both commercial users and dedicated hobbyists.

Common Issues with Stihl 066

When operating powerful chainsaws, users may encounter various challenges that can impact performance and efficiency. Understanding these frequent problems is essential for maintaining optimal functionality and ensuring safety during use.

Fuel-related Problems: One of the most common issues is related to fuel quality. Using old or contaminated fuel can lead to starting difficulties and erratic operation. It’s vital to use fresh, clean fuel mixed with the appropriate oil to prevent engine issues.

Starting Difficulties: Users often report challenges when attempting to start their machine. This can stem from several factors, including a faulty spark plug, air leaks, or improper choke settings. Regular inspection and maintenance can help mitigate these issues.

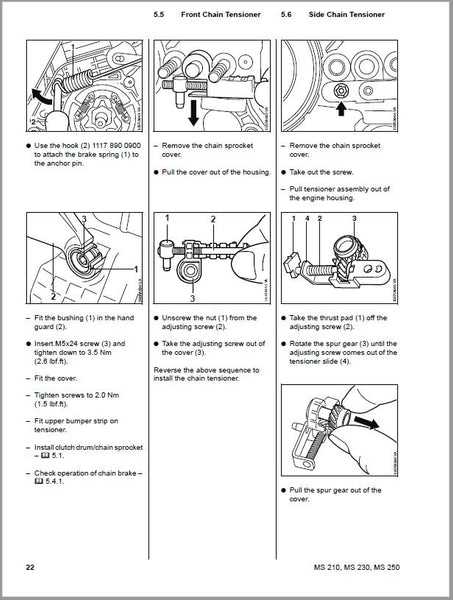

Chain Tension: Another prevalent concern is incorrect chain tension. A chain that is too loose may come off during operation, while one that is too tight can lead to premature wear or damage. It’s important to regularly check and adjust the tension according to the manufacturer’s specifications.

Overheating: Excessive heat buildup can result from prolonged use without adequate cooling. Signs of overheating include smoke or unusual smells. Ensuring proper ventilation and taking breaks during operation can help prevent this issue.

Bar and Chain Wear: Over time, the cutting bar and chain may experience wear and tear, leading to reduced cutting efficiency. Regularly inspecting these components and replacing them as needed is crucial for maintaining performance.

Essential Tools for Repairs

Having the right instruments is crucial for effectively maintaining and restoring equipment. The following tools will ensure that you can perform tasks efficiently, prolonging the lifespan of your machinery. Each tool serves a specific purpose, making your work smoother and more precise.

Wrenches are fundamental for loosening and tightening bolts. A set of both standard and metric sizes will allow for versatility in various situations. It’s important to choose high-quality materials to withstand frequent use.

Screwdrivers come in various shapes and sizes, enabling you to tackle different types of screws. A reliable set should include both flathead and Phillips options, providing adaptability for any project.

Pliers are indispensable for gripping, twisting, and cutting wires or small components. Needle-nose pliers, in particular, can reach tight spots that larger tools cannot.

Torque wrench is essential for ensuring that fasteners are tightened to the manufacturer’s specifications. This tool prevents damage caused by over-tightening and ensures safety during operation.

Cleaners and lubricants are vital for maintaining the efficiency of moving parts. Regular application of appropriate products helps reduce friction and wear, ensuring smoother operation.

Equipping yourself with these necessary instruments will not only facilitate repairs but also enhance your understanding of the equipment’s inner workings. By investing in quality tools, you are committing to better maintenance practices and improved performance.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to addressing common issues encountered with a specific type of outdoor power equipment. By following these systematic instructions, you can effectively troubleshoot and resolve various malfunctions, ensuring optimal performance and longevity of the device.

Identifying the Problem

Begin by carefully assessing the symptoms your equipment is exhibiting. Listen for unusual noises, observe any performance irregularities, and check for visible signs of wear or damage. This initial diagnosis is crucial in determining the necessary actions to take.

Disassembly and Inspection

Once the issue is identified, proceed with the careful disassembly of the unit. Make sure to keep track of all components and fasteners. Inspect each part for any signs of damage or wear. Pay close attention to critical areas such as the ignition system, fuel lines, and air filters. Replace any faulty components with high-quality substitutes to maintain efficiency.

After addressing all necessary repairs, reassemble the equipment and conduct a thorough test to ensure everything is functioning correctly. Regular maintenance and timely interventions can greatly extend the life of your outdoor power equipment.

Understanding the Engine Components

Grasping the intricacies of an engine’s architecture is essential for effective maintenance and optimal performance. Each part plays a vital role, contributing to the overall functionality and efficiency of the machinery. Familiarity with these components not only aids in troubleshooting but also enhances the user’s ability to make informed decisions during servicing.

The core of any engine is its power unit, which is responsible for converting fuel into mechanical energy. This process involves several critical parts, including the cylinder, piston, and crankshaft, which work in unison to generate power. The cylinder houses the piston, which moves up and down to create the necessary compression for combustion.

In addition to the power unit, the fuel system is crucial for delivering the right mixture of air and fuel to the engine. Components such as the carburetor or fuel injector ensure that the engine receives an optimal blend for efficient combustion. Moreover, the ignition system ignites the fuel-air mixture, relying on spark plugs or ignition coils to produce the necessary spark.

Cooling and lubrication systems also play indispensable roles in maintaining engine health. The cooling system prevents overheating, while the lubrication system minimizes friction between moving parts, thereby prolonging the lifespan of the engine. Understanding these components helps users effectively address any issues that may arise during operation.

Maintaining Your Stihl 066

Proper upkeep of your power tool is essential for optimal performance and longevity. Regular maintenance not only ensures efficiency but also enhances safety during operation. Following a systematic approach to care will help you avoid common issues and extend the life of your equipment.

Here are some key maintenance tasks to keep in mind:

| Task | Frequency | Description |

|---|---|---|

| Air Filter Cleaning | Every 5 hours | Remove and clean the filter to prevent dust buildup, ensuring proper airflow. |

| Chain Lubrication | Before each use | Apply oil to the chain to reduce friction and wear during operation. |

| Spark Plug Inspection | Every 25 hours | Check for wear and replace if necessary to ensure reliable ignition. |

| Fuel System Check | Every 10 hours | Inspect fuel lines and tank for leaks or damage; replace old fuel regularly. |

| Blade Tension Adjustment | Every 5 hours | Ensure the cutting blade is properly tensioned for safe and effective use. |

Consistent attention to these tasks will not only maintain functionality but will also provide peace of mind during your projects. Always refer to specific guidelines for detailed procedures related to your equipment.

Safety Precautions During Repairs

When undertaking maintenance tasks on mechanical equipment, ensuring personal safety and proper handling of tools is essential. This section outlines key guidelines to minimize risks and enhance overall safety during the process.

Personal Protective Equipment

Utilizing appropriate protective gear is crucial. Consider the following items:

- Safety goggles to protect eyes from debris.

- Gloves to shield hands from sharp edges and chemicals.

- Hearing protection when operating loud machinery.

- Steel-toed boots to guard against falling objects.

Work Environment Safety

Maintaining a safe workspace can prevent accidents and injuries. Keep these practices in mind:

- Ensure the area is well-lit to avoid mistakes.

- Keep the workspace tidy to prevent tripping hazards.

- Organize tools and equipment for easy access.

- Be aware of your surroundings and any potential hazards.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues is crucial for the optimal performance of any power tool. When encountering difficulties related to power supply, ignition, or operational functionality, a systematic approach can help pinpoint the underlying cause. This section will guide you through common electrical malfunctions and provide methods for effective diagnosis and correction.

1. No Power: If the tool does not turn on, start by checking the power source. Ensure that the battery is charged or the tool is properly plugged in. Inspect the power cord for any signs of damage. If everything appears intact, examine the internal fuse or circuit breaker for any tripped switches.

2. Weak Spark: In cases where the engine starts but runs poorly, the ignition system may be at fault. Inspect the spark plug for wear or carbon buildup, which can hinder performance. Replacing the spark plug or cleaning it may resolve the issue. Additionally, check the ignition coil to ensure it is functioning correctly.

3. Overheating: If the unit becomes excessively hot during operation, this could indicate an electrical short or a malfunctioning component. Ensure that all connections are secure and that there is no debris obstructing airflow. If overheating persists, further investigation of the wiring and internal parts is necessary.

4. Intermittent Functionality: Tools that operate sporadically can be particularly frustrating. This may be a result of loose connections or damaged wires. Conduct a thorough inspection of the electrical system, focusing on connectors and terminals for any signs of corrosion or wear.

By following these troubleshooting steps, users can effectively address and resolve electrical issues, ensuring their tools remain reliable and efficient in performance.

Replacing Chains and Bars

Maintaining optimal performance in cutting equipment involves regular updates to the chain and bar. These components are essential for ensuring efficiency and safety during operation. Knowing when and how to replace them can significantly extend the life of your tools.

Here are the steps to effectively change your chain and bar:

- Ensure the tool is powered off and disconnected from any power source.

- Use appropriate tools to loosen the bar nuts.

- Remove the old chain from the bar.

- Detach the bar from the drive assembly.

To install the new components:

- Position the new bar on the drive assembly.

- Thread the new chain around the bar, ensuring proper orientation.

- Tighten the bar nuts securely.

- Check the tension of the chain and make adjustments if necessary.

Regularly inspecting and replacing these parts will help maintain cutting efficiency and enhance safety during use.

Fuel System Troubleshooting Tips

Effective maintenance of the fuel system is crucial for optimal performance and longevity of your equipment. This section offers essential insights into identifying common issues and their solutions, ensuring that your machine runs smoothly without interruption.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Fuel Leak | Visible fuel puddles, strong odor | Inspect fuel lines for cracks; replace damaged hoses. |

| Hard Starting | Engine cranks but doesn’t start | Check for fuel blockage; clean or replace the fuel filter. |

| Engine Stalling | Engine shuts off unexpectedly | Examine fuel cap for proper ventilation; ensure fuel is fresh. |

| Poor Performance | Loss of power during operation | Adjust the carburetor settings; inspect the spark plug. |

| Excessive Smoke | Black or white smoke from exhaust | Check for improper fuel mixture; adjust as needed. |

Regular inspection and timely intervention can help prevent minor issues from escalating into significant problems. Keeping the fuel system in good condition is essential for maintaining peak performance.

Where to Find Replacement Parts

Locating quality components for your equipment is crucial for maintaining optimal performance. Whether you’re in need of specific elements for repairs or general upkeep, various sources offer a wide range of options to suit your needs. Understanding where to look can save you time and ensure you obtain the right items for your machinery.

Authorized Dealers

One of the most reliable sources for parts is through authorized distributors. They typically offer genuine components, ensuring compatibility and reliability. Here’s what you can expect:

| Benefits | Considerations |

|---|---|

| Genuine quality | Potentially higher prices |

| Expert assistance | Limited stock in some regions |

| Warranty coverage | Availability may vary |

Online Marketplaces

Another great option is online platforms that specialize in aftermarket components. These sites often provide a vast selection and competitive pricing. Keep the following in mind:

| Benefits | Considerations |

|---|---|

| Wide variety | Quality can vary |

| Convenience of shopping | Shipping times may be longer |

| User reviews for guidance | Risk of counterfeit products |

Expert Tips for DIY Repairs

When tackling maintenance and troubleshooting tasks on your outdoor power equipment, having a few expert insights can make the process smoother and more effective. Understanding the fundamentals of how your machinery operates will not only help you identify issues but also empower you to perform necessary adjustments confidently.

Preparation is Key

- Gather all necessary tools before starting the job. This includes wrenches, screwdrivers, and any specialized instruments.

- Read through the guidelines or documentation related to your equipment to familiarize yourself with its components and functions.

- Set up a clean, well-lit workspace to minimize the risk of losing small parts and ensure safety during the process.

Troubleshooting Techniques

- Start with a visual inspection. Look for signs of wear, damage, or loose connections.

- Test components systematically. Isolate each part and check its performance to pinpoint the source of the problem.

- Keep a notebook to track issues and solutions, which can be helpful for future reference and maintenance.