Understanding the intricacies of machinery operation and upkeep is essential for any equipment owner. Proper knowledge enables individuals to address issues effectively, ensuring optimal performance and longevity of their assets. This section delves into the essential aspects of maintaining your machinery, providing insights into common challenges and their solutions.

Equipping yourself with a detailed understanding of the technical specifications and operational guidelines is crucial. Not only does this knowledge empower you to handle minor adjustments and repairs, but it also fosters a proactive approach to potential issues. By familiarizing yourself with the essential components and mechanisms, you can significantly reduce downtime and enhance efficiency.

This resource aims to equip you with valuable information, practical tips, and systematic procedures. Whether you are a seasoned operator or new to the field, you will find practical insights to support your journey. With the right guidance, you can tackle any mechanical concerns with confidence and skill.

Understanding Mahindra 6000 Mechanics

Grasping the intricacies of agricultural machinery involves delving into the fundamental principles that govern their operation. This section focuses on the essential components and systems that contribute to the efficiency and functionality of a specific model. By familiarizing oneself with the mechanical structure, users can enhance performance and prolong the lifespan of their equipment.

Engine Dynamics play a crucial role in the overall performance of the machine. Understanding the combustion process, fuel delivery, and cooling mechanisms is vital for maintaining optimal operation. Regular monitoring of these systems can prevent significant malfunctions and ensure smooth performance in various agricultural tasks.

Transmission Systems are equally important, as they facilitate the transfer of power from the engine to the wheels. Familiarity with gear ratios and differential operations allows operators to make informed decisions regarding speed and torque, adapting to different terrain conditions effectively.

Additionally, the suspension and steering systems are designed to enhance maneuverability and comfort. A comprehensive understanding of these components ensures that the vehicle can navigate challenging landscapes while maintaining stability and control.

Lastly, maintenance practices are fundamental in preventing wear and tear. Regular inspections and timely servicing of key parts help avert costly repairs and downtime, ensuring that the equipment remains a reliable asset for agricultural operations.

Common Issues with Mahindra 6000

When it comes to agricultural machinery, certain challenges frequently arise that can affect performance and efficiency. Understanding these prevalent concerns can aid in maintaining optimal functionality and prolonging the lifespan of the equipment.

Engine Performance is often a significant area of concern. Users may notice irregularities such as stalling, poor acceleration, or unusual noises. Regular checks of fuel quality and air filters can help mitigate these issues.

Hydraulic System failures are another common problem. Operators may encounter difficulties in lifting or lowering attachments, which can stem from leaks or worn seals. Routine inspections can help identify these problems early.

Electrical Failures can lead to starting issues or malfunctioning lights. It’s essential to check battery connections and wiring for any signs of wear or corrosion to prevent breakdowns.

Transmission Issues may manifest as slipping gears or difficulty shifting. Ensuring that transmission fluid is at the appropriate level and in good condition can reduce the likelihood of these complications.

Addressing these typical concerns with proactive maintenance and timely interventions can significantly enhance the reliability and productivity of the machinery.

Essential Tools for Repairs

When tackling mechanical tasks, having the right equipment at your disposal is crucial for achieving successful outcomes. This section outlines the fundamental instruments and devices that facilitate efficient maintenance and troubleshooting. Proper tools not only enhance productivity but also ensure that tasks are completed safely and effectively.

First and foremost, a comprehensive set of hand tools is indispensable. Wrenches, pliers, and screwdrivers of various sizes allow for precise adjustments and fittings. Additionally, socket sets are vital for accessing hard-to-reach areas, providing versatility for different applications.

Power tools also play a significant role in streamlining work processes. Drills, impact wrenches, and grinders can significantly reduce manual effort and save time. When selecting power tools, consider the specific requirements of your tasks to ensure compatibility and efficiency.

Furthermore, measuring devices such as calipers and torque wrenches are essential for accuracy. These instruments help in ensuring that all components are fitted correctly and securely, preventing future complications.

Lastly, safety equipment should never be overlooked. Gloves, goggles, and ear protection are vital to safeguard against potential hazards during maintenance work. Equipping yourself with the appropriate safety gear is as important as having the right tools for the job.

Step-by-Step Maintenance Guide

Proper upkeep of machinery is essential to ensure optimal performance and longevity. This guide provides a systematic approach to maintenance tasks, helping you maintain your equipment effectively. Following these steps will prevent unexpected breakdowns and extend the lifespan of your machinery.

-

Inspect Fluid Levels

- Check engine oil, coolant, and hydraulic fluid levels.

- Top off any fluids as necessary.

- Replace fluids according to the schedule outlined in your documentation.

-

Examine Filters

- Inspect air and fuel filters for clogs and dirt.

- Clean or replace filters based on their condition.

- Ensure that all seals are intact to prevent contamination.

-

Check Belts and Hoses

- Look for signs of wear, fraying, or cracks.

- Adjust tension where applicable and replace damaged components.

- Ensure that all connections are secure and leak-free.

-

Inspect Tires and Tracks

- Check tire pressure and tread depth.

- Look for any signs of damage or uneven wear.

- For tracked vehicles, inspect for proper tension and wear.

-

Test Electrical System

- Check battery condition and connections.

- Inspect wiring for frays or corrosion.

- Ensure all lights and indicators function correctly.

-

Clean the Exterior

- Remove dirt and debris from the machine.

- Pay special attention to radiators and cooling vents.

- Apply protective coatings if necessary to prevent rust.

-

Schedule Professional Servicing

- Plan regular check-ups with a qualified technician.

- Keep a record of all maintenance performed.

- Stay informed about any manufacturer recalls or service bulletins.

Following these steps will help ensure that your equipment remains in peak condition. Consistent maintenance not only enhances performance but also reduces the risk of costly repairs in the future.

Engine Specifications and Troubleshooting

This section provides essential information about the power unit, including its technical characteristics and common issues that may arise during operation. Understanding these elements is crucial for maintaining optimal performance and ensuring longevity.

Technical Specifications

The engine typically features a robust design, characterized by its displacement, horsepower, and torque ratings. These specifications are vital for assessing compatibility with various attachments and ensuring efficient operation under varying loads. Key parameters also include fuel type, cooling system, and lubrication requirements, which all play a significant role in the engine’s functionality.

Common Issues and Solutions

Users may encounter several frequent problems, such as overheating, starting difficulties, and unusual noises. Identifying these symptoms early can prevent more severe damage. Regular checks of the cooling system, fuel filters, and electrical components can mitigate many common issues. When troubleshooting, always refer to the specifications to ensure that all adjustments and repairs are aligned with the manufacturer’s guidelines.

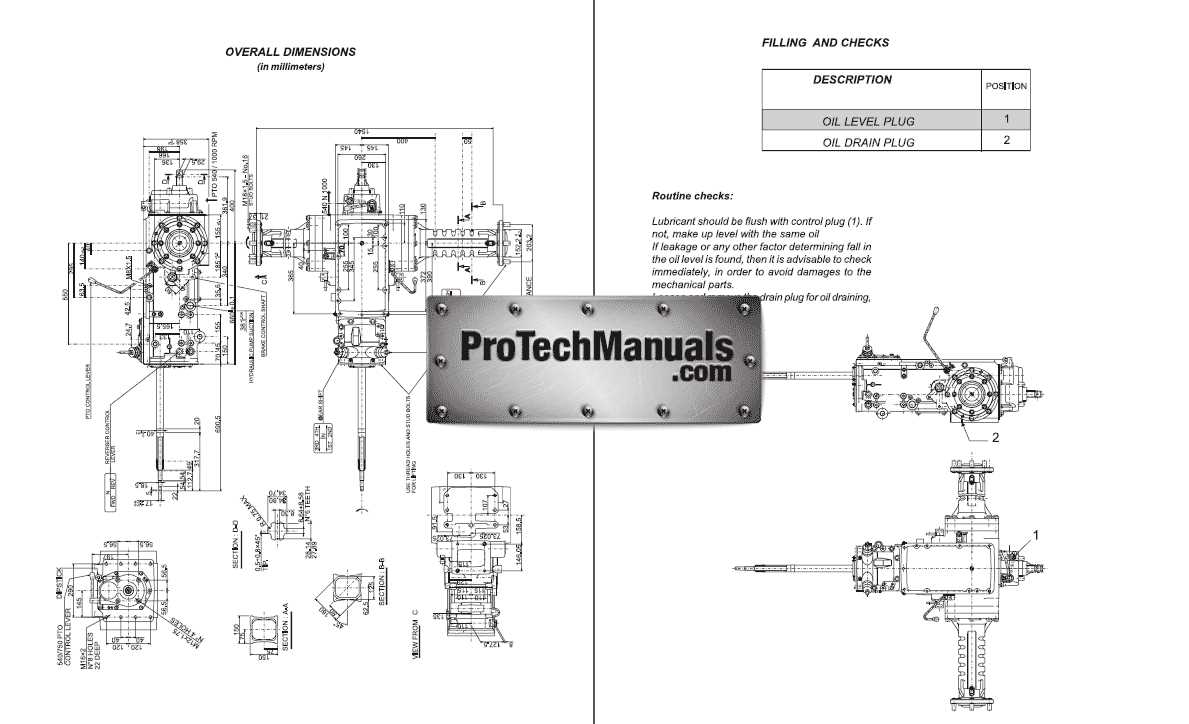

Hydraulic System Overview

The hydraulic system is a crucial component in various machinery, enabling powerful movements and operations through fluid dynamics. By utilizing pressurized fluid, it transforms mechanical energy into effective force, enhancing performance and efficiency in tasks requiring significant lifting or pushing power.

Key Components

Essential parts of the hydraulic system include the pump, cylinders, valves, and reservoir. The pump generates pressure, while the cylinders convert hydraulic energy into linear motion. Valves control the flow and direction of the fluid, ensuring the system operates smoothly and efficiently.

Operating Principles

Hydraulic systems operate on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted equally in all directions. This fundamental principle allows for the ultimate transfer of energy, making hydraulic systems highly effective for heavy-duty applications across various industries.

Transmission Care Tips

Maintaining the integrity of your vehicle’s transmission system is crucial for optimal performance and longevity. Proper care can prevent costly repairs and ensure smooth operation, enhancing your overall driving experience.

Here are some essential practices to keep your transmission in top condition:

- Regular Fluid Checks: Monitor the transmission fluid level and condition. Low or dirty fluid can lead to significant issues.

- Fluid Changes: Follow the manufacturer’s recommendations for fluid replacement intervals to ensure effective lubrication and cooling.

- Avoid Overheating: Keep an eye on the temperature gauge. Excess heat can damage the transmission components, so avoid heavy towing or stop-and-go traffic when possible.

Additionally, consider the following tips:

- Use Quality Fluids: Always opt for high-quality transmission fluid that meets the specifications outlined in your vehicle’s guidelines.

- Check for Leaks: Regularly inspect the ground where you park for any signs of fluid leaks, as this can indicate potential issues.

- Drive Smoothly: Avoid abrupt starts and stops. Gentle acceleration and deceleration help reduce strain on the transmission.

By implementing these straightforward maintenance practices, you can enhance the reliability and lifespan of your transmission system, ensuring a smooth ride for years to come.

Electrical System Diagnostics

The assessment of electrical systems is crucial for ensuring optimal performance and reliability. Proper evaluation helps identify issues that may impede functionality and can lead to larger problems if left unaddressed. This section outlines the key steps and considerations for effectively diagnosing electrical components.

Common symptoms indicating electrical issues may include:

- Inconsistent power supply

- Flickering lights

- Unresponsive controls

- Strange noises from electrical components

To initiate diagnostics, follow these essential steps:

- Visual Inspection: Examine wiring, connectors, and components for signs of wear, damage, or corrosion.

- Test Voltage: Use a multimeter to measure voltage levels at key points within the system.

- Check Continuity: Ensure that circuits are complete and functioning by testing continuity across connections.

- Assess Grounding: Verify that all grounding connections are secure and free of corrosion.

- Component Testing: Isolate and test individual components, such as relays, fuses, and switches, to confirm their operational status.

By adhering to these procedures, technicians can systematically identify and rectify electrical malfunctions, ensuring a reliable and efficient operation of the system.

Replacing Key Components

Maintaining optimal performance in machinery often requires the replacement of essential parts. This process not only ensures longevity but also enhances the overall efficiency of the equipment. Understanding the correct procedures and tools necessary for these replacements is crucial for achieving desired results.

Identifying Components for Replacement

Before beginning any replacement work, it is important to identify which components need attention. Common elements that may require changing include:

- Filters

- Belts

- Hoses

- Batteries

- Fluids

Steps for Component Replacement

Follow these steps to ensure a successful replacement process:

- Gather necessary tools and replacement parts.

- Disconnect power sources to avoid accidents.

- Carefully remove the old component.

- Install the new part, ensuring proper alignment and secure fit.

- Reconnect power sources and test the equipment.

By adhering to these guidelines, operators can effectively replace critical components, ensuring their machinery operates at peak performance.

Safety Precautions During Repairs

When conducting maintenance or troubleshooting on machinery, ensuring safety should be the top priority. Proper precautions help prevent accidents and injuries, allowing for a more efficient work environment. By adhering to recommended practices, individuals can significantly reduce risks associated with mechanical tasks.

Personal Protective Equipment (PPE)

Utilizing appropriate personal protective gear is essential. Always wear gloves to shield your hands from sharp edges and hazardous substances. Safety goggles protect your eyes from debris and chemicals, while ear protection is crucial when working with loud machinery. Ensure that your clothing is suitable for the task; loose garments can become entangled in moving parts.

Work Environment

Maintaining a clean and organized workspace is vital. Ensure that all tools are in good condition and easily accessible. Remove any unnecessary items that could pose tripping hazards. Adequate lighting is also important; poor visibility can lead to mistakes. Additionally, be aware of your surroundings and make sure that others are at a safe distance when performing any tasks that may involve heavy lifting or potential hazards.

Cost-effective Repair Solutions

Finding budget-friendly options for maintaining and restoring equipment can significantly enhance longevity and performance. By exploring various strategies and resources, owners can minimize expenses while ensuring their machinery operates efficiently. This section delves into practical approaches that can lead to substantial savings without compromising quality.

Utilizing Quality Aftermarket Parts

One effective method to reduce costs is to consider high-quality aftermarket components. These alternatives often provide comparable performance to original parts at a fraction of the price. Researching reliable suppliers and verifying the durability of these products can lead to smart investments that keep expenses in check.

DIY Maintenance Techniques

Embracing do-it-yourself maintenance can further cut down on service costs. Learning basic troubleshooting and maintenance techniques empowers owners to handle minor issues independently. Online resources, including instructional videos and forums, can offer valuable guidance, enabling individuals to tackle repairs confidently and efficiently.

When to Seek Professional Help

Recognizing when to turn to experts is crucial for maintaining the longevity and efficiency of your machinery. While many issues can be resolved independently, there are certain situations where professional intervention is necessary to prevent further complications or damage.

It’s important to consider several factors when deciding whether to consult a specialist. This includes the complexity of the problem, the tools required, and your own level of expertise. Below is a guide to help identify these situations.

| Situation | Action to Take |

|---|---|

| Complex mechanical issues | Consult a technician |

| Electrical malfunctions | Seek expert assistance |

| Lack of necessary tools | Hire a professional |

| Repeated failures | Request a diagnostic evaluation |

| Safety concerns | Prioritize professional help |

By staying vigilant and informed, you can make the best decisions for your equipment and ensure its optimal performance.

Long-term Maintenance Practices

Implementing effective long-term care strategies is essential for ensuring the longevity and optimal performance of machinery. Consistent attention to detail and adherence to established protocols can significantly reduce the likelihood of unexpected breakdowns and enhance operational efficiency. Below are some key practices to consider.

Routine Inspections

Regular assessments of equipment condition help identify potential issues before they escalate. It is advisable to:

- Conduct visual inspections for signs of wear or damage.

- Check fluid levels and look for leaks.

- Inspect belts and hoses for signs of deterioration.

- Test electrical systems and connections for reliability.

Scheduled Maintenance

Establishing a routine maintenance schedule ensures that all necessary tasks are completed on time. This should include:

- Changing oil and filters at specified intervals.

- Replacing worn components proactively.

- Calibrating systems for precise operation.

- Updating software and firmware as required.

By integrating these practices into a maintenance routine, users can significantly extend the life of their machinery and maintain peak performance levels.