Understanding how to address common issues and keep your appliance running smoothly can save time and reduce the need for professional assistance. This section provides an overview of strategies to identify and resolve operational challenges effectively. From general troubleshooting to specific care practices, this guide is crafted to help you maintain optimal performance.

Appliances are designed to handle a range of tasks, yet consistent use can lead to wear and occasional malfunctions. Knowing the essential components and common points of failure is key to efficient upkeep. Here, you will find step-by-step instructions on addressing these elements, covering everything from error signals to simple part replacements.

By following the practical advice provided, you can enhance the longevity and efficiency of your machine. Whether you’re a novice or have some experience with appliance upkeep, this resource aims to empower you with the knowledge to tackle everyday issues and maintain smooth operation for years to come.

Comprehensive Guide to Maytag Bravos XL Maintenance

Regular upkeep is essential for keeping your high-capacity laundry appliance operating smoothly and extending its longevity. By following simple maintenance steps, you can prevent common issues, enhance efficiency, and ensure dependable performance over time.

Cleaning and Care

One of the primary tasks in maintaining your washer involves periodic cleaning of key components. For instance, the drum and detergent dispenser should be cleaned every few months to prevent buildup and ensure optimal functionality. Run a cleaning cycle using hot water and an appliance-safe cleanser to remove residues that can affect the machine’s efficiency.

Inspecting Filters and Hoses

Filters and hoses should be checked regularly to prevent clogs and leaks. Remove and clean the filters in both the inlet and drainage systems to ensure uninterrupted water flow. Additionally, inspect hoses for signs of wear and replace any that appear cracked or damaged to prevent leaks or water pressure issues.

Maintaining Balance is also crucial. Make sure the washer remains level, as an uneven appliance may experience more wear and vibration. Use a leveling tool to adjust the feet as necessary. By following these steps, you’ll not only protect the appliance but also improve its performance over time.

Understanding Common Issues and Their Causes

Many large appliances, over time, encounter a variety of common performance issues. Recognizing these early can help in diagnosing and addressing minor concerns before they become costly repairs.

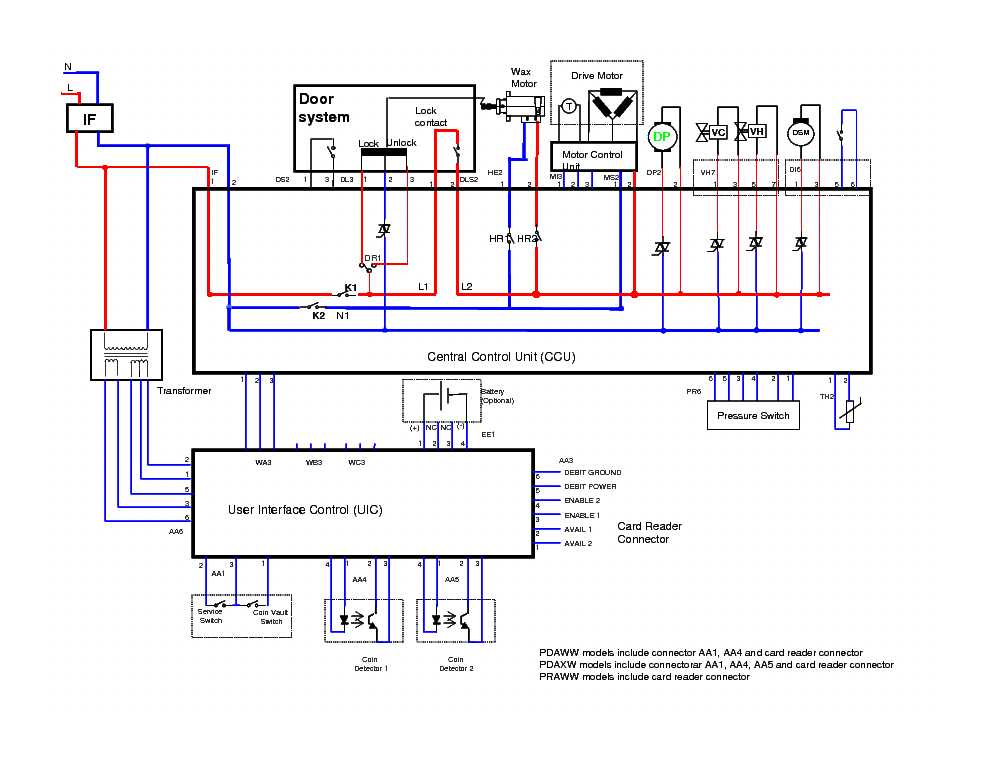

Power and Connectivity Problems: Appliances may sometimes experience interruptions in power supply or difficulty connecting to control systems. Such issues often arise due to loose wiring, worn-out power cables, or faults in the internal control board. Ensuring secure connections and testing the power source can help identify the root of these malfunctions.

Operational Noise and Vibrations: Unusual sounds and excessive vibrations can indicate imbalance or worn internal parts. This can result from overloaded loads, unbalanced installations, or components that have degraded over time. Regularly adjusting the load size and checking for even placement can reduce these disturbances.

Water and Temperature Concerns: Inconsistent water levels or temperature fluctuations are often due to blocked filters, malfunctioning thermostats, or clogged water inlet hoses. Keeping the filters clear and periodically examining hoses for obstructions can help maintain stable performance.

Performance and Efficiency Drop: When an appliance operates less efficiently, uses more energy, or doesn’t complete tasks as expected, it may indicate aging components or build-up inside the system. Routine maintenance, such as cleaning internal parts and inspecting belts or other key elements, can improve longevity and performance.

By familiarizing yourself with these typical issues and their causes, you ca

How to Troubleshoot Error Codes

Encountering error codes on a washing machine can indicate specific issues that prevent the machine from functioning correctly. By interpreting these codes, you can gain insights into possible malfunctions and apply straightforward solutions to address them. Understanding what each code signifies allows for faster identification of the root cause and more effective resolution of common problems.

Start by checking the user interface for any displayed codes, as each one typically correlates with a particular part or function of the machine. Refer to the control panel’s guide to match the displayed code with its meaning. For example, codes often signify issues related to water supply, drainage, or electrical connections.

For codes related to water supply, ensure that hoses are not kinked or blocked, and confirm that the water source is turned on. If the code points to drainage, examine the drain hose for obstructions and inspect the pump filter, cleaning it if necessary to restore flow. Addressing these aspects can often clear minor issues without professional assistance.

Electrical-related codes may indicate sensor or control board malfunctions. Power cycle the machine by unplugging it for a few minutes before reconnecting, as this may reset the system. If the issue persists, inspect wiring connections for looseness or corrosion, which could interfere with the system’s operation.

For persistent error codes or complex issues, cons

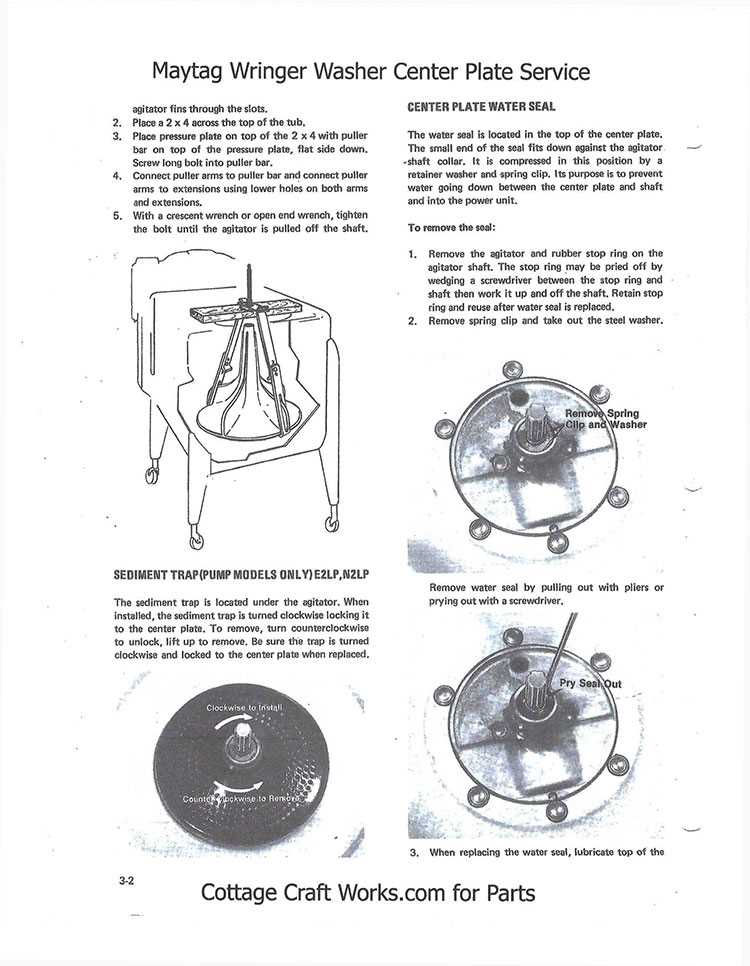

Replacing Worn Drum Components

Over time, the drum’s components may begin to show signs of wear, impacting the efficiency and overall performance of the appliance. Regular inspection and timely replacement of these parts help maintain optimal functionality.

Identifying Worn Components

Signs of wear can often be detected through unusual sounds, reduced performance, or visible wear marks on certain parts. Identifying these early can prevent further issues and ensure smooth operation.

- Drum Rollers: If you notice a loud, rumbling noise, it may be time to replace the drum rollers. Check for visible wear or flattening.

- Drum Bearing: When the bearing wears out, the drum may wobble or create scraping sounds. Inspect the bearing housing for damage or rust.

- Drive Belt: A loose or cracked belt can prevent the drum from rotating properly. Replace it if you observe fraying or stiffness.

Steps for Replacing Components

- Disconnect the Power: Before starting any maintenance, unplug the machine to ensure safety.

- Access the Drum Area: Remove any panels or guards needed to rea

Cleaning and Maintaining the Lint Trap

Proper care and regular upkeep of the lint trap are essential for the efficient and safe operation of your appliance. Removing lint build-up helps maintain optimal performance and reduces potential fire hazards. This guide covers the steps to keep the lint trap clean and ready for each use.

Why Regular Cleaning is Important

A clean lint trap not only enhances the machine’s drying performance but also conserves energy. Lint accumulation can obstruct airflow, causing the appliance to work harder and use more power. Frequent cleaning ensures better efficiency and longevity of the appliance.

Steps to Clean the Lint Trap

- Before each drying cycle, remove the lint trap from its slot.

- Using your hands, peel away any lint that has collected on the screen.

- For a more thorough clean, rinse the trap under warm water to clear out finer debris.

- Allow the screen to dry completely before reinserting it into the machine.

Deep Cleaning the Lint Trap

Every few months, it’s recommended to perform a deeper cleaning of the lint trap to eliminate any residues from fabric softeners or dryer sheets. This process helps maintain the trap’s effectiveness and ensures unrestricted airflow.

- Remove the lint screen and use a brush or vacuum to clean out the slot where it rests.

- Soak the screen in warm, soapy water for a few minutes to dissolve any build-up.

- Scrub gently with a soft brush if needed, then rinse thoroughly.

Steps to Fix Spin Cycle Problems

Addressing issues during the spinning phase of a washing machine can enhance its efficiency and extend its lifespan. This section outlines a series of troubleshooting steps to identify and resolve common difficulties associated with the spin function.

1. Check Load Balance

One of the most frequent causes of spin issues is an unbalanced load. Ensure that the items inside the drum are evenly distributed. If there are heavy items mixed with lighter ones, it can cause the machine to struggle. Remove excess items or redistribute the load for optimal performance.

2. Inspect Drainage System

A blocked drainage system can prevent the machine from spinning properly. Examine the drain hose for any kinks or clogs. Additionally, ensure the drain filter is clean. If the water does not drain correctly, the spin cycle will not initiate. Cleaning these components regularly can prevent future problems.

Adjusting Settings for Optimal Performance

Fine-tuning the various settings of your appliance can significantly enhance its efficiency and effectiveness. By making the right adjustments, users can ensure that the equipment operates at peak performance, saving both energy and time while achieving desired results.

Here are some key adjustments to consider:

- Temperature Settings: Ensure that the temperature settings are appropriate for the type of load being processed. For instance, using lower temperatures for delicate fabrics can prevent damage while conserving energy.

- Cycle Selection: Choose the right cycle for the load type. For heavy fabrics, select a more intense cycle, while lighter loads may benefit from a gentler setting.

- Load Size: Always adhere to the manufacturer’s guidelines regarding load size. Overloading can lead to poor performance and potential damage, while underloading can waste resources.

- Soil Level: Adjust the soil level setting based on the dirtiness of the items being cleaned. Higher soil levels are suitable for heavily soiled loads, ensuring thorough cleaning.

- Spin Speed: Modify the spin speed according to the fabric type. Delicate fabrics may require a lower spin speed to avoid damage.

Regularly reviewing and adjusting these settings can lead to improved performance, extending the lifespan of the appliance while achieving optimal results for each wash.

Repairing or Replacing the Control Board

The control board is a crucial component in many home appliances, acting as the central hub for managing operations and functions. When issues arise, it may lead to malfunctioning, impacting the overall performance of the unit. Understanding how to address problems with this component can save time and ensure your appliance operates efficiently.

Identifying Issues with the Control Board

Before proceeding with any adjustments or replacements, it is essential to diagnose the specific problem. Common signs of a faulty control board include unresponsive buttons, error codes, or inconsistent operation. Visual inspections can often reveal burnt circuits or damaged connections. If these issues are detected, troubleshooting steps should be taken to confirm the necessity of a replacement.

Steps for Replacement

If the decision is made to swap out the control board, begin by ensuring the appliance is unplugged to avoid any electrical hazards. Carefully remove the panel covering the control board, noting the placement of wires for reinstallation. Disconnect the old board and install the new one by following the reverse process. Once everything is secured, power the appliance back on to verify that it functions correctly. Proper handling and installation of this component are vital for restoring optimal operation.

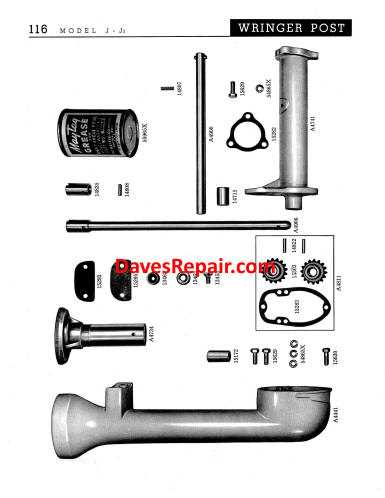

Guide to Diagnosing Motor Issues

Understanding the common problems associated with appliance motors is essential for effective troubleshooting and maintenance. This section aims to provide a clear approach to identifying and addressing motor-related concerns that may affect performance.

Here are some key symptoms to watch for when diagnosing motor difficulties:

- Unusual Noises: Listen for grinding, rattling, or humming sounds that may indicate mechanical failure.

- Inconsistent Operation: Pay attention to irregular spinning speeds or sudden stops during operation.

- Overheating: Check if the motor becomes excessively hot, which could signal an underlying issue.

- Vibration: Notice any unusual vibrations that could indicate misalignment or imbalance.

To proceed with diagnosis, follow these steps:

- Visual Inspection: Examine the motor and surrounding components for signs of wear, damage, or loose connections.

- Electrical Testing: Use a multimeter to check for continuity and proper voltage levels at the motor terminals.

- Resistance Measurement: Measure the resistance of the motor windings to identify potential shorts or opens.

- Lubrication: Ensure that moving parts are adequately lubricated to reduce friction and wear.

If issues persist after conducting these assessments, consider consulting a professional technician for further assistance and potential repairs. Prompt attention to motor problems can enhance performance and prolong the lifespan of your appliance.

Resolving Water Level and Drain Problems

Addressing issues related to water levels and drainage in your washing appliance can significantly enhance its performance and longevity. Understanding the common challenges associated with these functions will help you troubleshoot effectively.

Common symptoms of water level and drainage issues include:

- Insufficient water filling

- Overflow or excessive water retention

- Slow or complete drainage failure

To resolve these concerns, consider the following steps:

- Check the Water Supply:

- Ensure that the water supply valves are fully open.

- Inspect hoses for kinks or blockages.

- Verify that the water inlet screens are not clogged.

- Inspect the Drain Hose:

- Ensure the drain hose is positioned correctly, avoiding any bends or obstructions.

- Check for clogs in the drain hose or plumbing.

- Confirm the height of the drain hose complies with manufacturer specifications.

- Examine the Pressure Switch:

- Test the pressure switch for proper functionality.

- Check for any obstructions in the hose connected to the pressure switch.

- Evaluate the Pump:

- Inspect the drain pump for blockages or damage.

- Test the pump operation by checking for unusual noises during the drainage cycle.

By following these troubleshooting steps, you can effectively address water level and drainage issues, ensuring optimal operation of your appliance.

Best Practices for Preventing Future Repairs

Taking proactive measures can significantly extend the lifespan of your appliances and minimize the likelihood of future issues. By adopting a few best practices, you can ensure that your machine operates smoothly and efficiently for years to come.

Regular Maintenance

Consistent upkeep is essential in preventing potential problems. Follow these steps:

- Check and clean filters monthly to avoid clogs.

- Inspect hoses and connections for any signs of wear or leaks.

- Run maintenance cycles as recommended by the manufacturer.

- Keep the area around the appliance clean and free from debris.

Proper Usage Techniques

Using your appliance correctly can help prevent unnecessary strain. Consider the following guidelines:

- Load items evenly to maintain balance and reduce stress on components.

- Avoid overloading the machine to prevent motor strain.

- Use recommended settings for different types of fabrics or loads.

- Do not force items into the appliance; always ensure they fit comfortably.