Understanding the intricacies of textile equipment can greatly enhance both the functionality and longevity of your tools. This section delves into essential insights and techniques that can be applied to various types of equipment, ensuring they operate smoothly and efficiently.

In the world of fabric manipulation, having a thorough grasp of maintenance practices is crucial. Knowledge of common challenges and their solutions can empower users to troubleshoot issues independently, fostering a sense of confidence and expertise. Whether you’re a novice or an experienced enthusiast, these insights will serve as a valuable resource.

Proper care techniques not only preserve the quality of your tools but also elevate the crafting experience. By engaging with comprehensive guides, individuals can unlock the full potential of their equipment, transforming their creative endeavors into successful projects. Explore the wealth of information available to enhance your skill set and ensure your tools remain in peak condition.

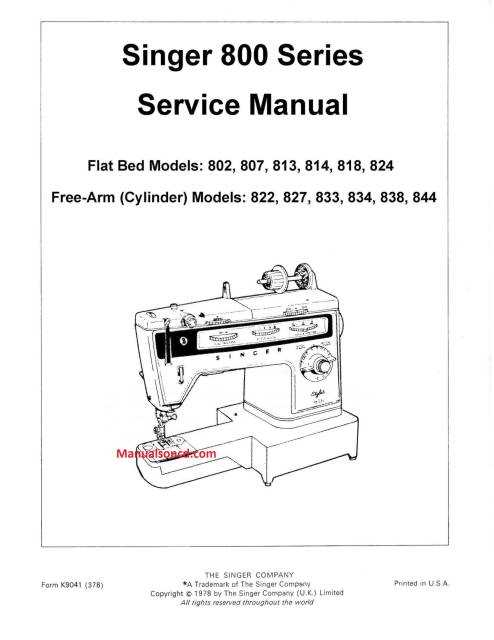

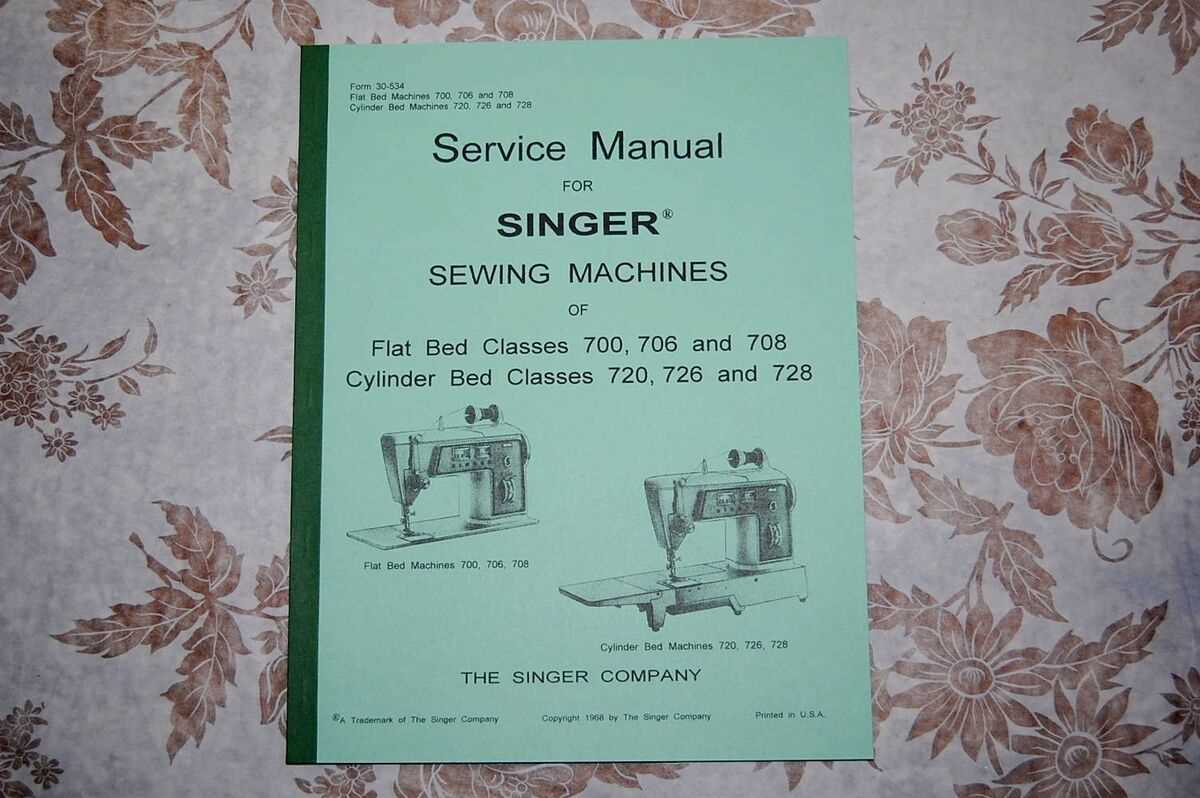

Singer Sewing Machines Repair Manuals

This section provides essential guidance for addressing common issues and performing maintenance tasks on various stitching devices. Understanding the intricacies of these tools is crucial for ensuring their longevity and optimal performance. The following information will aid users in troubleshooting and effectively managing their equipment.

Common Issues and Solutions

Users may encounter a range of challenges when utilizing their devices. Identifying these problems early can prevent further complications. Below is a list of typical concerns along with effective resolutions:

| Issue | Solution |

|---|---|

| Thread Jamming | Check for tangled thread and rethread the device. |

| Inconsistent Stitching | Adjust tension settings and inspect the needle for damage. |

| Machine Not Running | Verify power source and ensure all connections are secure. |

Maintenance Tips

Regular upkeep is vital for the seamless operation of these devices. Following a structured maintenance routine can help in extending their life. Here are some recommended practices:

- Clean the mechanism regularly to remove dust and lint.

- Oil moving parts as per the manufacturer’s recommendations.

- Store the equipment in a dry, cool place to prevent rust and wear.

Common Issues and Troubleshooting Steps

This section addresses frequent problems encountered during operation and offers practical solutions to resolve them effectively. Understanding these challenges can enhance the user experience and prolong the lifespan of the device.

Here are some typical issues along with suggested troubleshooting steps:

- Inconsistent Stitching:

- Check the threading to ensure it is properly set.

- Examine the needle for any signs of damage or dullness.

- Adjust the tension settings as necessary.

- Jamming:

- Remove any tangled threads from the feed area.

- Inspect the bobbin for proper installation.

- Clean the feed dogs to ensure smooth operation.

- Skipped Stitches:

- Use the correct needle type for the fabric.

- Check that the needle is inserted correctly and securely.

- Ensure the machine is properly lubricated as per guidelines.

- No Power:

- Verify that the power cord is securely connected.

- Check the outlet for functionality by testing with another device.

- Inspect for any blown fuses or tripped breakers.

By following these steps, users can often resolve common issues and maintain optimal functionality of their equipment.

Essential Tools for Repairing Machines

When tackling maintenance tasks, having the right instruments at your disposal is crucial for achieving optimal results. This section outlines the fundamental equipment needed to effectively address various issues that may arise.

Basic Instruments

Start with a good set of basic instruments, including screwdrivers, wrenches, and pliers. These tools allow for easy access to components and facilitate the tightening or loosening of screws and bolts.

Specialized Equipment

In addition to basic tools, consider adding specialized items like thread tension gauges and oil dispensers. These instruments help ensure precise adjustments and proper lubrication, essential for the longevity and efficiency of your device.

Preventative Maintenance Techniques

Implementing regular upkeep practices is essential for ensuring optimal performance and longevity of your equipment. By taking proactive measures, you can minimize wear and tear, enhance functionality, and avoid potential issues down the line.

Key practices to consider include:

- Regular cleaning to remove dust and debris that can impede performance.

- Lubrication of moving parts to reduce friction and enhance smooth operation.

- Periodic inspection of components for signs of wear or damage.

- Calibration to ensure precision and accuracy in functioning.

- Replacing worn-out elements promptly to maintain efficiency.

By incorporating these techniques into your routine, you can extend the life of your equipment and ensure reliable operation for years to come.

Understanding Machine Error Codes

Error codes can provide valuable insights into the functioning of your equipment, alerting you to specific issues that may need attention. By interpreting these codes, users can troubleshoot problems more effectively and ensure optimal performance.

Typically, these codes are displayed on the device’s interface and correspond to various malfunctions or operational anomalies. Recognizing the meaning behind each code is essential for timely intervention.

- Check the user guide for a list of common error codes and their meanings.

- Look for patterns in the codes to identify recurring issues.

- Consult online forums or communities for additional insights from other users.

By familiarizing yourself with these codes, you can enhance your understanding of the equipment’s behavior and potentially avoid costly repairs.

Step-by-Step Guide to Motor Repairs

This section provides a comprehensive approach to addressing issues related to the motor unit of a crafting device. Understanding the common problems and solutions can greatly enhance performance and longevity. Follow the outlined steps to effectively troubleshoot and resolve motor-related challenges.

Identifying Common Issues

- Unusual noises during operation

- Inconsistent power supply

- Overheating components

- Frequent stopping or stalling

Repair Steps

- Safety First: Disconnect the device from the power source to ensure safety during inspection.

- Visual Inspection: Examine the motor and surrounding areas for any visible damage or loose connections.

- Check the Power Supply: Ensure that the electrical outlet is functioning properly and that the power cord is intact.

- Clean the Motor: Remove any dust or debris that may be affecting performance. Use a soft brush for delicate areas.

- Lubricate Moving Parts: Apply appropriate lubricant to ensure smooth operation of the motor components.

- Reconnect and Test: Reconnect the device to the power source and conduct a test run to check for improvements.

Replacing the Needle and Presser Foot

Changing the needle and the presser foot is essential for maintaining optimal performance in your fabric crafting tasks. These components play a crucial role in achieving precise stitching and adapting to various fabric types. Regularly updating them ensures smoother operation and enhances the quality of your projects.

To successfully replace these parts, follow these simple steps:

| Step | Instructions |

|---|---|

| 1 | Turn off the device and unplug it for safety. |

| 2 | Raise the needle to its highest position using the handwheel. |

| 3 | Loosen the needle clamp screw and remove the old needle. |

| 4 | Insert the new needle with the flat side facing the back and tighten the clamp screw. |

| 5 | Release the presser foot lever and remove the current foot. |

| 6 | Align the new presser foot and secure it in place. |

| 7 | Check that both components are properly installed before powering on the device. |

By following these straightforward steps, you can ensure that your equipment is ready for all your creative endeavors.

Cleaning and Oiling Your Machine

Maintaining your equipment is essential for ensuring optimal performance and longevity. Regular cleaning and lubrication help prevent issues and keep all components functioning smoothly. This section outlines the basic steps you should follow for effective upkeep.

Before you start, gather the necessary supplies:

- Soft cloths

- Small brush

- Lubricating oil

- Screwdriver

Follow these steps to clean and oil your device:

- Turn off the power: Ensure the device is unplugged to avoid any accidents.

- Remove attachments: Take off any additional components, such as foot pedals or trays.

- Clean the exterior: Wipe down the outside with a soft cloth to remove dust and debris.

- Dust the interior: Use a small brush to clean out any lint or dirt inside the device.

- Apply oil: Place a few drops of lubricating oil on the moving parts as specified in your guidelines.

- Reassemble: Once everything is clean and oiled, put all components back in place.

Regular maintenance will enhance the performance and extend the life of your equipment, ensuring it remains in top condition for your projects.

Adjusting Tension for Optimal Performance

Achieving the perfect balance in thread tension is essential for ensuring high-quality results in textile projects. Proper adjustment can significantly enhance the overall stitching quality, preventing issues such as puckering or thread breakage.

To begin, it is crucial to understand that both upper and lower threads must be in harmony. If the upper thread is too tight, it may cause the fabric to pucker, while if it is too loose, the stitches can appear weak. Adjusting the tension settings allows for fine-tuning, helping to create a smooth and even stitch.

Start by testing on a scrap piece of fabric similar to what will be used in the project. Observe the stitches closely, adjusting the tension incrementally until the desired effect is achieved. Regular checks and adjustments can lead to consistently superior results.

How to Fix Thread Jamming Problems

Thread jamming can be a frustrating issue that affects the performance of your device. This problem often arises from a variety of factors, including improper threading, tension discrepancies, or even debris accumulation. Addressing these concerns effectively can restore smooth operation.

Identifying the Causes

Understanding the underlying causes is crucial for resolving thread jams. Common reasons include:

| Cause | Description |

|---|---|

| Incorrect Threading | Thread may not be properly inserted, leading to friction. |

| Tension Issues | Improper tension can cause the thread to become too tight or loose. |

| Debris Build-up | Lint or dust can obstruct the threading path. |

Steps to Resolve the Issue

To effectively eliminate jamming, follow these steps:

- Re-thread the device, ensuring the thread follows the correct path.

- Adjust the tension settings according to the material being used.

- Clean the area around the thread path to remove any accumulated debris.

Diagnosing Electrical Problems

Identifying electrical issues is crucial for ensuring the optimal functionality of your device. A systematic approach can help pinpoint the source of malfunctions, allowing for effective resolution. Understanding common signs of electrical problems can aid in swift diagnosis and prevent further complications.

Common Symptoms

Several indicators may suggest underlying electrical difficulties. Recognizing these signs early can facilitate timely intervention:

| Symptom | Possible Cause |

|---|---|

| Device does not power on | Faulty power cord or outlet issues |

| Unusual noises during operation | Loose connections or worn components |

| Inconsistent performance | Voltage fluctuations or internal faults |

| Burning smell | Overheating or short circuits |

Steps for Diagnosis

To effectively diagnose electrical challenges, follow these steps:

- Check all connections and ensure they are secure.

- Test the power supply to verify functionality.

- Inspect for any visible signs of damage or wear.

- Use a multimeter to measure voltage and continuity where applicable.

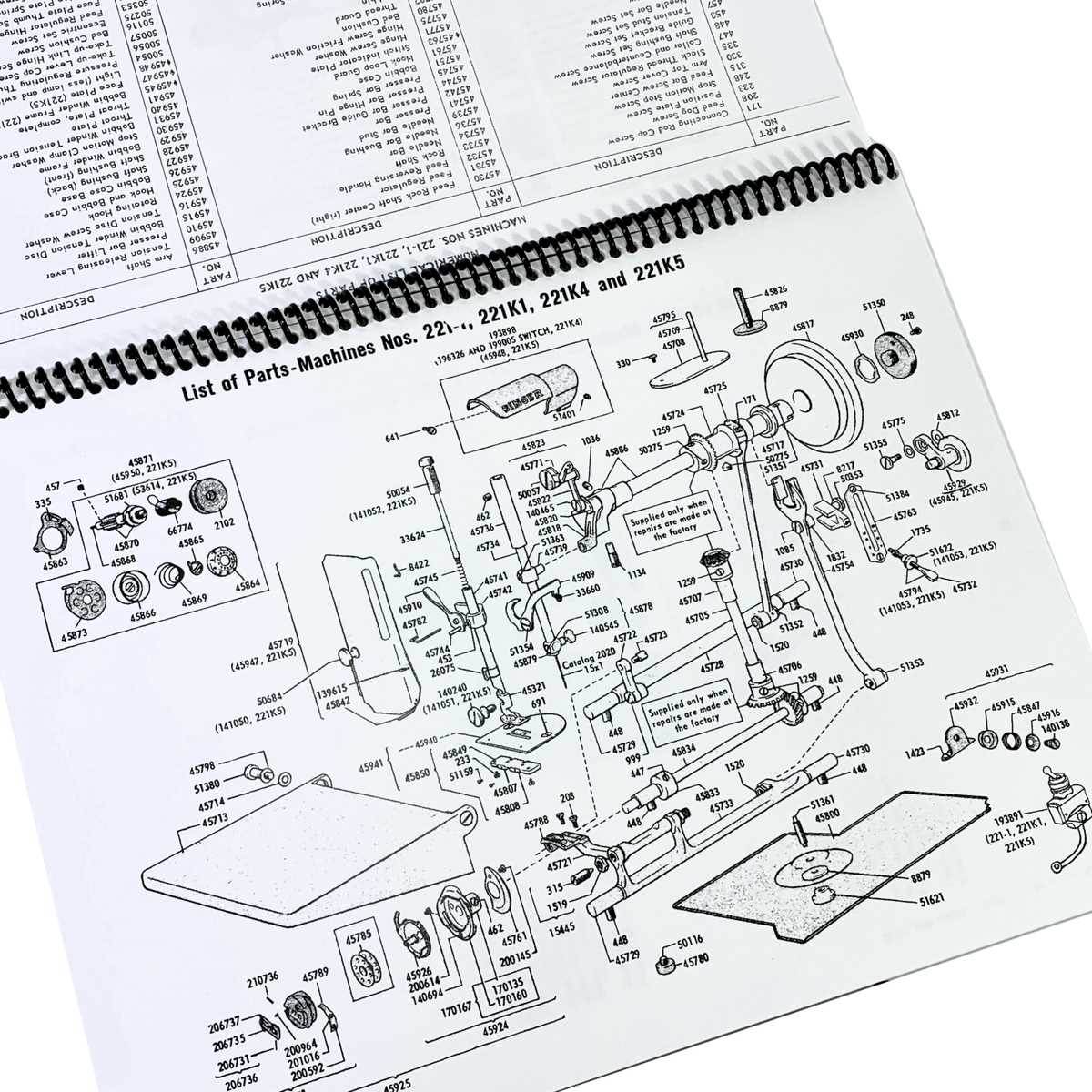

Finding Replacement Parts Easily

Locating the right components for your equipment can be straightforward if you know where to look. A variety of resources are available that cater to different needs, making the process efficient and less time-consuming.

Online Retailers and Marketplaces

Numerous online platforms offer a wide selection of parts. These websites often provide detailed descriptions and images to ensure compatibility with your device. Check customer reviews for additional insights.

Local Stores and Suppliers

Your nearby hardware or specialty shops may carry essential components. Building a relationship with local suppliers can lead to valuable advice and potential discounts on future purchases.

| Resource Type | Benefits | Considerations |

|---|---|---|

| Online Retailers | Wide variety, convenience | Shipping times, compatibility verification |

| Local Stores | Immediate availability, personal service | Limited selection, potential higher prices |