Ensuring optimal performance of your racing machine involves understanding its inner workings and maintaining it properly. This section provides valuable insights into the techniques and best practices for keeping your vehicle in top shape. From troubleshooting common issues to performing routine checks, having a solid grasp of these fundamentals is essential for any enthusiast.

Every component of your speedy companion plays a crucial role in its overall efficiency. Familiarizing yourself with these elements allows for timely interventions, preventing minor setbacks from escalating into significant problems. Regular attention to maintenance not only enhances safety but also extends the lifespan of your beloved ride.

Whether you’re a seasoned driver or a newcomer to the sport, knowing how to care for your vehicle can enhance your racing experience. This guide aims to equip you with the knowledge needed to tackle various tasks, empowering you to keep your machine performing at its peak. Dive in and discover the essential practices that will keep your adventures on the track enjoyable and trouble-free.

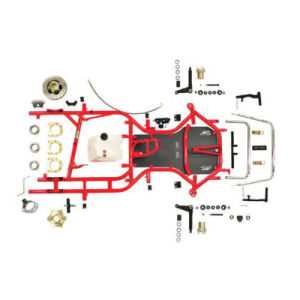

Understanding Go-Kart Components

Grasping the essential parts of a racing machine is crucial for enthusiasts and mechanics alike. Each element plays a significant role in the overall performance and safety of the vehicle. Familiarity with these components allows for better maintenance and optimization of the driving experience.

Chassis serves as the foundational structure, providing stability and support for other elements. Its design impacts handling and durability, making it vital for competitive performance. A well-constructed frame ensures that all components function harmoniously.

Engine is the heart of the vehicle, generating the power necessary for speed. Understanding its specifications and capabilities is essential for enhancing performance and addressing any issues that may arise. Regular checks and tuning can maximize efficiency and reliability.

Wheels and Tires are crucial for traction and control. Selecting the right type of tire for specific track conditions can significantly influence grip and cornering ability. Maintaining proper tire pressure and alignment is essential for optimal handling.

Braking System ensures safety by providing the means to slow down or stop effectively. Familiarity with the components of this system, including pads, calipers, and discs, is important for ensuring responsiveness and reliability during races.

Steering Mechanism allows the driver to maneuver the vehicle with precision. Understanding how this system works, including components like the steering wheel and linkage, helps in diagnosing issues and ensuring smooth operation.

Each of these elements contributes to the overall functionality of the racing vehicle. A comprehensive understanding of their roles not only aids in effective management but also enhances the overall driving experience.

Essential Tools for Repairs

Maintaining and restoring your racing vehicle requires a specific set of instruments to ensure optimal performance and longevity. Having the right gear at your disposal not only simplifies the process but also enhances the quality of your work. Below are some indispensable items that every enthusiast should consider for effective upkeep and modifications.

Basic Hand Tools

Start with a collection of hand tools that are fundamental for various tasks. Wrenches, screwdrivers, and pliers form the backbone of your toolkit. Investing in a good quality socket set can significantly speed up assembly and disassembly, while an adjustable wrench provides versatility for different bolt sizes. Ensure you have both metric and imperial options available.

Specialized Equipment

For more advanced tasks, specialized equipment is essential. A torque wrench ensures that fasteners are tightened to the correct specifications, preventing damage or failure. Additionally, a multimeter can be invaluable for diagnosing electrical issues, while a compression tester allows you to assess engine health. Keeping a well-stocked toolkit will facilitate smoother operations and help you tackle a wide range of challenges.

Common Go-Kart Issues

Understanding the frequent challenges that enthusiasts face can enhance performance and longevity. Identifying these problems early is crucial for optimal enjoyment and safety.

Performance Issues

- Loss of acceleration

- Difficulty steering

- Inconsistent handling

Mechanical Failures

- Engine misfires

- Bent axles

- Worn tires

Addressing these concerns promptly can lead to a more enjoyable and safe experience on the track.

Step-by-Step Repair Techniques

This section provides a comprehensive approach to troubleshooting and maintaining your racing vehicle. By following these structured methods, you can ensure optimal performance and longevity of your machinery. Each step is designed to guide you through essential processes, making it easier to identify and address common issues.

Identifying Issues

Before diving into any maintenance tasks, it is crucial to pinpoint the exact problem. Start by conducting a visual inspection of all components. Look for signs of wear, damage, or loose parts. If you hear unusual noises during operation, take note of their source. Keeping a checklist can help you systematically identify potential areas of concern.

Performing Basic Adjustments

Once issues are identified, proceed with necessary adjustments. Tightening loose fittings is often the first step; use the appropriate tools to ensure secure connections. Next, check fluid levels and refill as needed, paying close attention to oil and fuel quality. Cleaning filters and air intakes can significantly enhance performance. Regular maintenance of these components can prevent larger problems down the line.

Engine Maintenance Best Practices

Maintaining optimal performance and longevity of your motor requires diligent attention and regular care. Implementing best practices ensures that components operate efficiently, minimizing wear and enhancing reliability over time. This section outlines essential techniques for maintaining your engine in peak condition.

Regular Inspections

Conducting frequent assessments is crucial. Check for leaks, cracks, and signs of wear on various components. Visual inspections can reveal potential issues before they escalate into serious problems. Pay close attention to fluid levels and ensure they are within recommended ranges.

Lubrication and Fluid Changes

Proper lubrication is vital for reducing friction and preventing overheating. Regularly change engine oil and other fluids as per the manufacturer’s guidelines. Using high-quality lubricants can significantly enhance engine performance and lifespan. Additionally, replace air and fuel filters periodically to maintain clean intake and fuel systems.

Tire Care and Replacement Tips

Proper maintenance of your vehicle’s wheels is essential for optimal performance and safety. Neglecting this aspect can lead to reduced efficiency, poor handling, and even accidents. By following some simple guidelines, you can ensure that your wheels remain in excellent condition and are replaced when necessary.

Regular Inspections: Make it a habit to inspect your wheels frequently. Look for signs of wear, such as uneven tread wear, cracks, or bulges. This can help you identify potential issues before they become serious.

Optimal Pressure: Maintaining the correct air pressure is crucial for maximizing grip and fuel efficiency. Check the pressure regularly and adjust it according to the manufacturer’s recommendations. Under-inflated wheels can lead to excessive heat and faster deterioration, while over-inflated wheels may cause uneven wear and reduced traction.

Rotation: To promote even wear, consider rotating your wheels regularly. This practice ensures that each wheel experiences similar conditions and extends their lifespan. Refer to your vehicle’s guidelines for recommended rotation intervals.

Replacement Timing: Knowing when to replace your wheels is vital for maintaining safety. As a general rule, if the tread depth is below 2/32 of an inch, it’s time for a change. You can use a tread depth gauge or the penny test to assess the remaining tread.

Proper Storage: If you have a set of seasonal wheels, store them in a cool, dry place away from direct sunlight. Keep them upright or stacked correctly to prevent deformation.

By following these tips, you can prolong the life of your wheels, enhance your driving experience, and ensure safety on the road.

Brake System Troubleshooting

Understanding the intricacies of a braking mechanism is essential for maintaining optimal performance and safety. Issues within this system can lead to decreased effectiveness, which may compromise control and stability. This section will guide you through identifying and resolving common problems that can arise, ensuring a reliable stopping capability.

First, check for any visible signs of wear or damage on the components. Inspecting the pads for excessive thinning or the rotors for warping is crucial. Additionally, listen for unusual noises during operation, such as grinding or squeaking, which can indicate that the pads need attention.

Next, examine the fluid levels and quality. Low fluid can lead to poor performance, while contamination can cause serious malfunctions. Ensure there are no leaks in the lines, as this can significantly affect the pressure needed for effective stopping.

It is also important to assess the performance of the pedal. A spongy or unresponsive feel may suggest air in the lines or a failing master cylinder. Bleeding the system can often resolve this issue, restoring proper pressure and functionality.

Finally, evaluate the alignment and adjustment of the components. Misalignment can cause uneven wear and reduce the overall efficiency of the system. Regular maintenance checks will help catch these issues early and keep the stopping mechanism functioning smoothly.

Electrical System Diagnostics

The functionality of any racing vehicle relies heavily on its electrical components. Proper assessment of these systems is crucial for optimal performance and safety. This section will delve into techniques for evaluating electrical systems, identifying potential issues, and ensuring reliable operation.

Identifying Common Issues

Electrical failures often manifest through various symptoms, including starting difficulties, erratic behavior of lights, and inconsistent performance of the engine. Observing these signs early can prevent further complications. It’s essential to methodically inspect the wiring, connectors, and key components, focusing on any signs of wear or damage.

Testing Procedures

To diagnose electrical problems, utilize a multimeter to check voltage, resistance, and continuity across circuits. Begin by verifying the battery’s state, as a weak or dead battery can lead to widespread issues. Next, assess the charging system, ensuring that it effectively maintains the necessary voltage levels during operation. Lastly, pay attention to the ignition system, as it plays a vital role in engine performance.

Regular maintenance and diagnostics can significantly extend the lifespan of the electrical systems and enhance overall performance. By staying proactive, operators can enjoy a smoother and more reliable driving experience.

Chassis Alignment Procedures

Proper alignment of the frame is crucial for optimal performance and safety. Ensuring that all components are positioned accurately can significantly enhance handling, tire longevity, and overall stability on the track.

Before starting the alignment process, gather the necessary tools and materials:

- Measuring tape

- Level

- Wrenches

- Alignment tools

- Marker for adjustments

Follow these key steps for effective alignment:

- Inspect the Frame: Check for any signs of damage or wear that may affect alignment.

- Measure Wheelbase: Ensure that the distance between the front and rear wheels is consistent on both sides.

- Track Width Assessment: Measure the distance between the left and right wheels at both the front and rear to confirm they are parallel.

- Toe Angle Adjustment: Adjust the angle of the wheels to ensure they are aligned correctly with the frame. Positive toe means wheels point inward; negative toe means they point outward.

- Camber Angle Check: Verify the tilt of the wheels. Adjust if necessary to achieve the desired angle for improved grip.

- Final Measurements: Recheck all measurements to ensure accuracy. Make any necessary fine-tuning adjustments.

Regular alignment checks can prevent uneven tire wear and enhance the handling characteristics of your setup. Maintain a routine schedule for inspections to ensure continued performance and safety.

Safety Checks Before Racing

Ensuring a secure and enjoyable experience on the track requires thorough inspections and preparations. Prior to engaging in any competitive activity, it is crucial to conduct a series of assessments to guarantee that all components are functioning correctly and that safety measures are in place. This proactive approach not only protects the driver but also enhances overall performance.

| Safety Check | Description |

|---|---|

| Tires | Inspect for proper inflation and tread depth; replace if worn or damaged. |

| Brakes | Ensure that the braking system is responsive and fluid levels are adequate. |

| Fuel | Check fuel levels and confirm that there are no leaks or contamination. |

| Safety Gear | Verify that helmets, gloves, and suits are in good condition and meet regulations. |

| Steering | Test the steering system for any play or stiffness; adjust as necessary. |

| Suspension | Inspect for any signs of wear or damage; ensure components are secure. |

Completing these checks will significantly reduce risks and contribute to a safer racing environment. Always remember that diligence in preparation reflects not only on personal safety but also on the overall integrity of the event.

Performance Upgrades for Speed

Enhancing speed and overall performance is a key goal for many enthusiasts. By implementing specific modifications, you can significantly improve acceleration, handling, and top speed. Below are some effective strategies to boost performance.

- Engine Tuning:

- Adjusting the carburetor for optimal fuel-air mixture.

- Upgrading the ignition system for improved spark efficiency.

- Installing a high-performance exhaust system to enhance airflow.

- Weight Reduction:

- Replacing heavy components with lightweight alternatives.

- Removing unnecessary parts to decrease overall mass.

- Using lighter materials for bodywork.

- Tires and Suspension:

- Choosing high-grip tires for better traction.

- Adjusting suspension settings to optimize handling.

- Installing stiffer springs for improved cornering performance.

- Gear Ratios:

- Changing sprockets to alter acceleration and top speed.

- Finding the ideal balance between torque and speed through ratio adjustments.

Implementing these upgrades can lead to noticeable improvements in speed and driving experience. Prioritize changes that align with your specific goals for maximum impact.

Maintaining Fuel Systems Effectively

Ensuring optimal performance of fuel systems is crucial for the longevity and efficiency of any motorized vehicle. Regular attention to this essential component can prevent issues that may arise from neglect, ultimately enhancing reliability and performance on the track. By adopting a systematic approach to maintenance, users can identify potential problems early and keep the system functioning smoothly.

One of the key practices is to routinely check fuel lines for leaks or damage. Cracks or wear can lead to fuel loss and decreased performance. Additionally, maintaining clean filters is vital; clogged filters restrict fuel flow and can cause engine complications. Replacing these components at regular intervals is a straightforward yet effective way to ensure consistent operation.

Moreover, monitoring fuel quality is important. Using fresh, high-quality fuel can significantly reduce the risk of deposits and contamination, which can impair system functionality. It’s advisable to store fuel properly and avoid mixing different types unless explicitly recommended.

Lastly, keeping an eye on the fuel pump is essential. Ensuring it operates within specified pressure ranges can prevent a host of issues related to fuel delivery. A systematic inspection of these elements will go a long way in maintaining an efficient and effective fuel system.