In the world of agricultural machinery, understanding the intricacies of equipment maintenance is essential for optimal performance. Proper upkeep not only enhances the longevity of the machines but also ensures efficient operation during critical farming activities. This guide aims to provide essential insights and resources for individuals looking to navigate the complexities of their agricultural equipment.

Equipping oneself with the right knowledge and techniques can significantly improve the effectiveness of troubleshooting and servicing tasks. By delving into systematic procedures and practical tips, operators can cultivate a deeper understanding of their machinery, enabling them to address common issues with confidence. The following sections will outline the key aspects of maintaining and servicing tractors to help maximize their productivity.

From routine checks to more intricate repair tasks, having a comprehensive reference can transform the maintenance experience. This resource serves as a valuable tool for both novice and experienced users, guiding them through the essential practices needed to keep their equipment in prime condition. With this knowledge at hand, operators can ensure that their machines perform reliably, supporting their agricultural endeavors with greater ease.

Massey Ferguson 135 Overview

This section provides an insightful look into a classic agricultural machine, renowned for its reliability and efficiency. It has become a staple in farming operations, offering versatility across various tasks. Designed with practicality in mind, this unit combines robust engineering with user-friendly features, making it a favored choice among operators.

Engine and Performance: The heart of this model is its powerful engine, which delivers ample horsepower while maintaining fuel efficiency. Its design ensures smooth operation in both light and heavy-duty applications, catering to a wide range of farming needs.

Durability and Maintenance: Built to withstand the rigors of agricultural work, this equipment requires minimal maintenance to keep it in optimal condition. Regular checks and basic care can extend its lifespan significantly, making it a smart investment for any farmer.

Features and Functionality: With a user-friendly layout and straightforward controls, operators can easily navigate various functions. This machine is equipped with essential attachments that enhance its utility, allowing it to tackle everything from plowing to hauling with ease.

Conclusion: Overall, this agricultural powerhouse embodies a blend of efficiency, durability, and simplicity, making it an invaluable asset for modern farming practices.

Key Features of the MF 135

This section explores the essential characteristics that define this iconic agricultural machine, highlighting its practicality and efficiency in various farming tasks. The robust design and versatile functionality make it a valuable asset for operators.

| Feature | Description |

|---|---|

| Engine | Equipped with a reliable power unit that delivers impressive torque and performance. |

| Transmission | Smooth-shifting gearbox ensures ease of use in diverse terrains. |

| Hydraulics | Advanced hydraulic system enhances lifting capabilities and implement versatility. |

| Compact Size | Ideal dimensions for maneuverability in tight spaces without sacrificing power. |

| Durability | Built with high-quality materials to withstand harsh agricultural environments. |

Common Repairs for MF 135

Maintenance and troubleshooting are essential for ensuring the longevity and optimal performance of agricultural machinery. Familiarizing oneself with frequent issues and their solutions can save time and money while enhancing efficiency in the field. Below are some of the typical repairs encountered with this specific model.

-

Engine Overheating:

This can occur due to coolant leaks, a faulty thermostat, or a blocked radiator. Regular checks and flushing of the cooling system can prevent overheating.

-

Hydraulic System Malfunctions:

Common issues include leaks, slow operation, or complete failure. Inspecting hoses, checking fluid levels, and ensuring filters are clean are vital steps for troubleshooting.

-

Electrical System Problems:

Issues may arise from battery failure, faulty wiring, or damaged connectors. Routine inspection of the electrical components can help identify problems early.

-

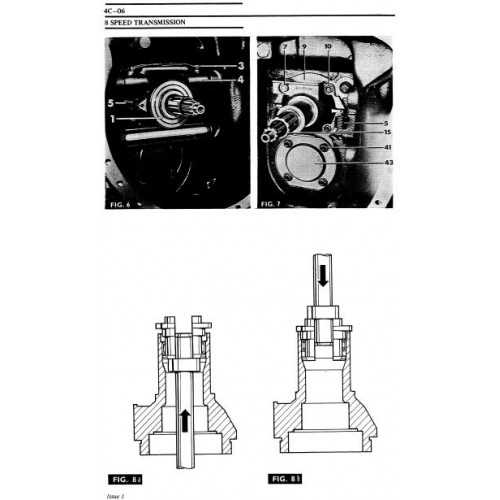

Transmission Issues:

Slipping gears or difficulty in shifting may indicate low fluid levels or worn components. Regularly checking and changing the transmission fluid is crucial for smooth operation.

By staying vigilant and addressing these common concerns promptly, operators can maintain the functionality of their equipment and minimize downtime.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the longevity and optimal performance of your agricultural machinery. By implementing a consistent maintenance routine, you can prevent costly repairs and extend the lifespan of your equipment. Here are some key practices to consider.

Routine Inspections

- Check fluid levels regularly, including oil, coolant, and hydraulic fluids.

- Inspect belts and hoses for signs of wear or damage.

- Examine tires for proper inflation and tread wear.

- Ensure all electrical connections are clean and secure.

Cleaning and Storage

- Clean the exterior after each use to remove dirt and debris.

- Store equipment in a sheltered location to protect it from the elements.

- Cover sensitive parts to prevent moisture accumulation.

- Maintain a clean workspace to avoid accidents and damage.

By adhering to these maintenance tips, you can enhance the durability of your machinery and ensure it remains in excellent working condition for years to come.

Essential Tools for Repairing MF 135

When working on agricultural machinery, having the right set of instruments is crucial for effective maintenance and troubleshooting. This section highlights the fundamental equipment needed to ensure efficient servicing of your tractor, facilitating both routine upkeep and more complex tasks.

Basic Hand Tools

- Wrenches (various sizes)

- Sockets and Ratchets

- Slip Joint Pliers

- Screwdrivers (flathead and Phillips)

- Hammer (ball-peen and claw)

Specialized Equipment

- Torque Wrench

- Multimeter for electrical diagnostics

- Oil Filter Wrench

- Fuel Line Removal Tool

- Hydraulic Jack and Stands

By equipping yourself with these essential tools, you’ll be well-prepared to tackle any maintenance challenges that arise, ensuring your machinery operates smoothly and efficiently.

Understanding the Engine Components

Engine components play a crucial role in the performance and efficiency of any machine. Each part contributes to the overall functionality, working in harmony to convert fuel into motion. A thorough understanding of these elements helps in diagnosing issues and ensuring optimal operation.

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and provides structure to the engine. |

| Pistons | Move up and down within the cylinders, converting fuel combustion into mechanical energy. |

| Cylinder Head | Seals the top of the cylinder and contains intake and exhaust valves. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion. |

| Camshaft | Controls the timing of valve openings and closings for efficient airflow. |

| Fuel Injector | Delivers fuel into the combustion chamber in a precise manner. |

| Oil Pump | Circulates oil to lubricate moving parts, reducing friction and wear. |

Familiarity with these essential parts not only aids in troubleshooting but also enhances maintenance practices, ensuring longevity and reliability in engine performance.

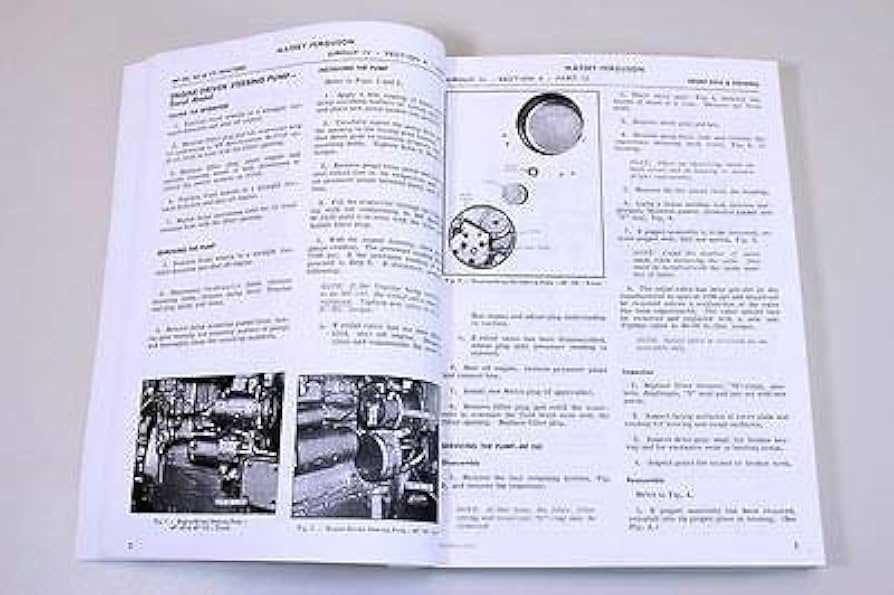

Hydraulic System Troubleshooting

The hydraulic system is a vital component in ensuring the smooth operation of machinery. Identifying and resolving issues within this system is crucial for maintaining efficiency and performance. Common problems can arise from various sources, including leaks, pressure fluctuations, or component failures. Understanding how to diagnose these issues can significantly enhance the lifespan of the equipment.

Common Symptoms of Hydraulic Issues

Several indicators can suggest problems within the hydraulic system. Unusual noises, such as whining or grinding, may signal low fluid levels or worn components. Inconsistent operation of hydraulic functions often points to air trapped in the system or a malfunctioning pump. Additionally, if the machinery struggles to lift loads or exhibits sluggish movements, it may indicate pressure loss or a blocked line.

Steps for Troubleshooting

To effectively troubleshoot hydraulic system problems, start by visually inspecting all connections and hoses for signs of leakage. Check fluid levels and ensure they are within the recommended range. Bleeding the system can help remove trapped air, while monitoring pressure gauges can provide insights into potential malfunctions. If issues persist, further investigation into the pump, valves, and actuators may be necessary to pinpoint the root cause.

Electrical Issues and Solutions

Electrical systems are vital for the optimal performance of agricultural machinery. Troubles with wiring, battery, or components can lead to significant operational delays. Identifying and addressing these challenges promptly ensures smooth functionality and enhances the longevity of the equipment.

Common Electrical Problems

One prevalent issue is battery failure. A dead battery can stem from various causes, including corrosion, old age, or a faulty charging system. Additionally, faulty wiring often leads to intermittent electrical failures, which can be difficult to diagnose. Loose connections and frayed wires may cause components to malfunction, resulting in a lack of power or erratic behavior.

Solutions and Preventive Measures

To tackle battery issues, regularly check connections and clean terminals to prevent corrosion. Replacing an aging battery is essential for reliability. For wiring concerns, conducting routine inspections to identify wear and tear can help. Using proper gauge wires and ensuring secure connections can minimize the risk of electrical failures. Implementing these practices not only resolves current problems but also prevents future complications.

Parts Replacement Guide for MF 135

This section provides essential information on how to effectively replace various components in your equipment. Understanding the right procedures and parts needed for substitution can greatly enhance the longevity and performance of your machine. Proper maintenance ensures optimal functionality and reduces the risk of unforeseen breakdowns.

Common Parts and Their Replacement

Here are some frequently replaced components along with guidelines for their substitution:

| Part Name | Signs of Wear | Replacement Procedure |

|---|---|---|

| Oil Filter | Reduced oil pressure, discoloration | Drain oil, remove the old filter, install the new one, and refill with oil. |

| Air Filter | Increased engine noise, reduced power | Remove the air intake cover, take out the old filter, replace with a new one, and reassemble. |

| Fuel Injector | Engine misfiring, poor fuel efficiency | Disconnect fuel lines, remove the injector, install a new one, and reconnect the lines. |

Tools Required for Replacement

To ensure a successful replacement, the following tools are recommended:

- Wrench set

- Screwdriver set

- Oil catch pan

- Replacement parts

- Cleaning rags

Regularly replacing worn-out components not only improves performance but also extends the overall life of your equipment. Always consult specific guidelines for each part to ensure proper handling and installation.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial to prevent accidents and injuries. Proper precautions can significantly reduce risks associated with machinery servicing. Adhering to these guidelines will promote a secure working environment for everyone involved.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear such as gloves, goggles, and sturdy footwear to protect against hazards. |

| Work Area Organization | Keep the workspace tidy and free of clutter to minimize tripping hazards and ensure easy access to tools. |

| Tool Inspection | Regularly check tools for damage or wear. Using defective equipment can lead to accidents. |

| Follow Guidelines | Adhere to the manufacturer’s recommendations and safety guidelines specific to the machinery. |

| Emergency Preparedness | Have first aid kits and emergency contacts readily available in case of an incident. |

By implementing these safety measures, individuals can effectively mitigate risks and ensure a safer atmosphere during maintenance activities. Vigilance and preparation are key components in maintaining a secure work environment.

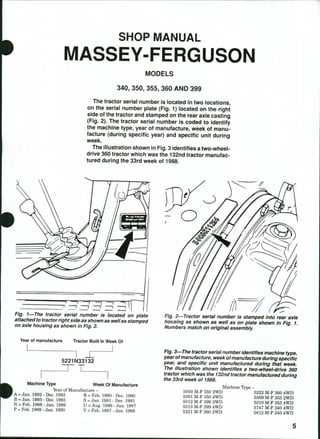

Finding a Reliable Repair Manual

When it comes to maintaining and fixing agricultural machinery, having access to trustworthy documentation is essential. A comprehensive guide not only simplifies the process of troubleshooting but also ensures that repairs are conducted efficiently and effectively. Identifying quality resources can save time, reduce costs, and enhance the lifespan of your equipment.

Firstly, consider the source of the documentation. Look for publications from reputable manufacturers or well-known publishers in the field. These often provide detailed instructions, diagrams, and specifications that are crucial for accurate maintenance. Online platforms and forums dedicated to farming machinery can also be invaluable, as they frequently share verified documents and user experiences.

Secondly, ensure that the material is up-to-date. Machinery evolves, and older manuals may not reflect the latest standards or techniques. Check the publication date and seek out the latest editions to guarantee that you’re working with current information. Additionally, user reviews can provide insights into the effectiveness and clarity of the guide.

Finally, consider digital options. Many modern resources are available online, offering easy access to the latest manuals. Digital formats often include searchable text and interactive features that enhance usability. Ensure that the platform you choose is trustworthy and provides comprehensive coverage of the topics relevant to your machinery.

Community Resources and Forums

In today’s digital age, enthusiasts and professionals alike can benefit greatly from shared knowledge and experiences. Engaging with a community dedicated to machinery and agriculture can provide valuable insights, troubleshooting tips, and practical advice. This section highlights various online resources where individuals can connect, share, and learn from one another.

Online Forums

Forums serve as a platform for discussion and support among users. Here are some popular options:

- Discussion Boards: These are dedicated spaces where members can post questions and receive answers from experienced users.

- Technical Support Threads: Many forums feature sections specifically for troubleshooting, allowing members to seek help on specific issues.

- Marketplace Sections: Users can buy, sell, or trade equipment and parts, facilitating resource sharing within the community.

Social Media Groups

Social media platforms offer vibrant communities that can be incredibly helpful. Consider the following:

- Facebook Groups: Numerous groups focus on machinery topics, providing a space for members to share tips and showcase their projects.

- Reddit Communities: Subreddits dedicated to machinery and agriculture foster discussions, tutorials, and Q&A sessions.

- Instagram and YouTube: Visual platforms where users share videos and photos of their work, often including tutorials and maintenance advice.

By participating in these communities, users can enhance their knowledge, find support, and contribute to a collective passion for machinery and maintenance.