Maintaining modern kitchen appliances is crucial for their longevity and optimal performance. Understanding the common issues that may arise and knowing how to address them can save both time and money. This section aims to provide insights into effective troubleshooting and upkeep strategies for specific models.

By familiarizing yourself with the operational principles and typical challenges, you can enhance your appliance’s efficiency. Equipped with the right knowledge, you will be better prepared to tackle any obstacles that may occur during usage.

Whether you are dealing with minor inconveniences or more significant malfunctions, having a comprehensive understanding of your equipment can lead to quicker resolutions. Explore the following tips and techniques to ensure your appliance remains in top condition.

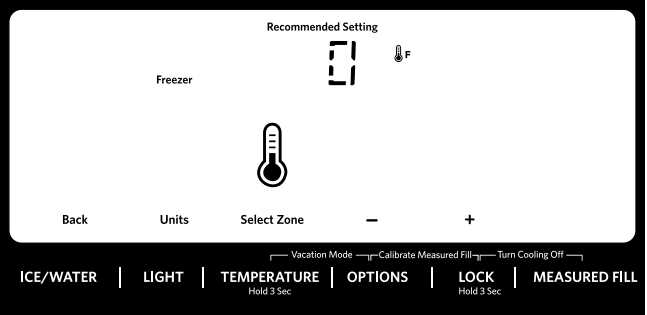

Troubleshooting Temperature Problems

Temperature issues in kitchen appliances can lead to a variety of challenges, affecting food preservation and cooking efficiency. Understanding common causes and solutions can help restore optimal performance and ensure reliable operation.

Identifying Temperature Fluctuations

To address temperature inconsistencies, first monitor the appliance’s settings. Make sure the thermostat is correctly set and not accidentally altered. Additionally, check for proper airflow; blocked vents can restrict circulation, leading to uneven temperatures.

Common Solutions

If fluctuations persist, inspect door seals for damage or wear, as gaps can allow warm air to enter, compromising cooling efficiency. Regularly clean the condenser coils to enhance performance. In cases where problems continue, consulting a professional may be necessary for further diagnosis.

Understanding Water Leak Causes

Water leaks can arise from various sources within appliances, often leading to significant issues if not addressed promptly. Identifying the underlying reasons for these leaks is crucial for effective resolution and prevention of further damage.

Common Sources of Leaks

Leaks may originate from damaged seals, improper installation, or worn-out components. Additionally, environmental factors can play a role in exacerbating these issues, leading to water accumulation in undesired areas.

Environmental Factors

Humidity and temperature fluctuations can affect the integrity of seals and fittings, making them more susceptible to failure. Understanding these environmental impacts can aid in the early detection of potential leaks.

| Cause | Description |

|---|---|

| Damaged Seals | Worn or cracked seals that fail to create a watertight barrier. |

| Poor Installation | Improperly fitted components that can lead to misalignment and leaks. |

| Worn Components | Parts that have degraded over time, reducing their effectiveness. |

| Humidity | Excess moisture in the air that can compromise seals and joints. |

Steps for Cleaning the Condenser Coils

Maintaining the efficiency of your appliance involves regular cleaning of its condenser coils. This task helps prevent overheating and ensures optimal performance. Follow these straightforward steps to keep your coils in top condition.

Before starting the cleaning process, gather the necessary tools: a vacuum cleaner with a brush attachment, a soft cloth, and a cleaning solution if needed.

| Step | Description |

|---|---|

| 1 | Unplug the appliance from the power source to ensure safety during the cleaning process. |

| 2 | Locate the condenser coils, typically found at the back or underneath the unit. |

| 3 | Use the vacuum cleaner to gently remove dust and debris from the coils. Be careful not to damage any components. |

| 4 | For stubborn dirt, dampen a soft cloth with the cleaning solution and wipe the coils thoroughly. |

| 5 | Allow the coils to dry completely before plugging the appliance back in. |

Regular maintenance of the condenser coils can significantly extend the life of your appliance and improve its energy efficiency.

How to Replace the Door Seals

Replacing the door seals on your appliance is a crucial maintenance task that can enhance efficiency and prevent energy loss. Over time, these seals may wear out, leading to leaks and reduced performance. This guide provides step-by-step instructions to help you complete the process smoothly.

Gather Necessary Tools

Before starting, ensure you have the right tools on hand. You will need:

- Screwdriver

- Replacement seals

- Cleaning cloth

- Sealant (if needed)

Steps for Replacement

Begin by removing the old seals carefully. Use the screwdriver to detach any screws holding the seal in place. Once removed, clean the surface to eliminate dirt and debris. Then, align the new seal with the edges and secure it according to the manufacturer’s guidelines. Ensure it fits snugly to create an effective barrier.

After installation, inspect the seal for any gaps or misalignments. A proper fit is essential for optimal performance. If necessary, apply sealant to reinforce the edges. Regularly check the seals to maintain your appliance’s efficiency and extend its lifespan.

Fixing Noisy Compressor Issues

Addressing loud compressor sounds can greatly enhance the overall performance and comfort of your appliance. Identifying the source of the noise is essential in implementing effective solutions.

Common causes of a noisy compressor include:

- Improper installation or alignment

- Loose components or mounting brackets

- Debris obstructing airflow

- Wear and tear on internal parts

To mitigate these issues, consider the following steps:

- Check Installation: Ensure the compressor is level and securely mounted.

- Tighten Loose Parts: Inspect and tighten any screws or brackets that may be causing vibrations.

- Clear Obstructions: Remove any debris that may be blocking airflow or affecting operation.

- Examine Internal Components: If noise persists, consult a professional to check for worn-out parts that may need replacement.

By following these guidelines, you can effectively reduce noise and improve the efficiency of your cooling system.

Maintaining the Ice Maker Functionality

Ensuring the optimal performance of your ice-making unit requires regular attention and care. Proper maintenance not only enhances efficiency but also prolongs the lifespan of the appliance. By following some straightforward guidelines, you can keep your ice maker in peak condition.

First and foremost, routinely inspect the water supply line for any signs of leaks or blockages. A clear and functioning water line is essential for the consistent production of ice. Additionally, regularly clean the ice bin and surrounding areas to prevent the buildup of residue or contaminants that could affect the quality of the ice.

Another crucial aspect is to monitor the temperature settings. Ensure that the freezer maintains an appropriate temperature for ice formation, typically around 0°F (-18°C). If the temperature is too high, ice production may be sluggish or insufficient.

Furthermore, check the ice maker’s components, such as the auger and motor, to ensure they are operating smoothly. Lubricating moving parts and addressing any unusual noises promptly can prevent more significant issues down the line. By staying proactive with these maintenance tips, you can enjoy a reliable ice maker for years to come.

Identifying Electrical Faults Safely

When dealing with electrical appliances, ensuring safety is paramount. Recognizing potential issues without risking personal safety involves careful observation and methodical approaches. This section outlines essential steps for safely identifying electrical malfunctions.

Essential Safety Precautions

- Always unplug the appliance before inspecting it.

- Use insulated tools to prevent accidental shocks.

- Work in a dry area to minimize the risk of electric shock.

- Wear rubber-soled shoes for additional protection.

Common Signs of Electrical Issues

- Unusual Noises: Buzzing or humming sounds may indicate a malfunction.

- Burning Smell: Any unusual odors could signify overheating components.

- Frequent Tripping: Circuit breakers that trip regularly suggest an underlying problem.

- Visible Damage: Frayed wires or scorch marks are clear indicators of issues.

Replacing Light Bulbs and Covers

Illumination is essential for the proper functioning of your appliance. Regular maintenance of light sources ensures optimal visibility inside the unit. In this section, you will learn how to efficiently replace bulbs and covers, keeping your appliance in top condition.

Follow these simple steps to safely change the light bulbs:

| Step | Description |

|---|---|

| 1 | Ensure the appliance is unplugged to avoid any electrical hazards. |

| 2 | Remove the light cover by twisting or sliding it off, depending on the design. |

| 3 | Take out the old bulb by gently twisting it counterclockwise. |

| 4 | Insert the new bulb by twisting it clockwise until secure. |

| 5 | Reattach the light cover by placing it back into position and securing it. |

| 6 | Plug the appliance back in and test the new bulb. |

Following these steps will help maintain a well-lit environment inside your appliance, enhancing both functionality and accessibility.

Upgrading Components for Better Performance

Enhancing the functionality of your appliance can significantly improve its efficiency and lifespan. By replacing or upgrading specific parts, you can achieve optimal performance and ensure that your unit operates at its best. This section explores various components that can be upgraded for superior operation.

Key Components to Consider

Several essential parts can be upgraded to boost overall performance. Focusing on these components can lead to improved functionality:

| Component | Benefits of Upgrading |

|---|---|

| Compressor | Increased cooling efficiency and reduced energy consumption. |

| Fan | Improved air circulation and reduced noise levels. |

| Thermostat | More precise temperature control and energy savings. |

Implementation Tips

When considering upgrades, ensure compatibility with your appliance. Research specifications and consult with professionals if necessary. Proper installation is crucial to maximize the benefits of any enhancements made.

When to Call a Professional Technician

Determining when to seek assistance from a qualified technician can be challenging. Certain situations may arise where expert intervention is necessary to ensure the proper functioning of your appliance. Recognizing these moments can save time, effort, and potentially costly mistakes.

Firstly, if you encounter persistent issues that do not resolve with basic troubleshooting, it may be time to contact a professional. Unusual noises, inconsistent performance, or error messages often indicate underlying problems that require specialized knowledge and tools.

Additionally, if you notice any signs of wear or damage, such as frayed wires or leaking components, it is essential to seek help immediately. Ignoring these issues can lead to further complications and safety hazards.

Lastly, if your appliance is still under warranty, attempting repairs on your own may void that coverage. Consulting with an expert ensures that any necessary repairs are conducted without compromising your warranty.