Keeping your outdoor machinery in top condition is essential for optimal performance and longevity. Whether you are a professional landscaper or a weekend warrior, understanding the intricacies of your equipment can greatly enhance your efficiency and results. This guide aims to provide comprehensive insights into the upkeep and troubleshooting of your grass-cutting devices.

In this section, we will explore various techniques and best practices for ensuring your equipment operates smoothly. From routine checks to in-depth fixes, having a reliable source of information can save time and money. Emphasizing proactive care will help you avoid common pitfalls and maintain peak functionality throughout the seasons.

Equipping yourself with knowledge about your machinery not only boosts your confidence but also empowers you to tackle any issues that may arise. This resource will serve as a valuable tool, guiding you through the essential aspects of maintenance, ensuring that your equipment remains reliable and efficient for years to come.

Understanding John Deere Mowers

When it comes to maintaining your outdoor space, the right equipment makes all the difference. This section explores the essential features and benefits of various cutting machines designed for efficiency and durability. With a variety of models available, each designed to cater to specific needs, it’s crucial to understand their functionalities and how they contribute to a well-groomed landscape.

Quality and Performance: Renowned for their robust construction, these machines are engineered to provide exceptional performance. The innovative designs not only enhance cutting efficiency but also ensure longevity, allowing users to tackle diverse terrains with ease.

Ease of Use: User-friendly controls and ergonomic designs are central to these tools. Whether you’re a seasoned landscaper or a weekend enthusiast, navigating the functionalities becomes intuitive, reducing the learning curve significantly.

Maintenance Considerations: Regular upkeep is vital to prolonging the life of any cutting device. Familiarity with common issues and preventive care can greatly enhance performance, ensuring that the machine remains reliable throughout its lifespan.

Understanding these aspects empowers users to make informed decisions, ensuring that their investment leads to a beautiful and manageable outdoor environment.

Common Issues with Lawn Mowers

Maintaining a healthy and lush lawn can be challenging, especially when the equipment encounters problems. Various issues may arise during operation, leading to inefficient performance or complete failure. Understanding these common challenges can help users troubleshoot and ensure optimal functionality.

- Engine Problems:

- Difficulty starting

- Unexpected stalling

- Overheating

- Cutting Issues:

- Uneven cuts

- Grass clumping

- Inability to cut tall grass

- Fuel System Concerns:

- Fuel leaks

- Contaminated fuel

- Clogged fuel lines

- Electrical Failures:

- Dead battery

- Faulty ignition switch

- Broken wiring connections

- Deck and Blade Issues:

- Dull blades

- Deck rust

- Improper blade alignment

Addressing these common challenges promptly can enhance performance and prolong the lifespan of the equipment.

Tools Needed for Repairs

When it comes to maintaining outdoor equipment, having the right tools at your disposal is essential for effective and efficient work. A well-equipped toolkit not only simplifies the process but also ensures that tasks are completed safely and accurately. Familiarity with the necessary instruments can make a significant difference in the overall experience and outcome of your maintenance efforts.

First and foremost, a set of basic hand tools is crucial. This typically includes wrenches, sockets, and screwdrivers in various sizes. These items are fundamental for loosening and tightening bolts and screws, allowing access to different components. Additionally, pliers can be invaluable for gripping, twisting, or cutting materials as needed.

Power tools also play a significant role in streamlining the work process. An electric or cordless drill can save time when making adjustments or replacements. Moreover, a high-quality impact wrench is beneficial for dealing with stubborn fasteners that require extra torque.

For safety and precision, it is advisable to have personal protective equipment. Safety goggles, gloves, and ear protection should be worn to safeguard against potential hazards during the servicing process.

Lastly, don’t forget the importance of organizational tools. A magnetic tray or small bins can help keep fasteners and small parts sorted, minimizing the risk of loss and enhancing efficiency throughout the task.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring your equipment operates efficiently and reliably. Regular upkeep is essential for enhancing performance and extending lifespan. Follow these steps to keep your machinery in top condition.

Essential Tools and Supplies

- Wrench set

- Screwdriver set

- Oil and filter

- Fuel stabilizer

- Clean cloths

Maintenance Steps

- Check and change the oil regularly.

- Inspect and replace air filters as needed.

- Sharpen blades to ensure clean cuts.

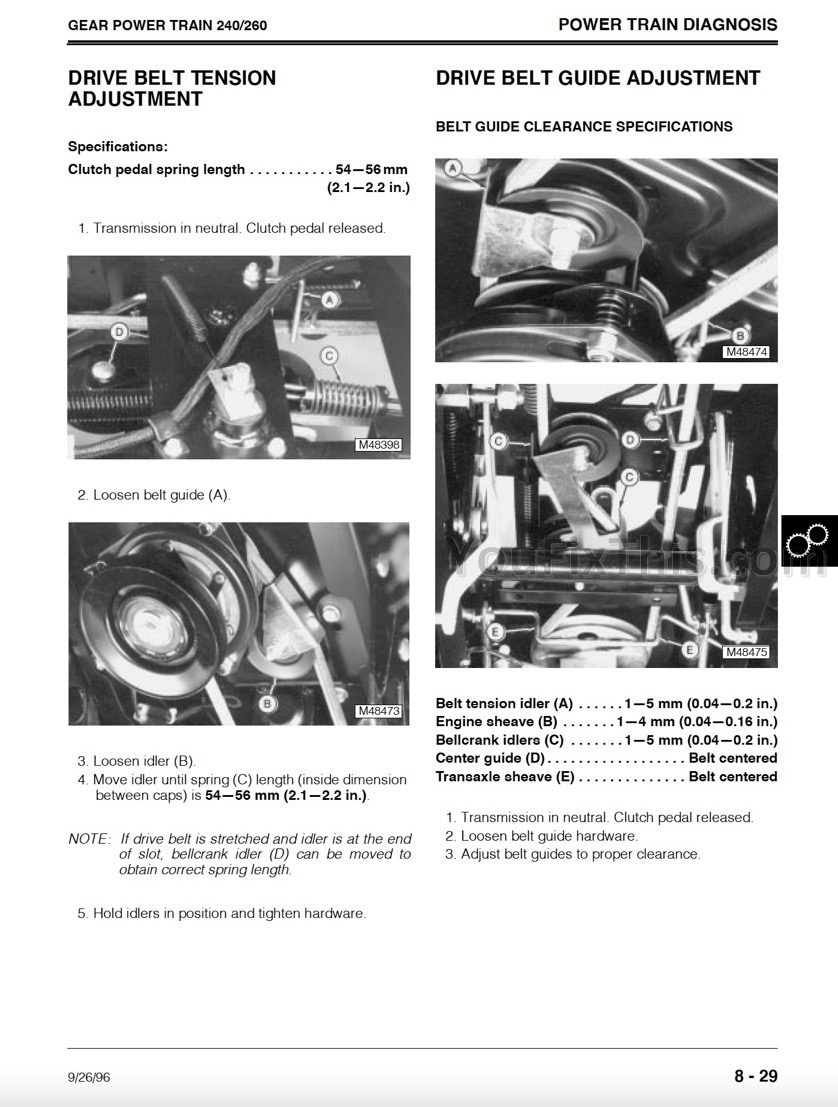

- Examine belts for wear and tension.

- Clean the exterior and undercarriage thoroughly.

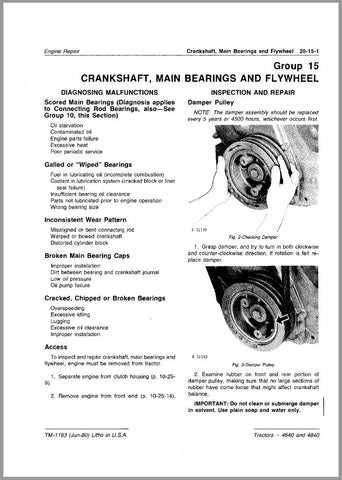

Diagnosing Engine Problems

Identifying issues within a power unit is crucial for maintaining optimal performance and longevity. Understanding the symptoms and potential causes can significantly streamline the troubleshooting process, allowing for effective resolutions and preventing further damage.

Common Symptoms of Engine Issues

- Unusual noises during operation

- Decreased power or performance

- Difficulty starting or frequent stalling

- Excessive smoke or exhaust emissions

- Vibrations or shaking while in use

Steps for Effective Diagnosis

- Inspect fuel levels and quality.

- Examine the air filter for blockages or damage.

- Check for loose or worn electrical connections.

- Evaluate the spark plug condition.

- Look for signs of oil leaks or contamination.

By methodically assessing these areas, operators can pinpoint the underlying causes and implement appropriate corrective actions, ensuring their equipment runs smoothly and efficiently.

Replacing Blades Effectively

Ensuring optimal performance of your cutting equipment often hinges on the condition of its sharp edges. Regularly swapping out worn or damaged blades is crucial for maintaining efficiency and achieving clean cuts. This section provides a concise guide to effectively replace these components, enhancing the overall functionality of your apparatus.

Step 1: Gather Necessary Tools

Before beginning the replacement process, collect essential tools such as a socket wrench, safety gloves, and a blade removal tool. Having everything at hand will streamline the procedure and minimize downtime.

Step 2: Safety First

Prioritize safety by disconnecting the power source. Ensure that the equipment is on a flat surface and stable to prevent any accidents during the replacement. Wearing gloves can protect your hands from sharp edges.

Step 3: Remove the Old Blades

Locate the bolts securing the blades and use the socket wrench to carefully unscrew them. Keep these bolts in a safe place, as they will be needed for attaching the new blades. Gently lift off the old blades and set them aside.

Step 4: Install New Blades

Position the new blades onto the mounting area, aligning them with the holes. Insert and hand-tighten the bolts to hold the blades in place before fully securing them with the wrench. Ensure they are snug but avoid over-tightening, which can lead to damage.

Step 5: Final Checks

After installation, double-check that everything is securely fastened. Reconnect the power source and run a test to ensure that the new blades are functioning correctly. Regular maintenance and timely replacements will keep your equipment running smoothly and effectively.

Electrical System Troubleshooting Tips

Troubleshooting electrical systems can often seem daunting, yet understanding some key principles can make the process more manageable. Identifying and resolving issues within these systems requires a systematic approach to ensure optimal performance and safety.

1. Check the Battery: A common source of electrical problems is a weak or dead battery. Ensure the battery is fully charged and that the terminals are clean and securely connected. A voltmeter can help determine if the battery is functioning correctly.

2. Inspect Fuses and Relays: Faulty fuses or relays can disrupt the flow of electricity. Examine these components for any signs of damage or corrosion. Replacing blown fuses or malfunctioning relays is a simple yet effective troubleshooting step.

3. Examine Wiring Connections: Loose or damaged wiring can lead to erratic performance. Carefully inspect all wiring for signs of wear, fraying, or disconnections. Secure any loose connections and consider replacing any compromised wires.

4. Test Switches: Malfunctioning switches can prevent systems from operating as intended. Use a multimeter to check the continuity of each switch. If a switch is found to be faulty, it should be replaced to restore proper functionality.

5. Monitor Ground Connections: A poor ground connection can lead to various electrical issues. Ensure that all ground points are clean, secure, and free from rust or corrosion. Improving ground connections can often resolve many electrical problems.

By following these troubleshooting tips, you can identify and resolve common electrical issues, helping to maintain efficient operation and prolong the lifespan of your equipment.

Seasonal Care for Mowers

Maintaining outdoor equipment throughout the year is essential for optimal performance and longevity. Seasonal care ensures that machines remain in top condition, ready to tackle tasks as they arise. By following a structured maintenance routine, operators can prevent issues and enhance the efficiency of their tools.

During spring, focus on cleaning and inspecting components. Remove debris, check for wear, and replace any damaged parts. Ensuring that sharp blades are ready for action is crucial for effective cutting. Additionally, changing the oil and filters at this time sets a solid foundation for the busy season ahead.

Summer demands regular checks, especially in hotter conditions. Monitor fuel levels and ensure that air filters are clean to avoid overheating. Keeping the equipment clean from grass clippings and dirt helps maintain its functionality and appearance.

As fall approaches, it’s time to prepare for storage. Clean the equipment thoroughly and check for any necessary repairs. Emptying the fuel system and changing the oil will help prevent issues during winter hibernation. Storing machines in a dry, sheltered area is also vital to protect them from the elements.

Winter care involves periodic checks to ensure that nothing has deteriorated during the off-season. Inspect for signs of rust or wear, and consider running the engine occasionally to keep it in good condition. Proper winterization will ensure that equipment is ready to perform when spring arrives.

Parts Replacement and Sourcing

Maintaining equipment requires attention to detail, particularly when it comes to sourcing and replacing components. Understanding where to find high-quality parts and how to effectively replace them is crucial for optimal performance and longevity of your machinery. This section will guide you through the essential steps for obtaining and installing replacement items.

Finding Quality Components

When it comes to sourcing parts, it’s vital to choose reliable suppliers. Look for authorized dealers, online marketplaces, or local retailers specializing in machinery components. Verify that the parts meet the original specifications to ensure compatibility and durability. Reading reviews and seeking recommendations can also help in identifying trustworthy sources.

Installation Tips

Proper installation of replacement components can prevent future issues. Always refer to the equipment’s specifications for guidance on the installation process. Use the right tools and follow safety protocols. If you encounter difficulties, consider consulting a professional to avoid costly mistakes. Regularly checking the condition of parts can help you anticipate replacements before they affect performance.

Enhancing Mower Performance

Improving the efficiency and effectiveness of your cutting equipment involves a combination of regular maintenance, optimal settings, and strategic upgrades. By focusing on these areas, you can ensure that your device operates at its best, providing a clean and precise cut while extending its lifespan.

| Improvement Area | Action Steps | Benefits |

|---|---|---|

| Regular Maintenance | Inspect and clean components, change filters, and sharpen blades. | Reduces wear and tear, enhances cutting efficiency. |

| Optimal Settings | Adjust height and speed according to grass type and conditions. | Ensures a uniform cut and prevents damage to the lawn. |

| Upgrades | Consider high-performance blades or advanced engine components. | Improves power output and reduces energy consumption. |

| Storage Practices | Store in a dry, clean area and cover when not in use. | Prevents rust and prolongs the life of the equipment. |

By implementing these strategies, you can significantly enhance the performance of your cutting device, making your tasks more efficient and enjoyable.

When to Seek Professional Help

Understanding the right moment to call in an expert can save time and prevent further complications. While some tasks may seem manageable, there are situations where professional intervention is crucial to ensure proper functioning and safety.

Consider reaching out for assistance if:

1. Complex Issues Arise: If you encounter problems that involve intricate systems or components, it’s wise to consult a specialist. These issues often require in-depth knowledge and specific tools that may not be available to the average user.

2. Safety Concerns Exist: If any situation poses a risk of injury or damage, prioritizing safety is essential. Professionals are trained to handle hazardous scenarios effectively.

3. Time Constraints: If you are pressed for time or unable to dedicate the necessary hours to troubleshoot and resolve the issue, seeking help can expedite the process.

4. Repeated Failures: If problems persist despite your attempts to fix them, it may indicate a deeper issue that requires expert analysis and repair.

5. Warranties and Guarantees: If your equipment is still under warranty, having a qualified technician handle the work ensures compliance with terms and protects your investment.