Understanding the intricacies of automobile upkeep is essential for any owner seeking longevity and optimal performance. A well-structured guide can serve as a valuable resource, providing insights into common issues, maintenance routines, and troubleshooting techniques.

Whether you are facing minor repairs or more complex challenges, having access to detailed instructions and expert advice can make all the difference. This resource aims to equip you with the knowledge necessary to tackle various tasks confidently, ensuring that your vehicle remains in peak condition.

From routine inspections to specific fixes, the information contained within can help demystify the repair process. By following step-by-step directions and leveraging practical tips, you can save time and money while enhancing your understanding of your vehicle’s mechanics.

Overview of the 2003 Trailblazer

This segment provides a comprehensive look into a versatile mid-size SUV, known for its robust performance and comfortable interior. Designed to meet the needs of families and adventure seekers alike, this vehicle combines functionality with style.

Key Features

- Spacious cabin with ample cargo space

- Available all-wheel drive for enhanced traction

- Variety of engine options to suit different preferences

- User-friendly infotainment system

Performance Highlights

- Strong towing capacity, ideal for hauling trailers

- Responsive handling for both city and highway driving

- Fuel efficiency ratings suitable for a vehicle in its class

Common Issues and Solutions

Vehicles often encounter a variety of challenges that can affect performance and safety. Understanding these prevalent problems and their corresponding remedies can help owners maintain their vehicles in optimal condition. This section outlines frequent concerns and effective solutions, empowering drivers to address issues promptly.

Electrical Problems: One of the most common issues involves electrical systems. Symptoms may include flickering lights or failure to start. Checking battery connections and replacing worn-out fuses can often resolve these issues. If problems persist, inspecting the alternator and wiring may be necessary.

Engine Overheating: Overheating can lead to serious engine damage. Common causes include low coolant levels, a malfunctioning thermostat, or a faulty water pump. Regularly checking coolant levels and maintaining the cooling system can prevent this issue. If overheating occurs, allow the engine to cool and inspect for leaks or damaged components.

Transmission Issues: Slipping gears or delayed engagement can indicate transmission problems. Regular fluid checks and changes are essential for maintaining transmission health. If issues arise, diagnosing the transmission fluid for contamination can help identify the problem early.

Suspension Noise: Unusual sounds from the suspension can signal worn-out components. Inspecting bushings, shocks, and struts can help pinpoint the source of the noise. Replacing damaged parts is crucial for a smooth and safe ride.

Brake Wear: Diminished braking performance often results from worn brake pads or rotors. Regularly inspecting brake components and replacing them as needed can enhance safety. Listening for squeaks or grinding noises can alert owners to potential issues before they escalate.

Essential Tools for Repairs

When tackling maintenance tasks, having the right equipment is crucial for achieving optimal results. Each project requires specific instruments to ensure efficiency and effectiveness, whether you’re performing minor adjustments or major overhauls. Below is a list of indispensable tools that every enthusiast should consider for their toolkit.

- Socket Set: A comprehensive socket set is essential for loosening and tightening various fasteners.

- Wrenches: Both adjustable and fixed wrenches are vital for gripping and turning nuts and bolts.

- Torque Wrench: This tool ensures that bolts are tightened to the correct specifications, preventing damage from over-tightening.

- Phillips and Flathead Screwdrivers: A variety of screwdrivers is necessary for working with different types of screws.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, bending, and cutting wire.

- Jack and Stands: These are crucial for lifting the vehicle safely during maintenance tasks.

- Oil Filter Wrench: This specialized tool simplifies the removal of oil filters during fluid changes.

- Multimeter: A multimeter is invaluable for diagnosing electrical issues and testing circuit components.

Equipping yourself with these fundamental tools will not only streamline the maintenance process but also enhance your ability to address a variety of tasks with confidence and precision.

Step-by-Step Maintenance Guide

Maintaining your vehicle is essential for ensuring its longevity and performance. This guide provides a systematic approach to keeping your automobile in optimal condition. By following these steps, you can enhance reliability and prevent potential issues.

1. Regular Oil Changes: Changing the oil at recommended intervals helps protect the engine. Use quality oil and replace the filter to maximize efficiency.

2. Tire Inspection: Check tire pressure monthly and inspect for uneven wear. Rotating tires regularly promotes even wear and extends their lifespan.

3. Brake System Check: Inspect brake pads and rotors for wear. Listen for unusual noises when braking, and address any issues promptly to ensure safety.

4. Fluid Levels: Regularly check and top off fluids, including coolant, transmission fluid, and brake fluid. Maintaining proper levels is crucial for optimal vehicle function.

5. Battery Maintenance: Inspect battery terminals for corrosion and ensure a secure connection. Test the battery periodically to avoid unexpected failures.

6. Filter Replacement: Change air and cabin filters as per the schedule. Clean filters improve air quality and engine performance.

7. Belts and Hoses Inspection: Regularly examine belts and hoses for cracks or wear. Replacing these components before failure can prevent breakdowns.

8. Light Functionality: Check all exterior and interior lights frequently. Replace any burnt-out bulbs to maintain visibility and safety.

By adhering to this comprehensive maintenance regimen, you can significantly improve the performance and reliability of your vehicle, ensuring a smooth driving experience for years to come.

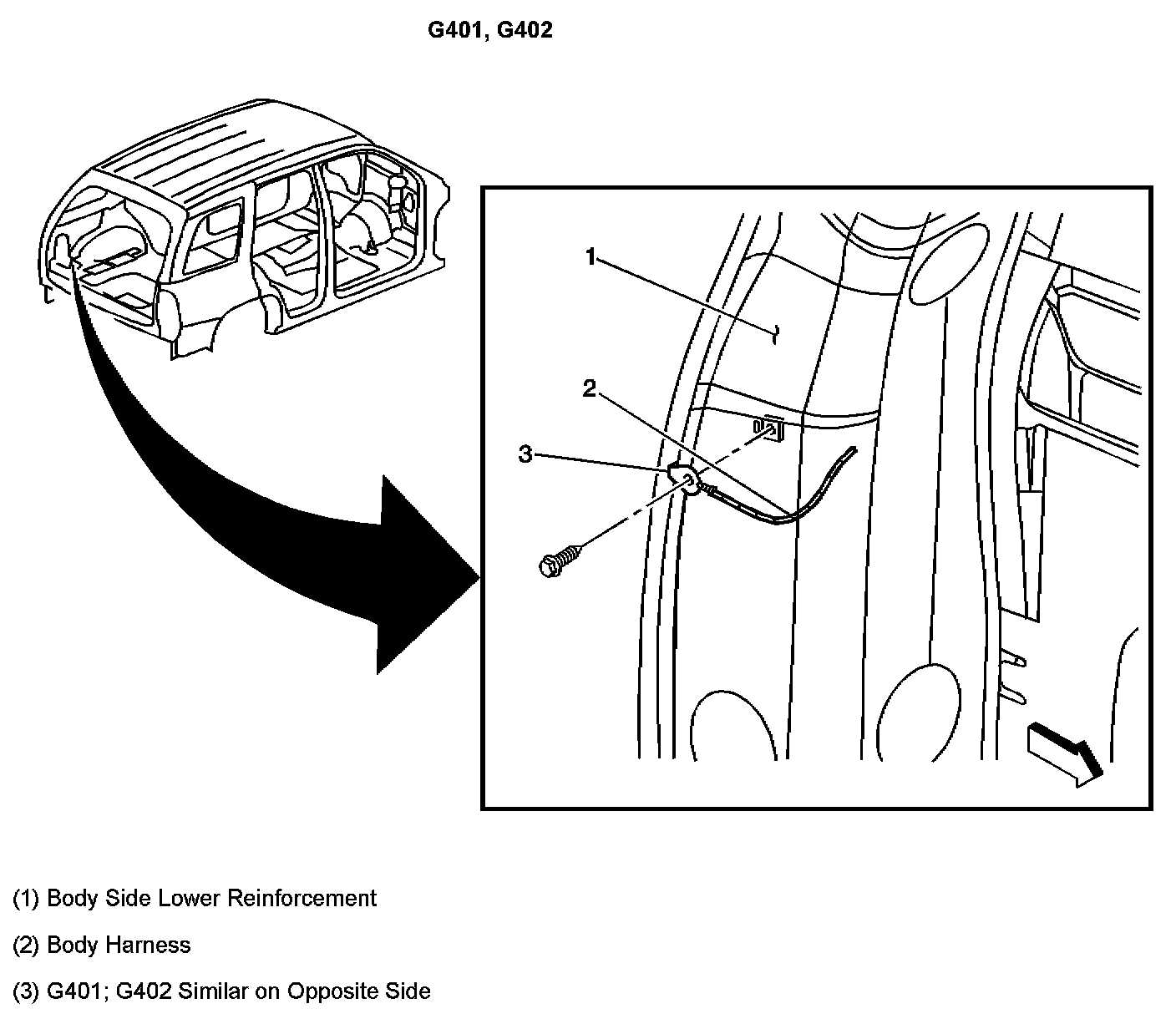

Electrical System Troubleshooting

The electrical system of a vehicle is crucial for its overall functionality and performance. When issues arise, it can lead to various malfunctions that affect everything from starting the engine to operating lights and other components. Understanding how to effectively diagnose and resolve electrical problems is essential for maintaining optimal vehicle operation.

Identifying Symptoms: The first step in troubleshooting is to observe any irregularities. Common indicators include dimming lights, intermittent starting issues, or malfunctioning accessories. Noting these symptoms can help narrow down potential causes.

Checking Fuses: A blown fuse is often the culprit behind electrical failures. Inspecting the fuse box for any damaged fuses is a simple yet effective way to troubleshoot. Replace any faulty fuses with the correct amperage to restore functionality.

Testing the Battery: A weak or dead battery can lead to numerous electrical problems. Use a multimeter to measure the battery voltage. A reading below 12.4 volts indicates a need for charging or replacement.

Examining Wiring and Connections: Damaged wiring or loose connections can create shorts or interruptions in the electrical flow. Carefully inspect all visible wires for fraying, corrosion, or disconnection. Secure any loose connections to ensure proper operation.

Utilizing Diagnostic Tools: Advanced troubleshooting may require specialized equipment such as a scan tool or oscilloscope. These tools can help pinpoint issues within the electrical system by providing detailed readings and diagnostic codes.

Consulting Circuit Diagrams: Understanding the vehicle’s electrical schematic can aid in identifying potential problem areas. Referencing these diagrams allows for targeted inspections and repairs.

By systematically following these steps, one can effectively troubleshoot and address electrical system issues, ensuring the vehicle operates smoothly and reliably.

Engine Performance Optimization Tips

Enhancing engine performance involves a combination of careful tuning and routine maintenance. By focusing on key areas such as airflow, fuel quality, and electronic management, vehicle owners can significantly improve efficiency and power output. Implementing a series of straightforward modifications can lead to noticeable gains in overall driving experience.

Air Intake and Exhaust Systems

Improving the air intake and exhaust pathways is crucial for optimizing performance. Upgrading to high-flow air filters and performance exhaust systems can enhance airflow, resulting in better combustion and increased horsepower.

| Modification | Benefit |

|---|---|

| High-Flow Air Filter | Increased airflow and improved throttle response |

| Performance Exhaust System | Reduced back pressure and enhanced engine sound |

Regular Maintenance Practices

Routine maintenance plays a pivotal role in sustaining optimal engine function. Regularly changing the oil, replacing spark plugs, and ensuring the fuel system is clean can prevent performance degradation over time. Additionally, keeping tires properly inflated and aligned contributes to overall vehicle efficiency.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 5,000 miles |

| Spark Plug Replacement | Every 30,000 miles |

| Fuel System Cleaning | Annually |

Transmission and Drivetrain Insights

This section delves into the complexities of power delivery systems and their pivotal role in vehicle performance. Understanding these components is essential for maintaining optimal functionality and ensuring a smooth driving experience. The intricacies of gear systems and the connections to the wheels play a significant role in the overall efficiency of the automobile.

Key Components

- Transmission: Responsible for regulating the power from the engine to the wheels, enabling the vehicle to change speeds effectively.

- Drivetrain: Comprises various elements that transfer power to the wheels, including the driveshaft, axles, and differential.

- Clutch: A crucial mechanism that engages and disengages the engine from the transmission, allowing for smooth gear transitions.

Common Issues and Maintenance Tips

- Regularly check fluid levels and condition to prevent overheating and component wear.

- Listen for unusual noises during operation, which may indicate underlying problems.

- Inspect connections and seals for leaks, ensuring all components remain secure and functional.

- Consider routine professional inspections to identify potential issues before they escalate.

By comprehensively understanding these elements, owners can enhance their vehicle’s longevity and performance, leading to a more enjoyable driving experience.

Cooling System Maintenance Procedures

Proper upkeep of the cooling system is essential for ensuring optimal performance and longevity of the vehicle’s engine. Regular checks and maintenance can prevent overheating and costly repairs. This section outlines the key procedures to keep the cooling system functioning effectively.

Inspection and Cleaning

Routine inspections are crucial for identifying any potential issues within the cooling system. This includes checking for leaks, examining hoses for wear, and ensuring that the coolant is at the appropriate level. Additionally, cleaning components such as the radiator and the reservoir helps maintain efficiency.

Fluid Replacement Schedule

Replacing the coolant at specified intervals is vital for preventing corrosion and maintaining proper heat transfer. Always refer to the manufacturer’s recommendations for the correct type and mixture of coolant to use. Below is a table outlining a general schedule for coolant replacement:

| Service Interval | Action |

|---|---|

| Every 30,000 miles | Replace coolant |

| Every 15,000 miles | Check for leaks and inspect hoses |

| Annually | Flush cooling system |

By adhering to these maintenance procedures, you can ensure that the cooling system remains reliable, thus safeguarding your engine’s performance and efficiency.

Brake System Repair Techniques

Maintaining the braking apparatus is essential for vehicle safety and performance. Proper attention to this system ensures reliable stopping power and longevity. This section outlines effective methods for addressing common issues related to braking components.

- Inspection

- Replacement

- Adjustment

- Cleaning

Regular inspection of the braking system is crucial. Look for:

- Wear on brake pads and shoes

- Fluid leaks in the hydraulic lines

- Corrosion on rotors and drums

- Wear on brake discs

If components show signs of wear, timely replacement is necessary to maintain safety. Follow these guidelines:

- Always use parts that meet OEM specifications.

- Ensure all fasteners are torqued to manufacturer standards.

- Break in new pads according to recommended procedures.

Adjustment of the braking system may be needed for optimal performance. Key areas include:

- Parking brake tension

- Caliper alignment

- Brake pedal height and free play

Finally, keeping components clean prevents dirt and debris from affecting performance. Suggested cleaning practices include:

- Using a brake cleaner for rotors and calipers.

- Avoiding oil-based products on braking surfaces.

- Regularly checking and cleaning the master cylinder.

Implementing these techniques will enhance the functionality and reliability of the braking system, contributing to safer driving experiences.

Suspension and Steering Adjustments

The proper functioning of the suspension and steering systems is crucial for a smooth and safe driving experience. Ensuring that these components are correctly calibrated can significantly enhance vehicle stability, handling, and comfort. Regular adjustments are necessary to address wear and tear, as well as to accommodate changes in driving conditions or vehicle load.

To maintain optimal performance, it is essential to understand the key elements involved in adjusting the suspension and steering. These include alignment angles, ride height, and the condition of various components such as shocks, struts, and linkages. Below is a summary of the important adjustments to consider:

| Adjustment Type | Description | Recommended Frequency |

|---|---|---|

| Wheel Alignment | Ensures wheels are parallel and aligned with the vehicle’s centerline. | Every 6 months or after hitting a large pothole. |

| Ride Height Adjustment | Modifies the distance between the vehicle chassis and ground for better handling and load capacity. | As needed, particularly after suspension modifications. |

| Suspension Component Inspection | Checks for wear in shocks, struts, and bushings that can affect ride quality. | Annually or with regular maintenance. |

| Steering Play Check | Identifies excessive movement in the steering wheel which can affect handling. | Every 6 months or if handling feels loose. |

By adhering to these guidelines, vehicle owners can ensure their suspension and steering systems operate effectively, ultimately improving the overall driving experience.

Safety Features and Recommendations

Ensuring the safety of occupants in a vehicle is paramount. This section highlights essential features designed to enhance protection during travel, along with practical recommendations for maintaining optimal safety standards.

Key Safety Features

- Airbags: Front and side airbags provide crucial cushioning during collisions, reducing the risk of injury.

- Anti-lock Braking System (ABS): This system prevents wheel lock-up during braking, maintaining steering control in emergencies.

- Electronic Stability Control (ESC): This feature helps maintain vehicle stability by detecting and reducing loss of traction.

- Traction Control: This technology prevents wheel spin during acceleration, enhancing grip on slippery surfaces.

- Safety Belt Reminder: Alerts occupants to fasten their seatbelts, promoting compliance with safety regulations.

Recommendations for Optimal Safety

- Regularly inspect and replace worn-out tires to ensure proper traction.

- Perform routine maintenance on brakes and suspension systems to enhance vehicle responsiveness.

- Keep safety features, such as airbags and seatbelt mechanisms, in good working order by adhering to service guidelines.

- Educate all passengers about the importance of seatbelt usage and proper seating positions.

- Stay informed about recalls or safety updates related to your vehicle model to ensure ongoing protection.