Effective maintenance of landscaping machinery is crucial for ensuring optimal performance and longevity. This section will delve into essential practices that help keep your equipment in peak condition, allowing you to tackle any outdoor task with confidence. Understanding the intricacies of your machinery can greatly enhance its efficiency and reliability.

Regular attention to mechanical systems can prevent common issues that arise during operation. Familiarity with troubleshooting techniques empowers users to address problems promptly, thus minimizing downtime. This guide aims to provide valuable insights into the necessary steps for proper upkeep, ensuring that your tools remain functional and efficient.

In addition to routine inspections, knowing how to perform adjustments and replacements is vital. This knowledge not only enhances the user experience but also extends the lifespan of the equipment. By following systematic procedures and guidelines, you can maintain your machinery effectively, ensuring that it serves you well for years to come.

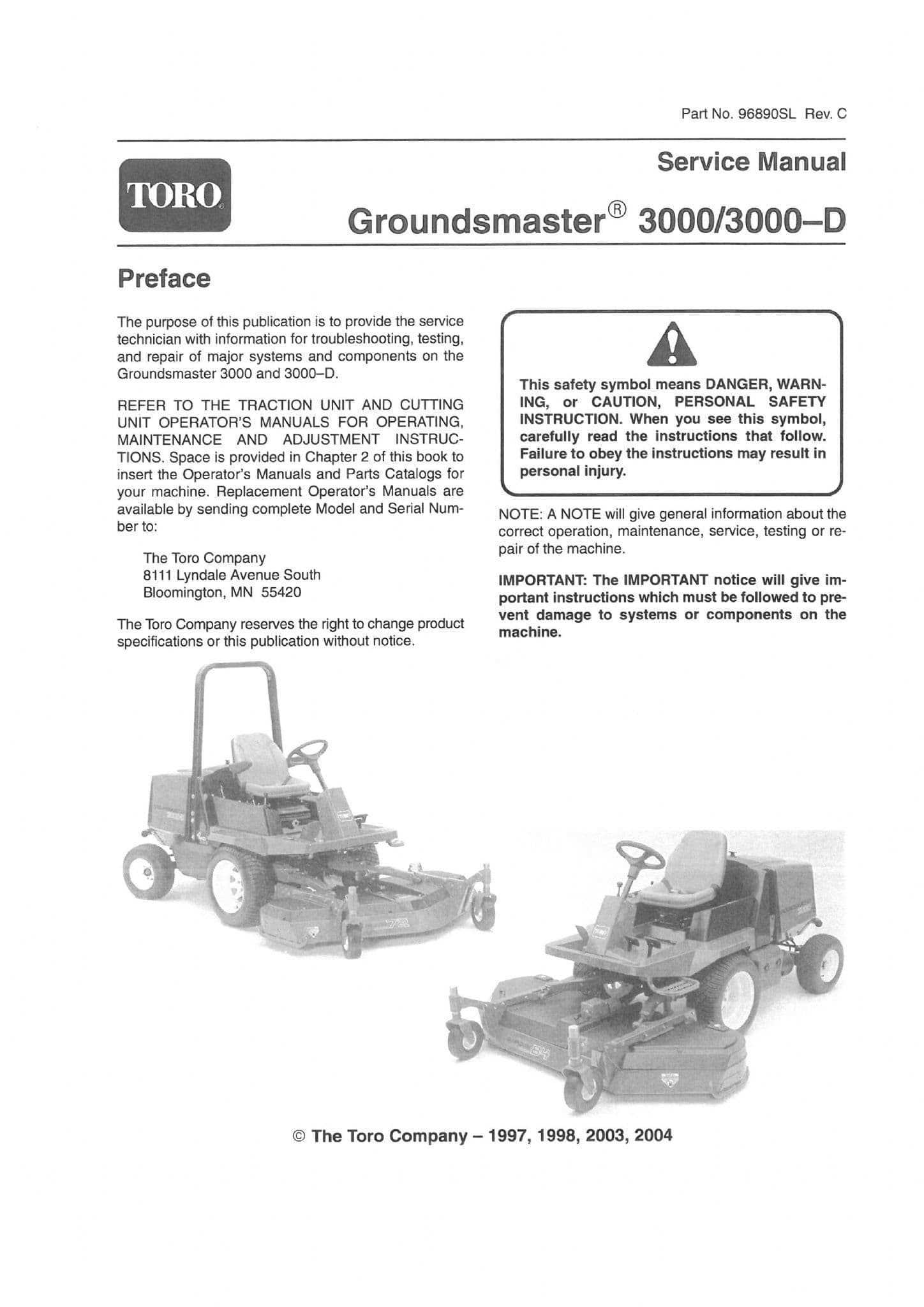

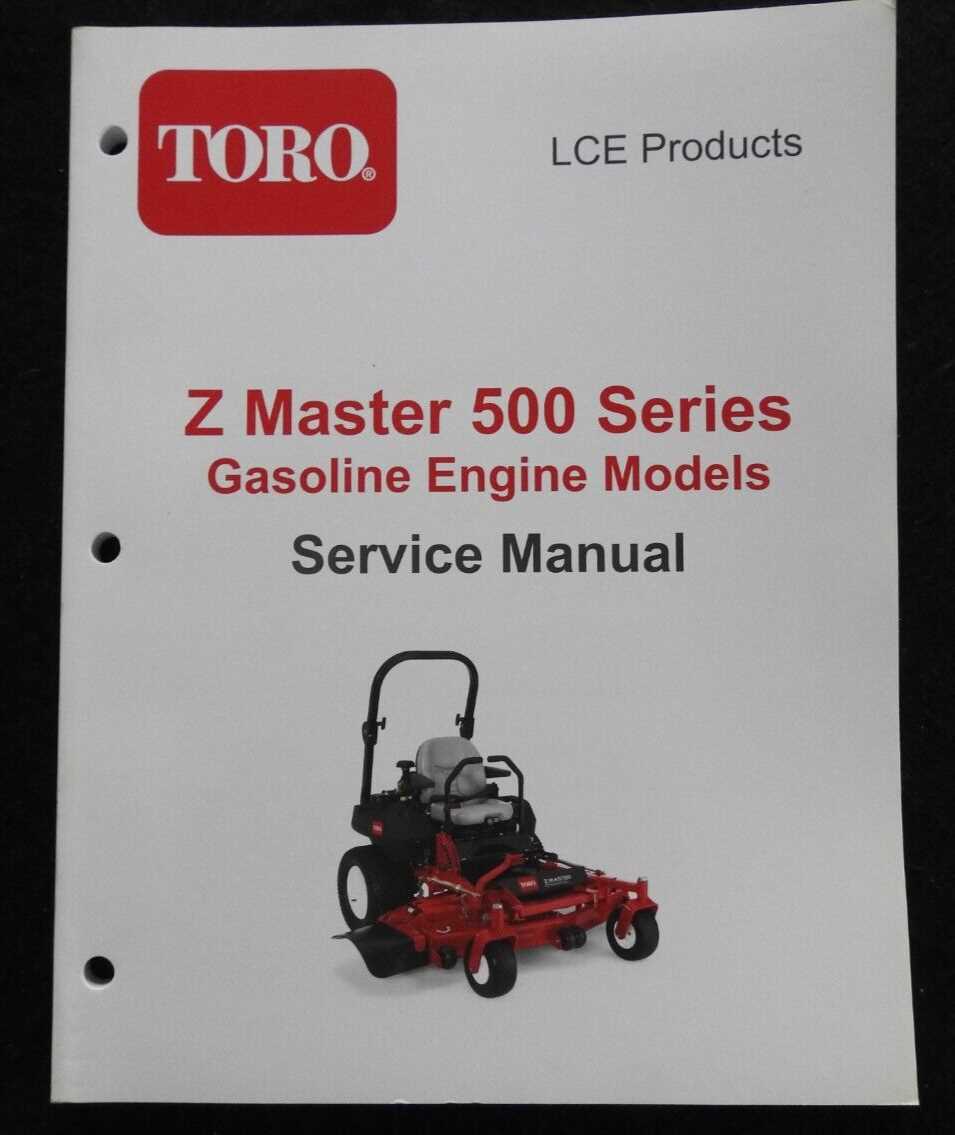

Toro Zero Turn Repair Manual

This section provides comprehensive guidance on maintaining and troubleshooting your mower to ensure optimal performance. By following the outlined procedures, you can effectively address common issues, enhance longevity, and maximize efficiency.

Understanding the intricacies of your mowing equipment is essential for seamless operation. Regular maintenance, including fluid changes, blade sharpening, and system inspections, is crucial to prevent mechanical failures. In addition, familiarizing yourself with the assembly and key components can aid in identifying potential problems before they escalate.

Furthermore, troubleshooting specific symptoms, such as poor cutting performance or engine difficulties, can help you implement timely solutions. This approach not only saves time but also minimizes repair costs, allowing you to enjoy uninterrupted use of your equipment throughout the season.

Overall, investing effort into proper upkeep will yield significant benefits, ensuring that your mower remains reliable and effective for all your landscaping needs.

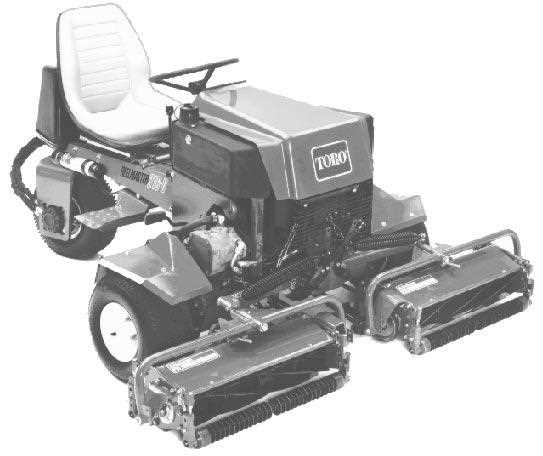

Understanding Zero Turn Mowers

These innovative mowing machines are designed to offer exceptional maneuverability and efficiency for lawn care. Their unique construction allows users to navigate around obstacles with ease, providing a professional finish to any landscape. With a focus on flexibility and performance, they have become a popular choice among homeowners and landscapers alike.

Key Features

- Enhanced Agility: The design allows for sharp turns and quick directional changes.

- Speed Control: Operators can adjust their pace easily, ensuring a consistent cut.

- Comfort: Many models come equipped with ergonomic seating and intuitive controls.

Advantages of Using This Type of Mower

- Time Efficiency: The ability to navigate around trees, flower beds, and other obstacles reduces mowing time.

- Quality of Cut: The design helps achieve a uniform cut, enhancing the overall appearance of the lawn.

- Versatility: Suitable for various terrains, making them ideal for both residential and commercial properties.

Common Issues in Toro Models

Many operators experience a range of problems with specific mower models, often stemming from mechanical and electrical components. Understanding these issues can enhance maintenance practices and improve overall performance.

Engine Performance Problems

Engine-related difficulties are among the most prevalent concerns. Symptoms can include stalling, reduced power, or failure to start. These issues may arise from fuel system blockages, air filter obstructions, or spark plug malfunctions. Regular checks and timely replacements can mitigate these complications.

Transmission and Steering Difficulties

Transmission failures can manifest as erratic movement or unresponsive steering controls. These problems often result from hydraulic fluid leaks, damaged hoses, or worn components. Proper maintenance of the hydraulic system and timely inspections can help prevent significant operational disruptions.

Basic Maintenance Guidelines

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. Following a structured maintenance routine can prevent issues and enhance the overall functionality of the machine. This section outlines fundamental practices that should be incorporated into your maintenance schedule.

Routine Checks

Performing routine inspections is crucial for identifying potential problems before they escalate. Key areas to focus on include:

| Component | Inspection Frequency | Action |

|---|---|---|

| Oil Level | Every 25 hours | Check and refill as necessary |

| Air Filter | Every 50 hours | Clean or replace if dirty |

| Blade Condition | Every 10 hours | Sharpen or replace if damaged |

Seasonal Maintenance

In addition to routine checks, seasonal maintenance tasks should be performed to prepare your machine for varying conditions. These tasks include:

- Inspecting belts and cables for wear and tear.

- Cleaning the undercarriage to prevent debris buildup.

- Checking tire pressure to ensure proper traction and stability.

Tools Required for Repairs

Having the right equipment is essential for maintaining and fixing machinery effectively. Proper tools not only make the task easier but also ensure safety and accuracy during the process. This section outlines the necessary implements needed for conducting maintenance and troubleshooting tasks.

Basic Hand Tools

Start with a set of basic hand tools, including wrenches, screwdrivers, and pliers. These items are fundamental for loosening and tightening various components. Additionally, a socket set can be particularly useful for accessing hard-to-reach bolts.

Specialized Equipment

For more intricate tasks, specific tools such as diagnostic gauges and multimeters may be required. These devices help in diagnosing electrical issues and monitoring performance. Additionally, investing in a torque wrench ensures that fasteners are tightened to the correct specifications, preventing damage.

Overall, assembling a comprehensive toolkit tailored for your machinery will facilitate efficient servicing and prolong its lifespan.

Step-by-Step Troubleshooting Process

When equipment experiences issues, a systematic approach to identifying and resolving problems is essential. This section outlines a comprehensive guide to troubleshooting common malfunctions, ensuring efficient operation and minimizing downtime.

The following steps will help in diagnosing and fixing issues:

- Identify the Symptoms: Observe the equipment and note any irregularities in performance.

- Check the Basics: Ensure that all components are functioning properly and that there are no obvious signs of damage or wear.

- Consult Documentation: Refer to relevant guides or manuals to understand standard operational procedures and specifications.

- Conduct Visual Inspections: Examine all accessible parts for loose connections, leaks, or signs of corrosion.

- Test Key Components: Use diagnostic tools to check the functionality of critical elements such as motors, belts, and electrical systems.

- Perform Systematic Checks: Work through the equipment systematically, testing one section at a time to isolate the issue.

- Document Findings: Keep a record of observations, tests conducted, and outcomes to help in future troubleshooting efforts.

By following these steps, operators can effectively troubleshoot equipment issues, ensuring optimal performance and longevity.

How to Replace Blades

Maintaining the cutting elements of your lawn maintenance equipment is essential for optimal performance and efficiency. Over time, blades can become dull or damaged, affecting the quality of the cut and the overall health of your lawn. Replacing the blades regularly ensures that your machine operates at its best, providing a clean and precise finish.

Gather Necessary Tools

Before beginning the blade replacement process, gather the necessary tools. You will need a socket wrench, a torque wrench, safety gloves, and, optionally, a blade removal tool. Ensure you have replacement blades that are compatible with your machine.

Step-by-Step Replacement Process

First, ensure the equipment is turned off and cooled down. Engage the parking brake for safety. Next, lift the machine using a jack or appropriate lifting equipment to access the underside easily. Using the socket wrench, remove the nuts or bolts securing the blades in place. Carefully detach the old blades and inspect the spindle for any signs of wear or damage.

Attach the new blades, ensuring they are positioned correctly according to the manufacturer’s specifications. Secure them tightly using the socket wrench, and if required, use the torque wrench to apply the recommended torque settings. Finally, lower the machine back to the ground and check the blade height to ensure proper cutting performance.

Regularly replacing the cutting elements is crucial for maintaining the efficiency of your lawn care equipment. Follow these steps to keep your blades sharp and ready for action.

Engine Maintenance Tips

Proper upkeep of your machine’s power unit is essential for optimal performance and longevity. Regular attention to various components can prevent costly repairs and ensure efficient operation. Below are key practices to maintain the engine effectively.

Regular Inspections

Conduct frequent visual assessments of the engine. Look for signs of wear or damage, such as leaks, corrosion, or loose connections. Ensuring that all parts are secure and functioning correctly helps avoid potential issues.

Fluid Checks and Changes

Monitoring and changing fluids is crucial for maintaining engine health. Regularly check oil levels, coolant, and fuel quality. Follow recommended intervals for oil changes and replace filters as needed.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours | Use manufacturer-recommended oil |

| Air Filter Inspection | Every 25 hours | Clean or replace if dirty |

| Coolant Level Check | Monthly | Top up if necessary |

| Fuel System Cleaning | Every 100 hours | Use fuel additives as needed |

Electrical System Troubleshooting

Diagnosing issues within the electrical system of a lawn maintenance machine is crucial for ensuring optimal performance. Problems may manifest as erratic behavior, failure to start, or intermittent power loss. A systematic approach is essential for identifying the root causes of these issues.

Begin troubleshooting by checking the power source, including the battery and charging system. Inspect connections for corrosion and ensure that all terminals are secure. Utilize a multimeter to measure voltage and continuity throughout the circuit.

| Component | Possible Issue | Solution |

|---|---|---|

| Battery | Low charge | Recharge or replace |

| Wiring | Frayed or damaged | Repair or replace |

| Switches | Malfunctioning | Test and replace if necessary |

| Fuses | Blown | Replace with correct amperage |

| Motor | Not starting | Check connections and test with a multimeter |

Following these steps can significantly improve the chances of identifying and resolving electrical issues effectively. Regular maintenance checks are also recommended to prevent future complications.

Hydraulic System Checkup

Regular inspection of the hydraulic system is essential for ensuring optimal performance and longevity of your equipment. This process involves checking various components to identify any potential issues that may affect functionality. A thorough examination helps maintain efficiency and prevent costly repairs in the future.

Key Components to Inspect

During the hydraulic system checkup, focus on the following critical elements:

| Component | Inspection Tips |

|---|---|

| Hoses | Look for signs of wear, leaks, or cracks. Ensure connections are secure. |

| Filters | Check for clogs or contamination. Replace if necessary to maintain flow. |

| Fluid Level | Verify that the hydraulic fluid is at the recommended level. Top up if needed. |

| Pump | Listen for unusual noises and check for leaks around seals. |

Routine Maintenance Practices

To ensure the hydraulic system operates smoothly, incorporate these maintenance practices into your routine:

- Change the hydraulic fluid as recommended by the manufacturer.

- Inspect and clean filters regularly to avoid blockages.

- Monitor the system’s performance and address any irregularities immediately.

Preparing for Seasonal Storage

As the seasons change, ensuring that your equipment is ready for storage is crucial for maintaining its longevity and functionality. Proper preparation can prevent damage from environmental factors and ensure that your machinery operates smoothly when the time comes for its next use.

Start by thoroughly cleaning the equipment. Remove any dirt, grass clippings, or debris that may have accumulated during use. This will help prevent corrosion and other damage while in storage. Next, consider draining any fuel left in the tank, as stale fuel can cause engine issues. If applicable, replace the oil and filters to ensure optimal performance when you resume use.

Check all components for wear and tear, making necessary repairs or replacements before storage. It’s also advisable to lubricate moving parts to protect against rust. Finally, cover the equipment with a breathable tarp to shield it from dust and moisture, while allowing any residual moisture to escape.

By following these steps, you can effectively prepare your machinery for seasonal storage, ensuring it remains in excellent condition and ready for action when needed.

Finding Replacement Parts

Locating the right components for your lawn maintenance equipment is essential for ensuring optimal performance and longevity. When the time comes for a replacement, it’s crucial to identify reliable sources where you can find high-quality parts that match your machine’s specifications.

Start by consulting the manufacturer’s official website or authorized dealers, as they typically provide an extensive catalog of original components. Many manufacturers offer online parts lookup tools that allow you to enter your model number to find the exact pieces needed.

Additionally, third-party suppliers and specialized retailers can be excellent alternatives. They often carry a wide variety of compatible components, sometimes at lower prices than original parts. Be sure to verify the reputation of these suppliers by checking customer reviews and ratings.

Online marketplaces also present a vast selection of parts. However, exercise caution by ensuring that you are purchasing from verified sellers to avoid counterfeit items. Always cross-reference part numbers and specifications before finalizing your purchase.

Lastly, joining forums or community groups dedicated to lawn care can provide insights and recommendations from fellow enthusiasts and professionals who have successfully sourced parts. This shared knowledge can be invaluable in your search for the right replacements.