Every motorcycle enthusiast knows the importance of understanding their machine’s inner workings. Proper upkeep not only enhances performance but also ensures longevity and safety on the road. This section delves into essential insights for owners looking to maintain their vehicles effectively, covering various aspects of maintenance and troubleshooting.

Equipping yourself with knowledge about your two-wheeled companion can make all the difference. Whether you’re tackling routine tasks or addressing specific issues, having a solid foundation of information is crucial. This guide aims to empower riders by providing a thorough exploration of key elements involved in maintaining high-performance motorcycles.

From routine inspections to intricate repairs, understanding the intricacies of your motorcycle fosters a deeper connection with the machine. Each model has its unique characteristics, and familiarizing yourself with these details will help you navigate any challenges that may arise. With the right approach, you can keep your motorcycle in optimal condition and enjoy countless adventures ahead.

Kawasaki ZX11 Maintenance Overview

This section provides a comprehensive guide on the essential upkeep and care required for optimal performance and longevity of your motorcycle. Regular maintenance is crucial to ensure reliability, safety, and overall functionality, encompassing a variety of tasks that should be performed periodically.

Establishing a routine maintenance schedule will not only enhance the riding experience but also prevent potential issues from escalating into more significant problems. The following table outlines key maintenance tasks along with their recommended intervals:

| Maintenance Task | Recommended Interval |

|---|---|

| Oil Change | Every 3,000 miles or annually |

| Air Filter Inspection | Every 6,000 miles |

| Brake Fluid Replacement | Every 2 years |

| Chain Lubrication | Every 500 miles |

| Tire Pressure Check | Monthly |

| Coolant Level Check | Every 3,000 miles |

| Spark Plug Replacement | Every 8,000 miles |

Following these guidelines will contribute significantly to the motorcycle’s performance and ensure a safe and enjoyable riding experience.

Essential Tools for ZX11 Repair

Effective maintenance and troubleshooting of your vehicle require a well-stocked toolkit. The right instruments not only facilitate smooth operations but also ensure safety and efficiency. This section outlines crucial equipment that will enhance your capability to perform tasks and manage issues efficiently.

Basic Toolkit Requirements

When preparing for mechanical tasks, certain fundamental tools are indispensable. These tools provide the versatility needed for various operations, from minor adjustments to significant overhauls.

| Tool | Purpose |

|---|---|

| Socket Set | Essential for loosening and tightening bolts and nuts. |

| Wrenches | Used for gripping and turning nuts and bolts. |

| Screwdriver Set | Required for fastening and removing screws. |

| Torque Wrench | Ensures bolts are tightened to specified torque settings. |

| Pliers | Useful for gripping, twisting, and cutting wires. |

Advanced Tools for Specific Tasks

For more complex procedures, additional specialized equipment may be necessary. These instruments allow for more precise work and help address specific challenges that may arise.

| Tool | Purpose |

|---|---|

| Multimeter | Used for electrical diagnostics and measurements. |

| Brake Caliper Tool | Facilitates brake system maintenance. |

| Compression Tester | Checks the engine’s compression levels. |

| Oil Filter Wrench | Assists in removing and installing oil filters. |

| Diagnostic Scanner | Helps in reading fault codes and troubleshooting issues. |

Understanding the ZX11 Engine Components

The engine serves as the heart of any high-performance motorcycle, with each component playing a vital role in ensuring optimal functionality. By grasping the intricate parts that make up this power unit, enthusiasts can enhance their knowledge and appreciation of mechanical engineering.

At the core of the engine is the cylinder block, which houses the pistons and provides the necessary structure for combustion. The cylinder head sits atop the block, containing vital components such as valves and camshafts that regulate airflow and manage the timing of the engine’s cycles.

Another essential part is the crankshaft, which converts the linear motion of the pistons into rotational motion, ultimately powering the motorcycle. Coupled with the crankshaft is the connecting rod, linking the pistons to the crankshaft, allowing for efficient energy transfer.

The fuel system also plays a crucial role, with components like injectors and carburetors working in tandem to deliver the right mixture of fuel and air for combustion. Additionally, the exhaust system expels spent gases, maintaining the engine’s performance and efficiency.

Understanding these components and their functions not only aids in maintaining the motorcycle but also enhances the overall riding experience by ensuring the engine operates at its peak performance.

Step-by-Step Brake System Servicing

Maintaining the braking mechanism is crucial for ensuring safety and optimal performance. Regular servicing helps identify wear and tear, allowing for timely replacements and adjustments. This guide outlines a systematic approach to inspect and maintain the brake system effectively.

Essential Tools and Materials

Before beginning the servicing process, gather the necessary tools and materials:

| Tool/Material | Purpose |

|---|---|

| Wrench set | For loosening and tightening bolts |

| Brake fluid | To refill the brake system |

| Torque wrench | For ensuring proper bolt tension |

| Cleaning solution | For cleaning brake components |

| Brake pads | To replace worn-out pads |

Servicing Procedure

Follow these steps for thorough servicing:

- Start by lifting the vehicle securely using a stand.

- Remove the wheel to access the braking components.

- Inspect the brake pads for wear and replace if necessary.

- Check the brake disc for any scoring or warping.

- Clean all components using a suitable cleaning solution.

- Refill the brake fluid reservoir with the recommended fluid.

- Bleed the brake system to remove any air bubbles.

- Reassemble the wheel and ensure all bolts are torqued to specifications.

- Conduct a test of the brake system to verify functionality.

Fuel System Troubleshooting Techniques

Troubleshooting the fuel delivery system is essential for maintaining optimal performance in any motorcycle. A variety of factors can affect fuel efficiency and engine operation, making it crucial to understand the common symptoms and their potential causes. By following a systematic approach, one can identify issues and implement effective solutions.

Step 1: Inspect Fuel Supply

Begin by examining the fuel supply lines for leaks, kinks, or blockages. Ensure that fuel is flowing freely from the tank to the engine. A clogged fuel filter can impede flow and lead to poor engine performance. Replacing a dirty filter is often a straightforward fix.

Step 2: Check Fuel Pump Functionality

The fuel pump plays a vital role in delivering the correct amount of fuel under pressure. Test the pump by listening for its operation when the ignition is turned on. If no sound is heard, or if the pump does not engage, it may need replacement. Additionally, measure the fuel pressure using a gauge to confirm it meets specifications.

Step 3: Examine Fuel Injectors

Fuel injectors must deliver the proper spray pattern and amount of fuel into the intake manifold. Remove the injectors and inspect them for clogs or signs of wear. Cleaning or replacing malfunctioning injectors can significantly enhance engine performance.

Step 4: Assess Air and Fuel Mixture

The air-fuel mixture must be balanced for optimal combustion. A malfunctioning sensor can disrupt this balance, leading to issues such as rough idling or stalling. Use diagnostic tools to check sensor readings and adjust as necessary to restore proper functionality.

Conclusion

By following these troubleshooting techniques, one can effectively identify and resolve fuel system issues. Regular maintenance and timely interventions can ensure a smooth-running engine and prolonged vehicle life.

Electrical System Diagnostics and Fixes

Diagnosing and addressing issues within the electrical system of a motorcycle is crucial for maintaining optimal performance and safety. This section provides insights into identifying common electrical faults and implementing effective solutions, ensuring that your ride remains reliable and enjoyable.

Common Electrical Issues

One frequent problem encountered is battery failure, which can manifest as difficulty starting the engine or dim lights. A multimeter can be used to check voltage levels, helping to determine if the battery is functioning correctly. Additionally, faulty wiring or corroded connections can lead to intermittent electrical failures. Inspecting the wiring harness for signs of wear or damage is essential for preventing further complications.

Effective Troubleshooting Techniques

To troubleshoot electrical problems, it’s essential to follow a systematic approach. Begin by checking fuses and relays, as these components often fail and can be easily replaced. Next, verify ground connections to ensure they are clean and secure. If issues persist, consider using a wiring diagram to trace circuits and identify specific areas that may be malfunctioning. Always remember to prioritize safety by disconnecting the battery before working on any electrical components. Regular maintenance and checks can significantly reduce the likelihood of encountering serious electrical issues.

Replacing the ZX11 Suspension Parts

Proper maintenance of the suspension components is crucial for enhancing the performance and safety of your motorcycle. Regularly inspecting and replacing worn or damaged parts ensures optimal handling and ride quality. This section provides detailed guidance on the process of replacing suspension elements, focusing on essential steps and best practices.

Identifying Components for Replacement

Before initiating the replacement process, it’s essential to identify which suspension parts require attention. Common components that may need replacing include:

- Shock absorbers

- Fork seals

- Springs

- Mounting brackets

Step-by-Step Replacement Process

- Gather necessary tools, including a socket set, wrenches, and a torque wrench.

- Raise the motorcycle using a lift or stand for better access to the suspension.

- Remove the old suspension parts carefully, taking note of their orientation and installation process.

- Inspect the surrounding components for any signs of wear or damage.

- Install the new parts, ensuring they are positioned correctly and securely fastened.

- Lower the motorcycle and perform a test ride to check the functionality of the new suspension components.

By following these guidelines, you can effectively replace suspension parts and maintain the overall performance of your vehicle.

Guidelines for Tire and Wheel Care

Proper maintenance of tires and wheels is essential for ensuring optimal performance and safety. Regular attention to these components not only extends their lifespan but also enhances the overall driving experience. Following a systematic approach to tire and wheel care can prevent potential issues and contribute to a smoother ride.

Regular Inspection

Conducting frequent checks on tire condition is crucial. Look for signs of wear, such as uneven tread patterns or bulges. Ensure that the air pressure is within the manufacturer’s recommended range, as incorrect pressure can lead to reduced traction and premature wear. Additionally, inspect the wheels for any cracks or damage that could compromise performance.

Cleaning and Maintenance

Maintaining cleanliness is vital for both tires and wheels. Regularly wash them with mild soap and water to remove dirt and grime, which can degrade materials over time. Apply a suitable tire dressing to protect against UV damage and enhance appearance. For wheels, consider using a dedicated cleaner to prevent corrosion and maintain their shine.

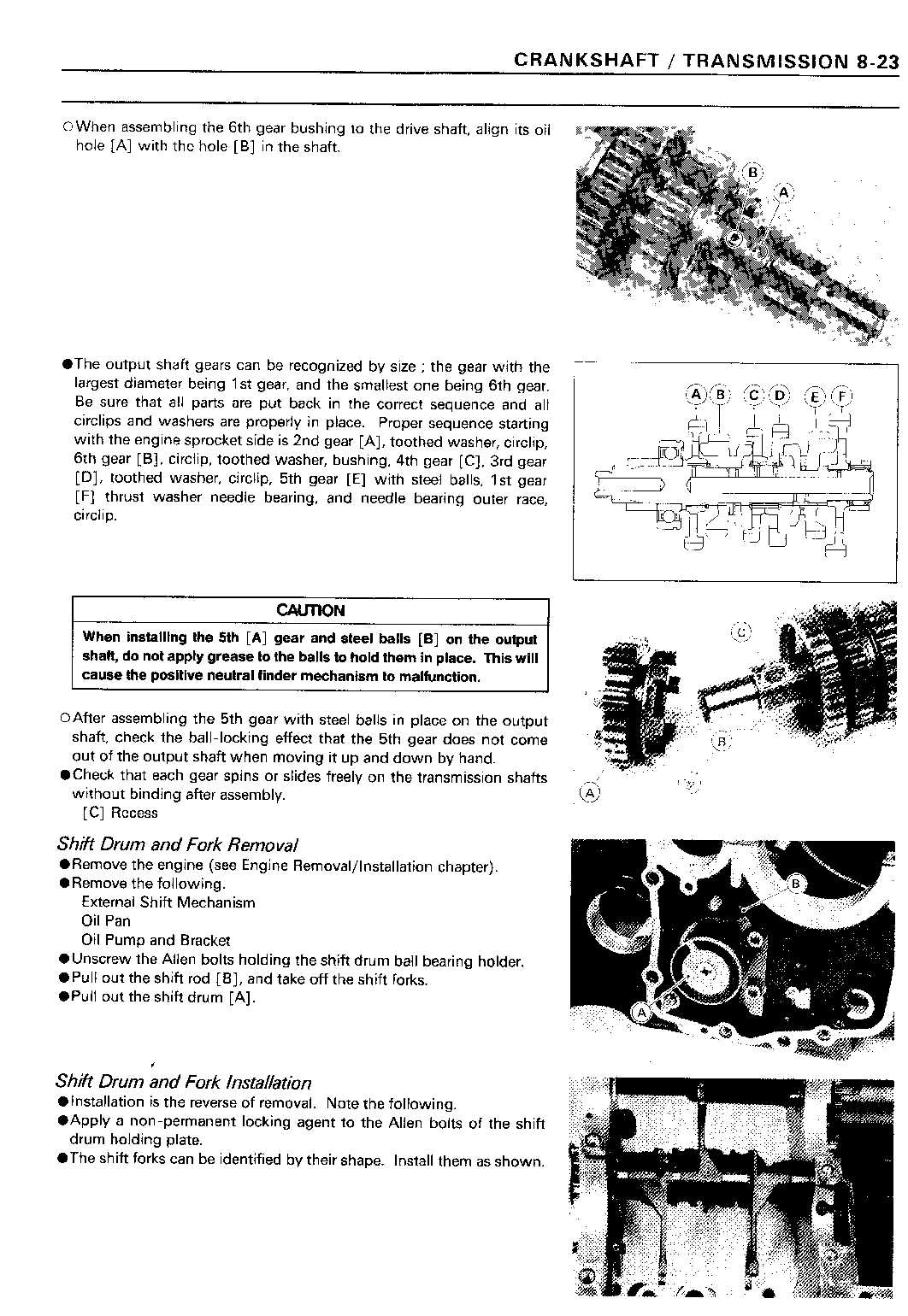

How to Maintain the ZX11 Transmission

Proper upkeep of the transmission system is essential for ensuring smooth performance and longevity. Regular attention to various components will enhance the overall functionality and reliability of the motorcycle. This section outlines effective strategies for maintaining the transmission system, ensuring optimal operation and preventing potential issues.

Regular Inspection and Fluid Replacement

Routine checks of the transmission fluid level and quality are crucial. Ensure the fluid is free of contaminants and has not degraded over time. Replacing the fluid at recommended intervals will help maintain proper lubrication and cooling, which is vital for the transmission’s performance.

| Maintenance Task | Frequency |

|---|---|

| Check Transmission Fluid Level | Every 1,000 miles |

| Replace Transmission Fluid | Every 10,000 miles |

| Inspect Seals and Gaskets | Every 5,000 miles |

| Clean Transmission Filter | Every 10,000 miles |

Component Care and Adjustment

In addition to fluid maintenance, attention to the various components of the transmission system is necessary. Regularly inspect gears, chains, and sprockets for wear and damage. Make adjustments as needed to ensure proper alignment and tension, which will contribute to smoother operation and reduce the risk of premature wear.

Common Issues and Their Solutions

This section addresses frequently encountered problems and their corresponding fixes for a popular high-performance motorcycle model. Understanding these common challenges can help owners maintain their machines efficiently and enhance their riding experience.

One prevalent issue involves the starting mechanism. Riders may notice difficulty in initiating the ignition, often due to battery depletion or faulty connections. To resolve this, check the battery voltage and connections for corrosion, ensuring all terminals are secure. If necessary, replace the battery with a compatible unit.

Another typical concern is engine overheating. Excessive heat can lead to significant damage if not addressed promptly. Regularly inspect the coolant level and radiator for leaks. Flushing the cooling system and replacing old coolant can improve temperature regulation and prevent overheating.

Transmission problems may also arise, manifesting as difficulty in shifting gears. This issue can be traced back to low fluid levels or worn clutch components. Regularly check the transmission fluid and replace it as needed. If the clutch feels spongy, consider adjusting or replacing the clutch cable.

Brake performance is crucial for safety, and any reduction in braking efficiency should be addressed immediately. Common signs include squeaking or grinding noises. Inspect the brake pads and rotors for wear, replacing them if they are below the recommended thickness. Additionally, ensure the brake fluid is at the appropriate level.

Finally, tire wear can affect handling and stability. Inspecting tire pressure and tread depth regularly is essential. If tires show signs of uneven wear or have reached their tread limit, replacement is necessary to maintain optimal performance and safety.

Upgrades and Performance Enhancements

Enhancing the performance of a motorcycle involves several strategies that focus on improving speed, handling, and overall efficiency. By implementing various upgrades, riders can achieve a more exhilarating experience while ensuring better control and reliability on the road.

Here are some effective modifications to consider:

- Exhaust System Upgrade: Replacing the stock exhaust with a high-performance system can significantly reduce weight and improve airflow, leading to better engine performance.

- ECU Remapping: Adjusting the engine control unit settings can optimize fuel delivery and ignition timing, enhancing power and throttle response.

- Suspension Improvements: Upgrading the suspension components, such as forks and shock absorbers, can provide better handling and comfort, especially during aggressive riding.

- Brake System Enhancement: Installing high-performance brake pads and rotors can improve stopping power, contributing to overall safety and performance.

- Air Intake Modification: Upgrading the air intake system can increase the amount of air entering the engine, boosting horsepower and torque.

It’s essential to ensure that all upgrades are compatible with the specific model and that they comply with local regulations. Regular maintenance and tuning after enhancements will also help maintain optimal performance over time.