Tools Required for Dupont Lighter Repair

Successful restoration of a premium ignition device often begins with the right set of tools. Each instrument plays a vital role in carefully disassembling, cleaning, and reassembling delicate components, ensuring a precise fit and functionality.

Precision Screwdrivers: These fine-tipped tools are essential for accessing small screws, allowing for accurate adjustments and secure assembly.

Needle-Nose Pliers: This tool helps grip and maneuver tiny parts, providing necessary control for repositioning or extracting delicate pieces during reassembly.

Soft Cleaning Brushes: Ideal for removing debris from intricate areas without causing scratches, these brushes maintain internal surfaces and moving parts free from buildup.

Compressed Air: Often used to dislodge dust from hard-to-reach crevices, this tool helps keep internal spaces clear, improving overall performance.

Lubricants: High-quality oils aid in reducing friction between moving elements, preserving smooth operation and extending the lifespan of the internal mechanism.

Carefully choosing and handling these tools ensures an efficient and meticulous restoration process, where each component is maintained in optimal condition.

Essential Instruments for Safe Maintenance

Proper upkeep of various devices requires the right set of tools and instruments to ensure safety and efficiency. Utilizing appropriate equipment not only enhances performance but also minimizes the risk of accidents during the maintenance process. This section outlines crucial instruments necessary for effective and secure handling of such tasks.

Key Tools for Effective Maintenance

- Protective Gloves

- Safety Goggles

- Precision Screwdrivers

- Multimeter

- Wrenches and Pliers

- Lubricants and Cleaners

Importance of Safety Equipment

Utilizing safety gear is paramount in any maintenance operation. This equipment safeguards against potential hazards associated with working on intricate devices. Here are some reasons why safety gear should be prioritized:

- Prevents injuries from sharp objects and chemicals.

- Reduces the risk of eye damage from debris.

- Ensures a comfortable working environment, enhancing focus and efficiency.

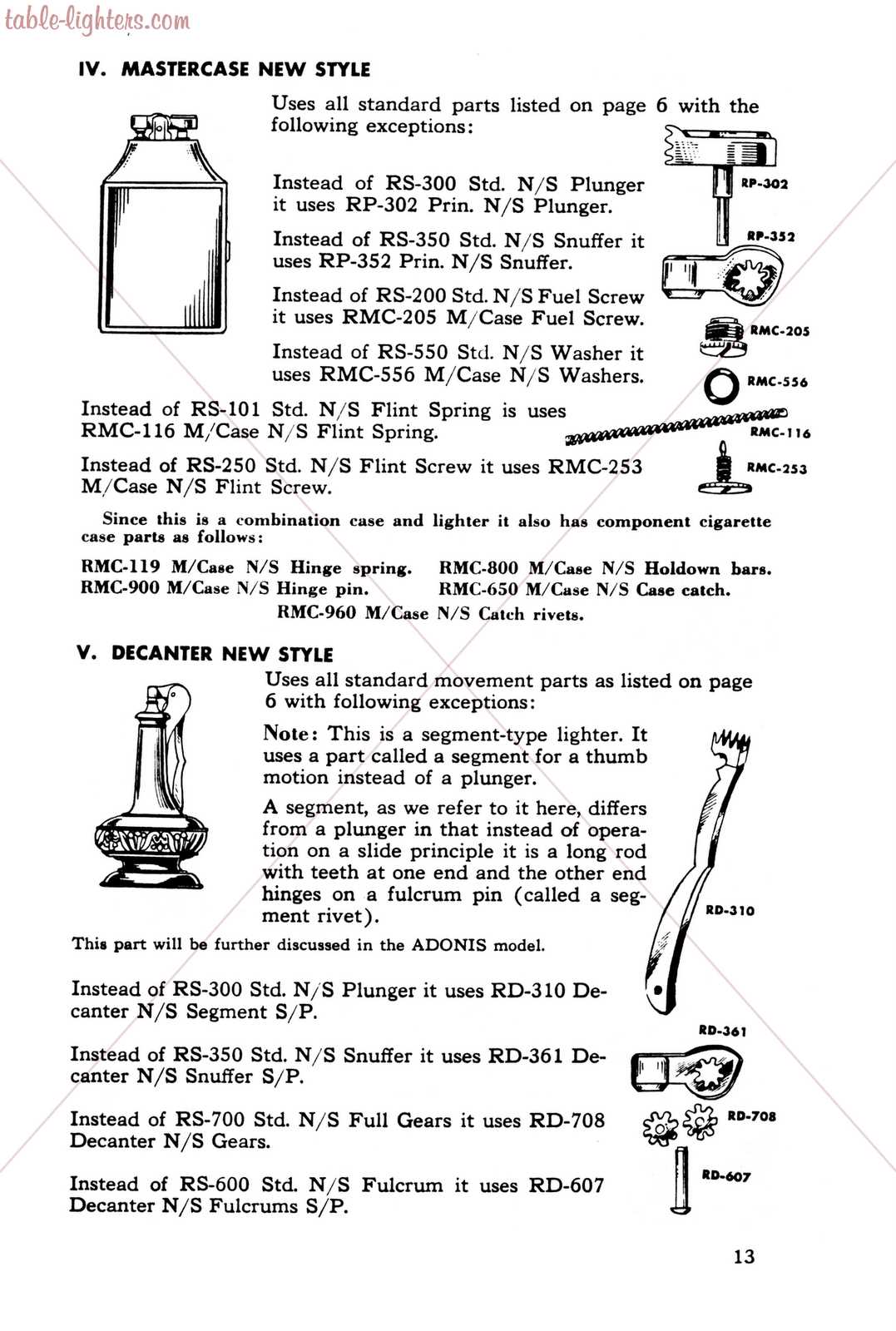

Disassembling the Lighter Safely

Taking apart a small ignition device requires careful attention to detail and safety measures. Understanding the internal components and their arrangement is crucial for a successful disassembly process. This section will guide you through essential steps to ensure you handle the task correctly and avoid any potential hazards.

Preparation and Tools

Before starting, gather the necessary tools, including a precision screwdriver set, tweezers, and a soft cloth to prevent scratches. Ensure you work in a clean, well-lit environment to minimize the risk of losing small parts. It’s also advisable to wear safety goggles to protect your eyes from any debris that may come loose during the process.

Step-by-Step Disassembly

Begin by carefully removing any exterior coverings, if applicable. Gently unscrew the fasteners, taking note of their sizes and positions. Place them in a small container to keep everything organized. As you access the inner workings, handle each component with care, as they can be delicate. If resistance is met, do not force anything, as this can lead to damage. Follow these steps methodically to ensure a smooth disassembly experience.

Step-by-Step Guide to Opening the Lighter

This section provides a detailed approach to safely accessing the internal components of a classic ignition device. Whether for maintenance or examination, following these steps will help ensure a smooth process without causing damage.

Tools Needed

- Flathead screwdriver

- Small Phillips screwdriver

- Plastic pry tool

- Soft cloth

Procedure

- Begin by laying the device on a soft cloth to avoid scratches.

- Identify the seams or joints where the casing meets. Carefully insert a flathead screwdriver into the seam.

- Gently twist the screwdriver to create a gap. Use a plastic pry tool to further separate the casing without damaging it.

- Once the casing starts to come apart, use the small Phillips screwdriver to remove any screws that may be securing the inner mechanism.

- Carefully lift the outer casing away, ensuring no components are caught or damaged in the process.

- Inspect the interior for any further maintenance needs or repairs.

Cleaning Techniques for Optimal Performance

Maintaining a high level of functionality in any portable ignition device is essential for ensuring longevity and reliability. Regular cleaning not only enhances performance but also prevents potential malfunctions that could arise from accumulated debris and residue. By employing effective techniques, users can maximize the efficiency of their device and enjoy a consistent experience.

Routine Inspection: Begin with a thorough examination of the external surfaces. Look for any signs of dirt or grime buildup that may hinder the device’s functionality. A soft, dry cloth can be used to gently wipe away any visible contaminants.

Use of Appropriate Cleaning Solutions: For stubborn stains, consider using a mild cleaning solution. Ensure that it is safe for the materials involved, as harsh chemicals can damage delicate components. Apply the solution sparingly and avoid soaking the device.

Focus on Internal Components: Accessing the internal mechanism is crucial for a comprehensive cleaning. Carefully disassemble the unit as per the guidelines, ensuring that all parts are laid out systematically. Utilize a soft brush or compressed air to remove dust and debris from intricate areas.

Reassembly and Final Checks: Once all components are cleaned and dried, reassemble the device with precision. Perform a final check to ensure everything is securely in place before testing the functionality. Regular upkeep will lead to a smoother and more enjoyable experience.

Removing Residue and Ensuring Smooth Operation

Regular maintenance is essential for maintaining optimal functionality and longevity of a fuel ignition device. Accumulation of residues can hinder performance and lead to malfunctions. This section outlines effective methods to eliminate buildup and promote seamless operation.

Identifying Residue: Before commencing the cleaning process, inspect the various components for signs of dirt, soot, or other residues. Pay special attention to areas where fuel is dispensed, as these are prone to accumulation.

Cleaning Techniques: Utilize a soft cloth or brush to gently remove surface contaminants. For stubborn residues, a mild solvent or cleaner can be applied. Ensure that all surfaces are thoroughly dried before reassembly to prevent moisture-related issues.

Lubrication: After cleaning, apply a suitable lubricant to moving parts to facilitate smooth operation. This step is crucial in preventing wear and ensuring that components function harmoniously. Avoid over-lubricating, as this can attract more dirt.

Final Inspection: Once maintenance is complete, conduct a thorough check to ensure all parts are securely reassembled. Test the device to confirm that it operates smoothly without any interruptions. Regular upkeep will significantly enhance its efficiency and lifespan.

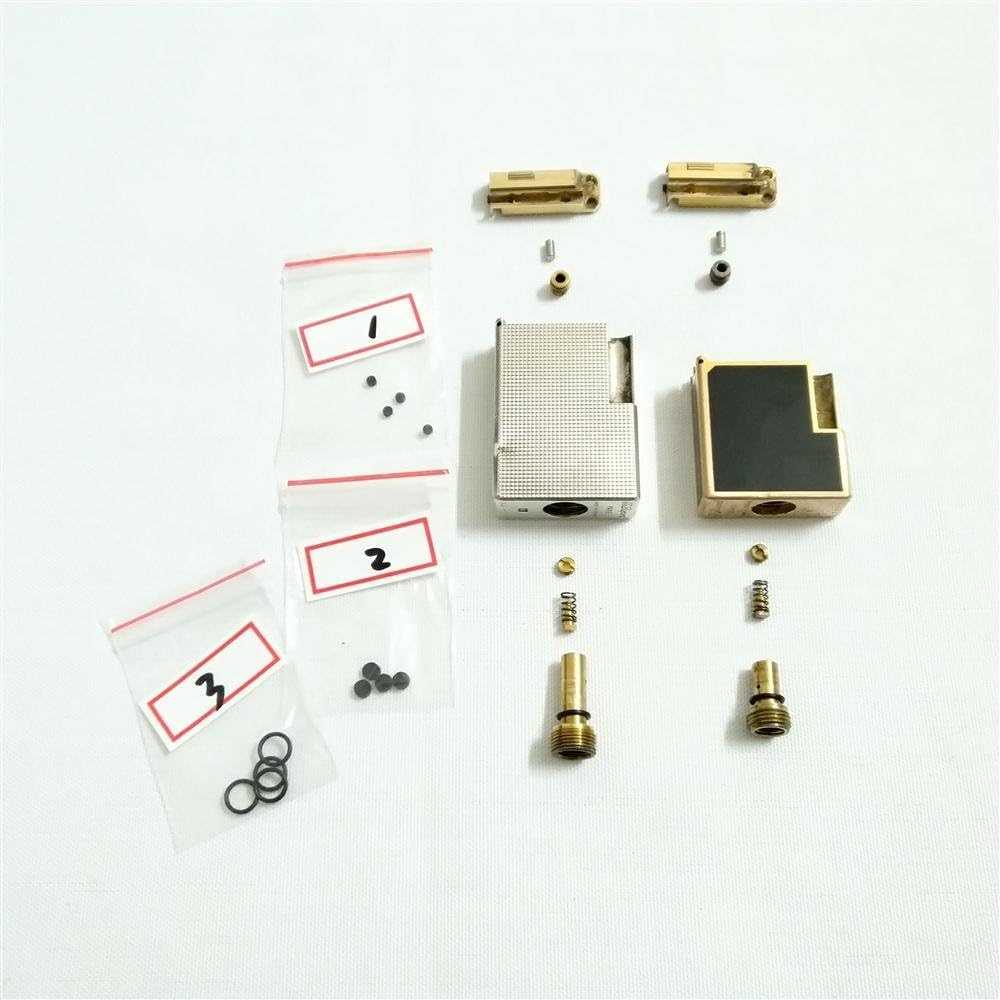

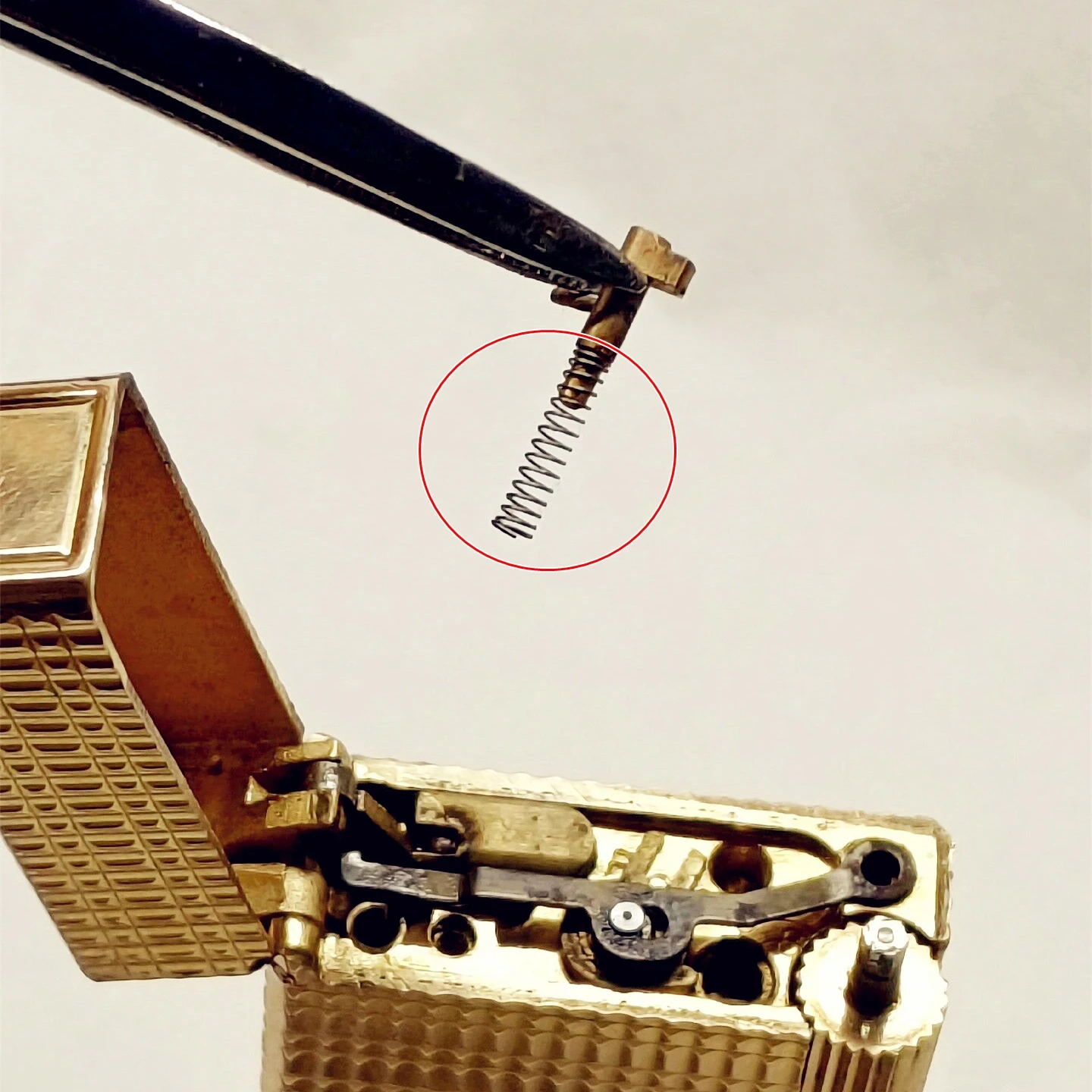

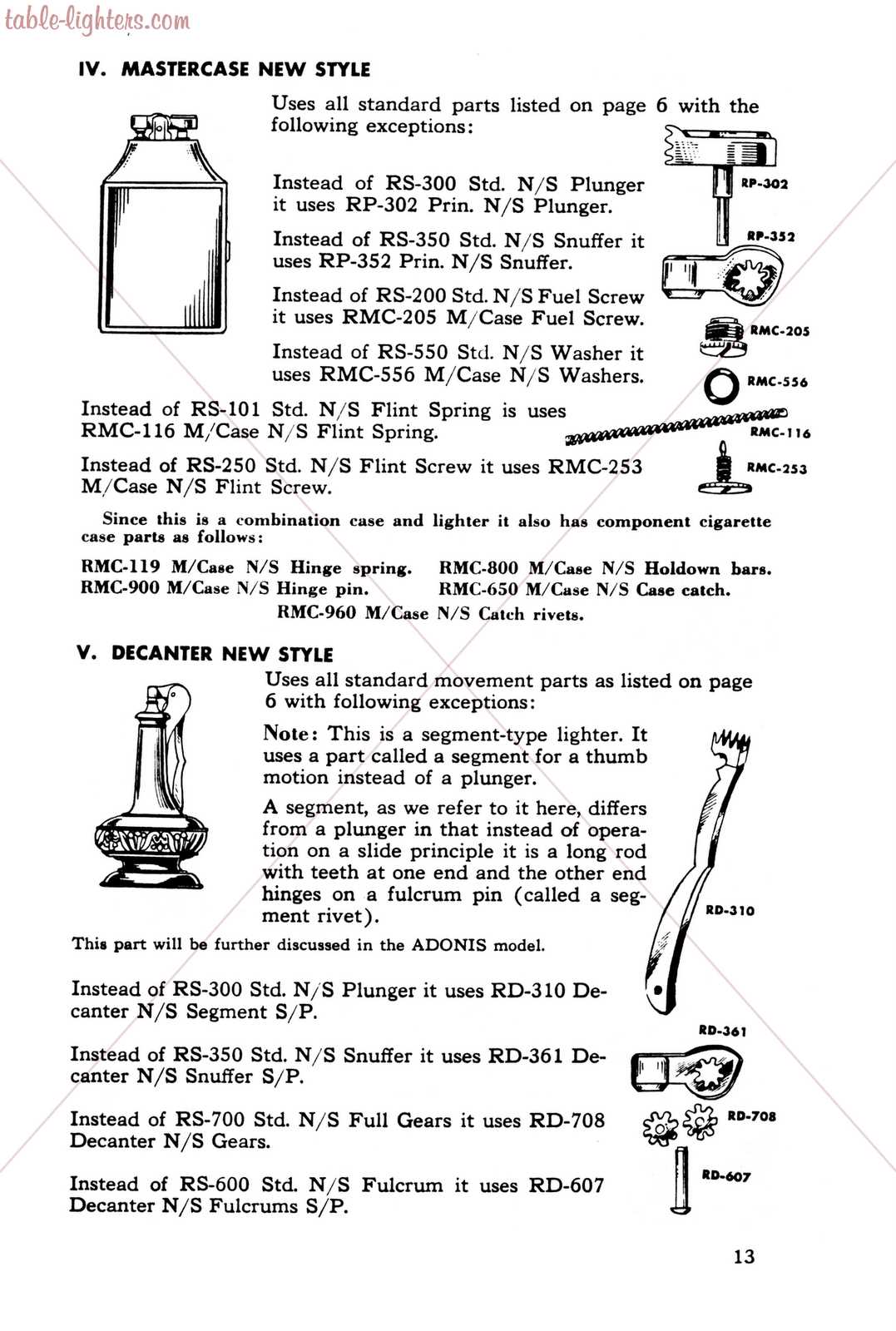

Replacing the Flint in a Dupont Lighter

Flint replacement is a vital maintenance task for ensuring the proper functioning of your ignition device. A worn-out flint can hinder the lighting process, causing frustration during use. This section provides a step-by-step guide to effectively replace the flint and restore optimal performance.

Tools Needed

- Small screwdriver

- Replacement flint

- Tweezers

- Cleaning cloth

Steps for Flint Replacement

- Begin by ensuring the device is completely empty of fuel to avoid any hazards.

- Locate the flint chamber, usually situated near the ignition mechanism.

- Carefully unscrew the cap or cover of the flint compartment using the small screwdriver.

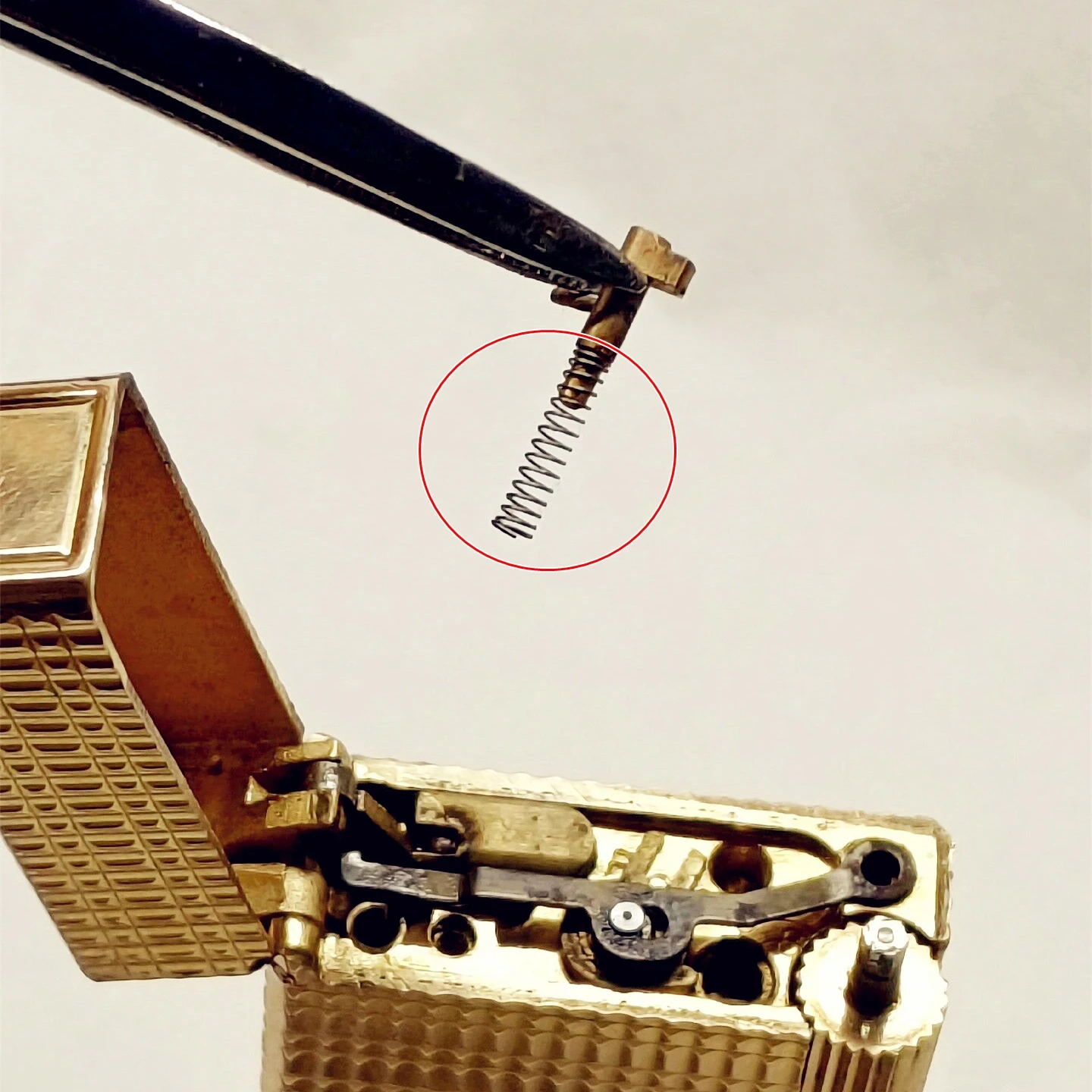

- Remove any remaining fragments of the old flint with tweezers.

- Insert the new flint into the chamber, making sure it fits securely.

- Replace the cap or cover and tighten it gently to avoid damage.

- Clean the exterior of the device with a cloth to maintain its appearance.

- Refill with fuel and test the ignition to ensure functionality.

Regularly checking and replacing the flint will help maintain the reliability and efficiency of your device, ensuring that it performs well when needed.

Detailed Instructions for Flint Replacement

Replacing the igniting element in a portable flame device is essential for maintaining its functionality. This process ensures that the device produces a reliable spark, allowing for consistent use. Follow these steps to successfully perform the replacement and restore your device to optimal performance.

Step 1: Begin by gathering the necessary tools and materials. You will need a replacement igniting element, a small screwdriver, and tweezers. Make sure to work in a well-lit area to facilitate the process.

Step 2: Carefully open the casing of the device using the small screwdriver. Take your time to avoid damaging any components. Once the casing is removed, locate the igniting element compartment.

Step 3: Gently remove the old igniting element using tweezers. Dispose of it properly, as it may contain sharp edges. Ensure the compartment is clean and free of debris before proceeding.

Step 4: Insert the new igniting element into the compartment. Make sure it fits snugly and is positioned correctly for optimal function. Avoid forcing it, as this could cause damage.

Step 5: Reassemble the casing, ensuring all parts are aligned correctly. Tighten any screws securely to maintain the integrity of the device. Double-check that the igniting element is still in place after closing the casing.

Step 6: Finally, test the device to ensure that it functions properly. A successful replacement will provide a strong spark, indicating that the device is ready for use.

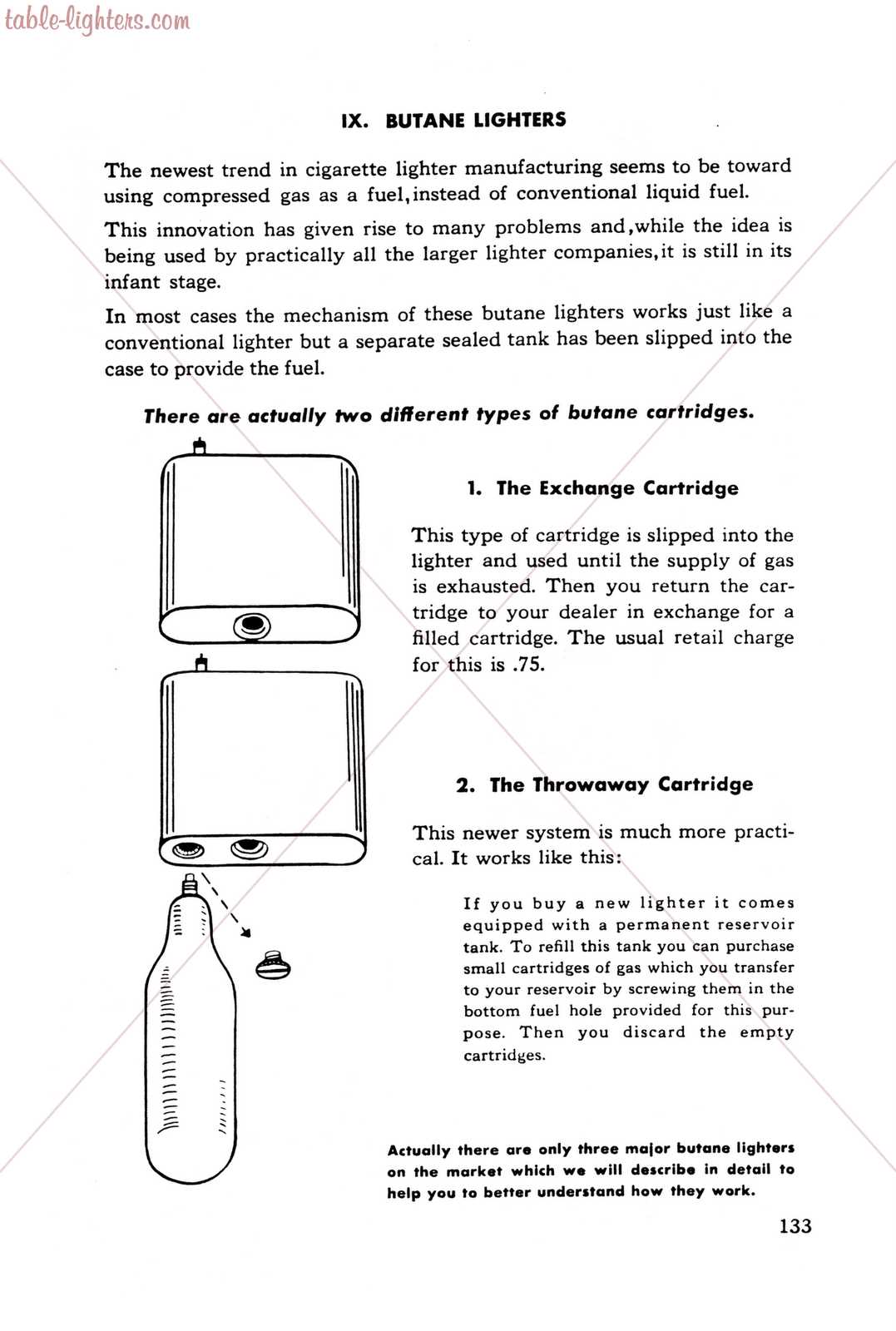

Refilling Dupont Lighters Correctly

Properly replenishing your igniting device is essential for optimal functionality and longevity. Understanding the correct technique not only enhances performance but also ensures safety during the process. Here, we will outline the necessary steps to effectively refill your instrument.

- Ensure the device is completely extinguished and cool to the touch.

- Locate the refill valve, usually situated at the bottom of the device.

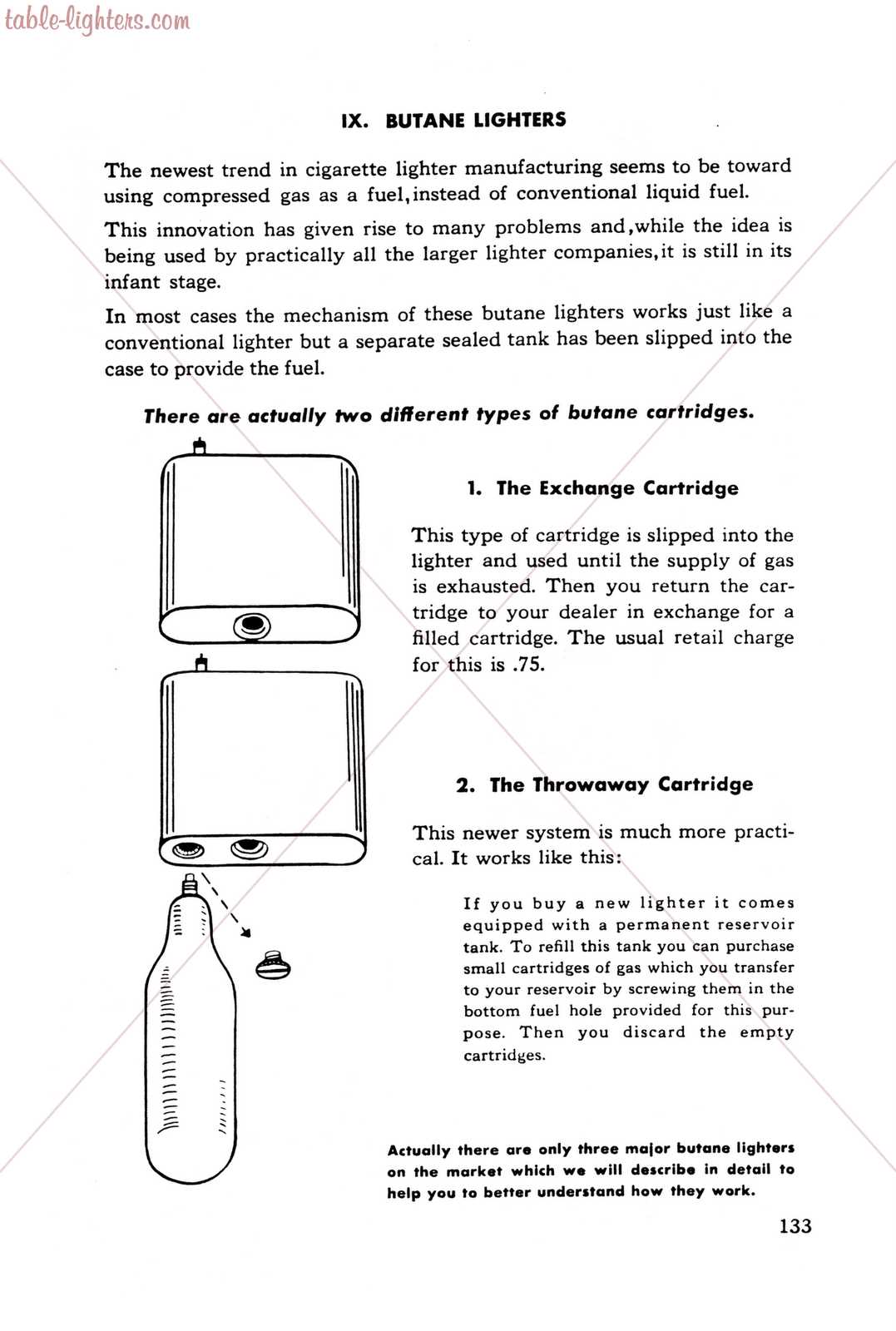

- Choose a compatible fuel source; butane is typically recommended.

- Hold the device upside down to prevent excess fuel from escaping.

- Align the fuel nozzle with the refill valve and press firmly.

- Allow the device to fill for several seconds, avoiding overfilling.

- Once filled, let the device rest for a few minutes to stabilize.

Following these steps will help maintain the integrity of your igniting apparatus. Regular maintenance and correct refilling techniques contribute significantly to its durability and performance.