In the world of two-wheeled transportation, maintaining optimal performance and longevity is essential. Enthusiasts and daily users alike seek to understand the intricacies involved in keeping their machines in peak condition. This section aims to provide comprehensive insights into the necessary procedures and tips for effective upkeep.

From routine inspections to addressing common issues, knowledge is key to ensuring a smooth riding experience. By familiarizing oneself with the fundamental components and their functions, owners can confidently navigate through any challenges that arise. This guide serves as a valuable resource for those looking to enhance their skills and gain a deeper understanding of their beloved vehicles.

Furthermore, exploring maintenance techniques empowers riders to take proactive measures, ultimately reducing the likelihood of unexpected breakdowns. With the right approach and information at hand, anyone can become adept at maintaining their two-wheeled companion, ensuring countless enjoyable journeys ahead.

Common Mechanical Issues

Understanding typical mechanical challenges is essential for maintaining optimal performance of two-wheeled vehicles. Owners often encounter various concerns that can affect functionality and safety. Recognizing these issues early can prevent more severe problems and ensure a smoother riding experience.

Frequent Problems Encountered

- Engine Overheating: Insufficient cooling can lead to overheating, resulting in decreased efficiency and potential engine damage.

- Transmission Difficulties: Issues with gear shifting can stem from worn components or improper lubrication, causing frustration during operation.

- Electrical Failures: Malfunctions in the ignition or lighting systems can lead to starting problems and decreased visibility.

- Tire Wear: Uneven or excessive tire wear can affect handling and stability, necessitating regular inspections.

Maintenance Tips

- Regularly check fluid levels to prevent overheating and ensure smooth operation.

- Inspect the drive system and replace worn parts as needed to maintain shifting quality.

- Test electrical components periodically to identify and address issues promptly.

- Monitor tire condition and adjust pressure to enhance grip and prolong lifespan.

By being aware of these common mechanical issues and implementing proactive maintenance strategies, owners can enjoy a reliable and enjoyable riding experience.

Tools Required for Repairs

When it comes to maintaining two-wheeled vehicles, having the right instruments at your disposal is crucial. A well-equipped toolkit can make the difference between a smooth fix and a frustrating experience. Below are essential implements that every enthusiast should consider for effective servicing.

First and foremost, a reliable set of wrenches is indispensable. These tools allow for the adjustment and tightening of various components, ensuring everything functions as intended. Additionally, screwdrivers of different sizes are necessary for securing panels and accessing internal parts.

Another key item is a socket set, which provides versatility in handling various fasteners. This collection can simplify tasks such as removing the engine cover or adjusting the suspension. Pliers and wire cutters are also vital for gripping, twisting, and cutting wires or cables, making them essential for electrical troubleshooting.

Moreover, a torque wrench is highly recommended to apply precise force when fastening critical components. This helps avoid damage and ensures safety during operation. Lastly, an oil change kit, including an oil filter wrench and an oil pan, is important for maintaining the engine’s health.

Equipped with these tools, enthusiasts can confidently tackle maintenance tasks, prolonging the lifespan of their vehicles while enhancing their performance.

Step-by-Step Maintenance Guide

This section offers a comprehensive approach to ensuring optimal performance and longevity of your two-wheeled vehicle. Regular upkeep is essential for maintaining functionality and safety, and this guide provides clear instructions for various maintenance tasks.

The following table outlines essential maintenance activities, their frequency, and the necessary tools:

| Maintenance Task | Frequency | Required Tools |

|---|---|---|

| Oil Change | Every 1,000 miles | Wrench, Oil Filter |

| Brake Inspection | Every 2,000 miles | Socket Set, Screwdriver |

| Tire Pressure Check | Monthly | Tire Pressure Gauge |

| Battery Check | Every 6 months | Multimeter, Cleaning Brush |

| Chain Lubrication | Every 500 miles | Lubricant, Cloth |

Following this guide will help ensure that your vehicle remains in excellent condition, providing a smooth and safe riding experience.

Troubleshooting Electrical Problems

Addressing issues related to electrical systems can be challenging, yet understanding the fundamentals can simplify the process. Proper diagnostics are essential for identifying the root cause of malfunctions, ensuring effective solutions.

Common Symptoms and Causes

Various indicators can signal electrical difficulties. Look for:

- Inconsistent starting: This may indicate a failing battery or faulty connections.

- Dim lights: Reduced brightness often points to inadequate voltage or a malfunctioning alternator.

- Unresponsive gauges: A lack of movement in instruments can suggest wiring issues or blown fuses.

Diagnostic Steps

To effectively address these problems, follow these steps:

- Visual Inspection: Begin with a thorough examination of wiring and connections for any visible damage.

- Testing Voltage: Utilize a multimeter to check the voltage at various points in the electrical system.

- Fuse Check: Inspect fuses and replace any that are blown to restore functionality.

By systematically assessing these areas, you can effectively identify and rectify electrical complications, ensuring a smoother operation.

Replacing the Battery Safely

Ensuring the proper replacement of the power source in your two-wheeled vehicle is crucial for optimal performance. This section outlines essential steps and precautions to take when handling the power unit, preventing damage and ensuring personal safety.

Preparation Before Replacement

Before starting the process, it’s important to gather necessary tools and materials. Here’s a checklist of what you’ll need:

- New power unit

- Wrench set

- Safety gloves

- Safety goggles

- Multimeter

Step-by-Step Replacement Process

Follow these steps to safely replace the power source:

| Step | Description |

|---|---|

| 1 | Ensure the vehicle is turned off and parked on a flat surface. |

| 2 | Remove any covers or panels that obstruct access to the power unit. |

| 3 | Disconnect the negative terminal first, followed by the positive terminal. |

| 4 | Carefully remove the old power unit from its compartment. |

| 5 | Install the new power unit, connecting the positive terminal first, then the negative terminal. |

| 6 | Replace any covers or panels that were removed during the process. |

| 7 | Perform a test to ensure the new power unit is functioning correctly. |

Adjusting the Carburetor

Tuning the fuel delivery system is essential for optimal engine performance. Proper adjustments can enhance efficiency, improve throttle response, and reduce emissions. This section outlines the steps necessary to fine-tune the air-fuel mixture for peak operation.

Understanding the Components

Before proceeding with adjustments, familiarize yourself with the main parts involved in the process. The critical components include the float chamber, jets, and adjustment screws. Each part plays a vital role in regulating the mixture of air and fuel.

Adjustment Process

Begin by ensuring the engine is warm and idling smoothly. Next, locate the mixture screw, typically found on the side of the carburetor. Turning this screw clockwise will lean the mixture, while turning it counterclockwise will enrich it. Make small adjustments, about a quarter turn at a time, and listen for changes in engine response.

After each adjustment, allow the engine to stabilize before testing its performance. If the engine hesitates or stalls, it may indicate that the mixture is too lean. Conversely, excessive fuel consumption or black smoke may suggest a rich mixture. Aim for a balance that provides smooth acceleration and efficient operation.

Brake System Maintenance

Proper upkeep of the braking mechanism is crucial for ensuring optimal performance and safety. This section outlines essential practices for maintaining the components that contribute to effective stopping power, thereby enhancing the overall reliability of your vehicle.

Regular Inspections should be conducted to assess the condition of brake pads, rotors, and fluid levels. Look for any signs of wear or damage, such as uneven wear patterns on the pads or corrosion on the rotors. Addressing these issues promptly can prevent further deterioration and potential safety hazards.

Fluid Replacement is another vital aspect of maintenance. Brake fluid absorbs moisture over time, which can lead to reduced effectiveness. It is advisable to replace the fluid according to the manufacturer’s recommendations, typically every 1-2 years. Make sure to use the appropriate type of fluid to avoid compatibility issues.

Adjustment and Cleaning of the braking system components is necessary to ensure they function correctly. Remove any dirt or debris that may have accumulated, particularly around the calipers and pads. Proper alignment of the components can also improve performance and longevity.

By adhering to these maintenance practices, you can significantly enhance the performance and lifespan of the braking system, ensuring a safer riding experience.

Wheel and Tire Care

Maintaining the wheels and tires of your two-wheeled vehicle is essential for optimal performance and safety. Proper attention to these components can enhance ride quality, improve handling, and prolong their lifespan. Regular inspection and maintenance help prevent unexpected issues and ensure a smooth journey.

Regular Inspection

Frequent checks of the wheels and tires are crucial. Look for signs of wear, such as uneven tread or cracks in the rubber. Ensure that the air pressure meets the manufacturer’s specifications, as both under-inflation and over-inflation can adversely affect performance. Additionally, inspect the rims for any damage that may compromise their integrity.

Cleaning and Protection

Keeping the wheels and tires clean not only improves their appearance but also extends their longevity. Use a gentle cleaner and a soft brush to remove dirt and grime. After cleaning, applying a protective dressing can help shield the rubber from harmful UV rays and environmental elements, preserving its quality over time.

Engine Oil and Lubrication

Maintaining optimal performance in two-wheeled vehicles relies heavily on proper fluid management. The significance of high-quality lubricants cannot be overstated, as they play a vital role in ensuring the longevity and efficiency of the engine. Selecting the right type of oil and adhering to recommended maintenance intervals are essential practices for any owner.

Types of Engine Oil are categorized primarily by their viscosity ratings and additive compositions. Synthetic options often provide superior protection and performance under extreme conditions, while conventional oils may be suitable for everyday use. It is crucial to consult the manufacturer’s specifications to determine the most appropriate choice for your specific model.

Regular lubrication not only reduces friction between moving parts but also aids in heat dissipation. Proper circulation of oil ensures that all components receive adequate protection, minimizing wear and tear. Moreover, periodic checks and changes of the oil contribute significantly to the overall health of the engine, preventing potential breakdowns.

Best Practices involve regularly inspecting oil levels and quality. Dark, gritty oil can indicate contamination and may necessitate an immediate change. Maintaining a consistent schedule for oil changes and using a high-quality filter can enhance the overall performance of the engine and extend its lifespan.

Restoring Vintage Models

Breathing new life into classic two-wheeled vehicles is a rewarding endeavor for enthusiasts and hobbyists alike. The process of rejuvenation requires careful attention to detail, a deep understanding of the vehicle’s mechanics, and a passion for preserving history. This section will guide you through essential steps and considerations to ensure a successful revival of these cherished models.

Essential Tools and Supplies

Before embarking on the restoration journey, it is crucial to gather the necessary tools and materials. Here’s a list of items that can aid in the process:

- Basic hand tools (wrenches, screwdrivers, pliers)

- Specialty tools (for engine and electrical components)

- Cleaning supplies (degreasers, brushes, cloths)

- Replacement parts (gaskets, seals, filters)

- Paint and finishing materials

Steps to Revitalize

Once equipped with the right tools, follow these steps to effectively restore your vintage model:

- Assess the condition: Examine the vehicle for any visible damage or wear.

- Disassemble carefully: Take apart components while noting their arrangement for reassembly.

- Clean thoroughly: Remove dirt and grime from all parts, paying special attention to intricate areas.

- Replace worn parts: Install new or refurbished components where necessary.

- Reassemble with precision: Ensure all parts are correctly fitted and secure.

- Test functionality: Conduct a thorough check to ensure everything operates as intended.

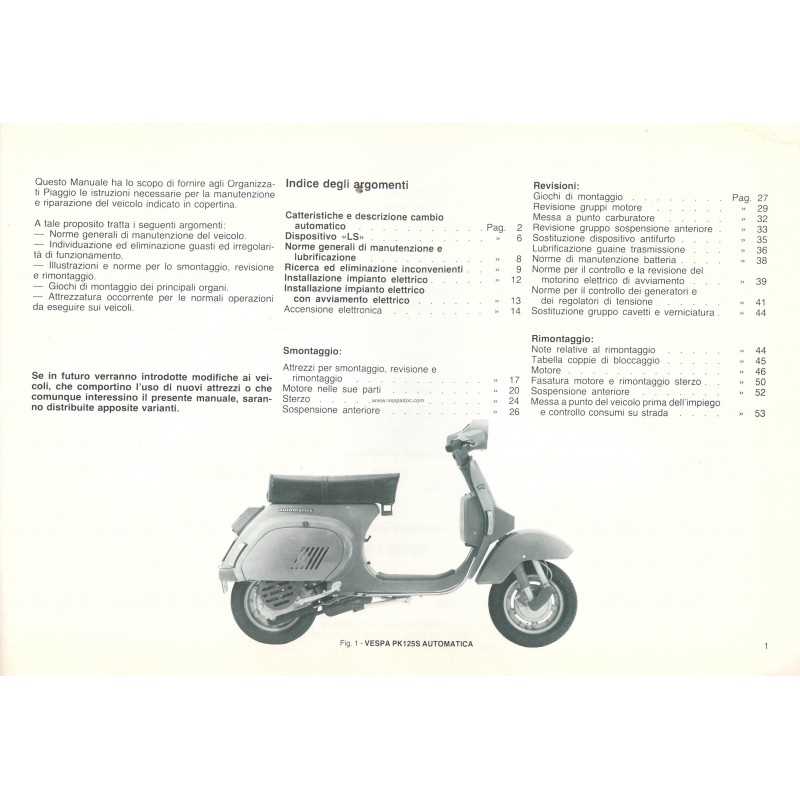

Resources for Vespa Enthusiasts

For those who share a passion for two-wheeled vehicles, a wealth of information and support is available to enhance your experience. From forums to instructional content, these resources provide invaluable insights, tips, and community connections to help you maintain and enjoy your beloved ride.

Online Communities

Engaging with fellow aficionados can greatly enrich your journey. Numerous online forums and social media groups serve as platforms for enthusiasts to share their knowledge, ask questions, and exchange experiences. These communities foster a sense of camaraderie and provide support, ensuring you never feel alone in your pursuit of excellence.

Instructional Content and Guides

A plethora of instructional resources is at your disposal, ranging from detailed guides to video tutorials. These materials cover various topics, including maintenance techniques, troubleshooting methods, and performance enhancements. Utilizing these resources can empower you to confidently tackle projects and deepen your understanding of your cherished machine.