Ensuring the longevity and efficiency of garden equipment requires a thorough understanding of its mechanics and functionalities. This section aims to provide valuable insights into the maintenance processes that will keep your machinery in optimal condition, thereby enhancing performance and reliability.

Within these pages, you’ll discover essential techniques for diagnosing common issues and implementing effective solutions. By familiarizing yourself with the intricacies of your equipment, you empower yourself to tackle problems proactively, ultimately saving time and resources.

Whether you’re a seasoned user or a newcomer, this guide serves as a crucial resource. It highlights practical steps and tips that can transform your approach to upkeep, ensuring that your equipment remains a dependable companion in your gardening endeavors.

Understanding Wt3100 Wheeled Trimmer

This section delves into the functionalities and features of a versatile gardening tool designed for efficient maintenance of outdoor spaces. Its innovative design combines mobility with effectiveness, making it suitable for various landscaping tasks.

Key Features

- Mobility: Engineered for easy navigation across different terrains, ensuring users can access hard-to-reach areas with ease.

- Power: Equipped with a robust engine that provides ample power for cutting through thick vegetation and overgrowth.

- Durability: Constructed with high-quality materials that withstand harsh weather conditions and heavy use.

- Adjustable Settings: Offers customizable height and cutting settings to cater to various gardening needs.

Benefits of Using This Tool

- Enhanced Efficiency: Streamlines yard work, allowing for quicker completion of tasks.

- Reduced Physical Strain: Designed to minimize user fatigue, promoting comfort during extended periods of use.

- Versatile Applications: Suitable for both residential and commercial landscaping projects.

- Improved Aesthetics: Helps maintain a neat and tidy outdoor environment, contributing to overall property value.

Common Issues with Wt3100 Trimmer

Every piece of gardening equipment can encounter various challenges over time. Understanding the common problems associated with these tools can help users identify and resolve issues more efficiently. This section explores typical malfunctions and the signs that indicate maintenance is required.

Frequent Problems

- Engine Starting Issues: Difficulty in starting the machine can arise from several factors, including fuel blockages, clogged air filters, or spark plug failure.

- Uneven Cutting: This can be caused by dull blades or improper height adjustments, leading to unsatisfactory results.

- Overheating: Prolonged use without breaks can cause the engine to overheat, often due to inadequate lubrication or air circulation.

- Excessive Vibration: This may indicate loose components or imbalanced parts, which can affect performance and user comfort.

Preventive Measures

- Regularly check and replace filters and spark plugs.

- Keep blades sharpened and properly aligned.

- Ensure proper lubrication of moving parts.

- Perform routine inspections to identify loose or worn components early.

Essential Tools for Repairing Trimmer

To effectively maintain and fix outdoor cutting equipment, having the right instruments is crucial. A well-equipped toolkit not only simplifies the process but also enhances efficiency, ensuring that every task can be completed with precision. Whether you are tackling minor adjustments or significant overhauls, certain tools are indispensable for achieving optimal results.

Basic Hand Tools

Starting with the fundamentals, a set of quality hand tools is vital. Wrenches, screwdrivers, and pliers are essential for loosening and tightening various components. Additionally, a sturdy pair of wire cutters can assist in managing any electrical connections. Having these basics on hand allows for straightforward disassembly and assembly of parts, making the overall process smoother.

Specialized Equipment

Beyond the basic tools, certain specialized instruments are beneficial for more intricate tasks. A torque wrench ensures that bolts are fastened to the manufacturer’s specifications, preventing damage from over-tightening. A multimeter is invaluable for diagnosing electrical issues, allowing for accurate troubleshooting. Furthermore, having a cleaning kit designed for outdoor machinery helps maintain performance and longevity.

Step-by-Step Troubleshooting Guide

This section provides a structured approach to identifying and resolving common issues that may arise during the operation of your equipment. By following these systematic steps, you can efficiently pinpoint the source of the problem and implement effective solutions, ensuring optimal performance and longevity.

Identifying Common Issues

Begin by observing the symptoms your device exhibits. Common signs may include unusual noises, inconsistent performance, or failure to start. Make a list of these indicators, as they will help in narrowing down potential causes. Check for any visible damage or loose components that may contribute to the malfunction.

Step-by-Step Diagnosis

1. Power Supply: Ensure that the power source is functioning correctly. Verify connections and check for any blown fuses or tripped breakers.

2. Components Inspection: Examine all critical parts, such as the motor, belts, and blades. Look for wear and tear, and replace any damaged components.

3. Fuel and Oil Levels: Inspect the fuel tank and oil reservoir to confirm they are adequately filled and free of contaminants.

4. Air Filter: A clogged air filter can hinder performance. Clean or replace it as necessary.

5. Consult Documentation: Refer to the manufacturer’s guidelines for troubleshooting tips specific to your model.

By methodically working through these steps, you can efficiently diagnose and resolve many of the issues that may arise during use.

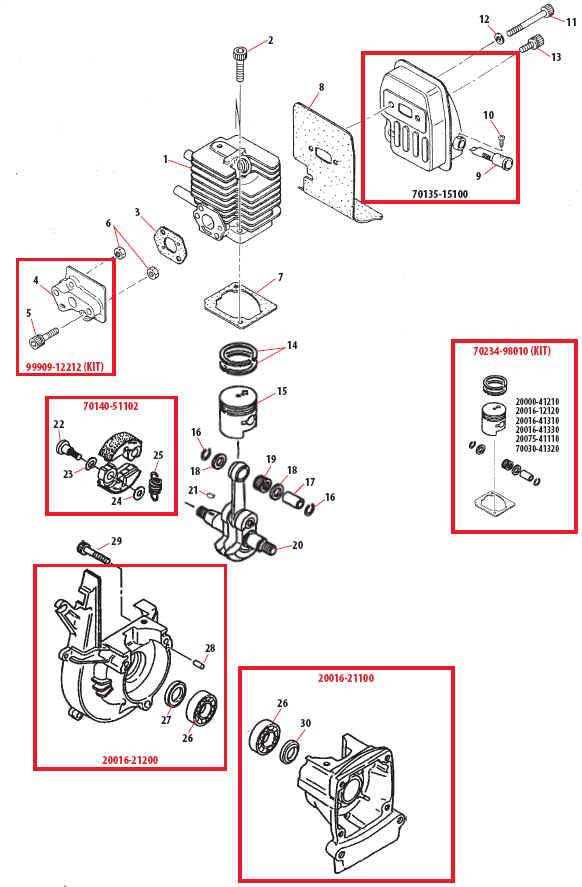

Replacing the Cutting Head Assembly

Replacing the cutting head is a crucial task that ensures optimal performance of your equipment. Over time, wear and tear can affect the efficiency of the cutting mechanism, making it necessary to install a new assembly. This section will guide you through the steps needed to successfully perform this replacement, allowing your device to operate at its best once again.

Preparation Steps

Before you begin, make sure to gather all the necessary tools, including a wrench and a screwdriver. Disconnect the power source to ensure safety during the replacement process. It’s also advisable to wear protective gloves to prevent any injuries. Review the user guide for specific details related to your model, as there may be unique considerations to keep in mind.

Installation Process

Start by removing the old cutting head assembly. This typically involves unscrewing the bolts that secure it in place. Once removed, take the new assembly and align it correctly with the mounting brackets. Secure it using the previously removed screws, ensuring it is tightly fastened to prevent any movement during operation. Finally, reconnect the power source and perform a test run to confirm that the installation was successful and that everything is functioning properly.

Maintaining the Engine for Longevity

Ensuring the durability and efficiency of your machinery requires consistent attention to its core components. Proper upkeep not only enhances performance but also extends the lifespan of the engine. Regular maintenance routines are essential for preventing issues that could lead to costly repairs or replacements.

Here are some key practices to consider for optimal engine care:

- Regular Oil Changes: Replace engine oil at recommended intervals to keep the internal components lubricated and functioning smoothly.

- Air Filter Maintenance: Clean or replace air filters periodically to prevent dirt and debris from entering the engine, which can affect performance.

- Fuel System Care: Use high-quality fuel and consider adding fuel stabilizers to prevent degradation and buildup in the fuel system.

- Cooling System Checks: Regularly inspect and clean cooling fins and ensure that coolant levels are adequate to prevent overheating.

- Spark Plug Inspection: Examine spark plugs for wear and replace them as needed to ensure efficient ignition and combustion.

Following these guidelines can help maintain optimal performance, reduce the risk of breakdowns, and enhance the overall lifespan of your engine. Make maintenance a priority to enjoy a reliable and efficient machine for years to come.

Electrical Components and Their Maintenance

Understanding the significance of electrical parts in any machinery is crucial for optimal performance and longevity. Regular maintenance of these elements not only ensures smooth operation but also prevents potential failures that could lead to costly repairs. This section focuses on the essential components that require attention and care to maintain their functionality.

Inspection and Cleaning are fundamental aspects of maintaining electrical components. Dust, dirt, and moisture can accumulate over time, affecting the efficiency of connections and circuits. Regularly inspect connectors, switches, and wiring for any signs of corrosion or wear. Cleaning these areas with appropriate materials can enhance conductivity and prolong their lifespan.

Connection Integrity is another critical factor. Loose or damaged connections can result in poor performance or complete failure of the equipment. Ensure that all electrical connections are secure and free from oxidation. It is advisable to use dielectric grease to protect metal parts from corrosion.

Electrical Testing should be performed periodically to identify any issues before they escalate. Utilizing a multimeter to check voltage and continuity can help pinpoint problems. If irregularities are detected, it’s essential to address them immediately to avoid further complications.

Component Replacement is sometimes necessary when wear is beyond repair. Familiarize yourself with the specifications of each part to ensure compatibility. When replacing components, always follow the manufacturer’s recommendations for proper installation.

By adhering to these maintenance practices, you can significantly enhance the reliability and performance of electrical components in your equipment. Prioritizing their upkeep not only extends the life of the machinery but also ensures safe operation in the long run.

Identifying Fuel System Problems

Proper functioning of the fuel delivery system is crucial for optimal performance. Issues within this system can manifest in various ways, leading to poor operation or complete failure. Recognizing these problems early can save time and enhance efficiency.

Common Symptoms of Fuel System Issues

Understanding the typical signs of fuel system malfunctions can help in diagnosing the problem accurately. Some prevalent symptoms include:

| Symptom | Possible Cause |

|---|---|

| Difficulty starting | Clogged fuel filter |

| Engine sputtering | Inadequate fuel supply |

| Poor acceleration | Dirty carburetor |

| Excessive smoke | Incorrect fuel mixture |

Steps for Troubleshooting

To effectively address these issues, follow a systematic approach. Start by inspecting the fuel lines for leaks or cracks. Next, examine the fuel filter and replace it if necessary. Ensure the fuel being used is fresh and appropriate for the system. Lastly, check the carburetor for blockages or dirt accumulation.

Adjusting the Trimmer’s Height Settings

Properly configuring the cutting height is essential for achieving optimal results while maintaining your gardening equipment. Adjusting these settings ensures that you can tackle various terrain types and vegetation efficiently. This guide will walk you through the process of modifying the height to meet your specific needs.

Follow these steps to adjust the height settings:

- Locate the adjustment mechanism, usually found near the wheels or the cutting unit.

- Determine your desired height based on the type of grass or plants you are working with.

- Using the appropriate tool, loosen the locking mechanism if necessary.

- Raise or lower the cutting unit to the preferred height, ensuring it is level on both sides.

- Tighten the locking mechanism to secure the new height in place.

It’s advisable to check the height periodically, especially if you are working in varied conditions. Making adjustments as needed will help maintain the health of your lawn and ensure efficient operation of your equipment.

For additional tips, consider the following:

- Consult your user guide for specific height recommendations for different plant types.

- Perform height adjustments when the machine is turned off and cool to prevent accidents.

- Regularly inspect the adjustment mechanism for wear and tear.

By following these guidelines, you can ensure that your equipment operates effectively and keeps your outdoor spaces looking their best.

Cleaning and Caring for Blades

Maintaining sharp and clean cutting edges is essential for optimal performance and longevity of your equipment. Regular attention to blade care not only enhances efficiency but also ensures safety during operation. This section outlines effective methods for keeping blades in prime condition.

Begin by regularly inspecting the blades for any signs of damage, rust, or buildup of debris. Remove any grass, dirt, or other materials that may accumulate, as these can hinder performance. Use a soft brush or cloth to gently clean the surfaces, taking care not to dull the edges.

For deeper cleaning, consider soaking the blades in soapy water to loosen stubborn grime. After soaking, scrub gently with a non-abrasive pad. Rinse thoroughly and dry completely to prevent rust formation. It’s also advisable to apply a light coat of oil on the blades after cleaning to protect against corrosion and to maintain their sharpness.

Sharpening blades is another crucial aspect of maintenance. Dull edges can lead to uneven cuts and increased strain on the equipment. Use a file or a sharpening tool specifically designed for the type of blade you are working with. Regular sharpening intervals depend on usage, but checking the blades frequently will help determine the right time.

Finally, store the equipment in a dry place to avoid moisture buildup, which can lead to rust. Keeping blades in good condition through regular cleaning, sharpening, and proper storage will ensure that your equipment performs effectively for years to come.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance or servicing tasks is paramount to prevent accidents and injuries. It is crucial to adhere to specific guidelines and practices that promote a secure working environment. Following these precautions not only protects the individual performing the work but also extends the life of the equipment.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and hearing protection.

- Ensure the equipment is powered down and disconnected from any power source before beginning any servicing.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep your workspace organized and free from clutter to minimize the risk of tripping or accidents.

Additionally, being aware of your surroundings and understanding the tools and parts involved can significantly enhance safety. It is advisable to follow these further guidelines:

- Read and understand all provided instructions before starting work.

- Use the correct tools for the job to avoid damaging components or causing injury.

- Take breaks when needed to maintain focus and prevent fatigue-related mistakes.

- Be cautious of sharp edges and moving parts that could cause harm.

By adhering to these safety measures, individuals can perform their tasks with confidence, ensuring both personal well-being and the effective functioning of the equipment.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining optimal performance and longevity. Whether you need a new blade, handle, or any other essential part, several reliable sources can assist you in your search.

First, consider checking with authorized dealers who specialize in your specific brand. These retailers often carry a comprehensive inventory of original parts and can provide valuable guidance on compatibility and installation. Additionally, visiting the manufacturer’s website can offer insights into available components and their specifications.

Online marketplaces also present a wealth of options. Websites like eBay and Amazon frequently feature listings from various sellers, allowing you to compare prices and read reviews to ensure you’re making an informed choice. Remember to verify the seller’s reputation to avoid counterfeit products.

Local hardware stores and gardening supply shops may stock common replacement items, providing a convenient option if you need a part quickly. It’s advisable to call ahead to check availability before making a trip.

Finally, specialized forums and community groups online can be excellent resources. Members often share tips on where to find parts and may even have suggestions for alternative solutions. Engaging with fellow enthusiasts can lead you to hidden gems in your search for replacements.