Exploring the process of restoring a beloved vintage two-wheeler offers an opportunity to dive into the intricacies of mechanical craftsmanship. Enthusiasts who take on such projects often find themselves on a rewarding journey, where attention to detail and a deep understanding of components play crucial roles. This guide provides essential insights for anyone looking to breathe new life into a timeless small bike, ensuring that each step is approached with confidence and precision.

From understanding the core elements of the engine to addressing specific issues that may arise with aging parts, this resource covers the various aspects involved in reviving a miniature motorcycle. Whether it’s about maintaining optimal performance or bringing the appearance back to its former glory, the goal is to provide a comprehensive roadmap for enthusiasts, from basic upkeep to more advanced techniques.

In addition, there will be tips on sourcing parts, best practices for disassembly and reassembly, and strategies for diagnosing common issues. With these insights, the restoration process becomes not only a technical challenge but also a passion-driven experience, where dedication meets the art of mechanical restoration.

Overview of Honda Z50 Maintenance

Proper upkeep of this compact two-wheeler ensures longevity and smooth operation, requiring regular attention to various mechanical aspects. Keeping the machine in top shape involves consistent inspection, tuning, and timely replacement of worn-out parts. Understanding which components need care and how often they should be serviced is key to maintaining optimal performance.

Routine checks are essential for identifying potential issues early. Regularly examining the engine, tires, and suspension components helps prevent minor problems from escalating. Ensuring that all moving parts are well-lubricated and free of debris will also contribute to reliable functionality.

Fluid levels should be monitored frequently, as these are crucial for the vehicle’s operation. Brake fluid, engine oil, and coolant all play a role in keeping the system running smoothly. It’s important to change these fluids according to the recommended schedule to avoid unnecessary wear.

Furthermore, electrical systems require periodic inspection to ensure the wiring and connections are secure. Checking the battery and lights regularly will help avoid electrical failures. Kee

Common Issues and Troubleshooting

Understanding frequent problems and knowing how to address them can significantly improve the performance and lifespan of your two-wheeled vehicle. This section highlights typical challenges that may arise, offering practical solutions to help identify the root cause and restore functionality. Regular checks and timely maintenance can prevent minor inconveniences from escalating into larger issues.

Engine Performance Problems

If you notice reduced power, unusual noises, or inconsistent acceleration, it might indicate issues within the motor’s internal components. Common causes can include improper fuel mixture, clogged filters, or spark plug failure. Start by inspecting the fuel system for blockages or leaks, and replace any worn-out spark plugs to ensure efficient combustion. Regularly cleaning or changing the air filter can also improve airflow and boost performance.

Electrical System Malfunctions

Electrical difficulties often manifest as dim lights, non-responsive switches, or failure to start. These problems can be traced back to

Engine Disassembly and Reassembly Tips

Understanding the process of taking apart and putting back together an engine is crucial for ensuring optimal performance and avoiding damage. This guide provides essential advice for safely dismantling components, inspecting parts, and reassembling them correctly to achieve smooth operation.

- Organize Your Workspace: Before starting, arrange a clean and spacious area. Keep tools and containers ready for bolts, nuts, and other small parts, labeling them if necessary to avoid confusion during reassembly.

- Follow a Logical Sequence: Disassemble components in a systematic order, starting from the external parts and moving inward. This helps keep track of the process and ensures no steps are overlooked.

- Inspect Parts Carefully: As each component is removed, examine it for signs of wear or damage. Replace any faulty parts to prevent further issues. Clean each

Electrical System Diagnosis Techniques

Diagnosing issues within an electrical setup requires a methodical approach to identify the source of the problem and implement a suitable solution. The process involves examining various components, analyzing connections, and understanding how electrical flow behaves under different circumstances. These techniques can help ensure that all parts work together efficiently, avoiding potential malfunctions.

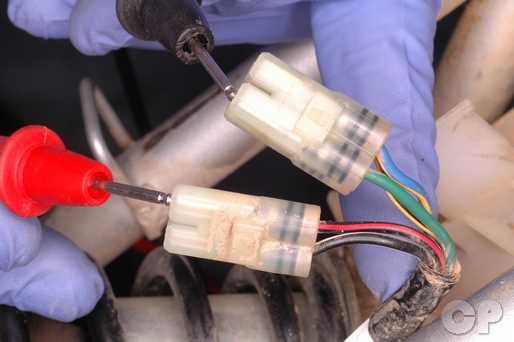

Inspecting the Wiring

A crucial step in evaluating an electrical system is checking the wiring for any visible signs of wear or damage. Common issues may include frayed wires, corrosion at connection points, or loose terminals. Using a multimeter, test the continuity of the wires to confirm they conduct electricity properly without any interruptions. Replacing or repairing faulty sections can significantly improve the system’s reliability.

Testing Electrical Components

Once the wiring has been checked, it’s essential to assess the functionality of individual components, such as switches, relays, and connectors. A multimeter can be used to measure voltage, resistance, and current flow, helping to identify whether specific parts are operating within their normal parameters. If any readings fall outside the expected range, it may indicate a need for adjustment or replacement.

- Check all fuses for continuity, replacing any that show signs of being blown.

- Verify that connectors are secure and free from corrosion to ensure proper contact.

-

Carburetor Cleaning and Adjustment Guide

The carburetor plays a crucial role in ensuring the engine runs smoothly by mixing fuel and air in the right proportions. Over time, it may accumulate dirt and residue, leading to suboptimal performance. Proper maintenance, including regular cleaning and precise tuning, can help restore optimal operation and enhance the overall efficiency of the engine.

Cleaning the Carburetor is the first step in maintaining its function. Start by safely disconnecting the carburetor from the engine and draining any remaining fuel. Use a carburetor cleaner to spray all accessible surfaces, focusing on jets, passages, and chambers where residue tends to build up. A soft-bristle brush can be used to gently remove stubborn deposits. Make sure to clear all the openings and ports to ensure smooth fuel flow.

Adjustment for Optimal Performance involves fine-tuning the air-fuel mixture. Begin by locating the idle and mixture screws. Turn the screws to a baseline position, usually recommended as one and a half turns out from the fully closed position. Gradually adjust while the engine is running to achieve a steady idle and responsive throttle. It may be necessary to fine-tune these settings further to suit specific conditions or preferences.

Regular maintenance not only extends the life of the carburetor but also ensures reliable engine performance. Thorough cleaning and proper adjustment should be part of a routine to keep the vehicle operating at

Transmission Inspection Procedures

This section outlines the essential steps for evaluating the functionality and condition of the transmission system in a small engine vehicle. Regular assessment is crucial to ensure optimal performance and longevity of the equipment.

Begin by examining the external components for any visible signs of wear or damage. Check for leaks, cracks, and loose fittings that may indicate underlying issues. A thorough inspection of the casing and seals is necessary to maintain a reliable operation.

Inspection Step Description Visual Check Inspect the transmission housing for cracks, corrosion, and fluid leaks. Fluid Level Verify that the transmission fluid is at the recommended level, topping off as needed. Fluid Condition Assess the color and consistency of the fluid; dark or gritty fluid may require replacement. Linkage Inspection Examine the shift linkage for proper operation and any signs of wear or binding. Gear Engagement Test the transmission by shifting through all gears, ensuring smooth transitions and no grinding noises. Noise Check Listen for any unusual sounds during operation, which could indicate internal problems. After completing these steps, any identified issues should be addressed promptly to avoid further complications. Proper maintenance and regular inspections are key to extending the life of the transmission system.

Replacing Worn-Out Suspension Components

Maintaining optimal performance and safety in your vehicle requires regular attention to its suspension system. Over time, components such as shocks, struts, and bushings may wear out, leading to decreased handling capabilities and a less comfortable ride. Addressing these issues promptly can enhance both performance and longevity.

Here are the key signs that indicate it’s time to replace suspension components:

- Excessive bouncing or swaying while driving

- Uneven tire wear

- Difficulty steering or poor handling

- Visible leaks from shock absorbers

- Noises such as clunks or rattles when driving over bumps

To successfully replace worn components, follow these steps:

- Gather necessary tools and parts: Ensure you have all required tools, including a jack, wrenches, and replacement parts.

- Lift the vehicle: Use a jack to raise the vehicle securely and support it with jack stands.

- Remove old components: Carefully detach the worn suspension parts. Follow any specific guidelines for your model to avoid damaging surrounding areas.

- Install new components: Align and attach the new parts according to the manufacturer’s specifications, ensuring everything is tightened properly.

- Lower the vehicle: After installation, remove the jack stands and lower the vehicle back to the ground.

- Test the vehicle: Take a short drive to assess handling and comfort, making sure everything functions as expected.

Regularly inspecting and replacing suspension elements can prevent further damage and enhance the overall driving experience.

Brake System Repair Instructions

This section outlines the essential procedures for maintaining and restoring the braking system of your vehicle. A well-functioning braking system is crucial for safety and performance. Regular checks and prompt attention to any issues can prevent accidents and enhance the longevity of your machine.

Inspection Steps

Before diving into any repairs, it’s important to conduct a thorough inspection. Follow these steps:

- Check the brake fluid level and quality.

- Inspect brake pads for wear and replace if necessary.

- Examine brake lines for leaks or damage.

- Verify the condition of the brake rotors and drums.

- Test the brake lever and foot pedal for responsiveness.

Common Issues and Solutions

Understanding common problems can help you troubleshoot effectively:

- Spongy Brake Lever: This may indicate air in the brake lines. Bleed the brakes to remove any trapped air.

- Noisy Brakes: Squeaking or grinding sounds can be caused by worn pads or debris. Inspect and clean the braking components.

- Brake Fluid Leaks: Identify the source of the leak and replace damaged lines or seals.

By adhering to these instructions and maintaining vigilance, you can ensure the braking system operates at its best, providing you with both safety and peace of mind on the road.

Chain and Sprocket Replacement Steps

Replacing the chain and sprockets of your vehicle is an essential maintenance task that ensures optimal performance and longevity. This process involves a series of systematic steps to remove the old components and install new ones, maintaining the efficiency of power transfer from the engine to the wheels.

Begin by gathering the necessary tools, including a chain breaker, wrenches, and a torque wrench. It is crucial to ensure that the vehicle is securely elevated using a stand to access the chain and sprockets easily. Remove the rear wheel to gain better access to the components that need to be replaced.

Next, detach the old chain by breaking it at the master link or cutting it with a chain breaker. Once the chain is removed, inspect the sprockets for any signs of wear or damage. If they show excessive wear, they must be replaced as well. To remove the sprockets, unscrew the retaining bolts and take them off carefully.

Before installing the new chain and sprockets, clean the area thoroughly to remove any debris or old lubricant. Fit the new sprockets onto the shaft, ensuring they are aligned correctly, and secure them tightly with the bolts. Next, thread the new chain around the sprockets, making sure it is properly seated in the grooves.

Finally, adjust the chain tension according to the manufacturer’s specifications. It is vital to ensure the chain has the correct amount of slack for optimal performance. After adjusting, reattach the rear wheel, and perform a final check to ensure all components are securely fastened. Test the vehicle to confirm that the new chain and sprockets are functioning correctly.

Upgrading the Exhaust for Performance

Enhancing the exhaust system of your two-wheeler can significantly improve its overall performance. By upgrading this crucial component, riders can expect better airflow, increased horsepower, and a more responsive throttle. These modifications not only boost the bike’s performance but also contribute to a more aggressive and engaging sound, enriching the riding experience.

Choosing the Right Exhaust System

When selecting an upgraded exhaust system, consider factors such as material, design, and compatibility with your bike’s engine. Stainless steel and titanium options are popular due to their durability and weight advantages. Additionally, performance headers and slip-on options can vary in design, affecting the sound and power delivery. It’s essential to choose a system that complements your riding style and desired performance enhancements.

Installation Tips and Best Practices

Proper installation of the new exhaust is vital for maximizing performance gains. Begin by ensuring all necessary tools are available, and read the manufacturer’s instructions thoroughly. Make sure to replace any gaskets and hardware to prevent leaks. After installation, conduct a test ride to evaluate changes in performance and make any necessary adjustments. Regular maintenance of the exhaust system will help sustain its benefits over time.

Bodywork Restoration and Painting Tips

Restoring the exterior of a small vehicle can significantly enhance its overall appearance and value. Proper techniques and materials are essential for achieving a professional finish. This section provides practical advice on how to prepare surfaces, select the right products, and apply finishes effectively.

Here are some key steps to consider during the restoration process:

- Assessment: Begin by examining the bodywork for damage, rust, or imperfections. Take note of areas that require repair or replacement.

- Cleaning: Thoroughly clean the surfaces to remove dirt, grease, and old paint. Use a degreaser for effective cleaning.

- Repairing: Fill any dents, scratches, or rust spots with appropriate filler material. Sand the repaired areas smoothly to ensure an even surface.

- Sanding: Sand the entire body to create a key for the new paint. Start with a coarser grit and progress to finer grits for a smooth finish.

- Priming: Apply a primer suited for the type of paint you will use. This step helps with adhesion and can enhance the final color.

- Painting: Choose high-quality paint and apply it in thin, even layers. Multiple light coats are preferable to a single heavy coat to avoid runs and drips.

- Curing: Allow the paint to cure properly according to the manufacturer’s instructions. This step is crucial for achieving durability.

- Finishing: Once cured, consider applying a clear coat for added protection and shine. Buffing the surface can enhance the overall finish.

By following these tips and using the right materials, you can achieve a stunning restoration that brings new life to the exterior of your small vehicle.

Essential Tools for DIY Repairs

When embarking on a do-it-yourself project involving mechanical devices, having the right tools is crucial for achieving success. A well-equipped workspace enhances efficiency and ensures that tasks are completed effectively. This section outlines the fundamental instruments necessary for carrying out maintenance and upgrades on your machinery.

Basic Toolkit

A solid foundation for any DIY enthusiast starts with a basic toolkit. This should include a variety of hand tools that cater to a range of tasks. Below is a list of essential items to have on hand:

Tool Purpose Screwdrivers Used for tightening or loosening screws in various components. Wrenches Essential for gripping, fastening, and loosening nuts and bolts. Pliers Helpful for gripping, twisting, or cutting wire and other materials. Socket Set Allows for easy access to bolts in tight spaces with a ratchet for efficiency. Specialized Equipment

In addition to basic tools, certain specialized equipment can significantly aid in complex tasks. Consider incorporating the following into your toolkit:

Equipment Function Torque Wrench Ensures bolts are tightened to the manufacturer’s specified torque, preventing damage. Multimeter Measures voltage, current, and resistance, crucial for diagnosing electrical issues. Jack and Stands Allows for safe lifting of machinery to access components underneath. Cleaning Supplies Essential for maintaining a tidy workspace and ensuring components are free of debris.