Proper maintenance of your aquatic devices is essential for ensuring optimal performance and longevity. Understanding the intricacies of upkeep can significantly enhance the user experience, allowing for seamless operation during your adventures on the water.

In this section, we will explore various methods and techniques to troubleshoot common issues, enabling you to keep your gear in peak condition. By applying these practices, you can minimize downtime and maximize your enjoyment while navigating lakes and rivers.

Whether you are a seasoned enthusiast or a newcomer to the aquatic world, having access to reliable information is invaluable. This guide aims to empower you with the knowledge needed to handle maintenance tasks effectively, ensuring that your equipment remains a trusted companion on all your outings.

This section focuses on assessing the electrical components and their functionality within the system. Proper diagnostics are essential for identifying issues and ensuring optimal performance.

Key areas to evaluate include:

- Power supply integrity

- Wiring connections and conditions

- Component functionality

- Control system behavior

To conduct thorough diagnostics, follow these steps:

- Begin by checking the power source for any inconsistencies.

- Inspect all wiring for damage or loose connections.

- Test individual components to verify their operational status.

- Evaluate the overall control system for any anomalies in response.

Maintaining accurate diagnostics can lead to improved reliability and longevity of the system.

Mechanical Component Inspection

Evaluating the functionality of mechanical elements is crucial for ensuring optimal performance and longevity. This process involves a thorough examination of various parts to identify any signs of wear, damage, or malfunction.

Visual Assessment: Begin with a detailed visual inspection. Look for cracks, corrosion, or any unusual markings that could indicate underlying issues. Pay close attention to joints and connections where stress may accumulate.

Functional Testing: Conduct tests to assess the operation of moving parts. Ensure that all components move freely without obstruction and that they operate within their designated parameters. Unusual noises during operation may signal the need for further investigation.

Measurement Checks: Utilize precise measuring tools to verify that components are within specified tolerances. This can help identify any deviations that might affect overall performance.

By following these steps, one can maintain the efficiency and reliability of mechanical systems, preventing potential failures before they occur.

Maintenance Tips for Longevity

To ensure the extended life of your equipment, regular upkeep is essential. By adhering to specific maintenance practices, you can prevent potential issues and enhance performance. Below are some valuable suggestions to help you maintain your device effectively.

Regular Cleaning: Keeping the exterior and components clean is crucial. Use a soft cloth and mild detergent to remove dirt and debris. This prevents buildup that can lead to corrosion or mechanical failures.

Inspect Components: Frequently check all parts for signs of wear or damage. Pay attention to moving elements and connections. Early detection of issues allows for timely repairs, preventing further complications.

Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer. This reduces friction and wear, ensuring smooth operation and extending the lifespan of the equipment.

Storage Practices: When not in use, store your device in a dry, sheltered environment. Protect it from extreme temperatures and humidity, which can cause deterioration over time.

By implementing these maintenance strategies, you can significantly enhance the durability and efficiency of your equipment, ensuring it remains in optimal condition for years to come.

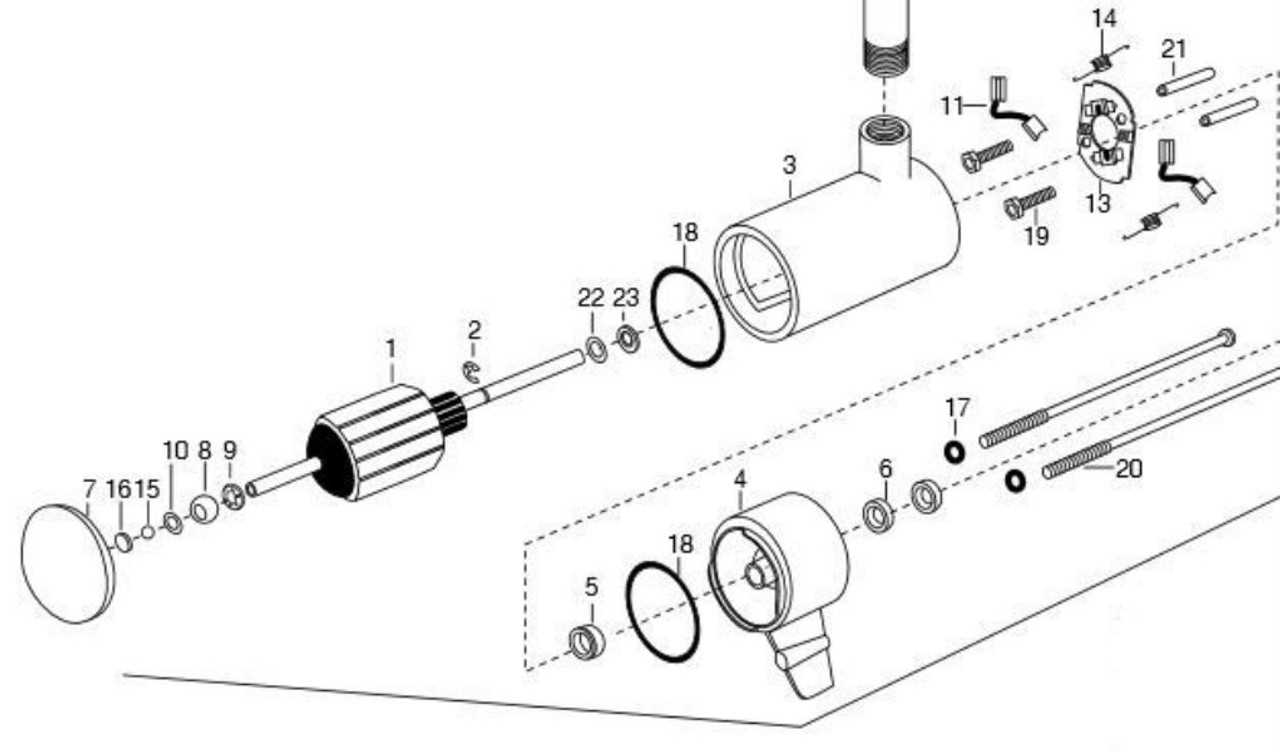

Replacing Damaged Parts

When dealing with issues in your equipment, identifying and replacing faulty components is essential for restoring functionality. This section outlines the process for effectively addressing damaged parts to ensure optimal performance and longevity.

Identifying Faulty Components

To begin, it’s crucial to thoroughly inspect the device to determine which parts require replacement. Common signs of wear or damage include unusual noises, diminished performance, or visible defects. Documenting these findings can aid in selecting the appropriate replacements.

Replacement Process

Once the damaged components have been identified, follow these steps for a successful replacement:

| Step | Action |

|---|---|

| 1 | Gather necessary tools and replacement parts. |

| 2 | Disconnect the power source to ensure safety. |

| 3 | Carefully remove the damaged parts following manufacturer guidelines. |

| 4 | Install the new components securely, ensuring proper alignment. |

| 5 | Reconnect the power source and test the device to confirm successful repairs. |

Reprogramming Your Talon Device

This section covers the steps to refresh and modify the settings of your device, ensuring optimal performance and compatibility with your systems. Reprogramming can resolve issues and enhance the overall functionality of your equipment.

Steps to Reprogram

- Power off the device and disconnect it from the power source.

- Locate the reset button, usually found on the side or bottom.

- Press and hold the reset button for approximately 10 seconds.

- Release the button and reconnect the power supply.

- Wait for the device to reboot completely.

Updating Settings

- Access the device menu using the control panel.

- Navigate to the settings section and select the option for reprogramming.

- Follow the prompts to input your desired configurations.

- Save the changes and exit the menu.

- Restart the device to apply the new settings.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance is crucial to prevent accidents and injuries. Proper awareness and adherence to safety guidelines can significantly mitigate risks during the process.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and masks. This gear protects against potential hazards and ensures your safety while handling tools and materials.

Workspace Organization

Keep your workspace tidy and organized. A clutter-free area reduces the likelihood of accidents and helps you locate tools and parts quickly. Regularly check for any hazards that may pose a risk during the task.

Frequently Asked Questions

This section addresses common inquiries and provides insightful answers to help users navigate their experiences. Here, you will find clarifications on various topics related to the operation and maintenance of your equipment.

Common Queries

- What should I do if my device is not functioning properly?

- How can I perform routine checks and maintenance?

- Are there any recommended troubleshooting steps for common issues?

Maintenance Tips

- Regularly inspect all components for wear and tear.

- Ensure that all connections are secure and clean.

- Consult the guidelines for optimal usage and care.

Resources for Further Assistance

When facing challenges with equipment, accessing the right resources can significantly enhance your troubleshooting experience. Various platforms and materials are available to provide guidance, support, and solutions tailored to your specific needs.

Online Communities and Forums

Engaging with online communities can be invaluable. Many enthusiasts share their knowledge and experiences, offering insights that may not be found in traditional resources. Consider joining forums dedicated to equipment usage where members frequently discuss common issues and solutions.

Professional Support Services

If you encounter persistent problems, reaching out to professional service providers can be beneficial. They offer expert advice and hands-on assistance. Many organizations provide helplines or consultation services to ensure your equipment operates smoothly.