Maintaining the longevity and performance of a specific type of power unit is essential for enthusiasts and daily users alike. Understanding the intricacies of this mechanical system can significantly enhance its reliability and efficiency. This guide aims to provide essential insights into the common issues faced, along with step-by-step procedures to address them effectively.

As users delve into the details, they will uncover various strategies to troubleshoot and enhance the functionality of this pivotal component. Whether you are a novice or an experienced individual, the information presented will empower you to navigate through maintenance challenges with confidence.

Throughout this section, readers will find a wealth of practical tips and techniques designed to facilitate effective oversight of the power unit. Emphasizing both preventive measures and corrective actions, the content strives to equip users with the knowledge needed to ensure optimal performance over time.

Toyota 2L Engine Overview

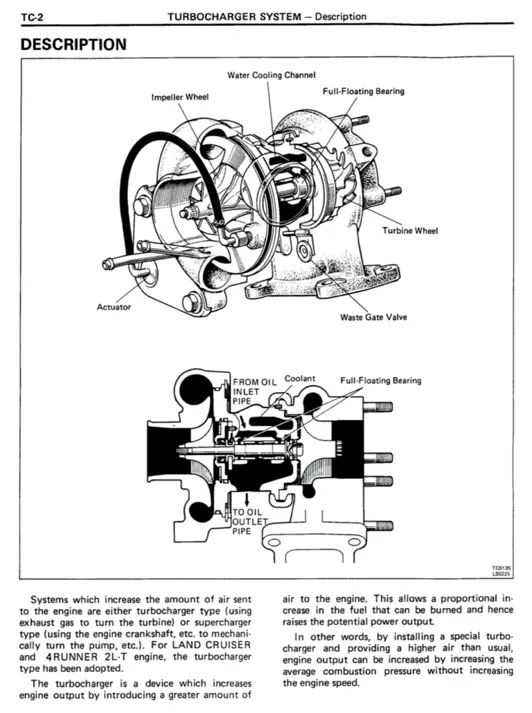

This section provides an insight into a specific internal combustion unit known for its reliability and efficiency. Designed with precision, this power unit is a favorite among automotive enthusiasts and professionals alike.

The unit features a four-cylinder configuration and is engineered for optimal performance in various applications. Its design prioritizes durability, making it suitable for both everyday use and demanding conditions.

| Specification | Details |

|---|---|

| Cylinder Configuration | Four-cylinder |

| Displacement | 2.0 liters |

| Fuel System | Direct injection |

| Power Output | Approx. 70-90 hp |

| Torque | 150-170 Nm |

With a reputation for longevity, this power unit remains a popular choice in various vehicle models, reflecting a perfect balance of performance and efficiency. Regular maintenance and careful operation are key to its sustained functionality.

Common Issues with Toyota 2L

Many owners of this particular vehicle configuration encounter a range of challenges that can affect performance and reliability. Understanding these typical problems can help in diagnosing and addressing them effectively.

Overheating Problems

One frequent concern is overheating, often caused by a malfunctioning cooling system. Issues may stem from a faulty thermostat, a leak in the radiator, or blocked hoses, leading to inadequate coolant circulation. Regular checks of these components can prevent serious damage.

Oil Leaks

Another common issue is oil seepage, which can arise from worn seals or gaskets. Noticing oil spots under the vehicle or a drop in oil levels can be indicators. Timely inspection and replacement of affected parts are crucial to avoid further complications.

Tools Needed for Repairs

When undertaking maintenance or fixing tasks on a vehicle, having the right instruments at your disposal is essential. Proper equipment not only facilitates the process but also ensures safety and effectiveness. A well-prepared toolkit can make a significant difference in the outcome of your work.

Essential Hand Tools: Basic hand tools such as wrenches, screwdrivers, and pliers are indispensable. These allow you to handle a variety of components with precision. Ensure you have a complete set to accommodate different sizes and types of fasteners.

Power Tools: Electric or battery-operated tools can significantly speed up the process. Drills and impact wrenches, for example, are great for loosening stubborn bolts and speeding up assembly tasks.

Specialty Instruments: Certain repairs may require specialized tools like torque wrenches, oil filter wrenches, or compression testers. Having these on hand can save time and provide accurate results, especially in more intricate procedures.

Safety Equipment: Don’t overlook the importance of safety gear. Gloves, goggles, and masks protect you from potential hazards. Always prioritize safety when working on any mechanical project.

With the right set of tools and equipment, tackling vehicle maintenance becomes a more manageable and efficient task, leading to better results and increased satisfaction.

Disassembling the Engine

This section provides a comprehensive overview of the steps necessary for taking apart a power unit. Proper disassembly is crucial for effective maintenance and troubleshooting, ensuring that all components are carefully handled and organized for reassembly.

Preparation

Before beginning the disassembly process, gather all necessary tools and materials. Ensure a clean and organized workspace to facilitate efficient work. Additionally, familiarize yourself with the components you will encounter, as this knowledge will aid in the reassembly phase.

Step-by-Step Process

Follow these steps for a systematic approach to disassembly:

| Step | Description |

|---|---|

| 1 | Disconnect all electrical connections and remove external attachments. |

| 2 | Drain fluids to prevent spills and contamination. |

| 3 | Remove the casing and access panels for internal access. |

| 4 | Carefully detach each component, labeling parts as necessary for easy identification. |

| 5 | Inspect each piece for wear or damage, noting any that require replacement. |

Inspecting Engine Components

This section focuses on the essential task of examining various parts of a power unit to ensure optimal functionality. Regular checks are vital for maintaining performance and preventing potential issues that may arise over time.

Visual Assessment

Begin with a thorough visual inspection of all accessible components. Look for signs of wear, damage, or corrosion. Pay attention to gaskets and seals, as any leaks can indicate problems that need immediate attention.

Functional Testing

After the visual assessment, proceed to functional tests of critical elements. Check for unusual noises, vibrations, or performance irregularities. These indicators can reveal underlying issues that might not be visible during a standard inspection.

Replacing Gaskets and Seals

Properly maintaining the integrity of components is crucial for optimal performance and longevity. One key aspect involves ensuring that connections remain airtight and fluid-tight. This section focuses on the process of replacing various sealing elements, which can prevent leaks and enhance overall functionality.

Understanding the Importance

Seals and gaskets play a vital role in keeping systems secure from external elements. Over time, wear and exposure can cause these components to degrade, leading to potential issues such as leaks or operational inefficiencies. Regular inspection and timely replacement can save both time and resources in the long run.

Steps for Replacement

To effectively replace these critical components, follow these steps:

- Preparation: Gather the necessary tools and materials before starting the task.

- Removal: Carefully detach the old gasket or seal, ensuring no debris is left behind.

- Cleaning: Thoroughly clean the surfaces to prevent contamination.

- Installation: Position the new component accurately, applying the appropriate torque if necessary.

- Final Checks: Inspect for proper alignment and ensure everything is securely fastened.

Following these guidelines will help maintain the reliability of the system and prevent future complications.

Cleaning Engine Parts Effectively

Maintaining the internal components of a vehicle is crucial for optimal performance and longevity. Regularly cleaning these parts not only enhances their functionality but also prevents premature wear and costly breakdowns. This section will explore effective methods to ensure cleanliness and efficiency of mechanical components.

Choosing the Right Cleaning Solutions

Selecting appropriate cleaning agents is essential for effective maintenance. Solvents and degreasers specifically formulated for automotive applications can remove grease, grime, and carbon deposits without damaging surfaces. Always refer to product guidelines to ensure compatibility with materials.

Cleaning Techniques

For best results, employ various techniques based on the type of part being cleaned. Soaking components in a suitable solution can loosen stubborn contaminants, while scrubbing with brushes or cloths helps to remove residual dirt. Rinsing thoroughly and allowing parts to dry completely will prevent moisture-related issues.

Reassembling the Engine

This section focuses on the systematic approach to putting back together a disassembled mechanical unit. Proper assembly is crucial for optimal performance and longevity. Each component must be correctly aligned and secured to ensure the functionality of the entire system.

Preparation Steps

Before starting the assembly process, it is essential to gather all necessary tools and parts. A clean workspace will help prevent any contamination. Review the specifications for each component to ensure compatibility.

Assembly Process

Begin by laying out all parts in an organized manner. Follow a logical sequence, typically starting from the bottom and working upwards. Secure each part as you progress, checking for correct fit and alignment.

| Component | Action | Notes |

|---|---|---|

| Crankshaft | Insert and secure | Check alignment with bearings |

| Pistons | Install with rings | Ensure rings are properly seated |

| Cylinder Head | Position and bolt down | Follow torque specifications |

| Valves | Install and adjust | Check clearance after adjustment |

| Timing Components | Align and secure | Verify timing marks are aligned |

Checking Timing and Alignment

Ensuring the correct synchronization of various components within the system is crucial for optimal performance. This process involves verifying that all moving parts are aligned properly, allowing for smooth operation and preventing potential issues that could arise from misalignment.

Tools and Preparation

Before starting the assessment, gather the necessary tools such as a timing light, alignment gauges, and wrenches. Make sure to have a clean workspace to prevent contamination and damage to the components. It is advisable to consult any relevant documentation that outlines specific procedures for alignment verification.

Steps for Verification

Begin by locating the timing marks on the relevant components. Rotate the main crankshaft until the marks align with the specified indicators. Ensure that all associated parts, such as pulleys and belts, are in their correct positions. Double-check the alignment to confirm that everything is positioned accurately. If any discrepancies are found, adjustments should be made accordingly to maintain proper synchronization.

Testing Engine Performance

Evaluating the functionality of your vehicle’s power source is crucial for ensuring optimal operation and longevity. This process involves a series of assessments designed to measure various parameters, helping to identify any underlying issues that may affect performance.

Initial Observations

Begin by checking for any irregular sounds or vibrations during idle and acceleration. These signs can indicate problems that may need further investigation.

Diagnostics Tools

Utilize diagnostic equipment to monitor parameters such as fuel efficiency, emissions, and temperature readings. This data is invaluable in pinpointing areas requiring attention.

Performance Metrics

Assess metrics like acceleration times and top speed to gain insights into overall functionality. Comparing these figures to manufacturer specifications can help determine if the system is operating as intended.

Follow-up Actions

Should any discrepancies arise, further analysis may be necessary. Regular checks not only enhance performance but also contribute to the vehicle’s overall health.

Maintaining the Toyota 2L

Proper upkeep of your vehicle’s power source is crucial for ensuring optimal performance and longevity. Regular maintenance can prevent common issues and enhance efficiency, leading to a smoother driving experience.

To achieve this, consider the following key practices:

- Regular Fluid Checks: Monitor oil and coolant levels frequently.

- Scheduled Oil Changes: Change the lubricant as per the recommended intervals to maintain smooth operation.

- Filter Replacements: Replace air and fuel filters regularly to ensure cleanliness and efficiency.

- Inspection of Belts and Hoses: Check for wear and tear, replacing any components that show signs of damage.

By adhering to these guidelines, you can significantly enhance the reliability and performance of your vehicle.

Upgrades and Modifications Options

Enhancing performance and customization of your vehicle can significantly improve your driving experience. Various enhancements can be implemented to boost power, efficiency, and overall aesthetics. This section explores several paths for optimizing your ride, from simple tweaks to more extensive modifications.

Performance Enhancements

To achieve a noticeable increase in output, consider installing high-flow air intake systems or performance exhaust components. These upgrades can enhance airflow, resulting in better combustion and higher horsepower. Additionally, reprogramming the vehicle’s control unit can optimize fuel delivery and ignition timing, further elevating performance.

Aesthetic Modifications

For those looking to personalize their ride, a range of cosmetic changes is available. Upgrading the wheels, adding a custom body kit, or applying unique paint finishes can transform the vehicle’s appearance. Interior enhancements, such as upgraded seating and modern infotainment systems, can also provide a more enjoyable driving environment.