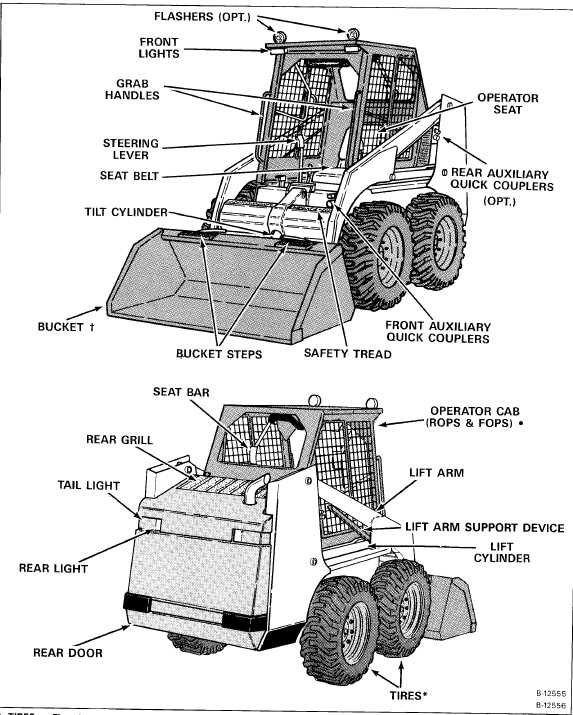

In the realm of heavy machinery, ensuring optimal performance and longevity is paramount. This section focuses on the essential upkeep and troubleshooting techniques for compact loaders, highlighting the importance of regular inspections and timely interventions. Understanding the intricacies of these machines can significantly enhance their functionality.

Detailed insights into common issues and their resolutions are crucial for operators and technicians alike. By following comprehensive guidelines, users can effectively address potential malfunctions, ensuring the equipment remains in peak condition. Proper knowledge empowers individuals to maintain their machinery, ultimately improving efficiency and reducing downtime.

Whether you are a seasoned professional or a novice, familiarizing yourself with maintenance protocols will yield significant benefits. This resource provides valuable information to help you navigate the complexities of compact loader care, equipping you with the skills needed to perform essential tasks and promote longevity.

Common Issues with Bobcat 753

When operating compact equipment, several frequent challenges may arise, impacting performance and efficiency. Understanding these common problems can facilitate timely interventions, ensuring smooth operation and longevity of the machinery.

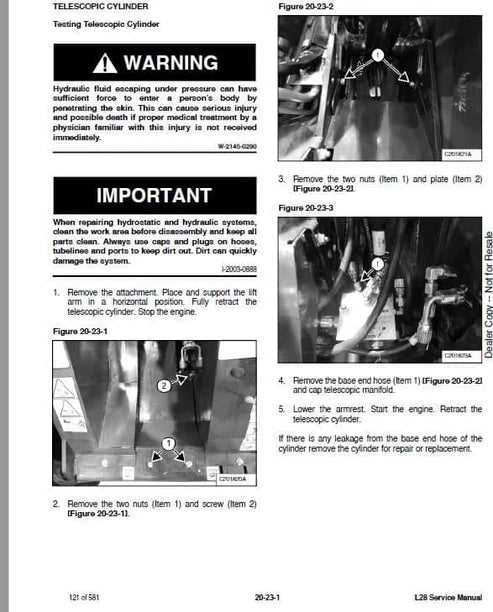

Hydraulic System Failures: A prevalent issue involves the hydraulic system, which can experience leaks or pressure drops. Regular inspections are essential to maintain optimal functionality.

Electrical Malfunctions: Electrical components may fail due to wear or connection issues, leading to operational disruptions. Checking wiring and connections can prevent unexpected shutdowns.

Engine Performance Issues: Engine-related problems, such as poor starting or stalling, can significantly affect productivity. Routine maintenance, including filter replacements and fluid checks, is crucial for engine health.

Essential Tools for Repair Tasks

Having the right equipment is crucial for effectively addressing maintenance and service jobs. A well-equipped workspace can significantly enhance productivity and ensure that tasks are completed efficiently and accurately.

- Wrenches: Various sizes are necessary for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips types are essential for a variety of fasteners.

- Socket Set: This tool allows for easier access to hard-to-reach bolts.

- Pliers: Useful for gripping, twisting, and cutting wires or other materials.

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

- Jack and Stands: Important for lifting equipment safely during inspections and repairs.

- Multimeter: Essential for diagnosing electrical issues and checking voltages.

Equipping your toolkit with these essentials can simplify tasks, promote safety, and contribute to successful outcomes in various maintenance endeavors.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identify and resolve common issues that may arise with your equipment. Following these detailed steps will help ensure optimal performance and prolong the lifespan of the machine.

Identify the Problem

Begin by observing the symptoms of the malfunction. Note any unusual sounds, vibrations, or warning indicators. Documenting these details will assist in pinpointing the root cause more effectively.

Check Key Components

Inspect critical parts such as the engine, hydraulic system, and electrical components. Look for signs of wear, leaks, or loose connections. Regular maintenance and prompt attention to these areas can prevent more severe complications.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan and optimal performance of machinery. Regular attention to maintenance tasks can prevent costly repairs and downtime. Adopting a proactive approach not only enhances reliability but also maximizes efficiency.

Regular Inspections

Conducting frequent inspections helps identify potential issues before they escalate. Check for wear and tear, fluid levels, and any unusual noises during operation. Addressing minor problems early can save significant time and resources.

Fluid Changes

Timely fluid changes are crucial for maintaining smooth operation. Follow the recommended schedules for oil and hydraulic fluid replacements to ensure that the system functions correctly. Clean fluids promote better lubrication and reduce the risk of overheating.

Engine Performance Optimization Techniques

Enhancing engine efficiency is crucial for achieving optimal performance and longevity. Various strategies can be implemented to improve power output and fuel economy, leading to a more effective operation overall.

- Regular Maintenance: Keeping the engine well-maintained ensures all components function correctly, preventing power loss.

- Fuel Quality: Utilizing high-quality fuel can lead to better combustion and efficiency, directly impacting performance.

- Air Intake Improvements: Upgrading air filters and intake systems allows for better airflow, enhancing engine responsiveness.

In addition to these practices, tuning the engine management system can optimize parameters for better performance.

- Monitor engine metrics to identify areas needing adjustment.

- Consider reprogramming the ECU for improved fuel mapping.

- Implement exhaust modifications to reduce back pressure and improve airflow.

By applying these techniques, operators can ensure that their machinery operates at peak performance, ultimately leading to increased productivity and reduced operational costs.

Hydraulic System Diagnostics

This section focuses on the evaluation and troubleshooting of hydraulic systems to ensure optimal performance and reliability. Proper diagnosis is essential for identifying issues that may affect the efficiency of machinery.

Common Issues and Symptoms

Identifying frequent problems, such as fluid leaks, irregular pressure readings, or sluggish operation, is crucial. These signs often indicate underlying malfunctions that require immediate attention to prevent further complications.

Diagnostic Techniques

Utilizing tools like pressure gauges, flow meters, and visual inspections can help pinpoint malfunctions. Regular monitoring and analysis of hydraulic fluid conditions also contribute to effective diagnostics, ensuring that systems remain in peak condition.

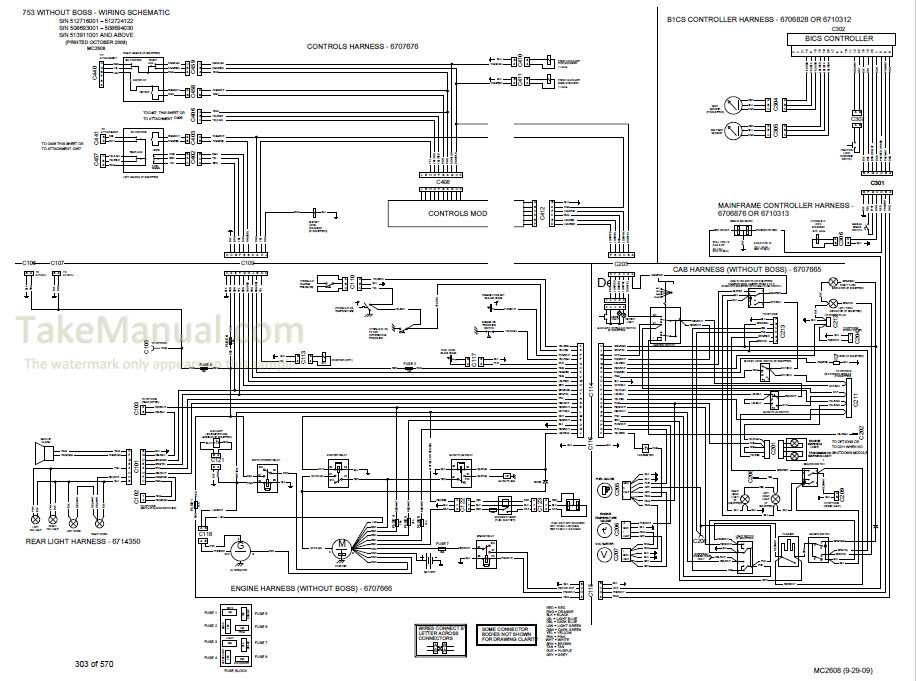

Electrical System Troubleshooting Methods

Diagnosing issues within an electrical system requires a systematic approach to identify faults and ensure optimal performance. By following structured troubleshooting techniques, operators can efficiently locate and rectify problems, enhancing the reliability of machinery.

Begin by inspecting all electrical connections for signs of wear, corrosion, or loose fittings. Proper contact is essential for uninterrupted power flow. Utilize a multimeter to measure voltage levels at various points, ensuring that they align with manufacturer specifications.

If discrepancies are noted, trace the wiring to identify any breaks or shorts. This may involve visually checking the harnesses and connectors for damage. In cases where components appear intact, further testing of individual parts, such as switches and relays, may be necessary to isolate the faulty element.

For persistent issues, consult technical documentation or schematics that outline the electrical layout. This resource can guide further investigation and assist in understanding circuit functionality. Engaging in methodical examination and testing not only resolves existing concerns but also promotes preventive measures for future reliability.

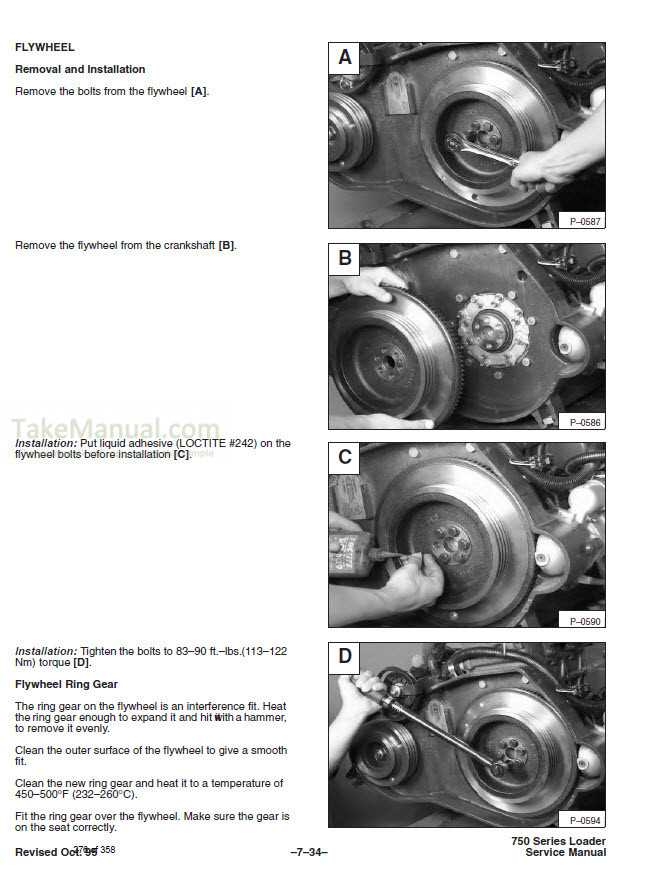

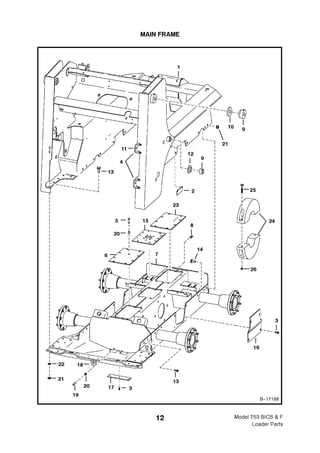

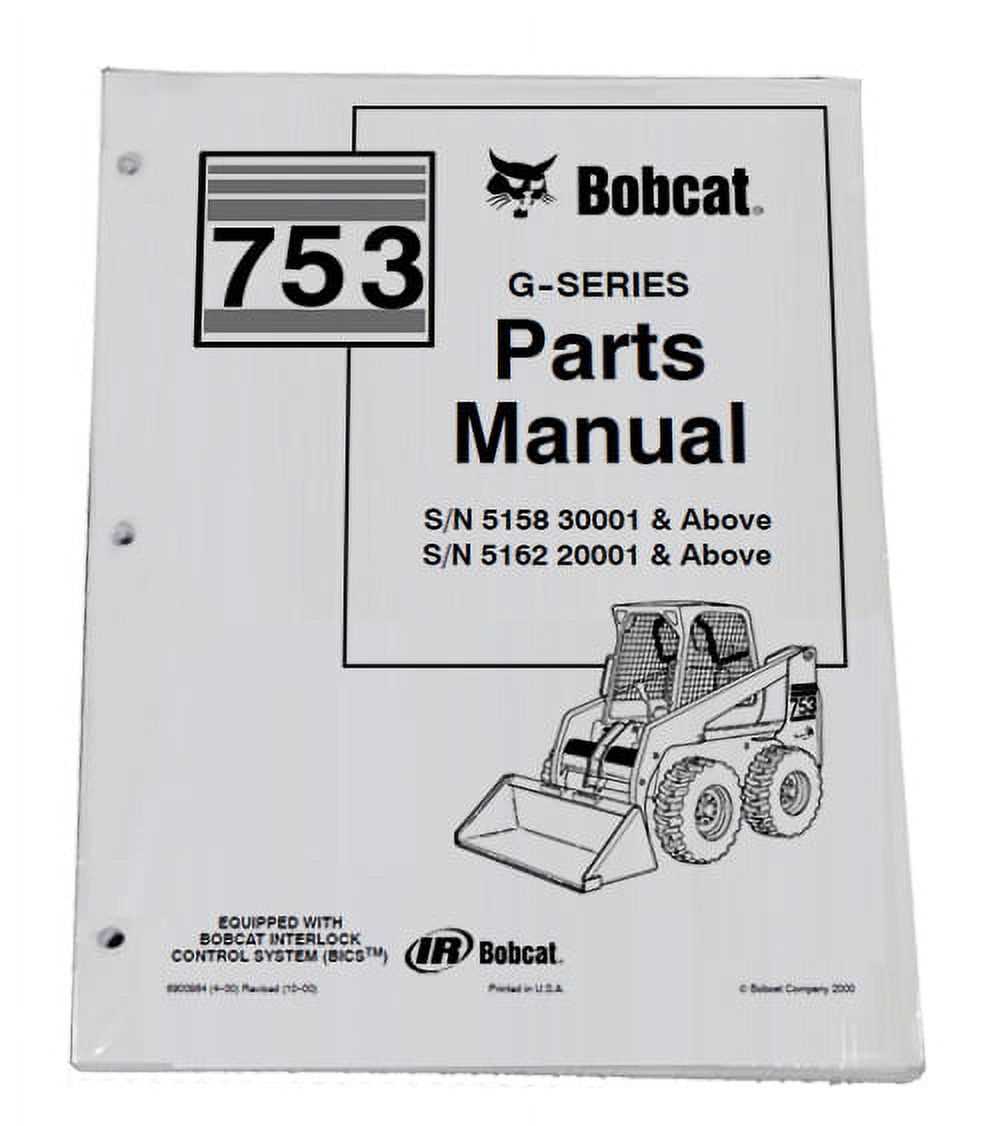

Parts Replacement: A Comprehensive Guide

This section provides essential insights into the process of substituting components in machinery, ensuring optimal performance and longevity. Proper part replacement not only enhances functionality but also contributes to the overall efficiency of the equipment.

Identifying Necessary Components

Understanding which parts require attention is crucial. Regular inspections can help detect wear and tear, enabling timely replacements. Pay close attention to components that show signs of fatigue or decreased efficiency, as addressing these issues promptly can prevent further complications.

Steps for Effective Replacement

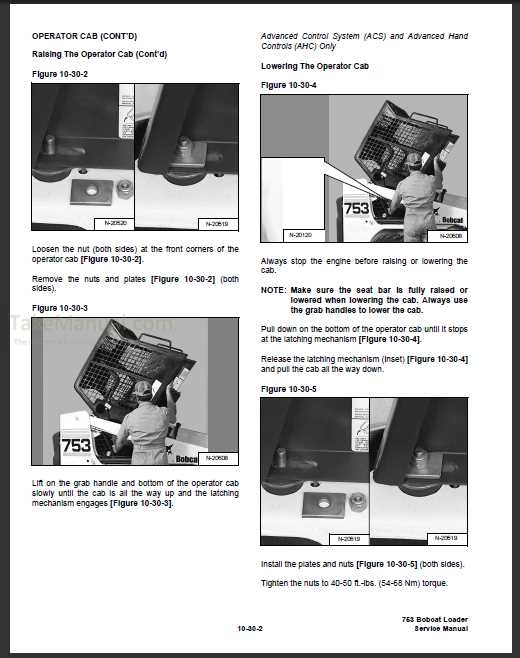

When embarking on a parts substitution journey, follow these structured steps:

- Gather Tools: Ensure you have the necessary tools for the job, including wrenches, screwdrivers, and safety gear.

- Follow Guidelines: Refer to specific guidelines for the equipment to ensure correct procedures are followed.

- Install New Parts: Carefully install the new components, ensuring a secure fit and proper alignment.

By adhering to these steps, users can effectively manage parts replacement, maintaining machinery in peak condition.

Safety Protocols During Repairs

Ensuring a secure environment while conducting maintenance tasks is paramount. Adhering to established safety measures not only protects individuals involved but also enhances the overall efficiency of the process. Proper preparation and awareness of potential hazards are essential for a successful outcome.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial. This includes items such as helmets, gloves, and eye protection. Wearing the right gear mitigates the risk of injuries caused by falling objects or sharp tools. Regularly inspect PPE for any signs of wear and replace as necessary to maintain safety standards.

Work Area Organization

Maintaining an orderly workspace is vital for minimizing accidents. Clear any clutter that may obstruct movement or hide potential hazards. Ensuring adequate lighting in the area further contributes to safety, allowing for better visibility of tools and equipment during the process. A well-organized environment fosters a more productive and secure atmosphere for maintenance activities.

Owner Experiences and Testimonials

This section highlights the insights and feedback from individuals who have utilized a compact machinery model in various settings. Their experiences provide valuable perspectives on performance, durability, and ease of maintenance, offering potential users a glimpse into real-world applications.

Many users have praised the reliability of this equipment, noting its consistent performance even in challenging conditions. One owner mentioned how it exceeded their expectations during heavy-duty tasks, proving to be an essential asset for their operations.

Several testimonials emphasize the user-friendly design, making it accessible for operators of all skill levels. A satisfied customer shared their experience of quickly adapting to the controls, stating that it significantly improved productivity on job sites.

Maintenance experiences have also been favorable, with many owners reporting straightforward procedures and accessible parts. One individual highlighted the ease of conducting routine checks, which contributed to prolonged equipment life and reduced downtime.

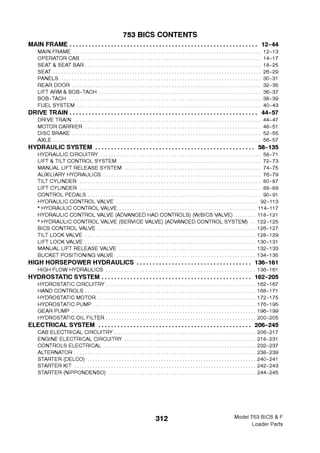

Upgrades and Modifications Available

Enhancements and customizations can significantly improve the performance and versatility of compact machinery. Various options are available to cater to specific operational needs, ensuring that equipment can handle a wider range of tasks and environments.

Performance Enhancements

Upgrading components can lead to improved efficiency and power output. Common modifications include engine tuning and enhanced hydraulic systems, allowing for greater lifting capacity and faster operation.

Custom Attachments

Custom attachments expand the functionality of the machine, making it suitable for diverse applications. Options include specialized buckets, forks, and grapples designed to optimize performance for particular tasks.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Engine Tuning | Adjusting engine parameters for increased horsepower. | Enhanced power and efficiency. |

| Hydraulic System Upgrade | Improving hydraulic components for better performance. | Increased lifting capacity and speed. |

| Custom Attachments | Specialized tools for various tasks. | Versatility for different operations. |