Proper upkeep of your gardening tool is essential for optimal performance and longevity. Understanding how to maintain and troubleshoot your equipment can save you time and money, ensuring that your outdoor tasks are completed efficiently. This section aims to provide comprehensive guidance on various aspects of care, focusing on common issues and practical solutions.

When faced with difficulties during operation, it is crucial to identify the underlying causes. Regular inspections and basic adjustments can often rectify problems before they escalate. This guide will delve into various techniques and methods that can enhance the functionality of your trimmer, making it an invaluable resource for enthusiasts and professionals alike.

By adhering to the outlined procedures, users can foster a deeper connection with their equipment, enhancing their gardening experience. With attention to detail and a proactive approach, keeping your trimmer in peak condition is within reach.

Understanding Stihl FS44 Overview

This section provides a comprehensive understanding of a popular outdoor power tool known for its versatility and efficiency in various landscaping tasks. It is designed for users seeking reliable performance, enabling effective trimming and cutting of vegetation in diverse environments.

Key Features

- Robust engine offering substantial power

- User-friendly design facilitating ease of operation

- Durable construction ensuring longevity

- Versatile attachments for multiple applications

Benefits of Usage

- Enhanced productivity for landscaping tasks

- Improved maneuverability in tight spaces

- Reduced operator fatigue through ergonomic design

- Low maintenance requirements for consistent performance

Common Issues with Stihl FS44

Users of string trimmers often encounter various challenges during operation and maintenance. Understanding these common problems can aid in ensuring optimal performance and longevity of the equipment. Below are some frequently reported issues that may arise when using this particular model.

Engine Starting Difficulties: One prevalent issue involves the engine’s reluctance to start. This can result from a variety of factors, including fuel blockage, a dirty air filter, or spark plug malfunctions. Regular inspection of these components can help mitigate this problem.

Overheating: Another common challenge is overheating during use. This can lead to decreased efficiency and potential damage. Users should ensure that the cooling fins are free from debris and that the fuel mixture is correctly formulated to avoid overheating.

Line Feed Problems: Many operators report difficulties with the automatic line feed system. This may manifest as the line not advancing as expected. Inspecting the spool for tangles and ensuring proper line installation can resolve these issues.

Excessive Vibration: High levels of vibration can be uncomfortable and indicate underlying issues. This can be caused by unbalanced cutting heads or worn components. Regular maintenance and balancing can help reduce excessive vibration during operation.

Addressing these common concerns promptly can enhance the user experience and extend the lifespan of the equipment. Regular checks and maintenance practices are essential for ensuring reliable operation.

Tools Required for Repairs

When it comes to maintaining outdoor power equipment, having the right instruments is essential for effective servicing and troubleshooting. This section outlines the necessary implements to ensure a successful maintenance process.

- Wrenches: A set of various sizes is crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are needed for different types of screws.

- Socket Set: This is useful for working with nuts and bolts in tighter spaces.

- Fuel and Oil Containers: These are necessary for safely storing and handling fluids.

- Cleaning Brushes: Useful for removing debris and buildup from components.

- Protective Gear: Safety glasses and gloves to ensure personal protection during work.

Having these tools on hand will streamline the upkeep process, making it more efficient and effective. Proper preparation allows for swift diagnostics and resolutions to any issues that may arise.

Step-by-Step Repair Instructions

This section provides a comprehensive guide for troubleshooting and fixing common issues related to outdoor power equipment. Follow these detailed steps to ensure proper functioning and longevity of your device. Each step is designed to be easy to follow, making the process accessible for both novice and experienced users.

| Step | Description |

|---|---|

| 1 | Begin by disconnecting the spark plug to prevent accidental starting. Ensure the device is on a stable surface. |

| 2 | Inspect the air filter for dirt and debris. If necessary, clean or replace it to maintain optimal airflow. |

| 3 | Check the fuel system for leaks or blockages. Use fresh fuel and replace any damaged lines to ensure proper fuel delivery. |

| 4 | Examine the cutting head for wear and tear. Sharpen or replace the blade as needed to improve cutting performance. |

| 5 | Reassemble all components carefully, ensuring that all screws and fasteners are tightened to avoid any loose parts. |

| 6 | Reconnect the spark plug and perform a test run to confirm that the machine operates smoothly. |

By following these organized steps, you can efficiently address and resolve various issues, enhancing the performance and reliability of your equipment.

Maintaining Your Stihl FS44

Proper upkeep of your outdoor power equipment is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances the efficiency of your device but also helps prevent costly repairs in the future. This section outlines key practices to keep your machine running smoothly throughout its lifespan.

Routine Inspection

Conducting frequent checks on your equipment is vital. Look for signs of wear and tear, including frayed cords, loose components, and any leaks. Ensuring that the cutting mechanism is sharp and free of obstructions will significantly enhance cutting performance. Keeping the air filter clean is equally important, as it allows the engine to breathe easily and operate efficiently.

Cleaning and Storage

After each use, clean the exterior and any debris from the cutting area. Storing the equipment in a dry, sheltered place will protect it from harsh weather conditions. If you plan to store it for an extended period, consider draining the fuel to prevent stale gas from clogging the system. These practices contribute to the reliability and readiness of your device for future tasks.

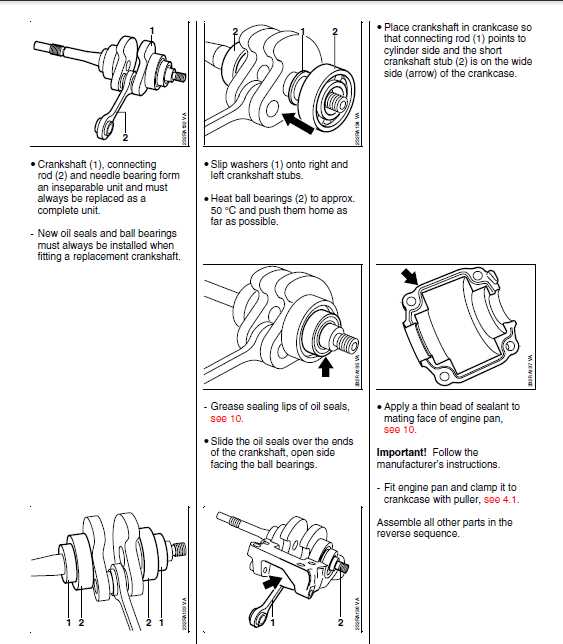

Parts Replacement Guidelines

Replacing components in a power tool is essential for maintaining its performance and longevity. Proper understanding of the necessary parts and their functions can help ensure effective and efficient operation. This section provides guidance on how to approach the replacement of various elements, focusing on key steps and considerations.

Identifying Components for Replacement

Before initiating any replacement process, it is crucial to accurately identify which parts require attention. Regular inspections can help detect signs of wear or damage. Referencing diagrams or specifications can assist in understanding the assembly and locating the specific components that need to be replaced.

Step-by-Step Replacement Process

Once the components have been identified, follow a systematic approach to the replacement. Begin by gathering the necessary tools and new parts. Ensure that the power tool is disconnected from any power source to avoid accidents. Carefully disassemble the housing to access the damaged parts, replacing them one at a time. Reassemble the tool meticulously, ensuring all connections are secure before testing the functionality.

Troubleshooting Common Problems

Identifying and addressing frequent issues with outdoor power equipment is essential for optimal performance and longevity. This section aims to guide users through some typical malfunctions, helping to restore functionality effectively.

Engine Won’t Start

If the engine fails to ignite, consider the following potential causes:

- Check the fuel level and ensure it is clean and fresh.

- Inspect the spark plug for wear or carbon buildup.

- Verify that the ignition system is functioning properly.

Unusual Noises During Operation

Unwanted sounds can indicate underlying issues. Examine these factors:

- Look for loose or damaged components within the assembly.

- Listen for abnormal vibrations that may signal imbalance.

- Check the cutting attachment for obstructions or damage.

Safety Precautions to Consider

When operating outdoor power equipment, ensuring safety is paramount. Proper precautions help prevent accidents and injuries, creating a secure environment for both the user and those nearby. Understanding and adhering to safety guidelines is essential for a successful and hazard-free experience.

Protective Gear: Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear. This gear minimizes the risk of injuries from debris and ensures that you are safeguarded against potential hazards.

Work Area: Before starting any task, assess the surroundings. Clear the area of any obstacles, debris, or flammable materials. A tidy workspace not only enhances safety but also improves efficiency while working.

Equipment Check: Regularly inspect your tools for any signs of wear or damage. Ensure that all components are functioning correctly and that safety features are operational. Maintaining equipment in good condition reduces the likelihood of accidents during use.

Fuel Handling: When refueling, do so outdoors and away from any ignition sources. Use containers designed for fuel storage and always follow manufacturer guidelines for safe handling. This practice prevents dangerous spills and fire risks.

Awareness: Stay vigilant while operating machinery. Be conscious of your surroundings and any bystanders. Understanding the environment and maintaining focus is critical for safe operation.

By prioritizing safety measures, users can enjoy their tasks with confidence, knowing they are taking steps to protect themselves and others while using outdoor power tools.

Frequently Asked Questions

This section aims to address common inquiries regarding maintenance and troubleshooting for your equipment. Here, you will find answers to questions that many users encounter, ensuring a smoother experience when operating and caring for your tool.

1. What should I do if my machine won’t start?

If your equipment fails to start, first check the fuel level and ensure that you are using fresh fuel. Additionally, inspect the ignition system and air filter for any blockages or wear that may prevent proper operation.

2. How can I improve the cutting performance?

To enhance cutting efficiency, regularly sharpen the blade or string. Proper tension and alignment of the cutting head are also essential for optimal performance.

3. What maintenance tasks are essential for longevity?

Routine checks on the air filter, spark plug, and fuel lines are crucial. Keeping the machine clean and free from debris will also help in extending its lifespan.

4. Is it necessary to use specific fuel types?

Yes, using the correct type of fuel as specified by the manufacturer is vital for ensuring engine efficiency and preventing damage.

5. How often should I perform maintenance checks?

Regular inspections should be conducted after every few uses, or at least once a month, depending on the frequency of use. Following the suggested guidelines will help in identifying issues early on.

Recommended Accessories and Upgrades

Enhancing the functionality of your gardening tool can significantly improve its performance and efficiency. This section focuses on various add-ons and enhancements that can elevate your experience and help you achieve better results in your outdoor tasks.

Essential Add-ons

- Cutting Blades: Upgrading to high-quality blades can lead to cleaner cuts and reduced wear on the equipment.

- Harnesses: A comfortable harness can distribute weight evenly, allowing for extended use without discomfort.

- Protective Gear: Safety should always come first. Investing in appropriate goggles, gloves, and boots is essential for protection during operation.

Performance Enhancements

- Upgraded Fuel System: Consider a more efficient fuel filter to ensure cleaner fuel flow and improve engine performance.

- Vibration Dampening Systems: Adding these systems can reduce operator fatigue during prolonged use.

- Smart Accessories: Look for innovative attachments that can expand the range of tasks, such as brush cutter heads or hedge trimmer attachments.

By investing in these accessories and enhancements, users can significantly boost the performance and comfort of their gardening tools, making outdoor maintenance tasks more manageable and efficient.

Stihl FS44 Performance Optimization Tips

To achieve maximum efficiency and enhance the operation of your outdoor power equipment, certain adjustments and practices can be implemented. This section focuses on essential strategies to fine-tune your device for superior performance, ensuring a smoother and more effective experience.

Regular Maintenance Checks

Conducting routine maintenance is crucial for optimal functionality. Regular inspections can prevent issues and improve overall performance.

- Inspect and clean the air filter to ensure proper airflow.

- Check the spark plug and replace it if necessary for a reliable ignition.

- Examine fuel lines for leaks or blockages to maintain proper fuel delivery.

Fuel Quality and Mixture

The type of fuel and its mixture can significantly impact the operation of your equipment. Using high-quality fuel ensures better combustion and efficiency.

- Always use fresh fuel to prevent degradation and poor performance.

- Mix fuel with the correct oil ratio, following manufacturer recommendations.

- Avoid using fuels containing ethanol, as they can lead to engine issues.